Combined rectification system of ultrasonic flowmeter

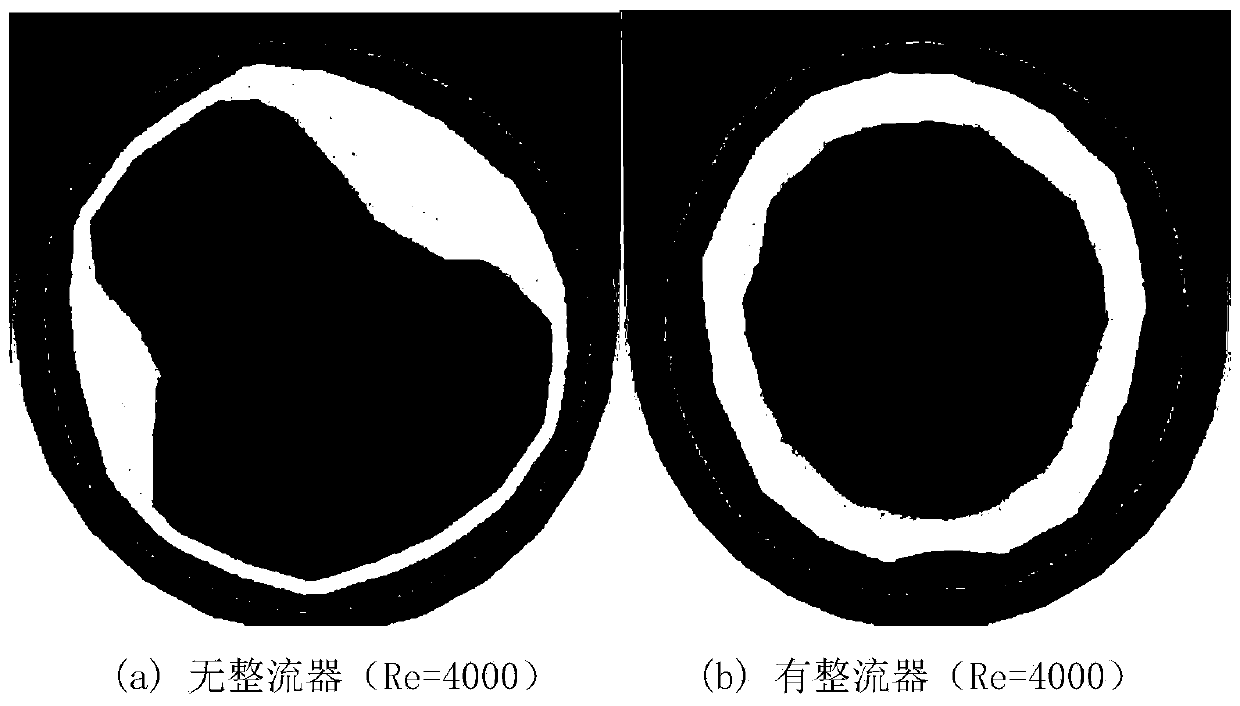

A technology of rectification system and flowmeter, which is applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, measuring device, etc. It can solve the problems of flow field distribution distortion and measurement error, and achieve long service life, convenient construction, and expansion The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

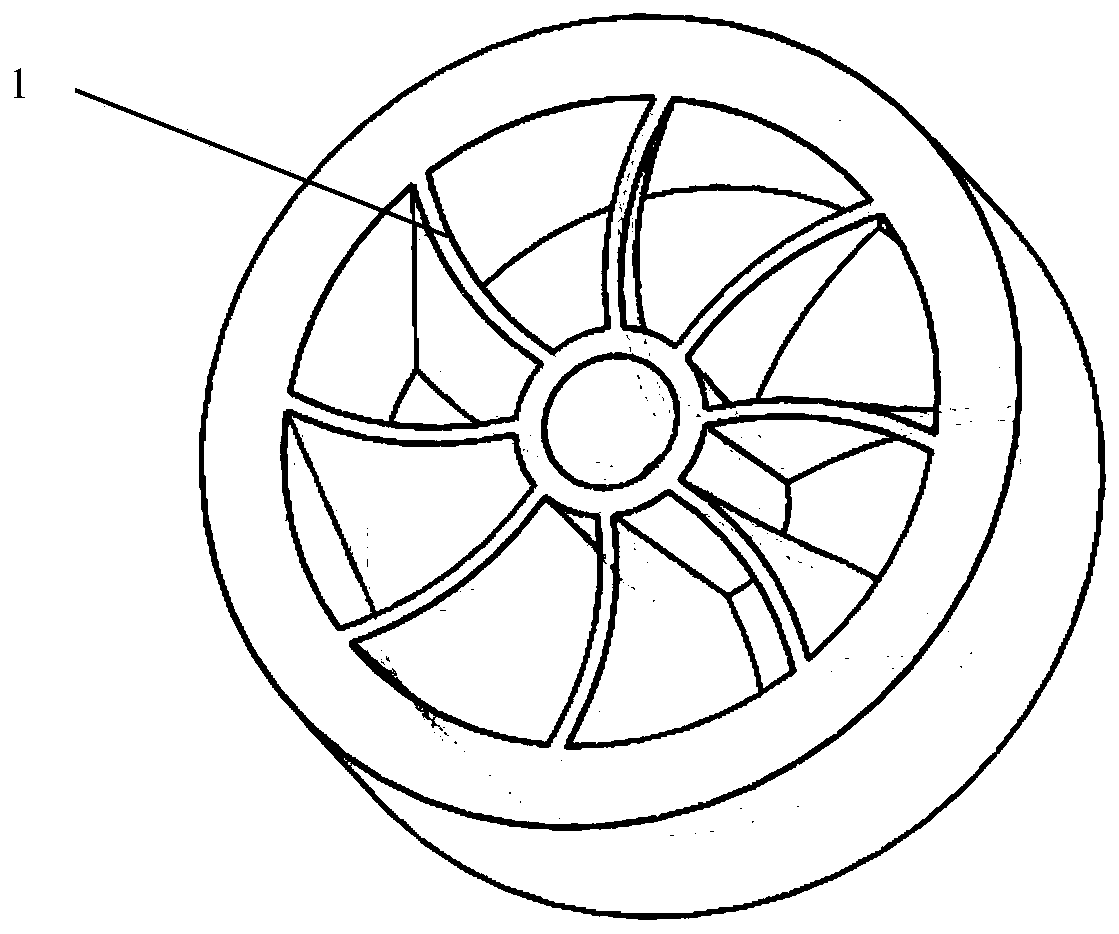

[0032] (1) The fan-type blade turbulence generator 1 of the combined rectification system of the present invention is designed as 8 pieces, and the torsional inclination of each fan blade is 30 degrees. The middle fixed axis of the generator is a hollow cylinder with an inner diameter of 3 mm and a wall thickness of 1 mm. , the axial length of the generator is 3 cm, and there is a 3 cm long buffer straight pipe section 2 between the turbulent flow generator 1 and the perforated plate 3 .

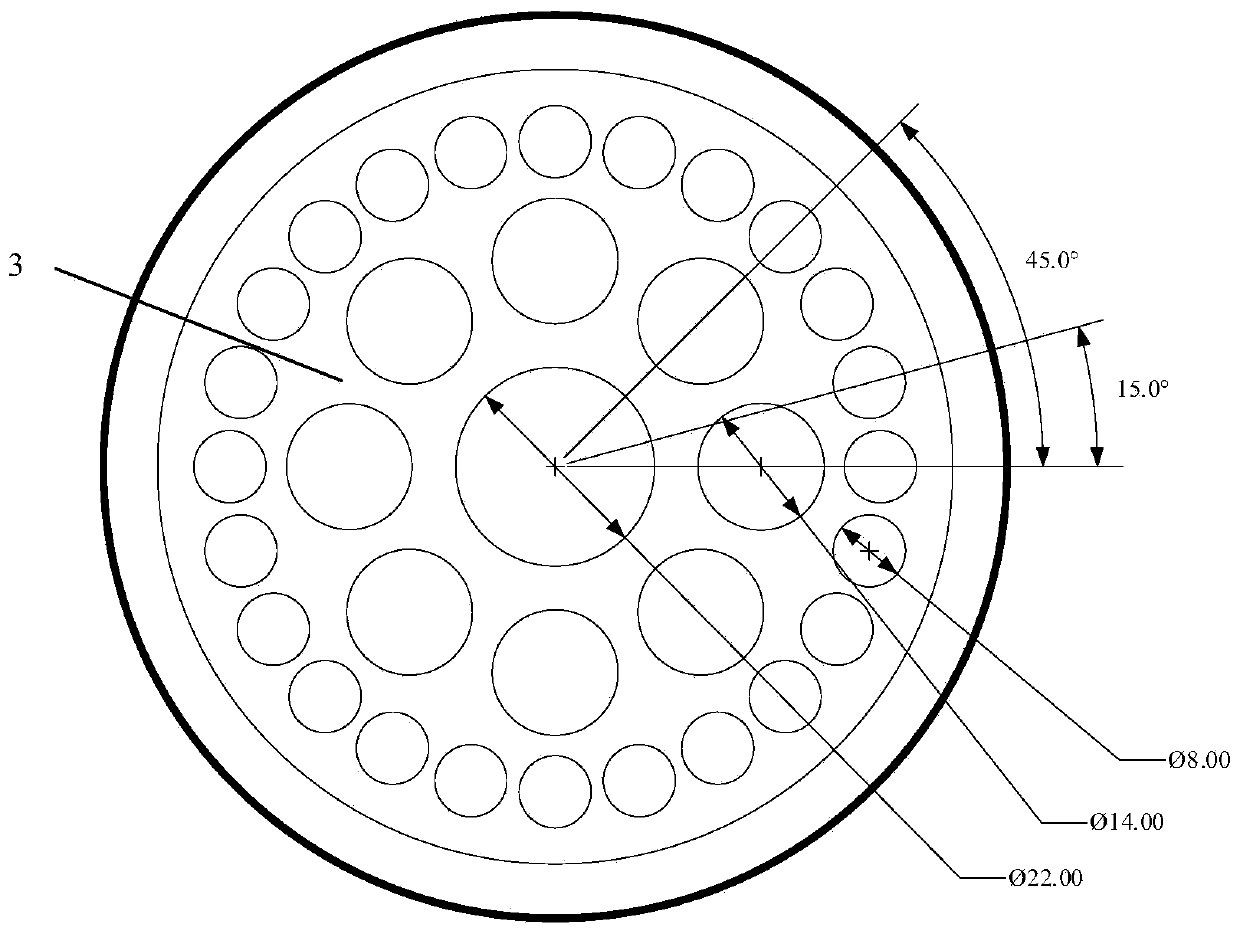

[0033] (2) if figure 1 As shown, the perforated plate 3 of the combined rectification system of the present invention is made by punching a corrosion-resistant metal plate, with an outer diameter of 100 mm, consisting of one rectification hole with an inner diameter of 22 mm, eight rectification holes with an inner diameter of 14 mm, and 24 rectification holes with an inner diameter of 8 mm. Each rectifying hole is circular and has an axial length of 3 cm.

[0034] (3) The combined rectific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com