Micro-moving mechanism for driving screen plate through servo motors in high-precision printing machine

A technology of servo motors and printing machines, applied in printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of reduced precision, low precision, waste of time, etc., and achieve improved precision, high precision reliability, and precision control high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

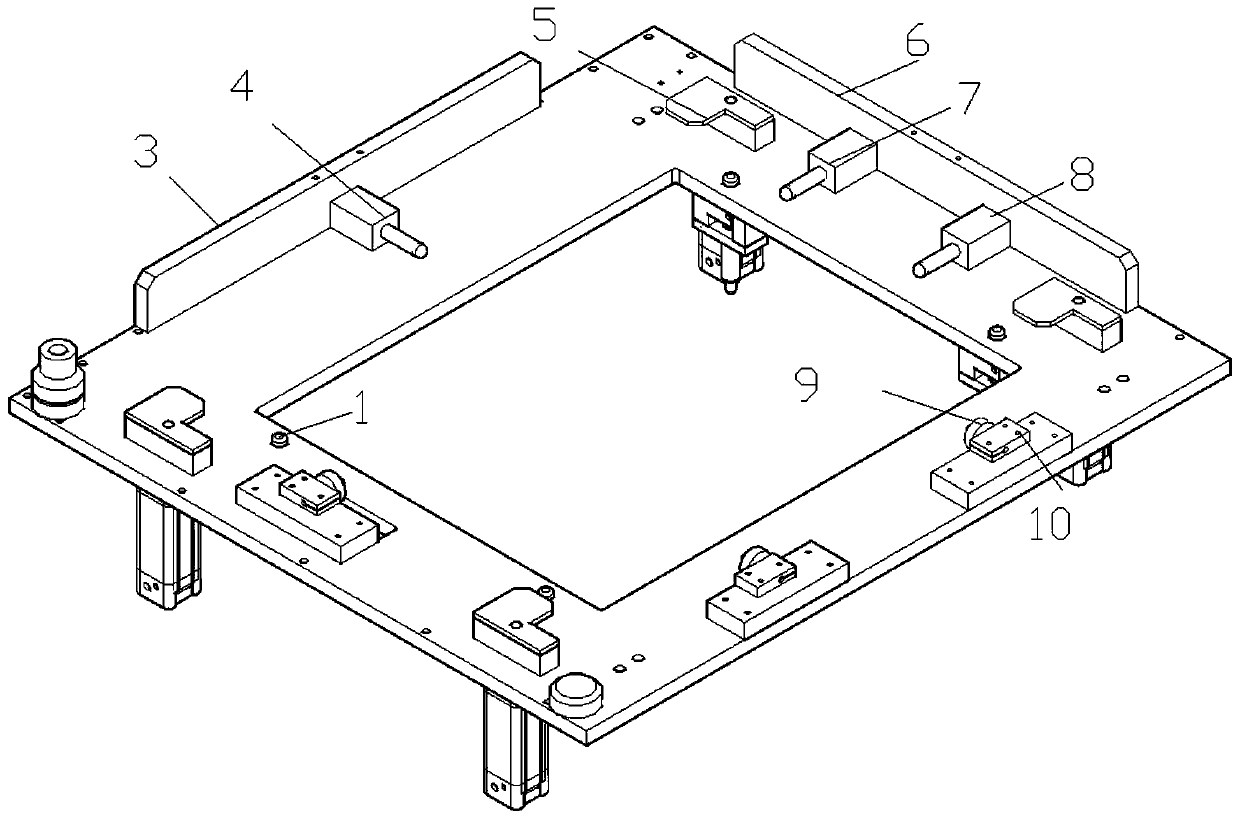

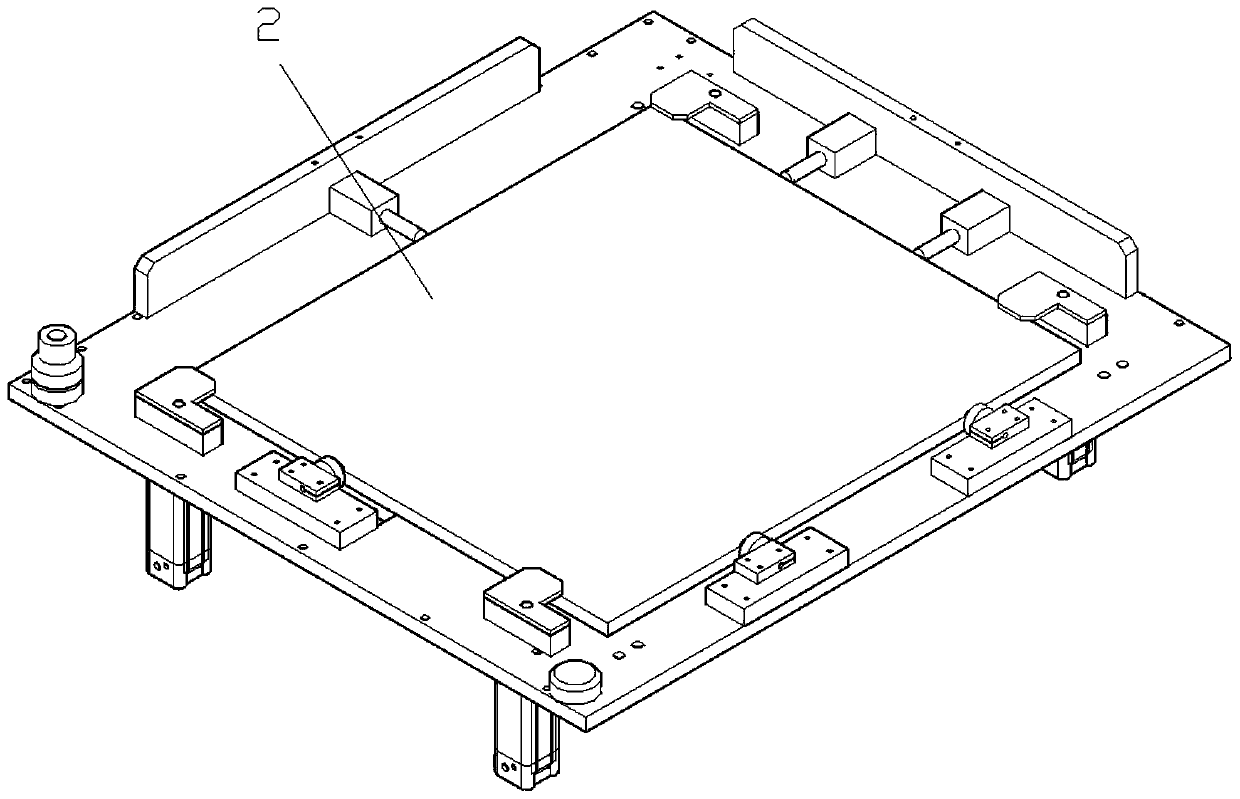

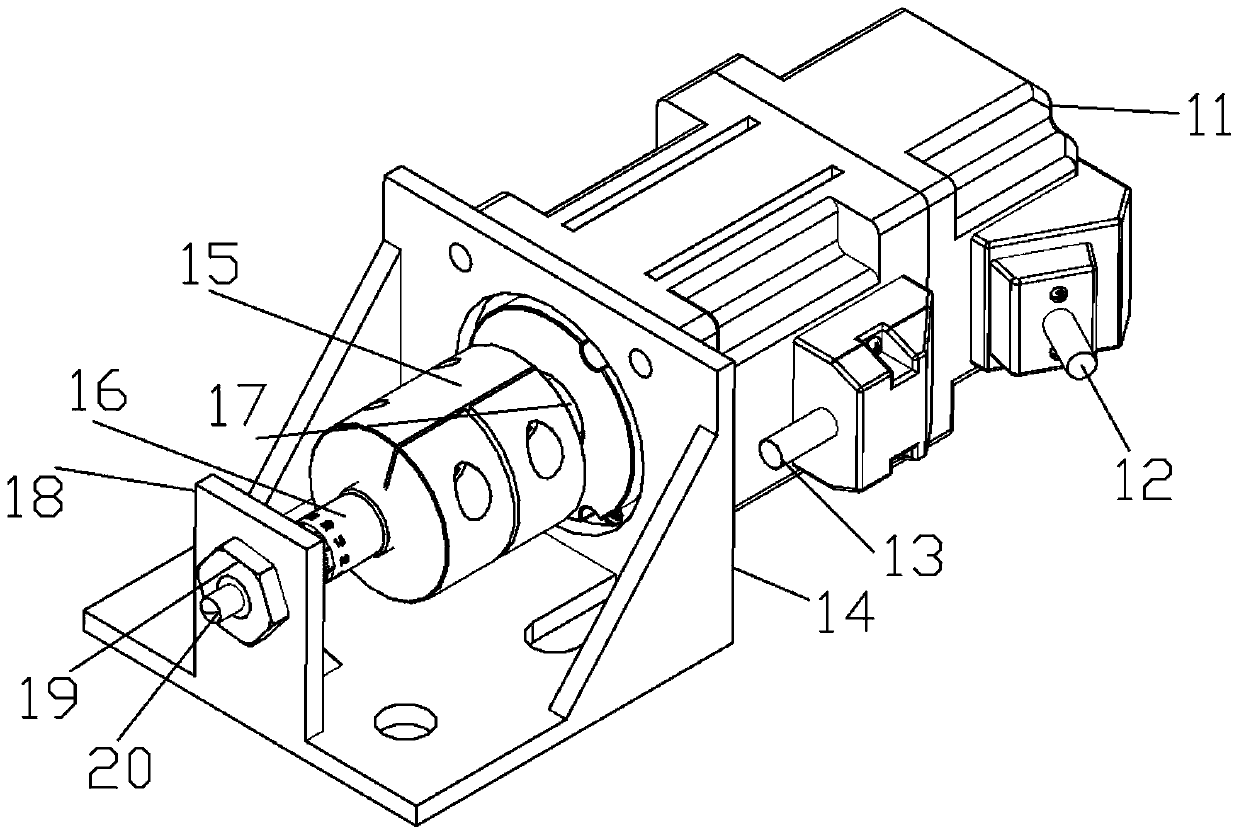

[0021] Such as Figure 1~3 As shown, it shows a specific embodiment of the present invention. As shown in the figure, the present invention discloses a micro-motion mechanism of a servo motor driving a screen plate in a high-precision printing machine.

[0022] Including the assembled horizontal plate, the assembled horizontal plate is a rectangular structure, including four frame sides and a rectangular hollow hole in the center; the four corners of the front side of the assembled horizontal plate are assembled with a hook plate cylinder and a pressure plate bolt; the piston rod of the hook plate cylinder passes through the Assemble the horizontal plate and install the hook plate at the end, the pressure plate bolts pass through the assembled horizontal plate and the end is the pressure head; the steel mesh is placed between the hook plate and the pressure head;

[0023] An X drive motor assembly and two X ejector rods are respectively arranged on the two frame edges of the X...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap