Industrial line-following conveying robot based on internet of things

A technology for handling robots and robots, applied in the field of handling robots, can solve problems such as performance to be improved, and achieve the effects of simple structure, low price and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

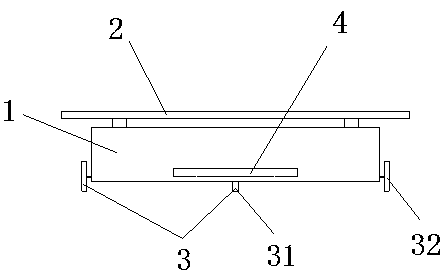

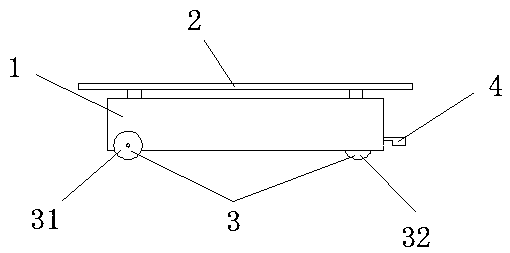

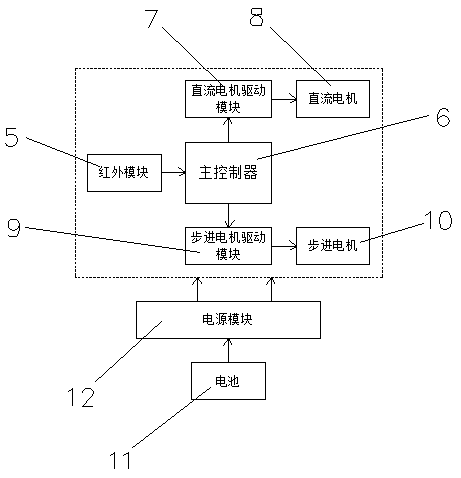

[0014] see figure 1 , figure 2 and image 3 , the present invention provides a technical solution: an industrial line-following robot based on the Internet of Things, including a robot shell 1, a transport plate 2, wheels 3, an infrared sensor probe 4 and a circuit part, and the transport plate 2 is located at the bottom of the robot shell 1. In the upper part, the wheel 3 includes a power wheel 3-1 and a steering wheel 3-2. There are two power wheels 3-1 and one steering wheel 3-2. The infrared sensor probe 4 is located at the front of the robot shell 1, and the circuit parts are all installed Inside the robot shell 1, the circuit part includes an infrared module 5, a main controller 6, a DC motor drive module 7, a DC motor 8, a stepper motor drive module 9, a stepper motor 10, a battery 11 and a power supply module 12, and the infrared module 5. Both the DC motor drive module 7 and the stepper motor drive module 9 are connected to the main controller 6 . The DC motor dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com