Special energy-saving extrusion screw and extruder for recycled plastic modification

A technology of extruder and screw, which is applied in the field of energy-saving extrusion screw specially used for the modification of recycled plastics, which can solve problems such as insufficient ball milling fineness, screw expansion, unstable performance, etc., increase service life, improve modification quality, and facilitate The effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

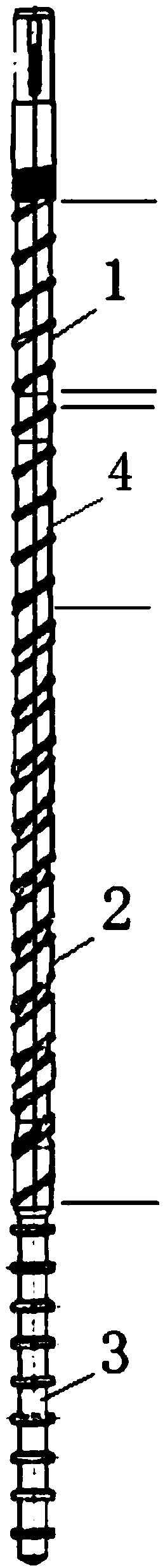

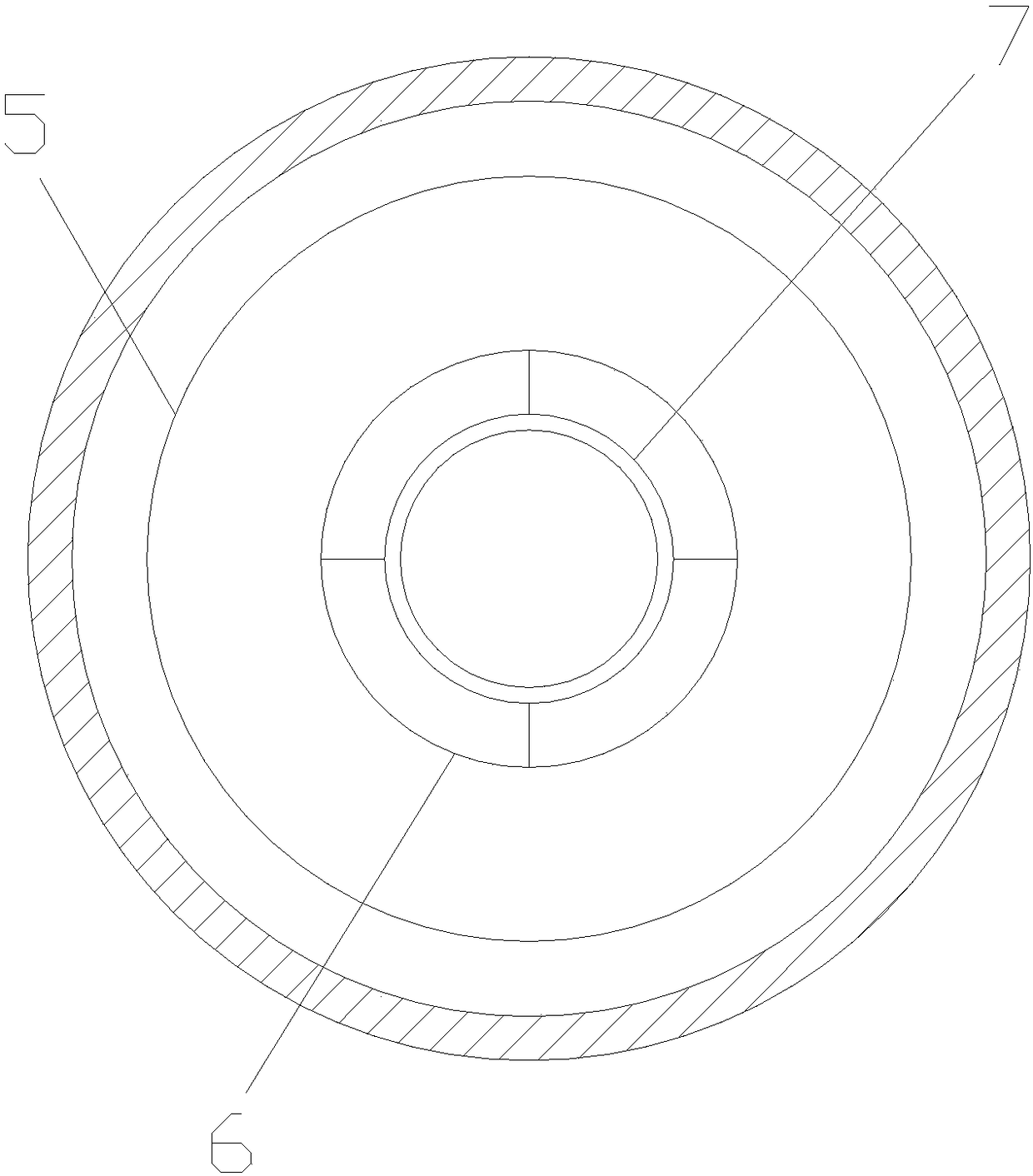

[0017] Such as figure 1 , figure 2 As shown, a special energy-saving extrusion screw for the modification of recycled plastics includes a screw body, the screw body is provided with a shaft hole along the axial direction, and the screw body is sequentially divided into a feeding section 1, a melting section 4, and a modification section. In section 2 and extrusion section 3, a PTC thermistor 7 is installed in the modified section 2. The PTC thermistor 7 is connected to an external DC or AC power supply through a wire through a shaft hole, and is connected to an external DC or AC power source through the PTC thermistor 7 The modification section is heated to make the surface of the screw of the modification section 2 emit heat, and the molten plastic passing through this section is heated again to be extruded and modified, so as to improve the physical and chemical properties of the plastic and make the extrusion The plastic has better toughness and high and low temperature res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com