Concrete shear wall with high shear performance and fiber reinforced composite grid reinforcement

A technology of concrete shear wall and reinforced composite material, applied in the direction of walls, building reinforcements, building components, etc., can solve problems such as corrosion of steel bars, and achieve the effects of delaying concrete crushing, increasing height, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

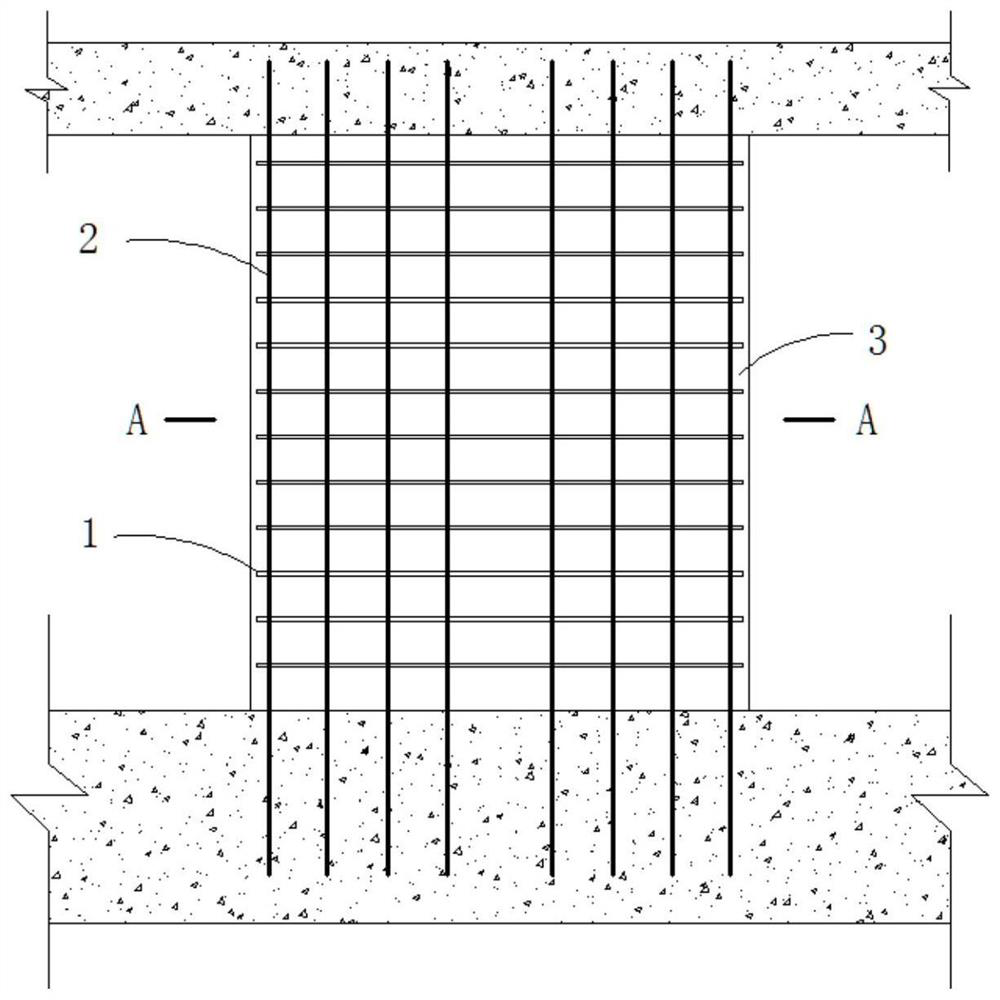

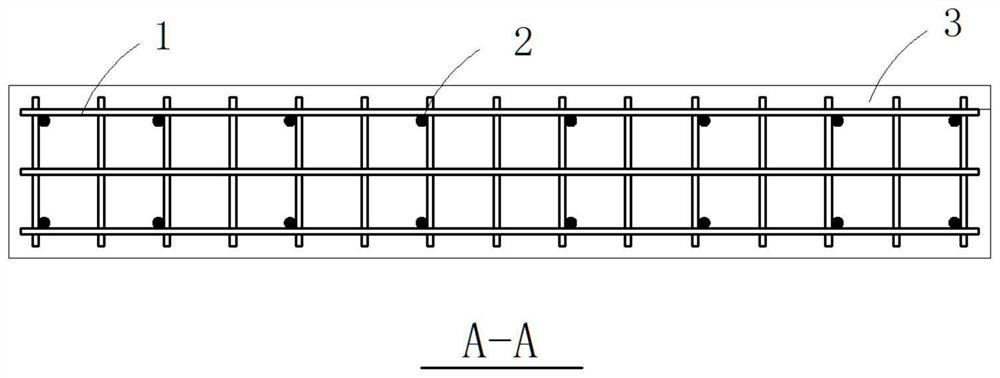

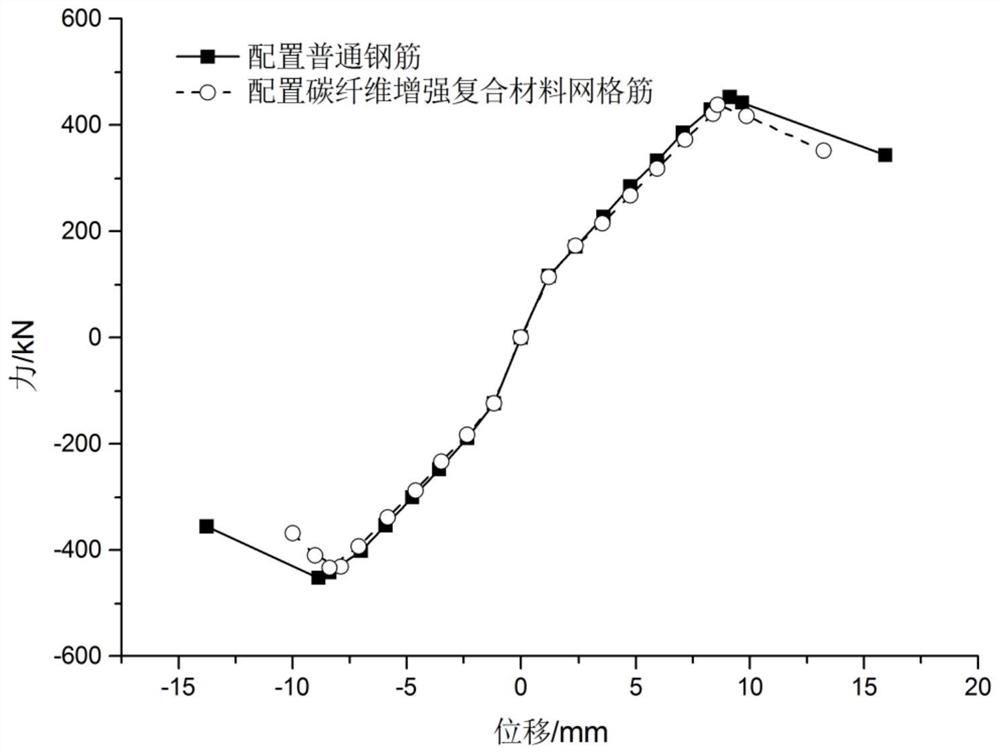

[0026] Such as figure 1 , figure 2 As shown, a high-shear performance concrete shear wall configured with fiber-reinforced composite grid bars, its structure includes fiber-reinforced composite material grid bars 1, ordinary steel bars 2, and concrete 3; the fiber-reinforced composite material grid The bars 1 are arranged horizontally according to the design spacing, replacing the horizontally distributed steel bars, stirrups and tie bars of conventional concrete shear walls; Arrangement, together with the fiber-reinforced composite material grid bars 1, form a concrete internal reinforced skeleton; the concrete 3 is integrally poured after the internal reinforced skeleton is formed.

[0027] Wherein, the fiber-reinforced composite grid reinforcement 1 can be one of carbon fiber-reinforced composite grid reinforcement, basalt fiber-reinforced composite grid reinforcement, glass fiber-reinforced composite grid reinforcement, and aramid fiber-reinforced composite grid reinforc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com