Solid ball sleeve pitch point

A technology of solid balls and sleeves, which is applied in the direction of architecture and building construction, can solve the problems of welded ball joints that cannot be assembled, hidden safety hazards in structural systems, and difficulties in closing plug rods, so as to achieve standardized production and assembly construction, improving site construction efficiency, and saving resources and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure of the present invention will be described below in combination with the processing process.

[0021] Each component of the present invention is processed by mechanical processing or first casting and then mechanical processing. In order to ensure the accuracy, each part can be processed by machining, or a combination of casting and machining.

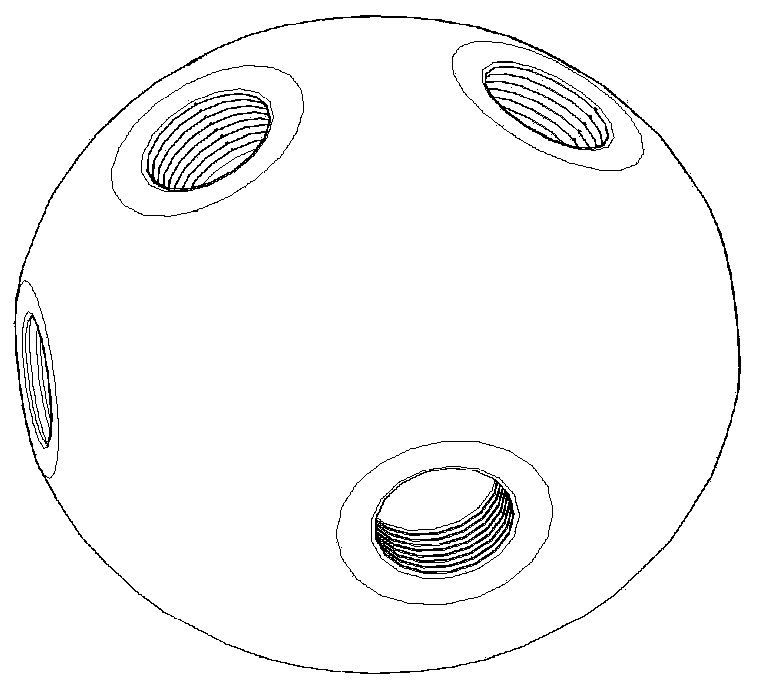

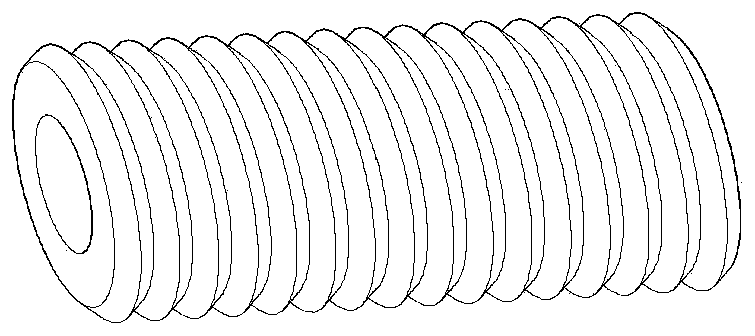

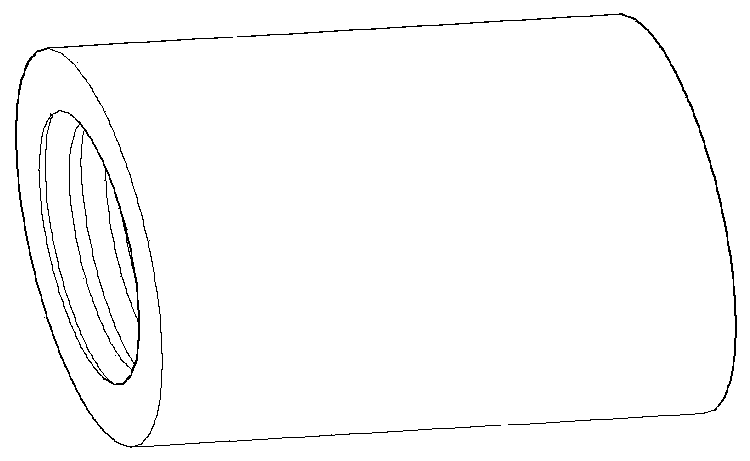

[0022] In this embodiment, the multi-screw solid ball (1) is provided with screw holes in 5 directions according to actual needs, and the specific number and directions can be adjusted according to actual conditions, such as Figure 9 shown. The length of the threaded section of the screw with external thread (2) is twice the length of the threaded section in each screw hole of the multi-screwed solid ball (1). The length of the threaded section of the sleeve (3) is equal to the length of the threaded section of the screw rod (2) with external threads. The length of the threaded section of the joint (4) with ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com