Method for screening and preparing characteristic components from tobacco and application

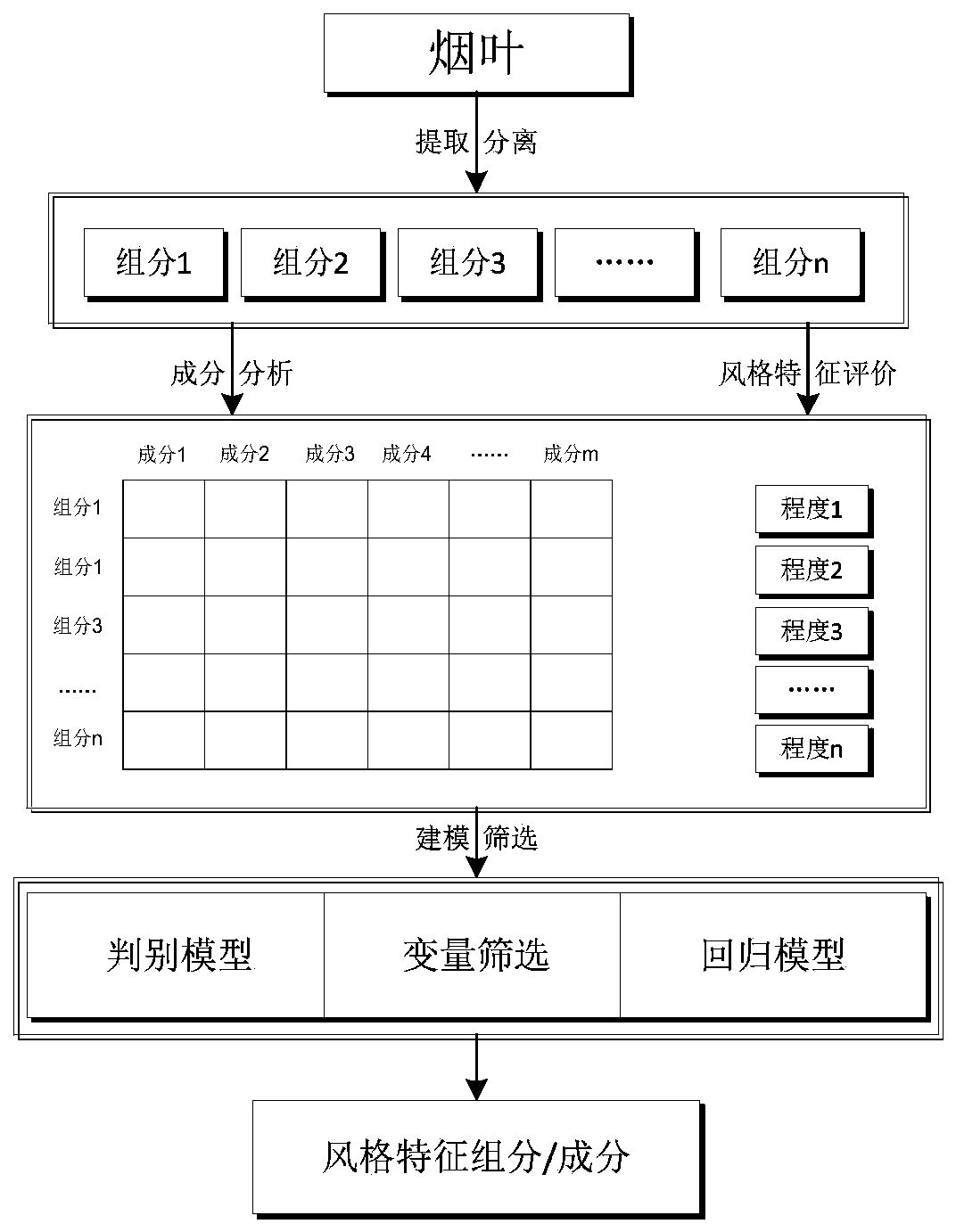

A technology for tobacco and cigarettes, which is applied in the field of preparing characteristic components with outstanding sensory quality, which can solve problems such as poor selectivity of preparation methods and uncertain target compound groups, and achieve the effects of improving specific sensory quality, reducing research waste, and strong targeting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) After the lower tobacco leaves of K326 were extracted with 100% ethanol, the extract was finely separated by HPD macroporous resin column to obtain 10 segments of K326 components;

[0034] (2) K326 components are relatively quantified by Waters 2690 high performance liquid chromatography, and at the same time, the degree of body fluid production of each component is determined through sensory evaluation;

[0035] Through the first and second steps, the X variable about the chromatographic information of the tobacco leaf components and the Y variable about the characteristics of the tobacco leaf component's body fluid effect are obtained.

[0036] (3) Using partial least squares regression, combined with model group analysis, to screen ingredients that contribute more to the sense of body fluid;

[0037] The parameters are set as follows: number of principal components of partial least squares: 3; parameter v: 0.2, parameter q: 0.7, number of iterations: 1000.

[00...

Embodiment 2

[0041] (1) After extracting the leaves of Tabacco tabacum with 50% ethanol, the extract was finely separated by HPD macroporous resin column to obtain 20 segments of tabacum tabacum;

[0042] (2) The red component is relatively quantified by the Agilent 6520-Q-Tof ultra-high performance liquid mass spectrometry system, and at the same time, the degree of sweetness of each component is determined through sensory evaluation;

[0043] Through the first and second steps, the X variable about the chromatographic information of the tobacco leaf components and the Y variable about the characteristics of the sweetening effect of the tobacco leaf components are obtained.

[0044] (3) According to the evaluation results of the sweetness of the components, the tobacco leaf components were divided into two groups, among which the aroma content was greater than the average value was group 1, and the aroma content was less than the average value was group 0. Weight analysis was used to scree...

Embodiment 3

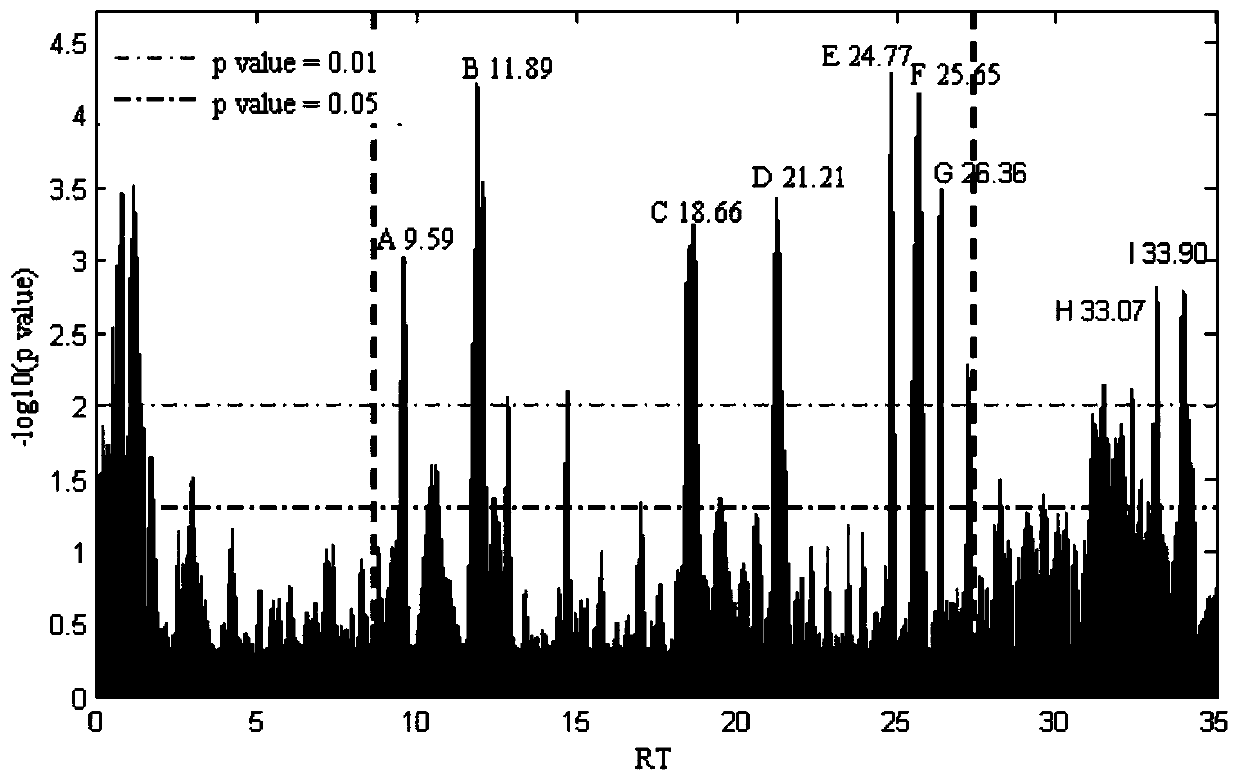

[0051] (1) After extracting the upper tobacco leaves of Yun 87 with pure water, the extract was finely separated by preparative chromatography to obtain 20 segments of Yun 87 components;

[0052] (2) The components of Yun 87 were relatively quantified by Agilent 1200 high-performance liquid chromatography, and at the same time, the aroma of each component was determined through sensory evaluation;

[0053] Through the first and second steps, the X variable about the chromatographic information of the tobacco leaf components and the Y variable about the aroma effect characteristics of the tobacco leaf components are obtained.

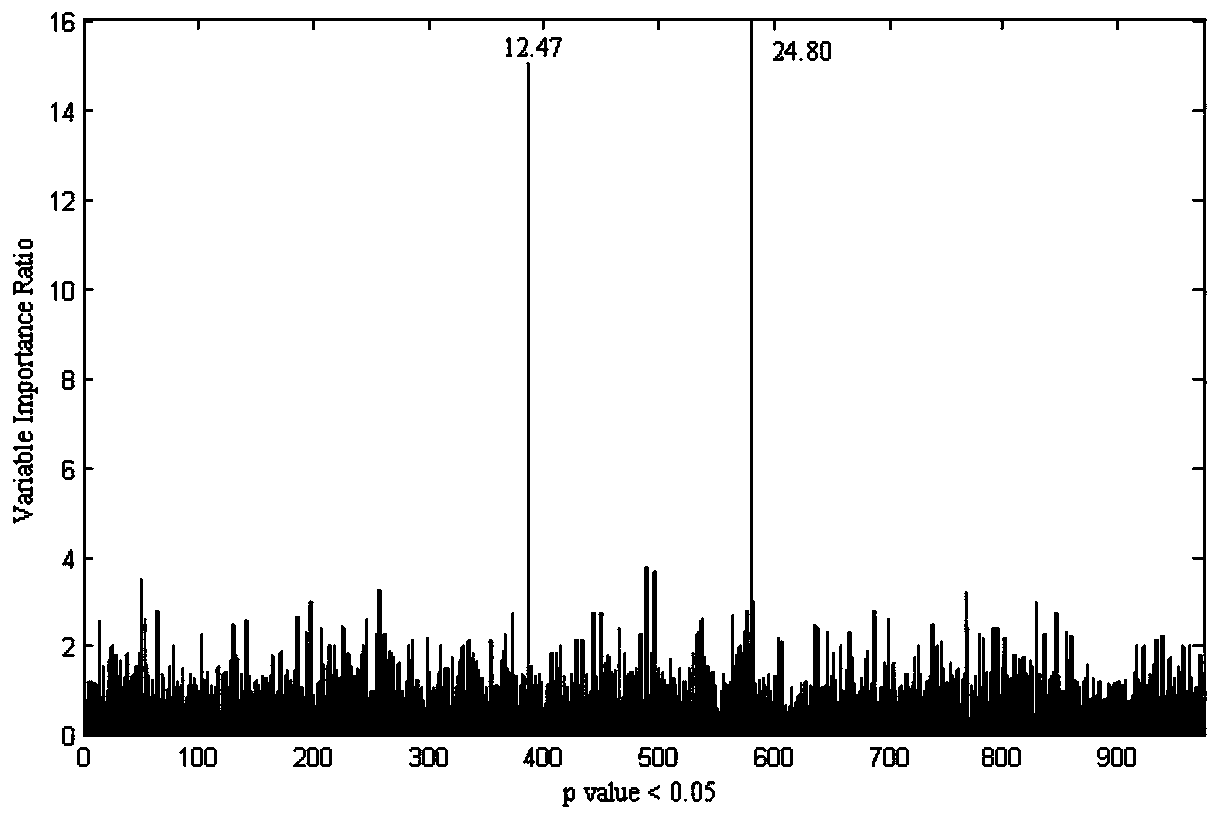

[0054](3) Use the discriminant analysis model, combined with the analysis of the ratio of advantages and disadvantages, to screen the ingredients that contribute more to the aroma;

[0055] The parameters of the ratio algorithm are set as follows: Monte Carlo variable selection ratio: 0.02; Monta Carlo sample selection ratio: 0.7; number of iterations: 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com