Surface coating method of iron-based metal rotating seal ring for dynamic seal of mechanical end face

An iron-based metal and mechanical seal technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve problems such as seal failure, and achieve the effect of easy start and stop and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

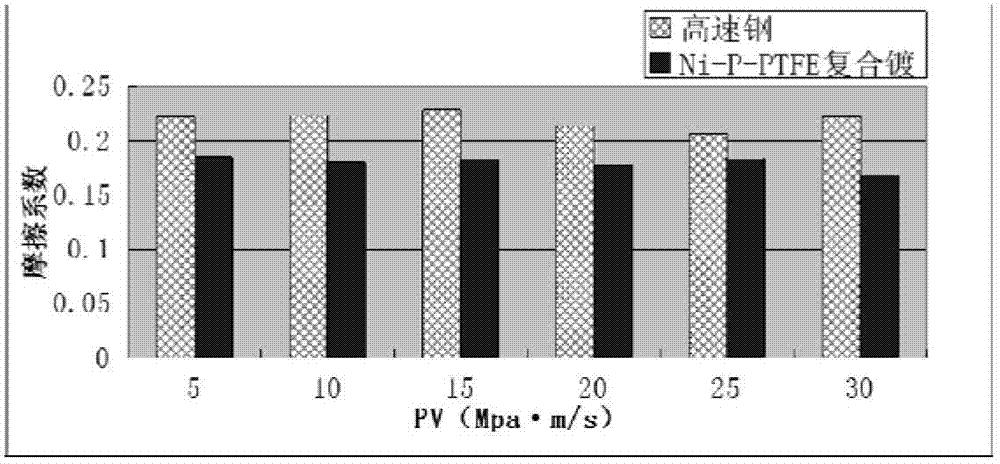

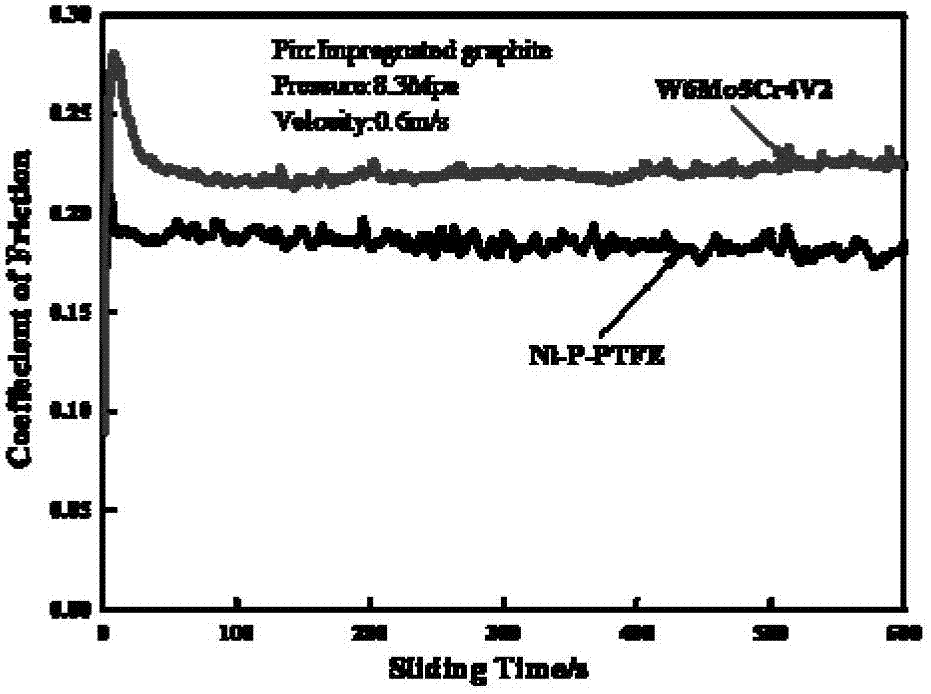

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment includes the following steps:

[0021] Step 1, preparing a composite plating solution, the composite plating solution is composed of a basic plating solution and a PTFE composite solution. The base bath consists of 24g / l NiSO 4 ·6H 2 O, 28g / l NaH 2 PO 2 ·H 2 O, 3.5 g / l of CH 3 COONa·3H 2 O, 30ml / l lactic acid, 2ml / l propionic acid, 2g / l succinic acid, 1.5mg / l Pb(Ac) 2 ·3H 2 O composition; PTFE composite solution is composed of 8g / l PTFE, 0.016g / l perfluoroalkyl quaternary ammonium iodide FC134 and 0.03g / l N-hydroxyethyl perfluorooctane sulfonamide; press before use Add the PTFE composite solution to the basic plating solution at a ratio of 1:1, and mix thoroughly to obtain a composite plating solution;

[0022] Step 2. Pretreatment of the mechanical seal dynamic ring before coating. The iron-based metal of the mechanical seal needs to be electrolytically polished in an acidic electrolyte before coating, and the micro-etching activation is comple...

Embodiment 2

[0026] This embodiment includes the following steps:

[0027] Step 1, preparing a composite plating solution, the composite plating solution is composed of a basic plating solution and a PTFE composite solution. The base bath consists of 24g / l NiSO 4 ·6H 2 O, 28g / l NaH 2 PO 2 ·H 2 O, 3.5 g / l of CH 3 COONa·3H 2 O, 30ml / l lactic acid, 2ml / l propionic acid, 2g / l succinic acid, 1.5mg / l Pb(Ac) 2 ·3H 2 Composed of O; PTFE composite solution is composed of 8g / l PTFE, 0.016g / l perfluoroalkyl quaternary ammonium iodide FC134; add PTFE composite solution to the basic plating solution in a ratio of 1:1 before use, and mix thoroughly Obtain composite plating solution;

[0028] Step 2. Pretreatment of the mechanical seal moving ring before coating. The friction surface of the mechanical seal iron-based metal such as high-speed steel moving ring needs to be electrolytically polished in an acidic electrolyte before coating, and the micro-etching activation is completed in one step t...

Embodiment 3

[0032] This embodiment includes the following steps:

[0033] Step 1, preparing a composite plating solution, the composite plating solution is composed of a basic plating solution and a PTFE composite solution. The base bath consists of 24g / l NiSO 4 ·6H 2 O, 28g / l NaH 2 PO 2 ·H 2 O, 3.5 g / l of CH 3 COONa·3H 2 O, 30ml / l lactic acid, 2ml / l propionic acid, 2g / l succinic acid, 1.5mg / l Pb(Ac) 2 ·3H 2 O composition; PTFE composite solution is composed of 8g / l PTFE and 0.03g / l N-hydroxyethyl perfluorooctane sulfonamide; add an appropriate amount of PTFE composite solution to the basic plating solution before use, and fully mix to obtain composite plating liquid;

[0034]Step 2. Pretreatment of the mechanical seal moving ring before coating. The friction surface of the mechanical seal iron-based metal such as high-speed steel moving ring needs to be electrolytically polished in an acidic electrolyte before coating, and the micro-etching activation is completed in one step to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com