Patents

Literature

40results about How to "High precision and reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

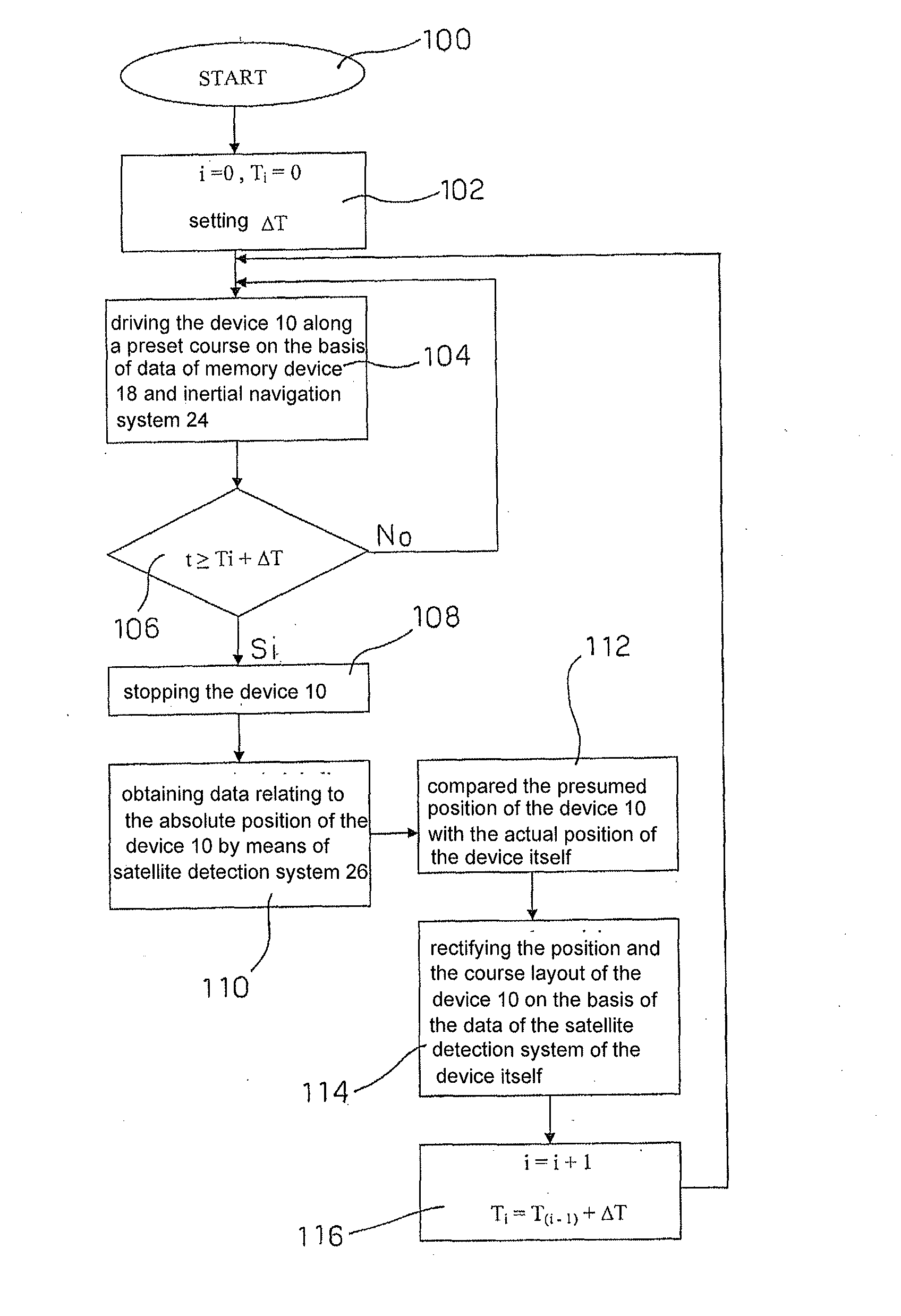

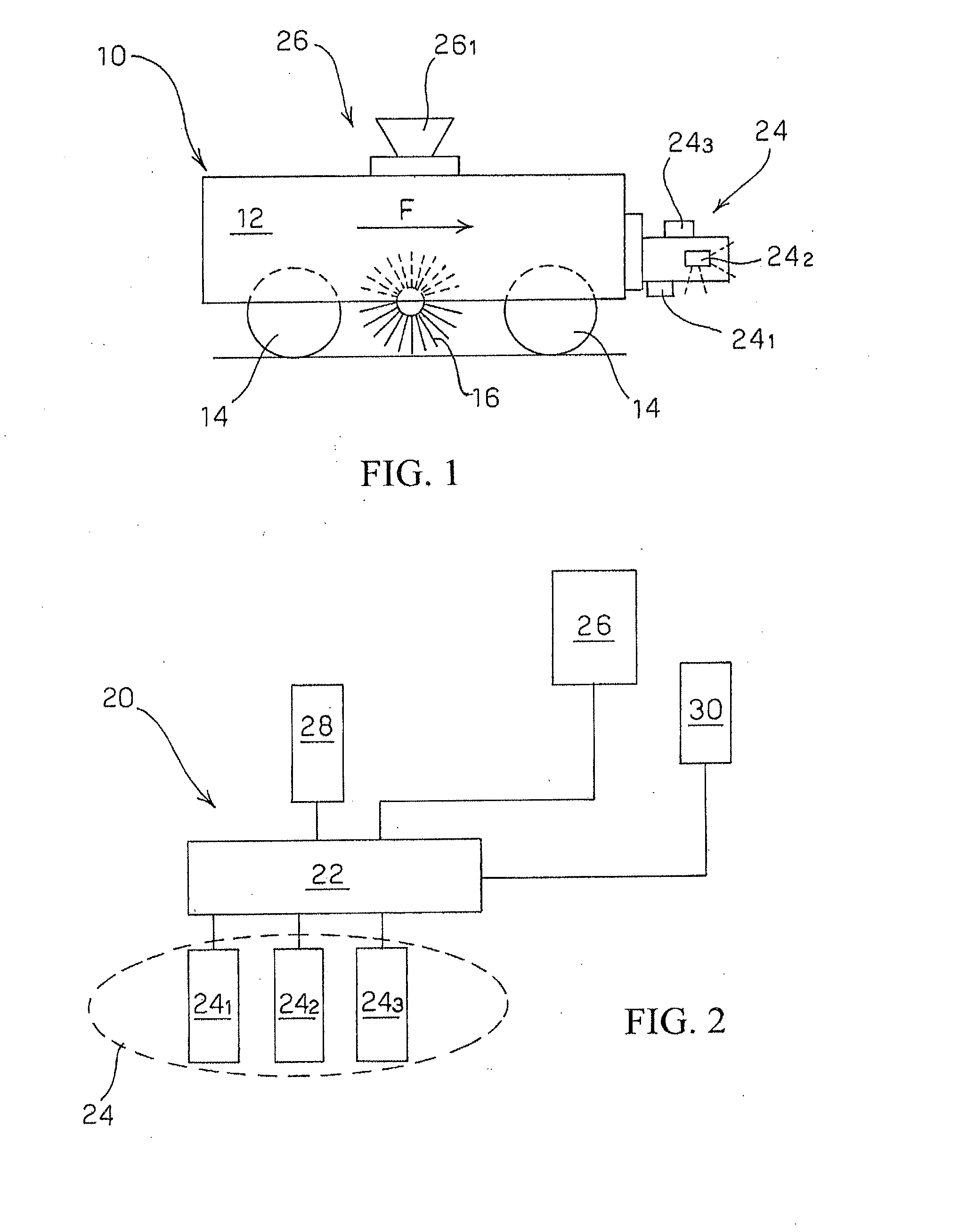

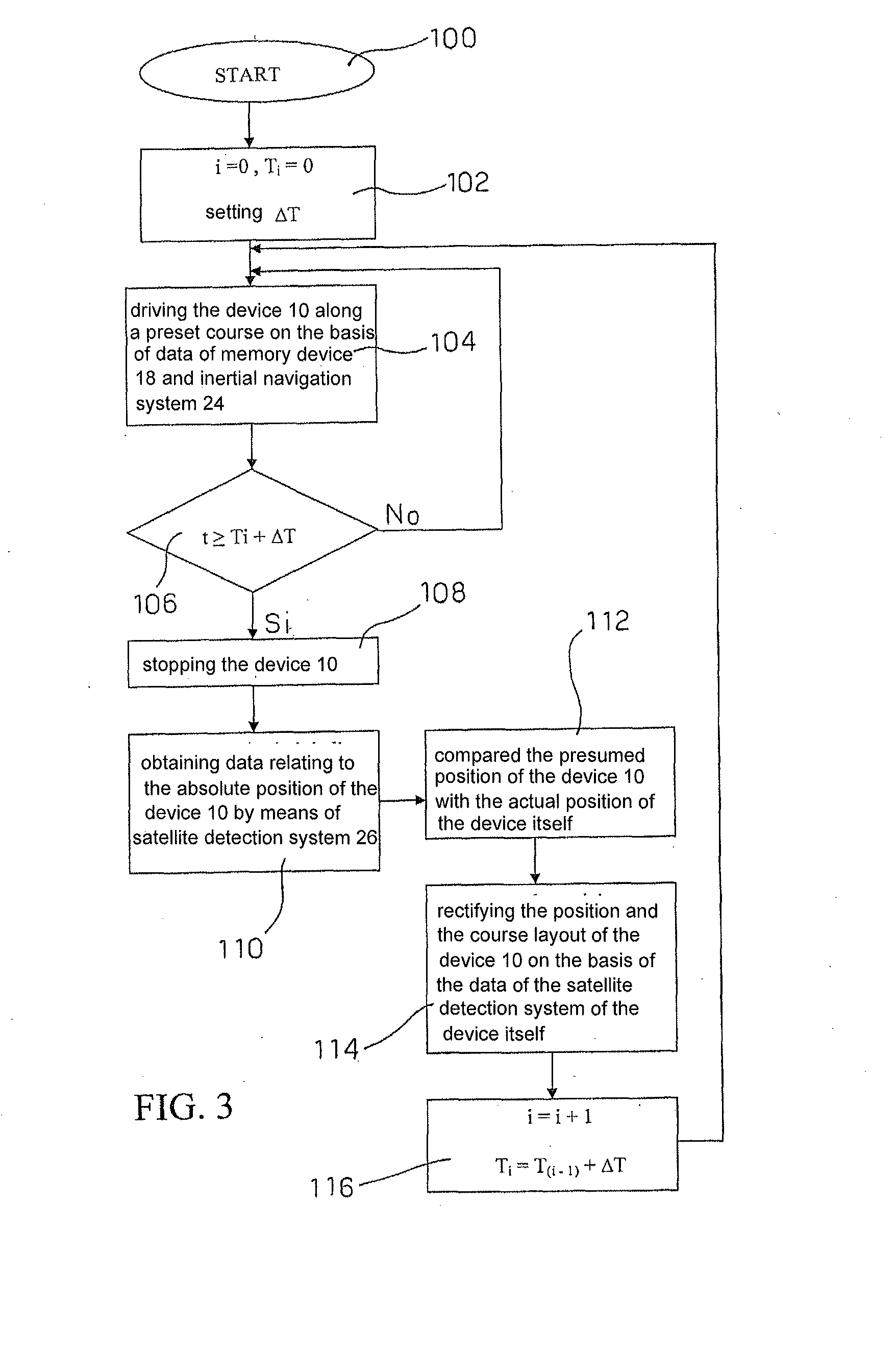

Method and system for controlling a self-propelled robot device

InactiveUS20130218397A1High precisionImprove reliabilityMowersNavigation by speed/acceleration measurementsControl systemSimulation

The present invention relates to a method for controlling a self-propelled robot device, such as a robot device for mowing grass, and a control system that carries out the aforementioned method. According to the invention, the self-propelled robot device is driven by an inertial navigation system for a set time period or distance and the device is periodically stopped for rectifying the position and advancing course thereof by a satellite detection system: the periodic correction of the inertial navigation system using satellite detections thus prevents course errors from accumulating. The correction based on the satellite detection system can be possibly optimized through a further selection of the obtained values according to a statistical basis. Preferably, the control method according to the invention also provides a procedure for detecting, recording and mapping the operating region wherein the device is operated.

Owner:ACTIVE NETWORK LLC

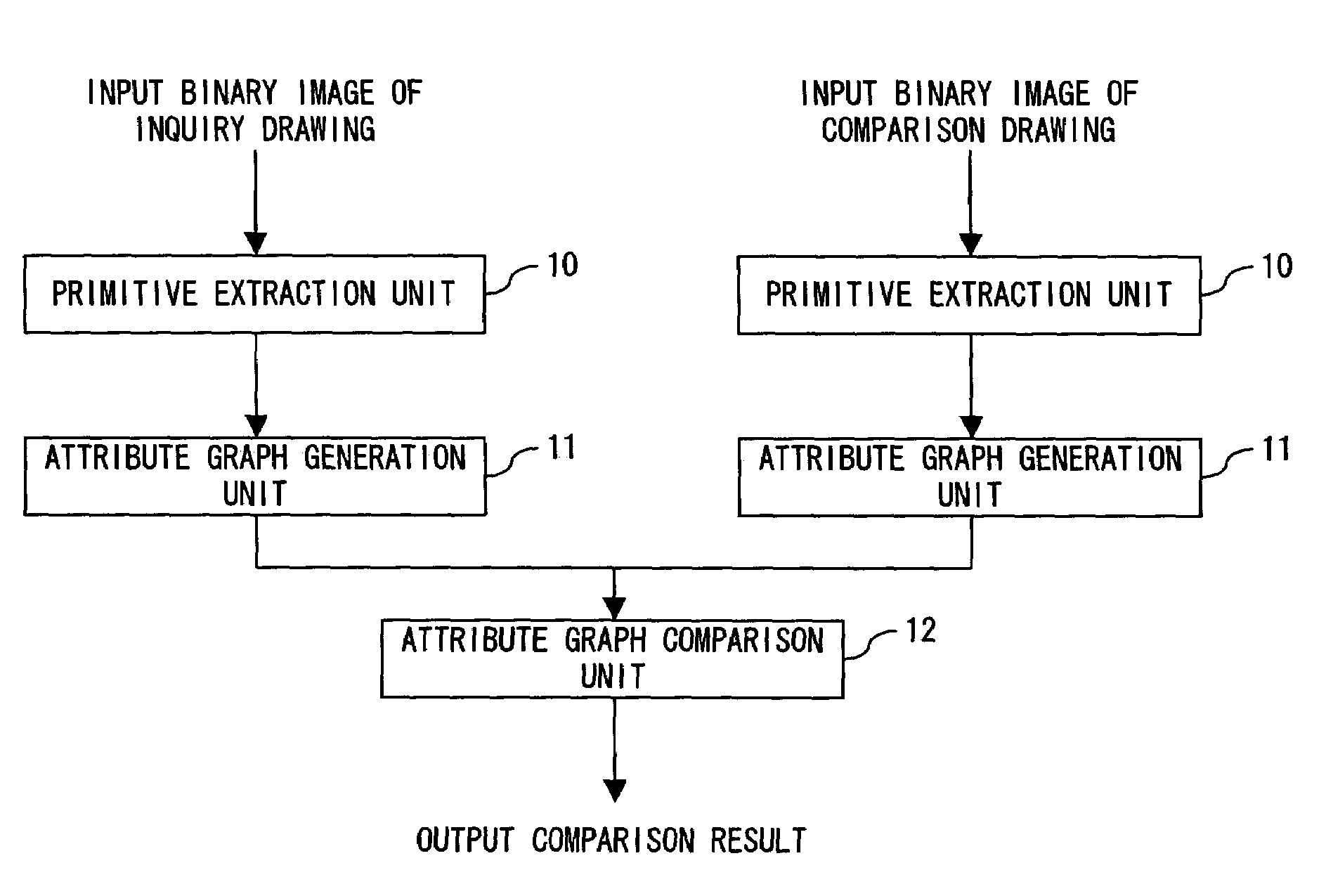

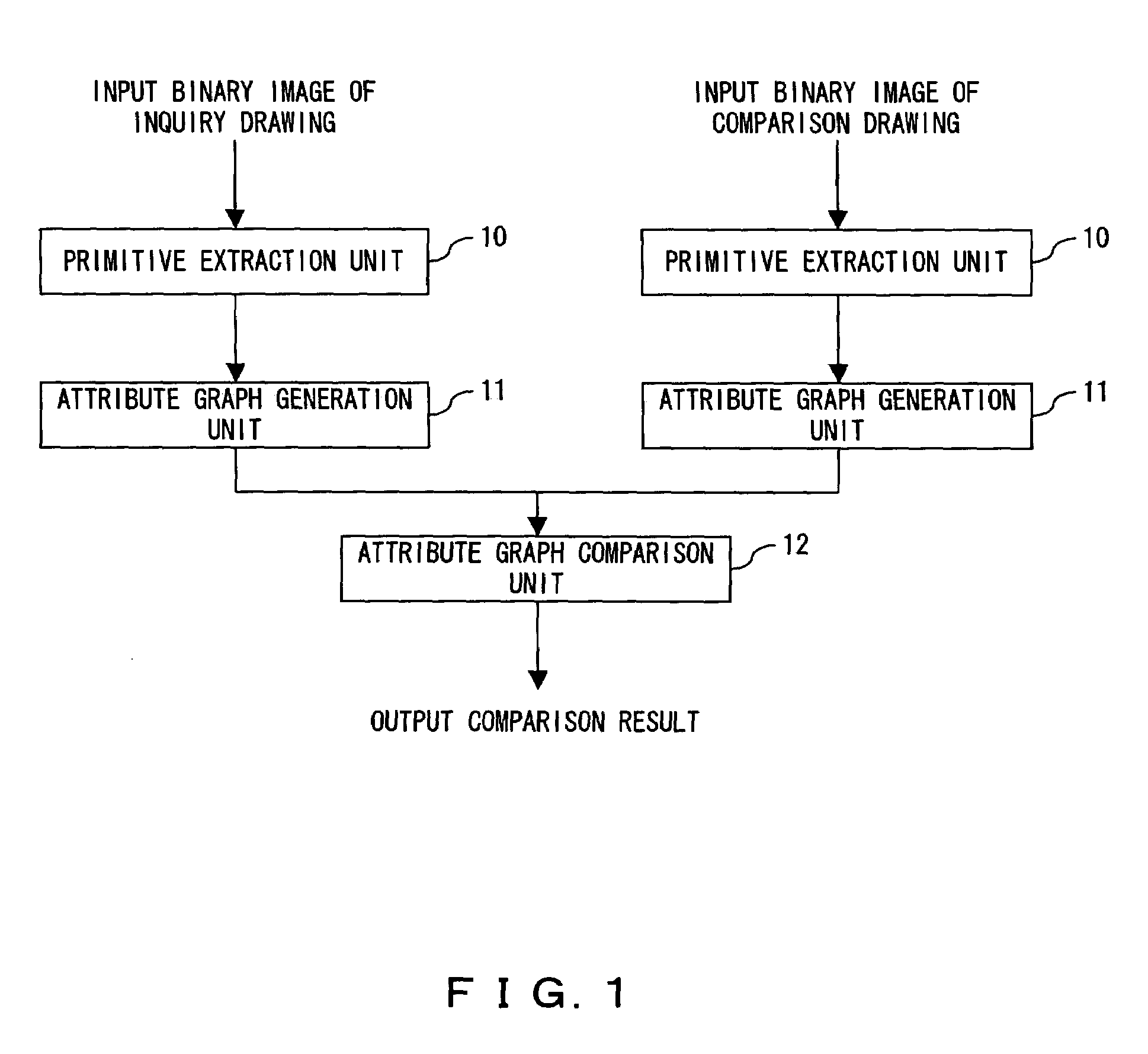

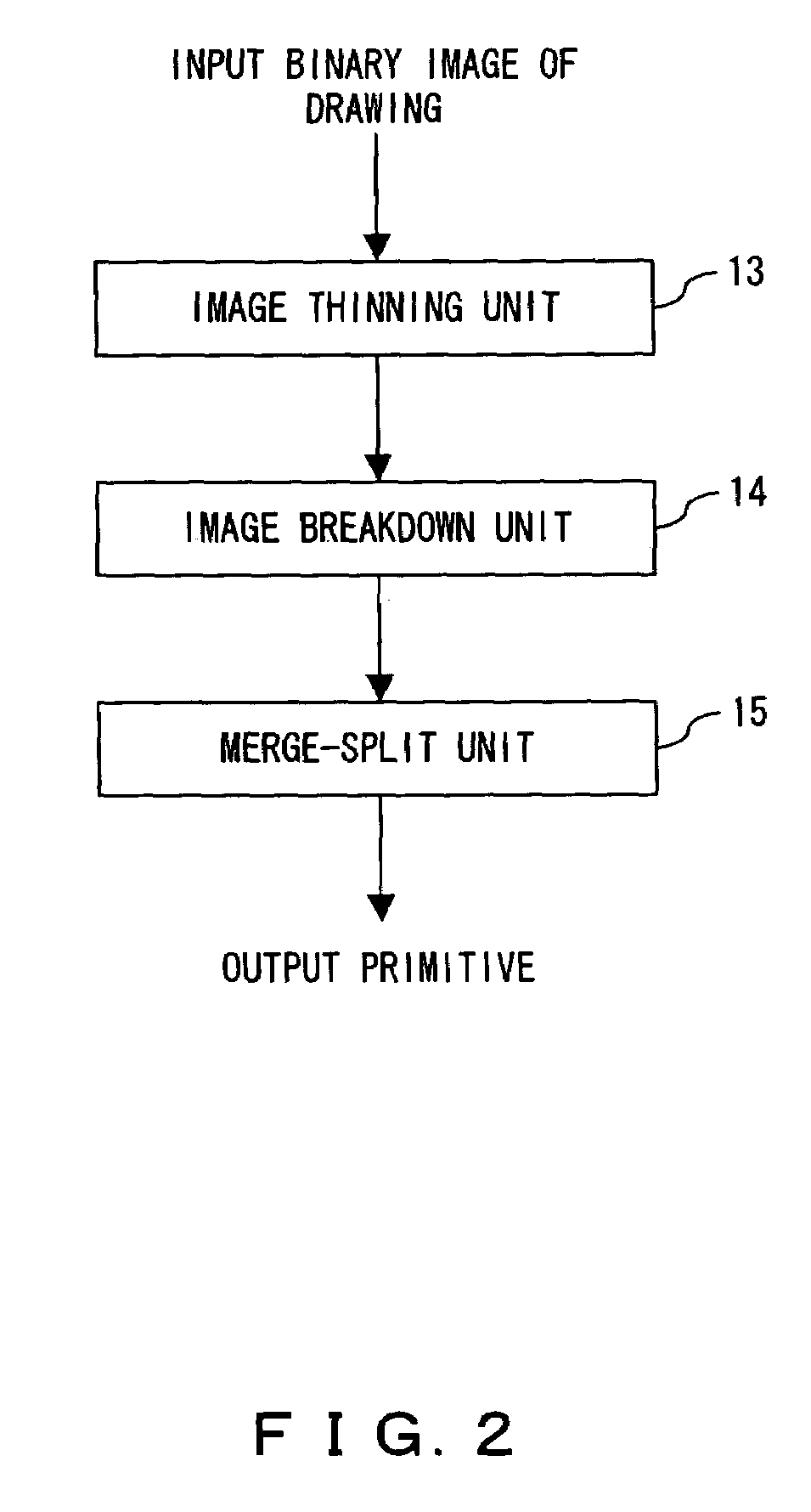

Drawing comparison apparatus

InactiveUS7106330B2High precision and reliabilityImprove accuracyDrawing from basic elementsData processing applicationsSpatial correlationAttribute grammar

Owner:FUJITSU LTD

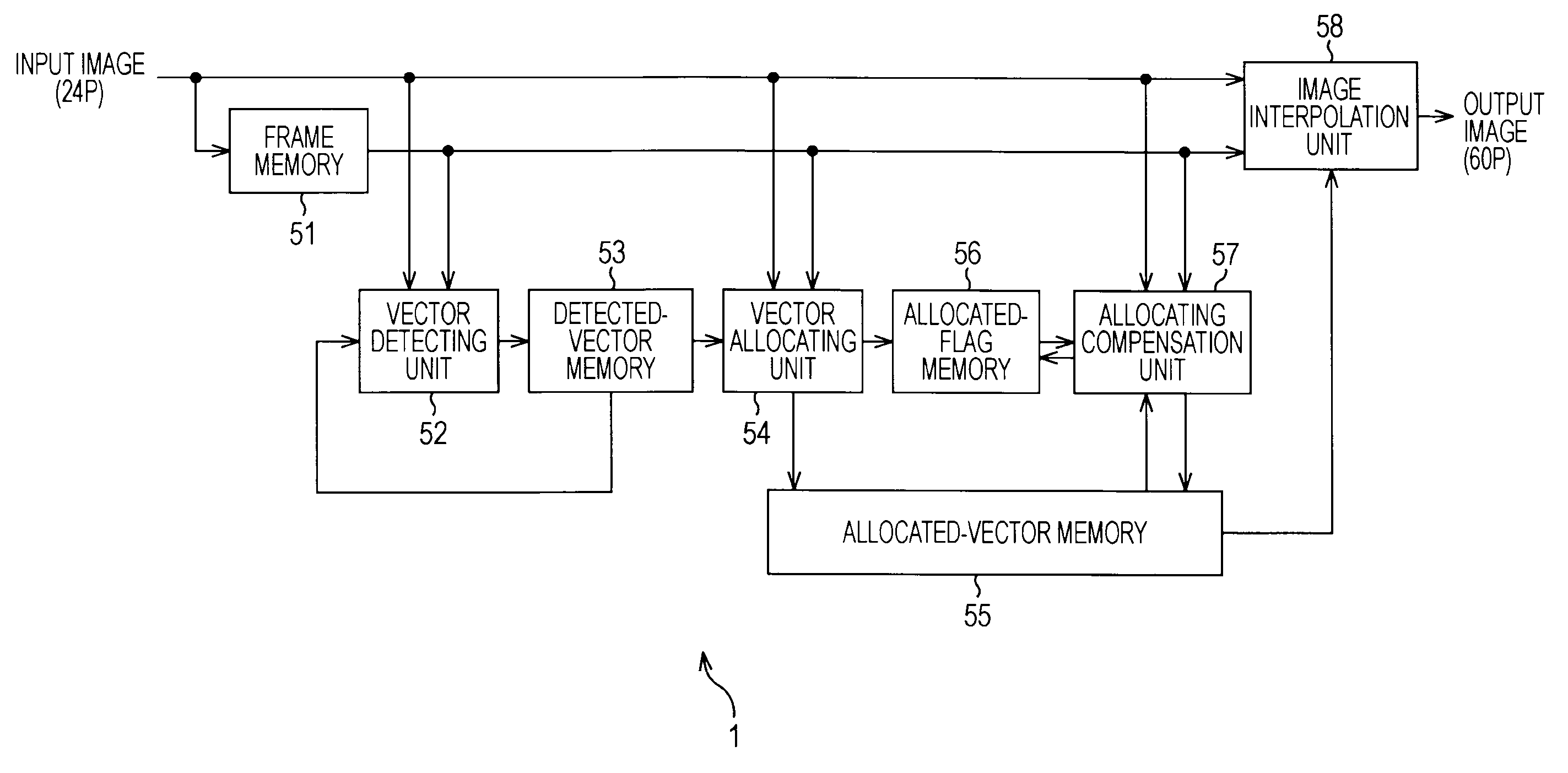

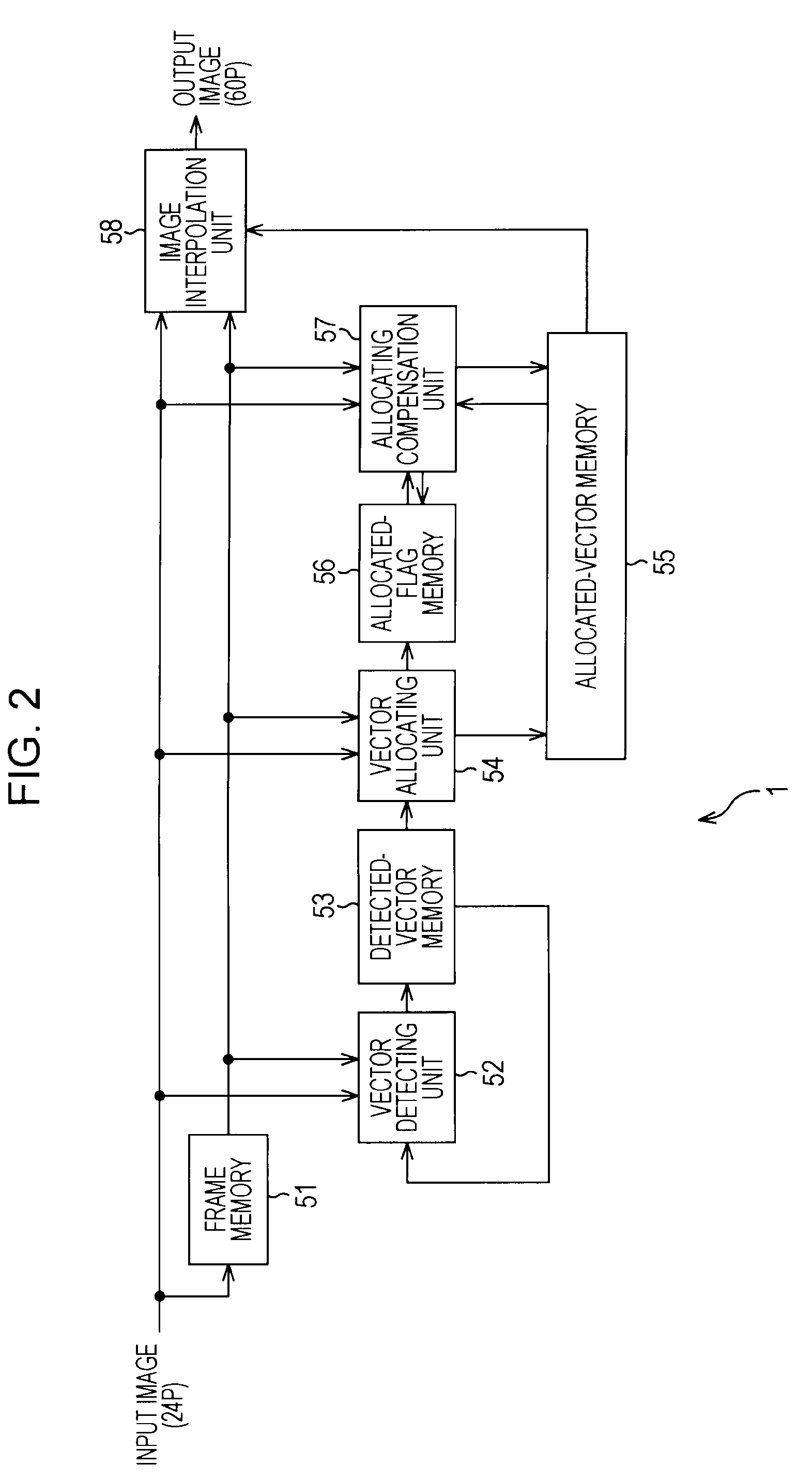

Image processing device and method, program, and recording medium

InactiveUS20090167959A1Easy to detectAccurate detectionImage enhancementTelevision system detailsLight sourceFrequency conversion

The present invention relates to an image processing device and method, a program, and a recording medium whereby the evaluation regarding the reliability of a motion vector can be performed even in the case of an average brightness level between frames changing greatly. On a frame t+1, a block B1 at the position shifted from a pixel p1 to which a pixel p0 on a frame t corresponds by the vector quantity of a correct motion vector v1, and a block B2 at the position shifted from the pixel p1 to which the pixel p0 corresponds by the vector quantity of an incorrect motion vector v2 are shown. Here, the movement of a light source or the like is performed upon the block B1 alone, and even if the brightness level of the block B1 decreases as a whole, determination is made that the evaluation value of the block B1 is high in reliability as compared with the evaluation value of the block B2 by employing the sum of squared brightness values from which the average brightness value within a computation block is subtracted for each frame as an offset. The present invention can be applied to a signal processing device for performing frame frequency conversion processing from a 24P signal to a 60P signal.

Owner:SONY CORP

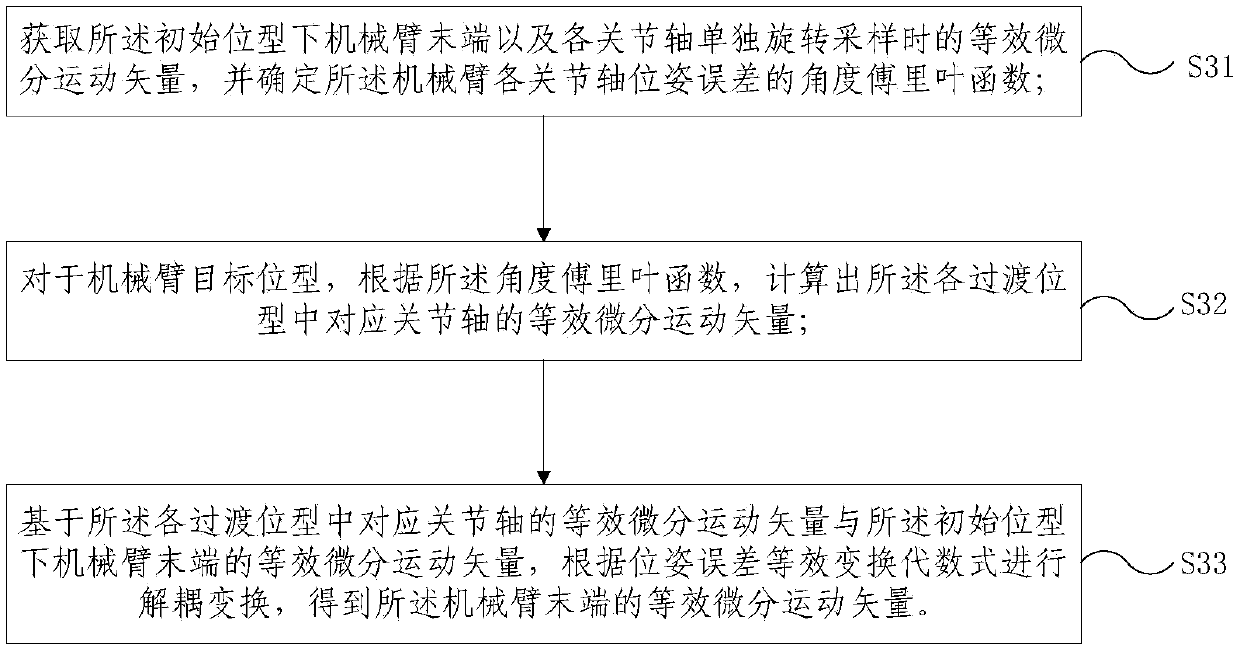

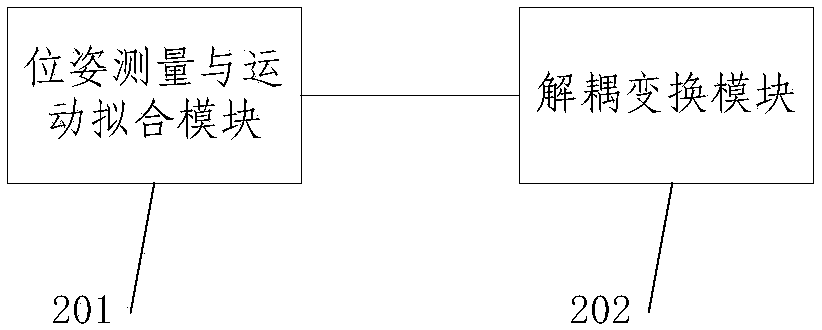

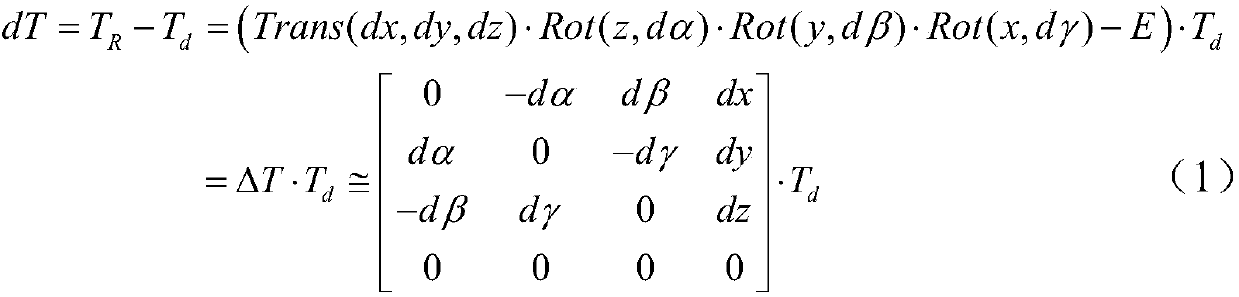

Method and system for calibrating pose error of mechanical arm

ActiveCN107639635AHigh precision and reliabilityProgramme-controlled manipulatorIndependent motionDifferential transformation

The invention provides a method and system for calibrating the pose error of a mechanical arm. The method includes: performing equivalent differential transformation on the pose error of the tail endof the mechanical arm to obtain an equivalent differential motion vector, decomposing the equivalent differential motion vector into the equivalent differential motion vector of each joint shaft, during independent motion, of the mechanical arm, and performing calibration and decoupling transformation on the pose error of each joint shaft, during independent rotation sampling, of the mechanical arm to calibrate the pose error of the tail end of the mechanical arm. The method and system has the advantages that equivalent different transformation description is performed on the pose error at thetail end of the mechanical arm to obtain the equivalent differential motion vector, the equivalent differential motion vector is decomposed into the equivalent differential motion vector of each connecting rod coordinate system, and decoupling calculation and transformation are performed on the connecting rod coordinate systems and joint motion coupling relations to achieve high-precision and high-reliability synchronous calibration of the absolute pose error of the mechanical arm in a full working space range.

Owner:杨聚庆

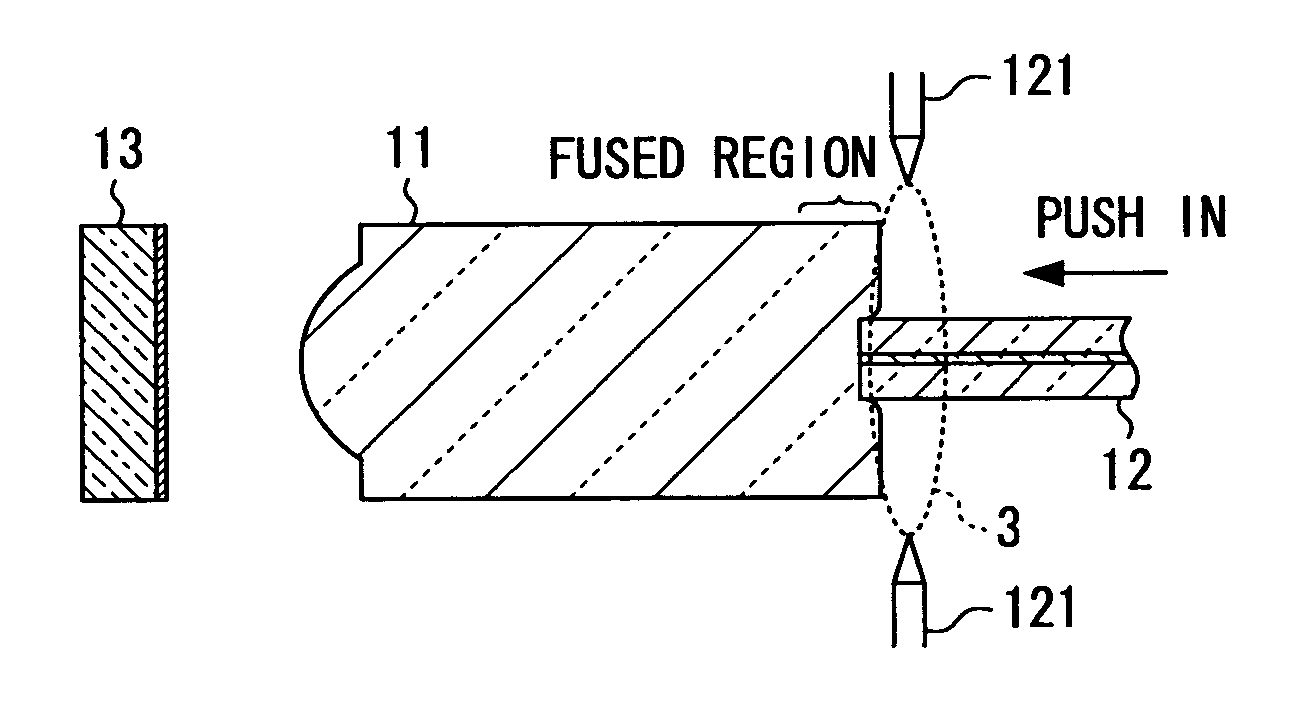

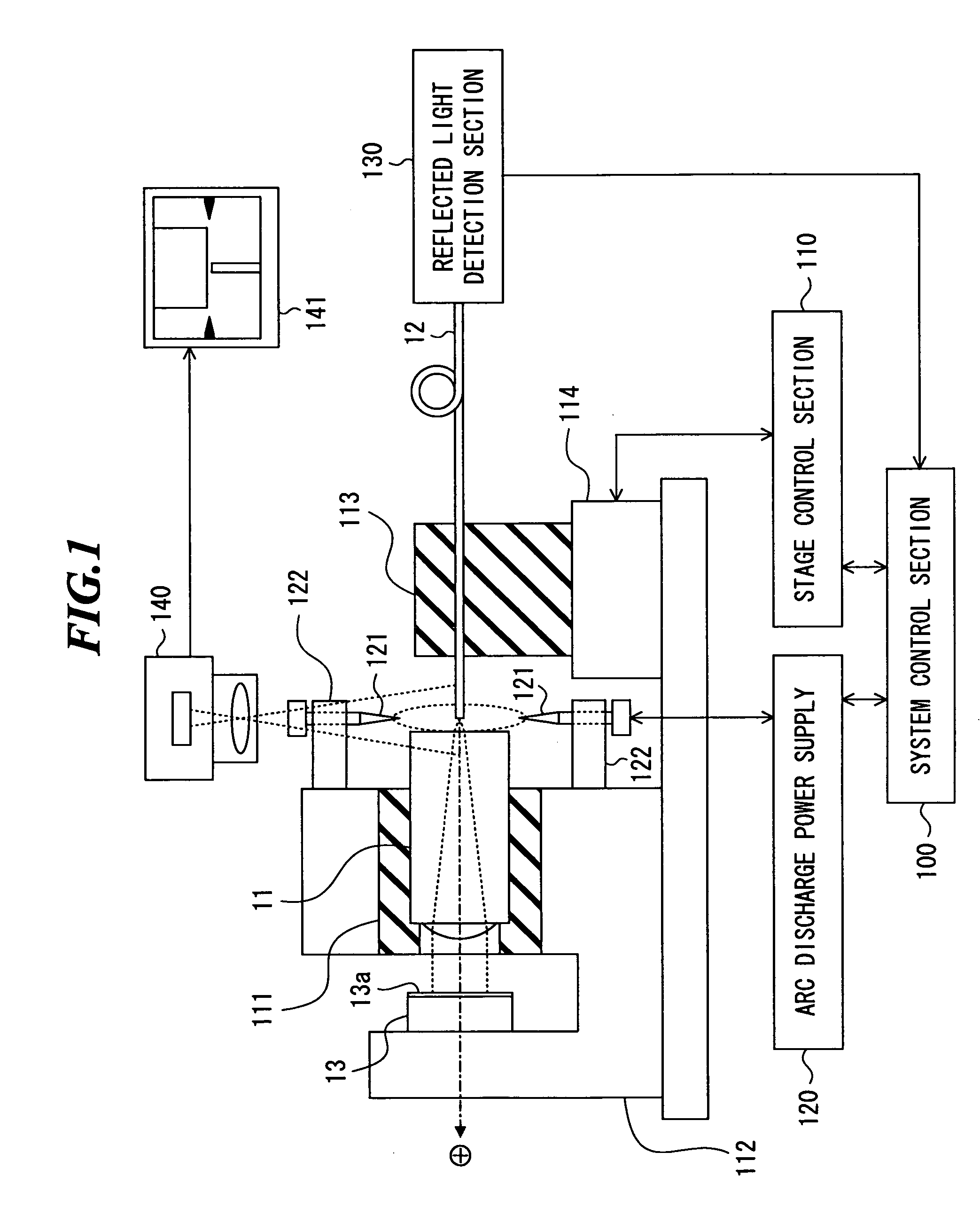

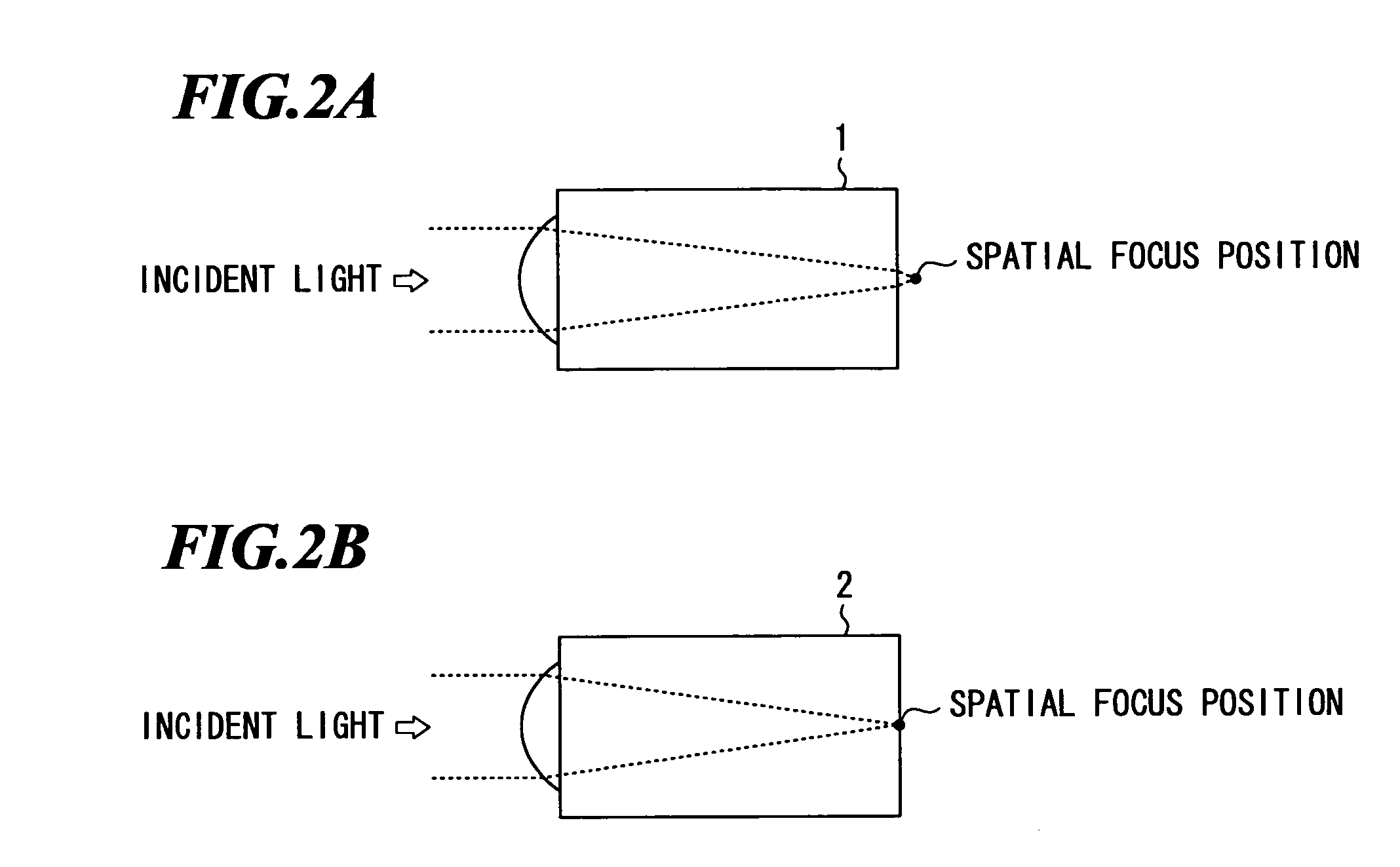

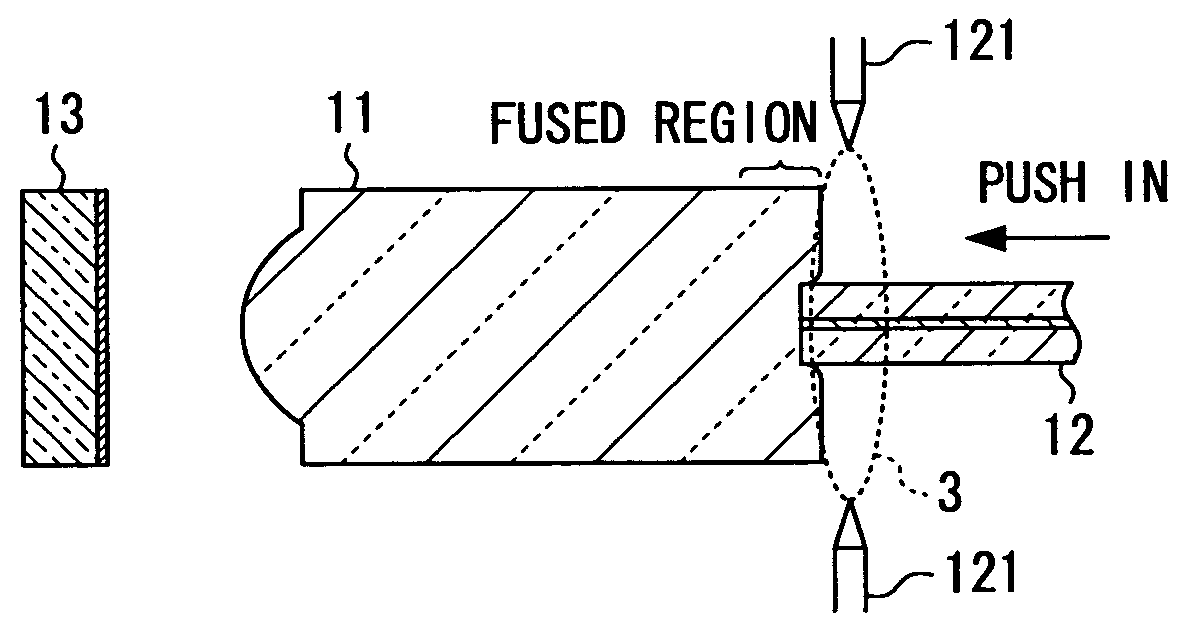

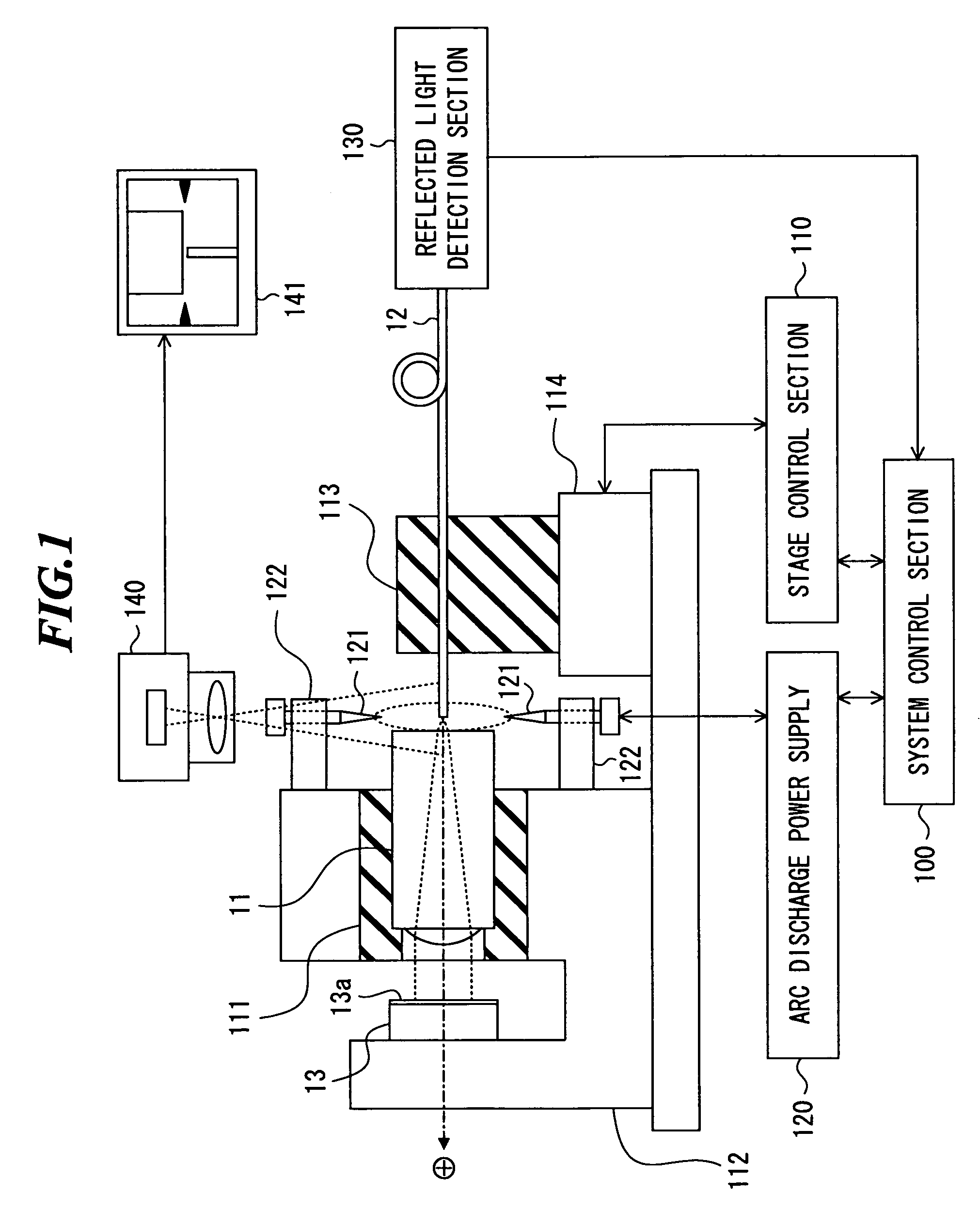

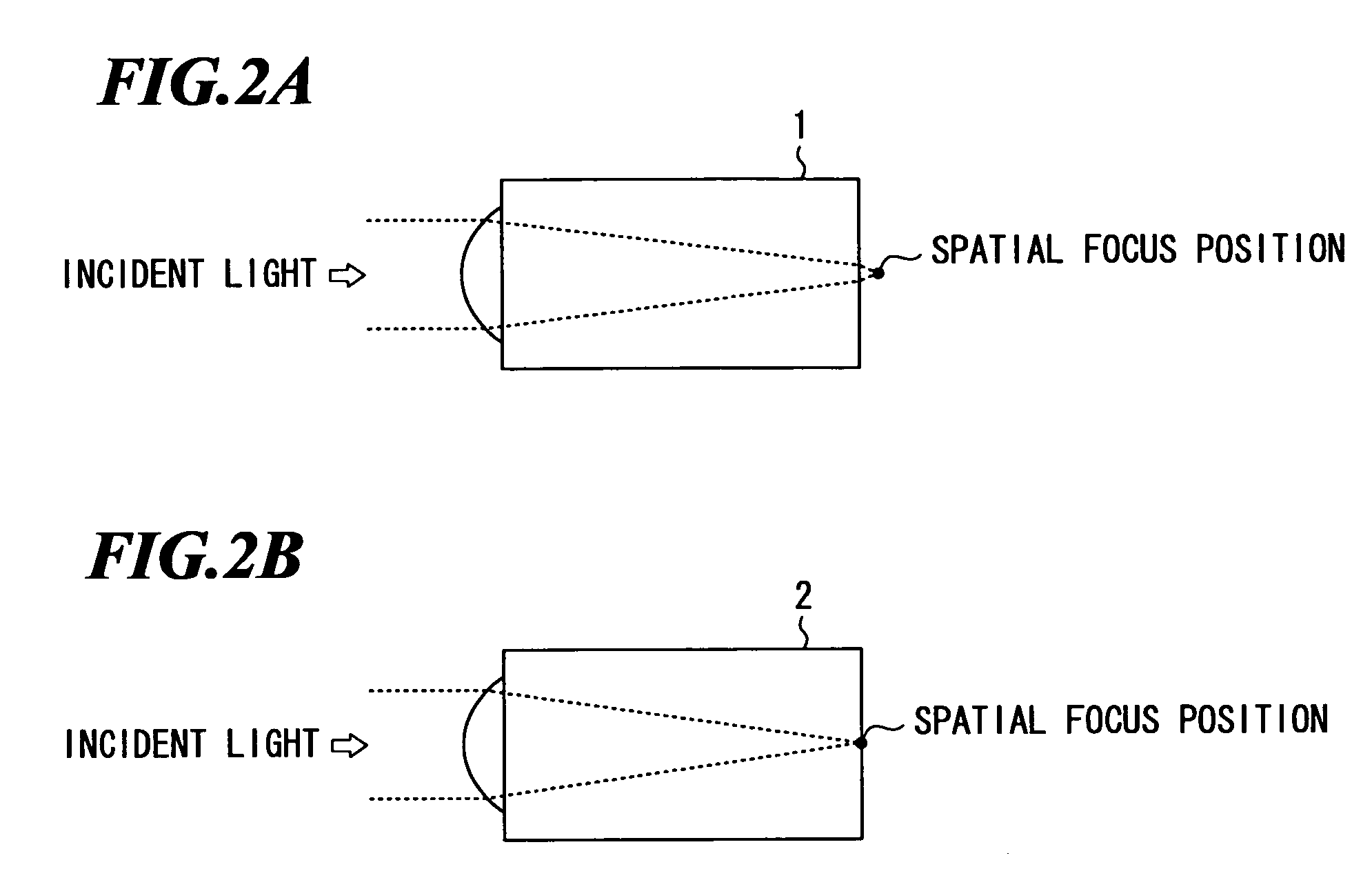

Optical device and fabrication method and apparatus for the same

An optical device fabrication method capable of fabricating optical devices with high precision and reliability in a simple process and at a low cost. The method of splicing a first optical device and a second optical device to fabricate a third optical device includes the steps of: (a) starting heating of an end surface of the first optical device to soften the end surface; (b) pushing the second optical device into the softened end surface to splice the first optical device and a joint surface of the second optical device to each other; (c) pulling back the second optical device to arrange the joint surface of the second optical device onto or outside of the end surface of the first optical device; and (d) terminating heating of the end surface to fix the first and second optical device spliced to each other.

Owner:PRECISE GAUCO

Optical device and fabrication method and apparatus for the same

InactiveUS7400799B2High precision and reliabilitySimple processCoupling light guidesEngineeringJoint surface

An optical device fabrication method capable of fabricating optical devices with high precision and reliability in a simple process and at a low cost. The method of splicing a first optical device and a second optical device to fabricate a third optical device includes the steps of: (a) starting heating of an end surface of the first optical device to soften the end surface; (b) pushing the second optical device into the softened end surface to splice the first optical device and a joint surface of the second optical device to each other; (c) pulling back the second optical device to arrange the joint surface of the second optical device onto or outside of the end surface of the first optical device; and (d) terminating heating of the end surface to fix the first and second optical device spliced to each other.

Owner:PRECISE GAUCO

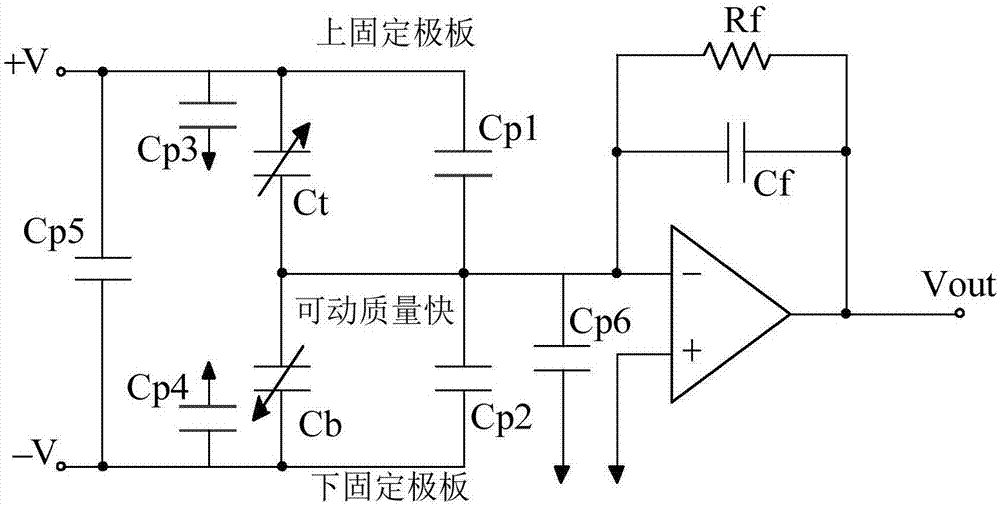

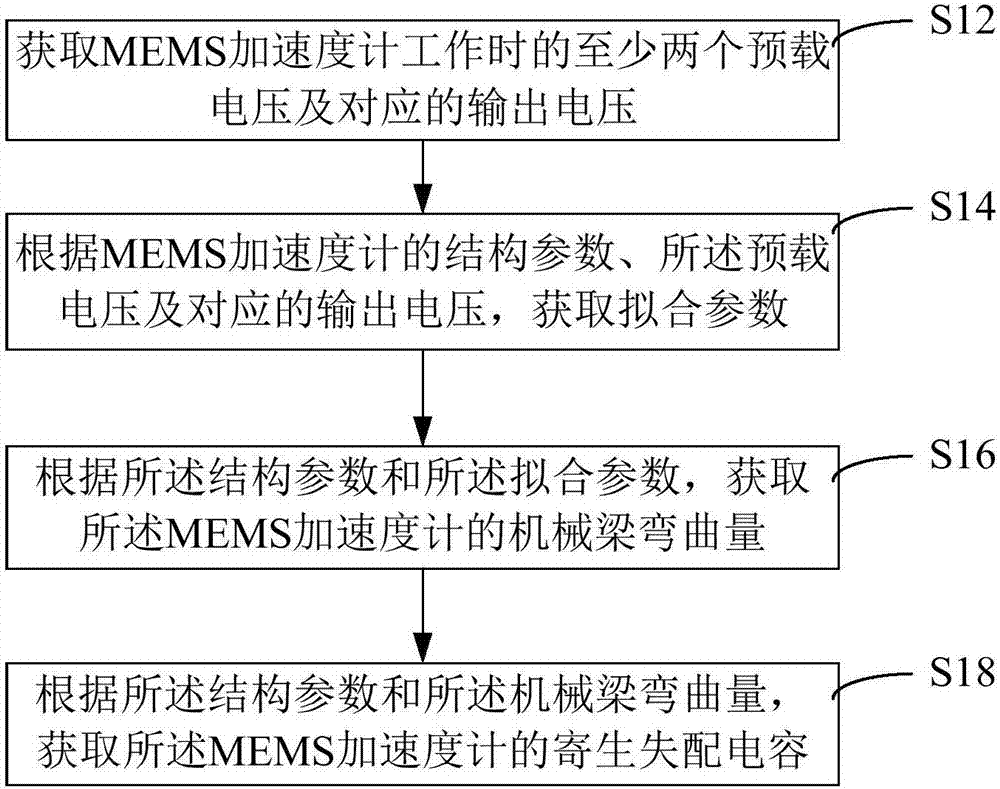

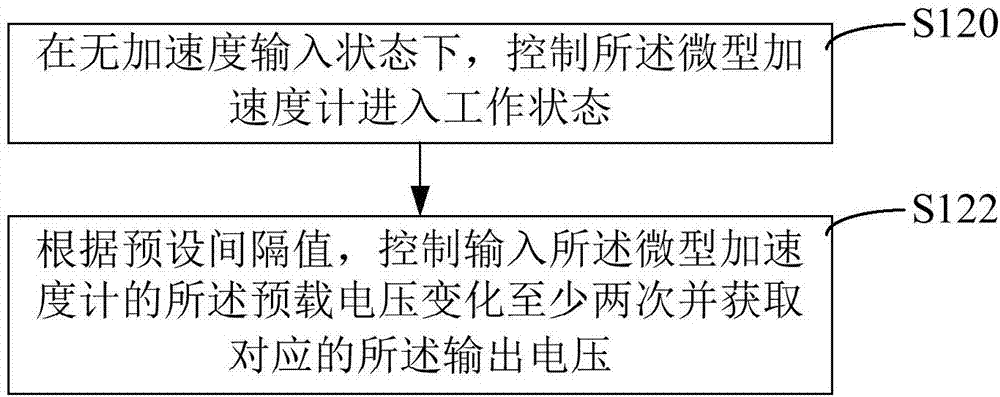

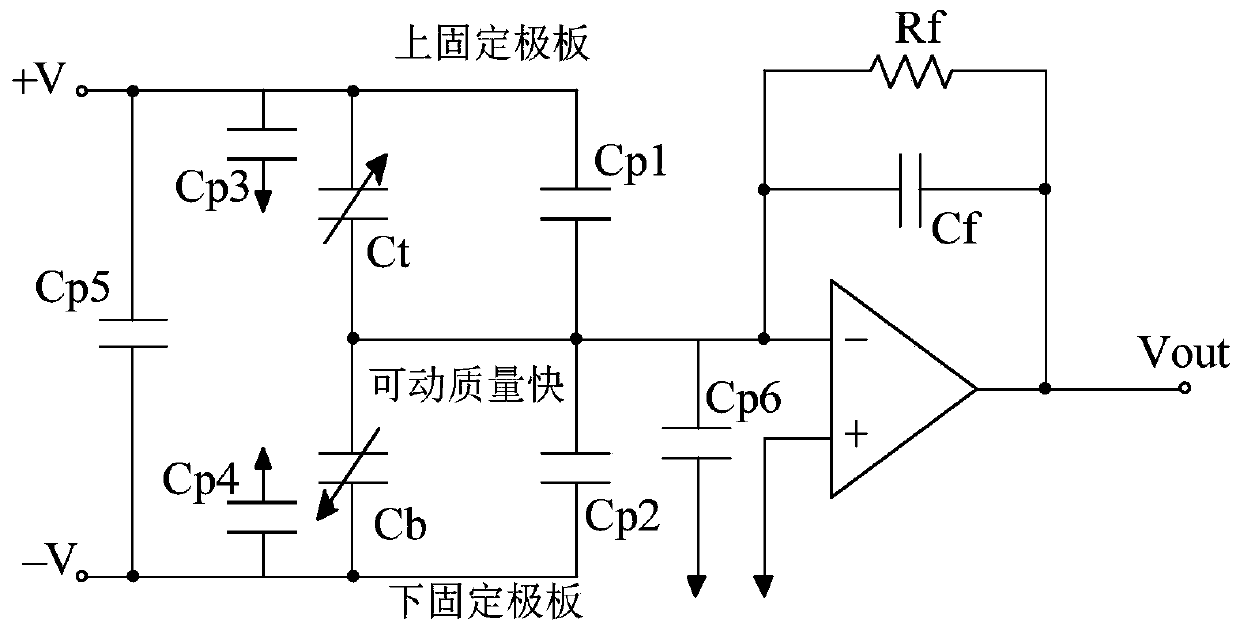

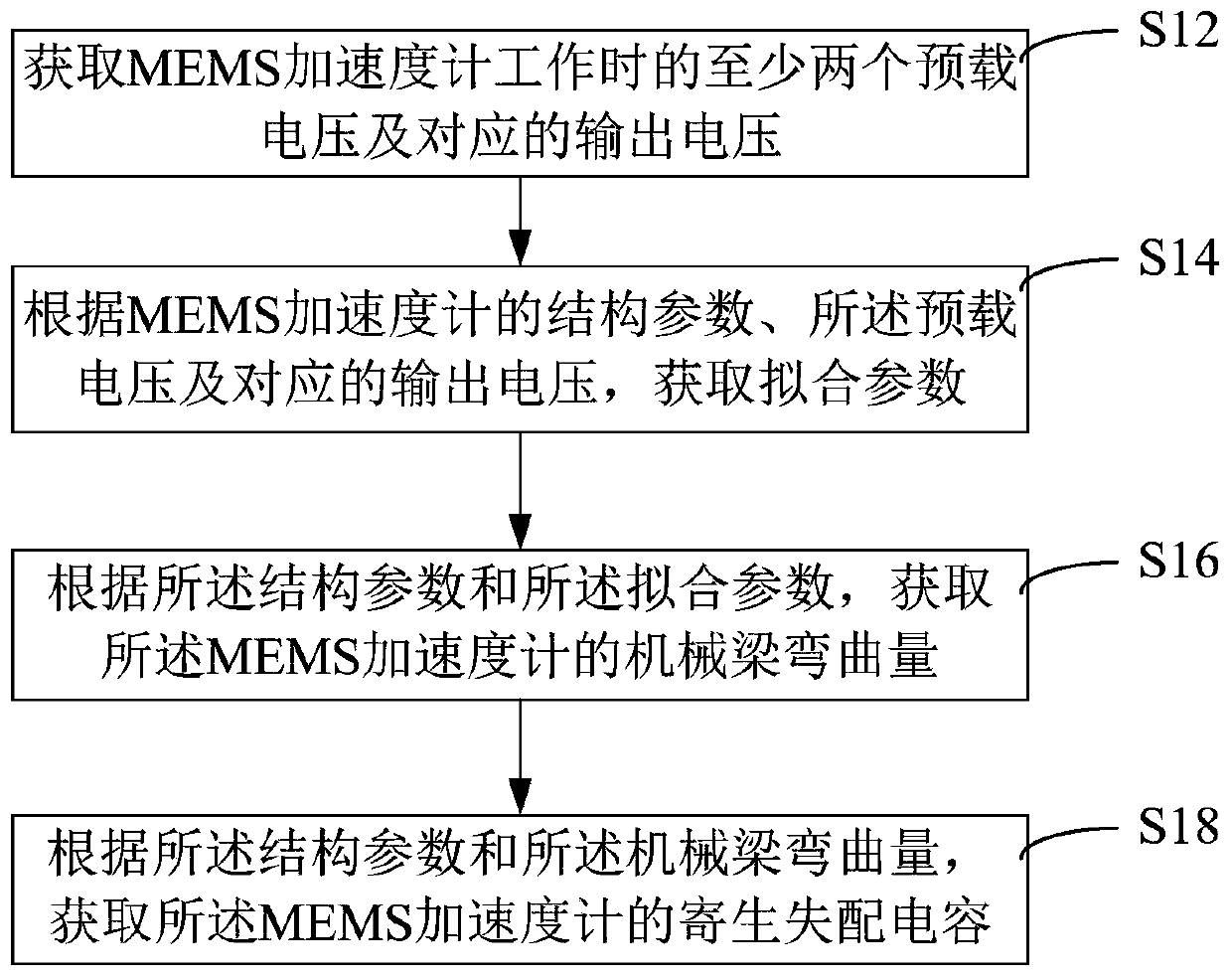

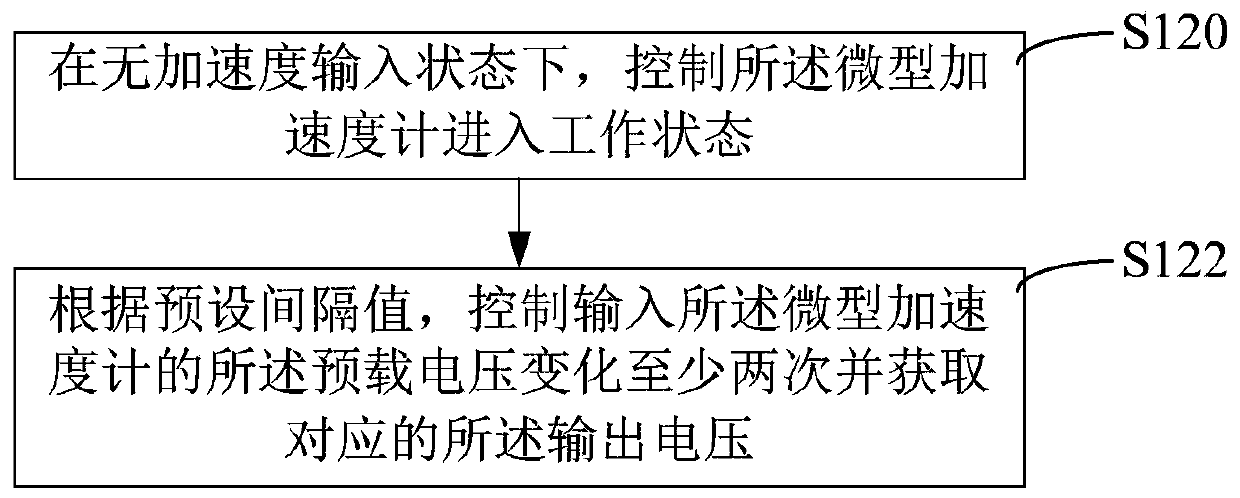

Method and device for acquiring parasitic mismatch capacitance of MEMS accelerometer

ActiveCN108008152AHigh precision and reliabilitySolve the low measurement accuracyAcceleration measurementTesting/calibration of speed/acceleration/shock measurement devicesAccelerometerParasitic capacitance

The invention discloses a method for acquiring the parasitic mismatch capacitance of an MEMS accelerometer, including the following steps: acquiring at least two preload voltages of an MEMS accelerometer during normal work and corresponding output voltages; acquiring fitting parameters according to the structure parameters, the preload voltages and the output voltages of the MEMS accelerometer; acquiring the bending amount of the mechanical beam of the MEMS accelerometer according to the structure parameters and the fitting parameters; and acquiring the parasitic mismatch capacitance of the MEMS accelerometer according to the structure parameters and the bending amount of the mechanical beam. The invention further discloses a device for acquiring the parasitic mismatch capacitance of an MEMS accelerometer. Through the process, the parasitic mismatch capacitance of the MEMS accelerometer during work is obtained. The problem that the traditional method for acquiring the parasitic mismatch capacitance has low measurement precision is solved. An effect of precise and reliable acquisition of the parasitic mismatch capacitance is achieved.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

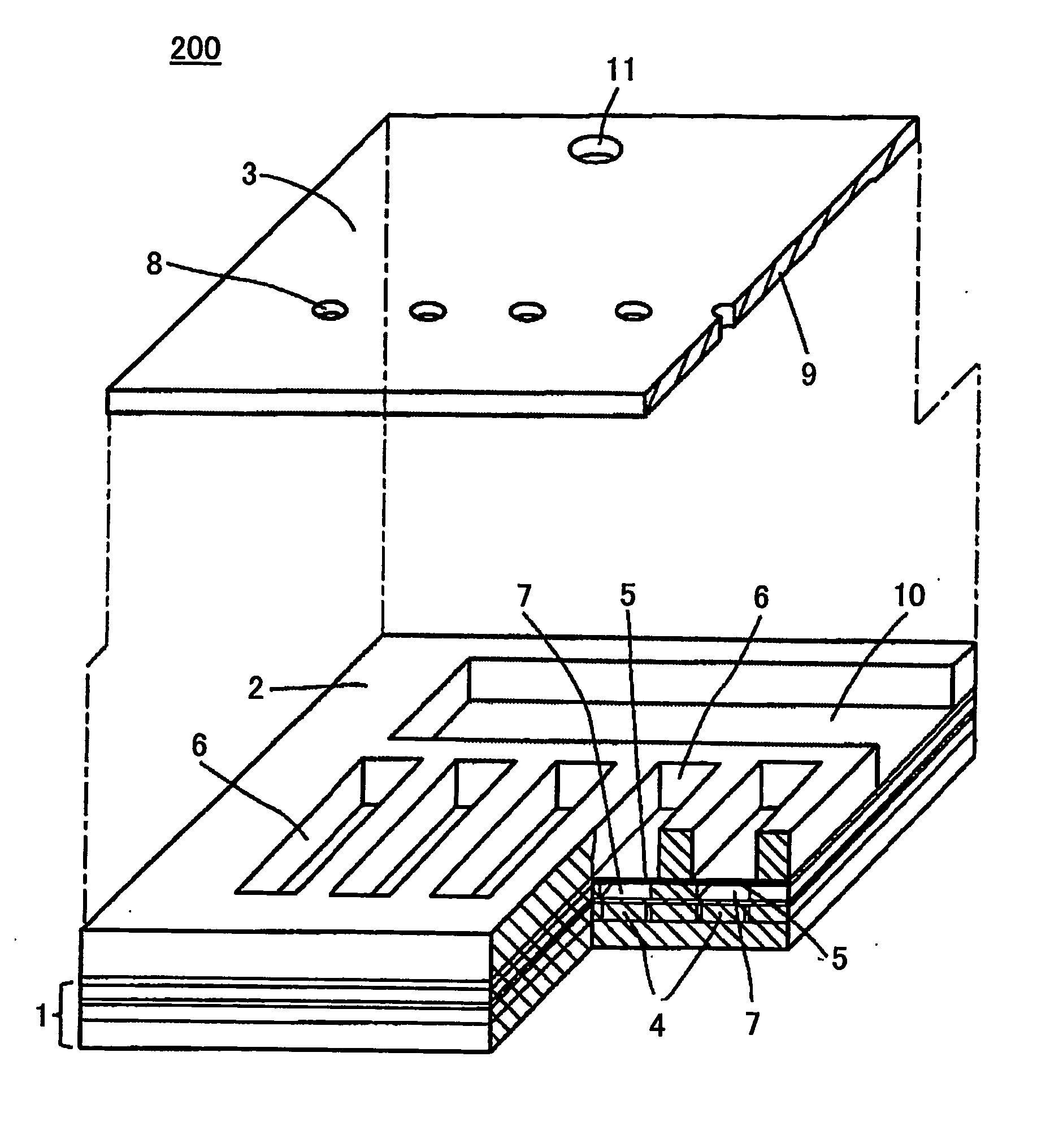

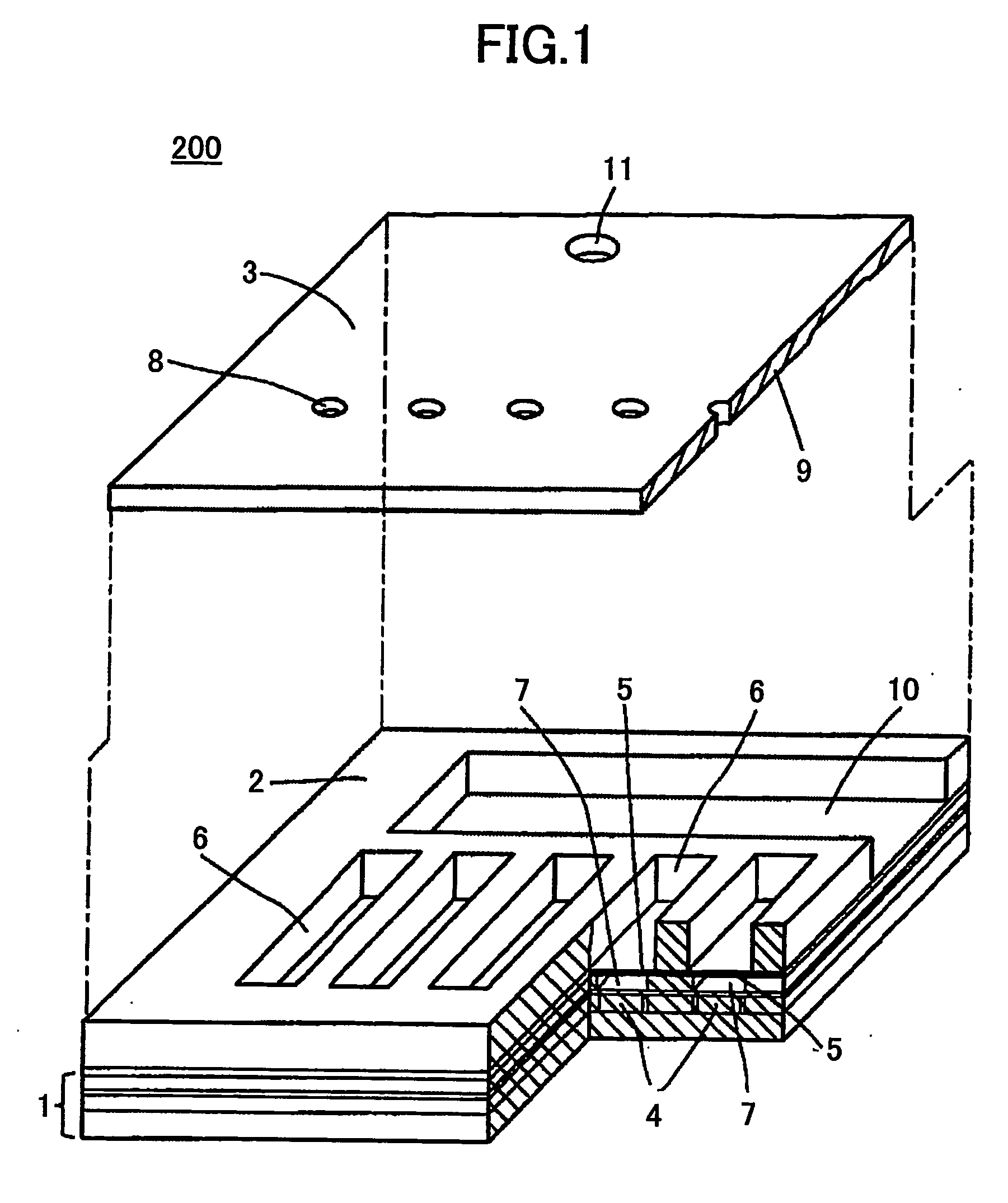

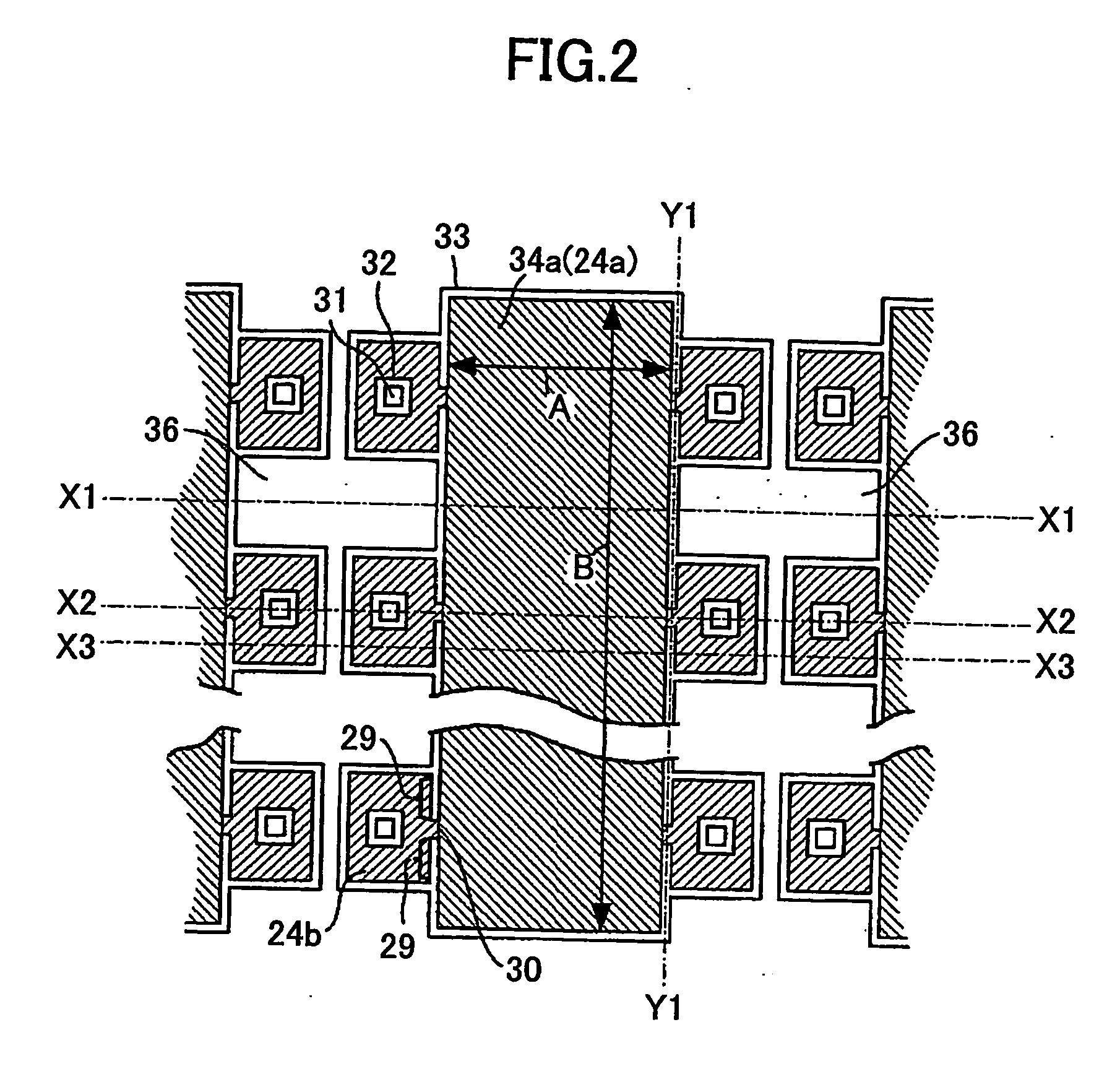

Actuator, liquid drop discharge head, ink cartridge, inkjet recording device, micro pump, optical modulation device, and substrate

InactiveUS20060232638A1High precisionImprove reliabilityPrintingPiezoelectric/electrostrictive devicesEngineeringActuator

An actuator includes a vibration plate area displaced by an electrostatic force, and electrodes facing each other via a first space in the vibration plate area The first space is formed by a sacrificial layer process using a sacrificial layer removing hole. A barrier as a fluid resistance is formed between the first space and a second space situated in the vicinity of the sacrificial layer removing hole.

Owner:RICOH KK

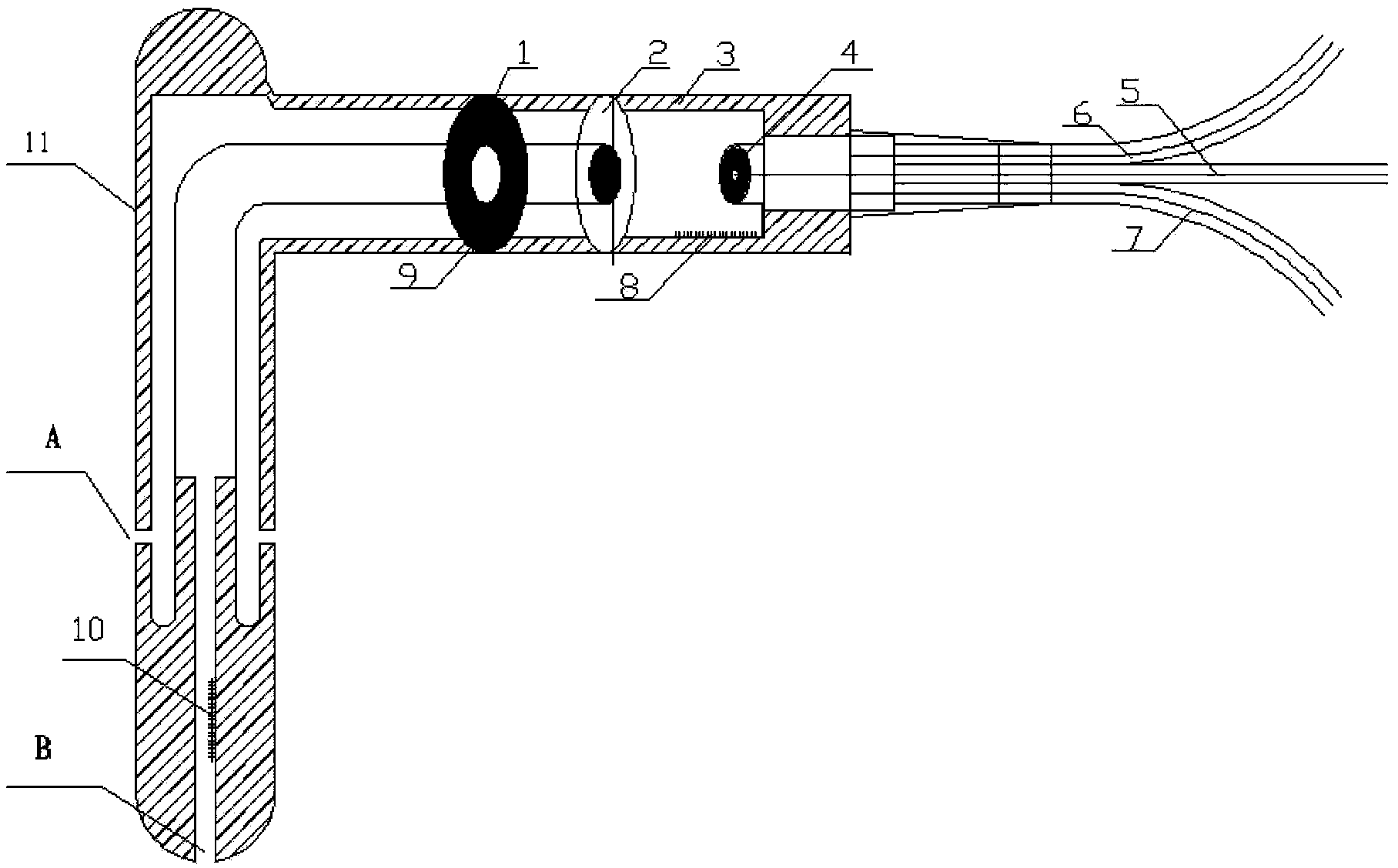

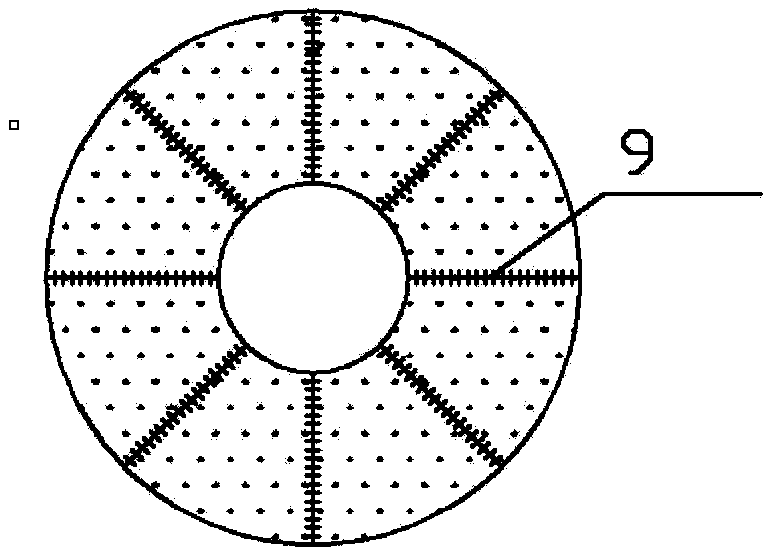

Optical fiber sensor and method for measuring multiple parameters of air compressor fluid

The invention provides a light intensity and optical grating type hybrid fiber flow sensor and a measuring method. Bragg grating type fibers are symmetrically distributed on the surface of an annular elastic strain disc, and static pressure is calculated by the aid of wavelengths in centers of the fibers; light intensity fibers are perpendicularly irradiated to the center of the elastic strain disc, reflected light is received through two groups of receiving fibers, and an offset distance of the elastic strain disc is calculated through light intensity ratios of the two groups of the receiving fibers, so that total pressure is calculated; a temperature measuring grating fiber is adhered to the inner wall of a pitot tube, and the total temperature of the air compressor is calculated according to an offset amount of the center wavelength of the temperature measuring grating fiber; and another temperature measuring grating fiber is horizontally fixed on the inner side of a cylindrical metal casing for measuring the temperature of a work environment, and the total pressure and the static pressure are subjected to temperature compensation. The optical fiber sensor has the characteristics of small size, simple structure, high interference resistance and the like, and the multiple parameters such as the total pressure, the total temperature, the flow and the like of the fluid can be measured through one sensor.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

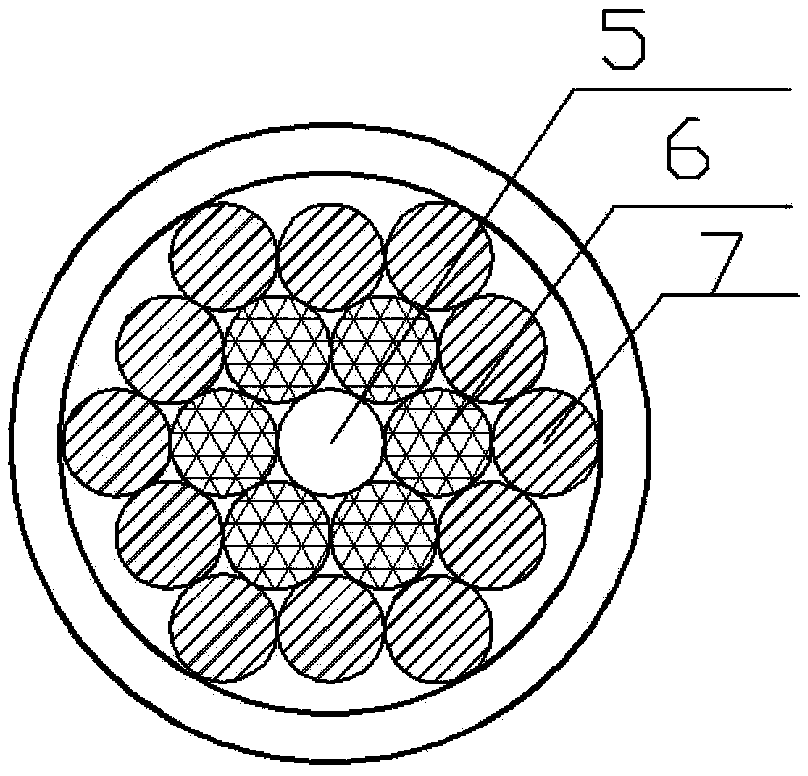

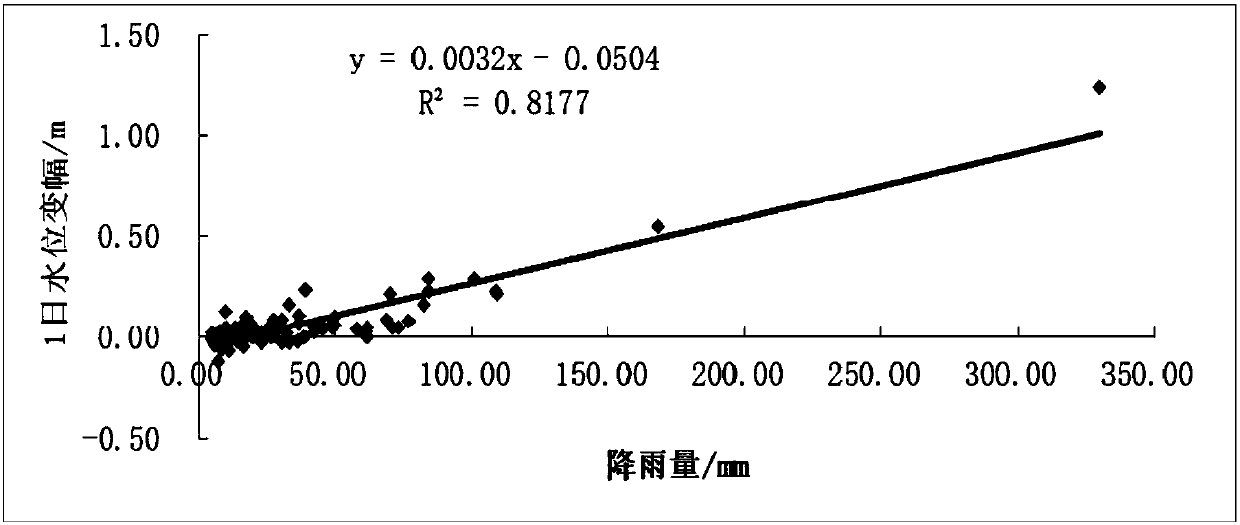

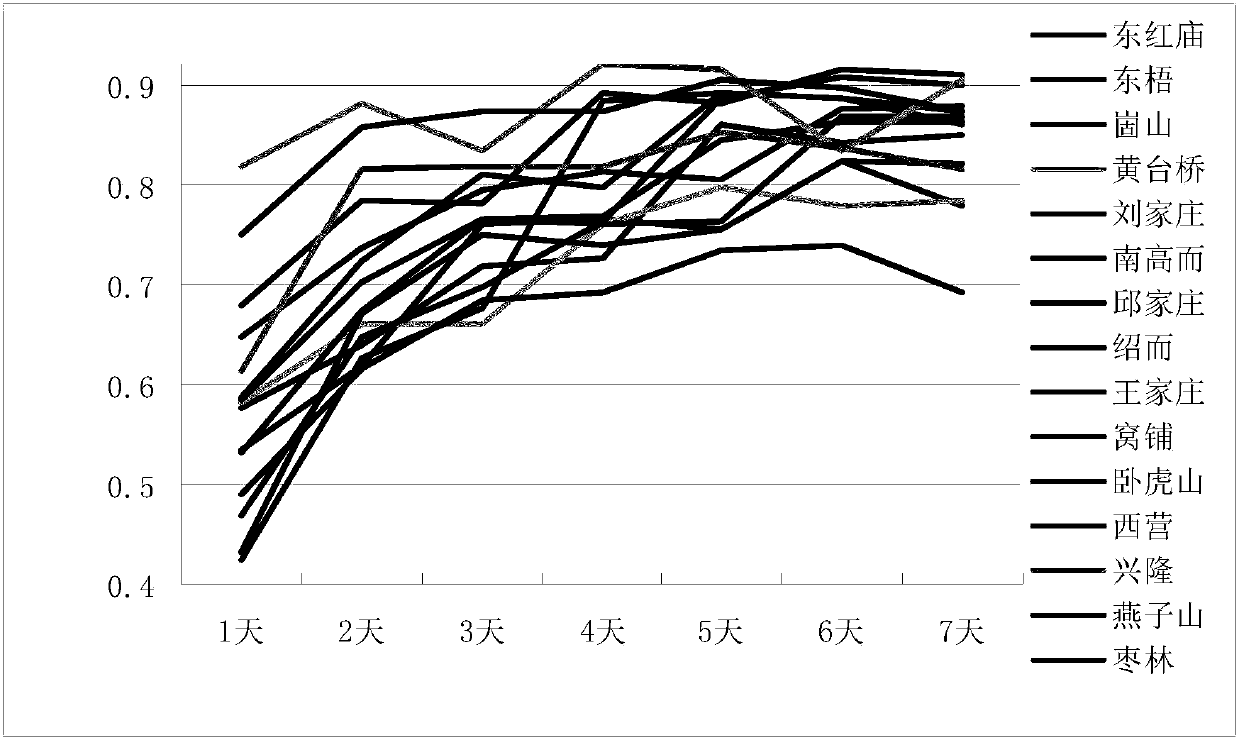

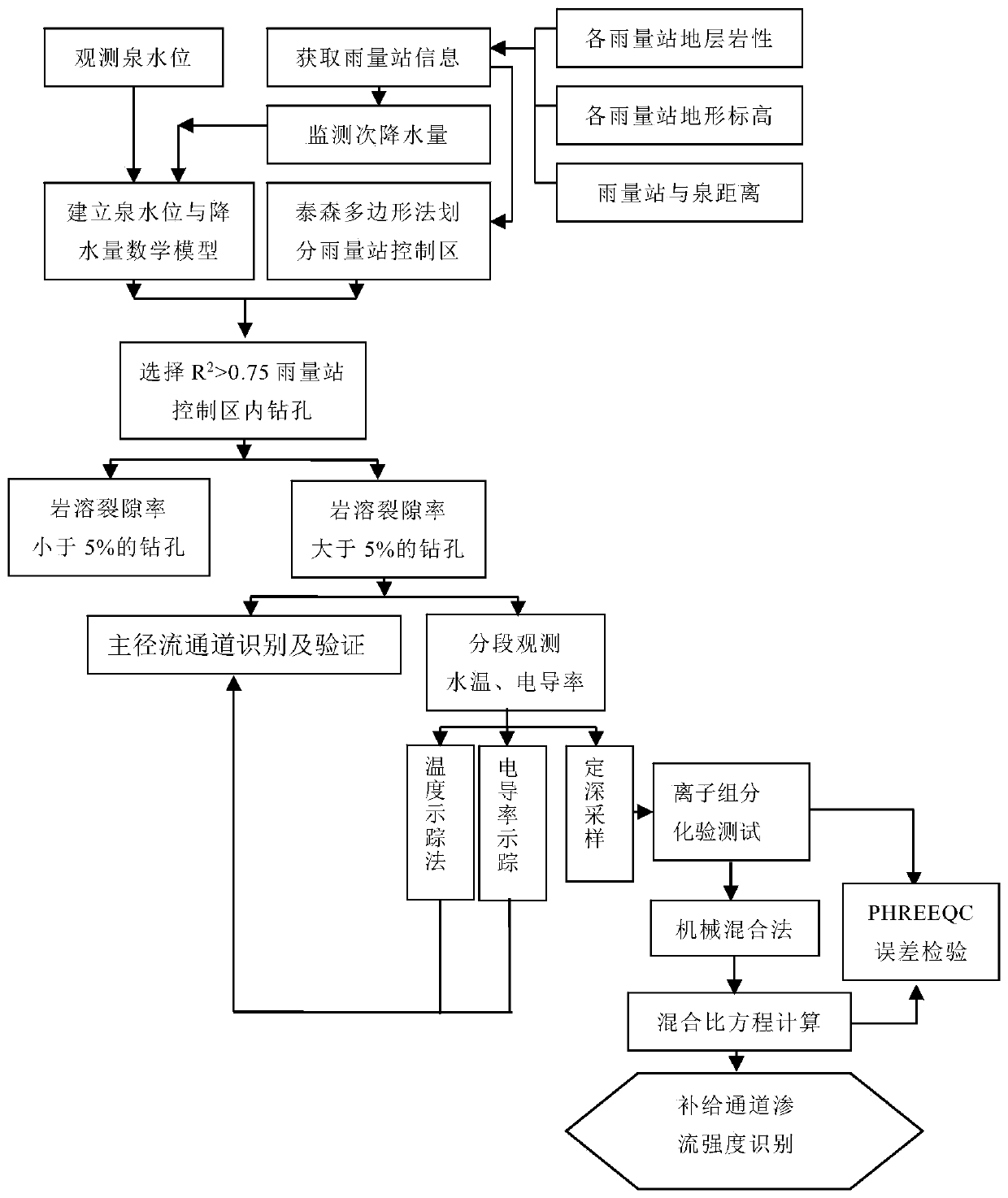

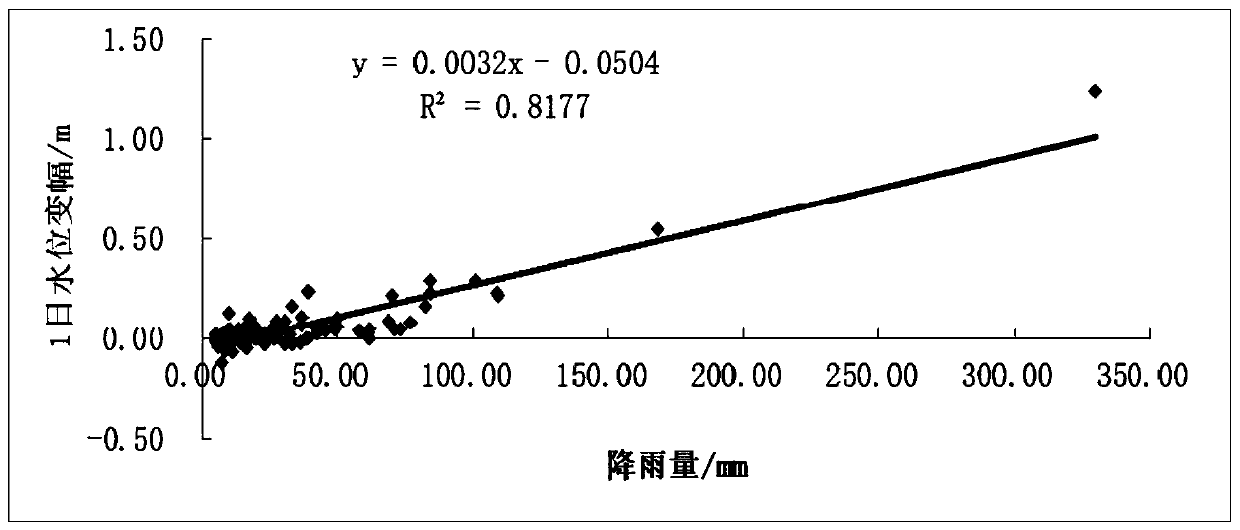

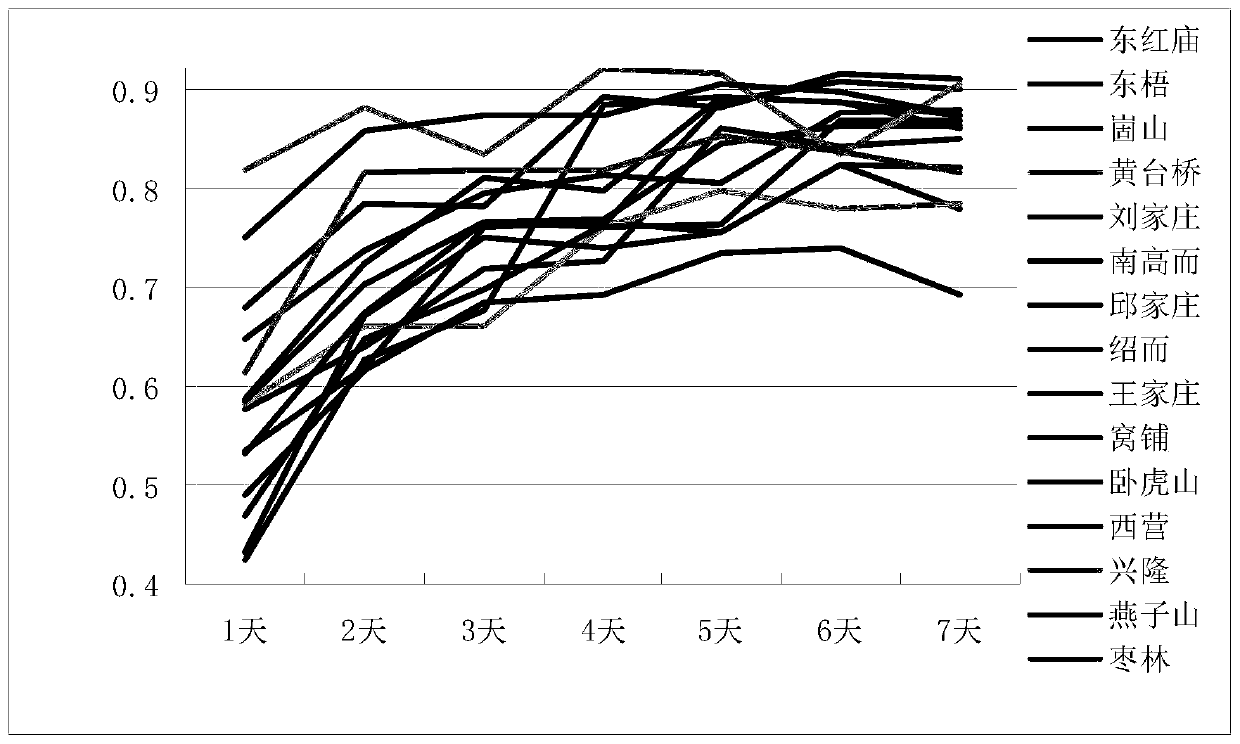

Method for determining large karst spring replenishment channel and intensity

ActiveCN108020649AComprehensive index factorsImprove scienceRainfall/precipitation gaugesEarth material testingKarstWater quality

The invention discloses a method for determining the large karst spring replenishment channel and intensity. The method comprises the following steps of 1, using a spring water position to judge the sensitivity of a rainfall station; 2, determining the main runoff zone depth and distribution thereof; 3, verifying the main runoff zone depth and distribution thereof determined in the step 2 througha temperature and conductivity tracer technique; 4, calculating the intensities of different runoff replenishment sources. By means of the method for determining the large karst spring replenishment channel and intensity, on the basis of the nature of a regional hydrogeological condition, through the four elements of the relevance of the rainfall station and the spring water position, the karst fissure rate, the temperature tracer and the water chemical mixing ratio, the outdoor large-scale karst spring replenishment channel is precisely identified, a scientific basis is provided for protection of large karst spring water flow and water quality, and decision-making support is provided for related government departments to manage groundwater resources.

Owner:UNIV OF JINAN

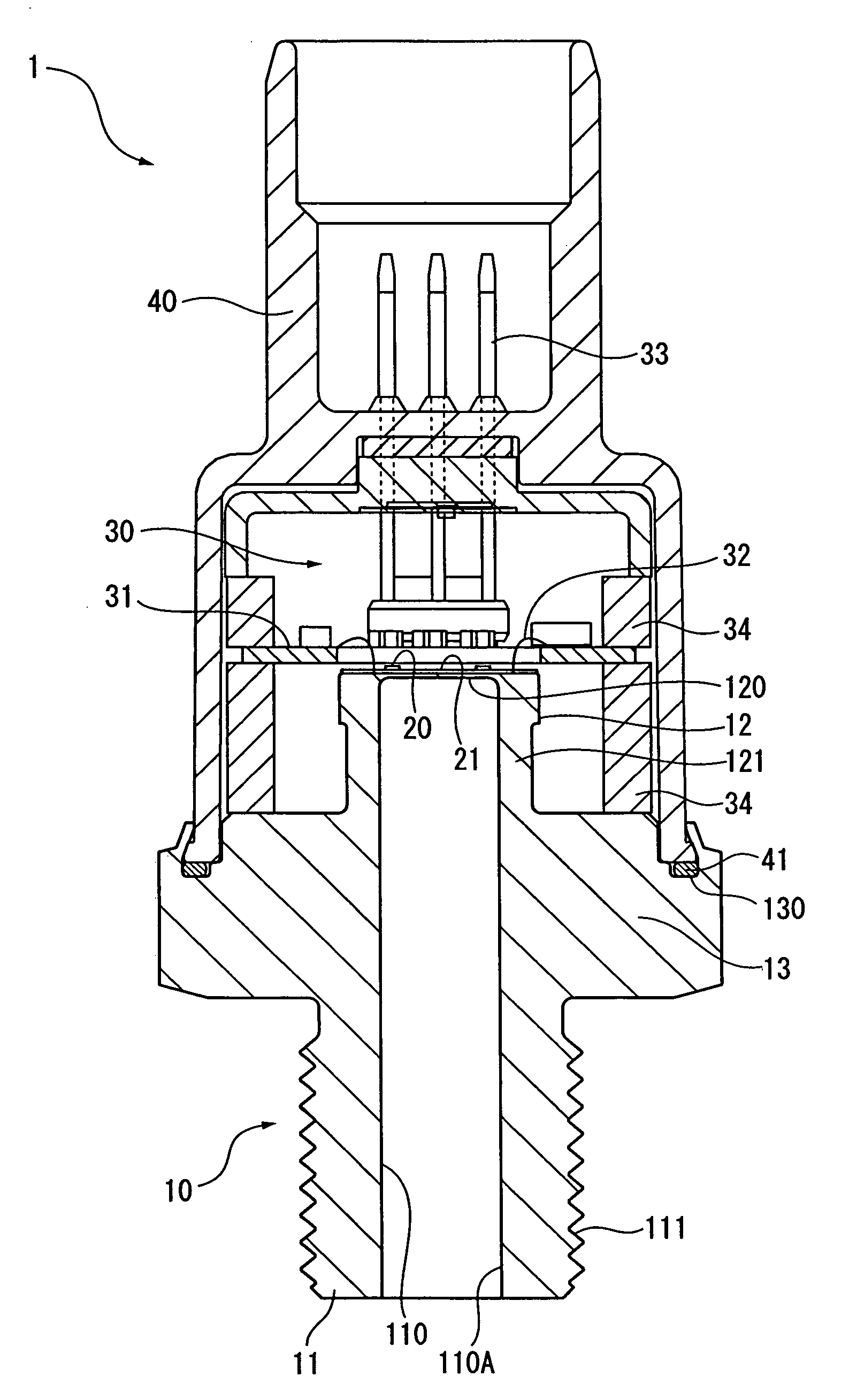

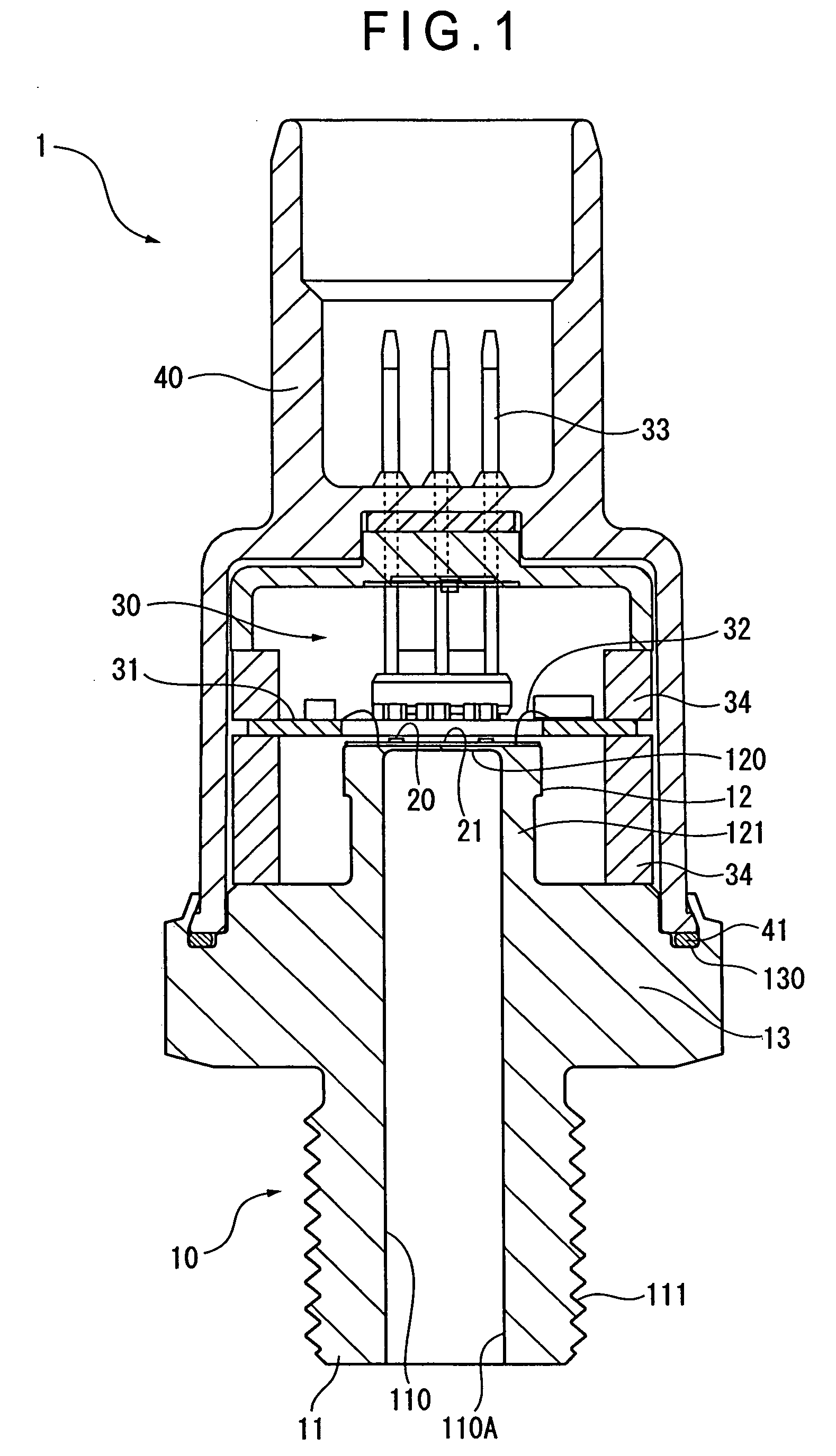

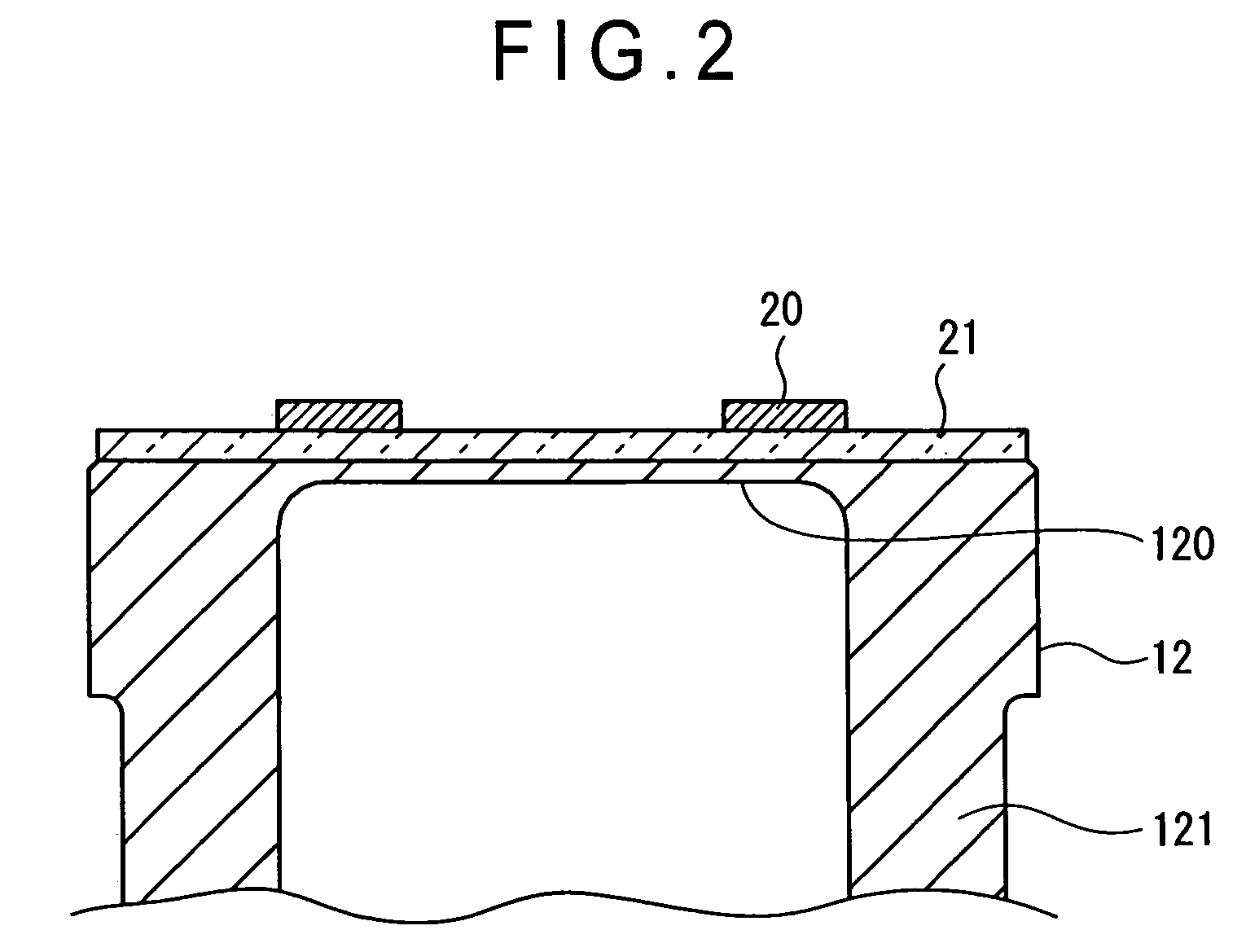

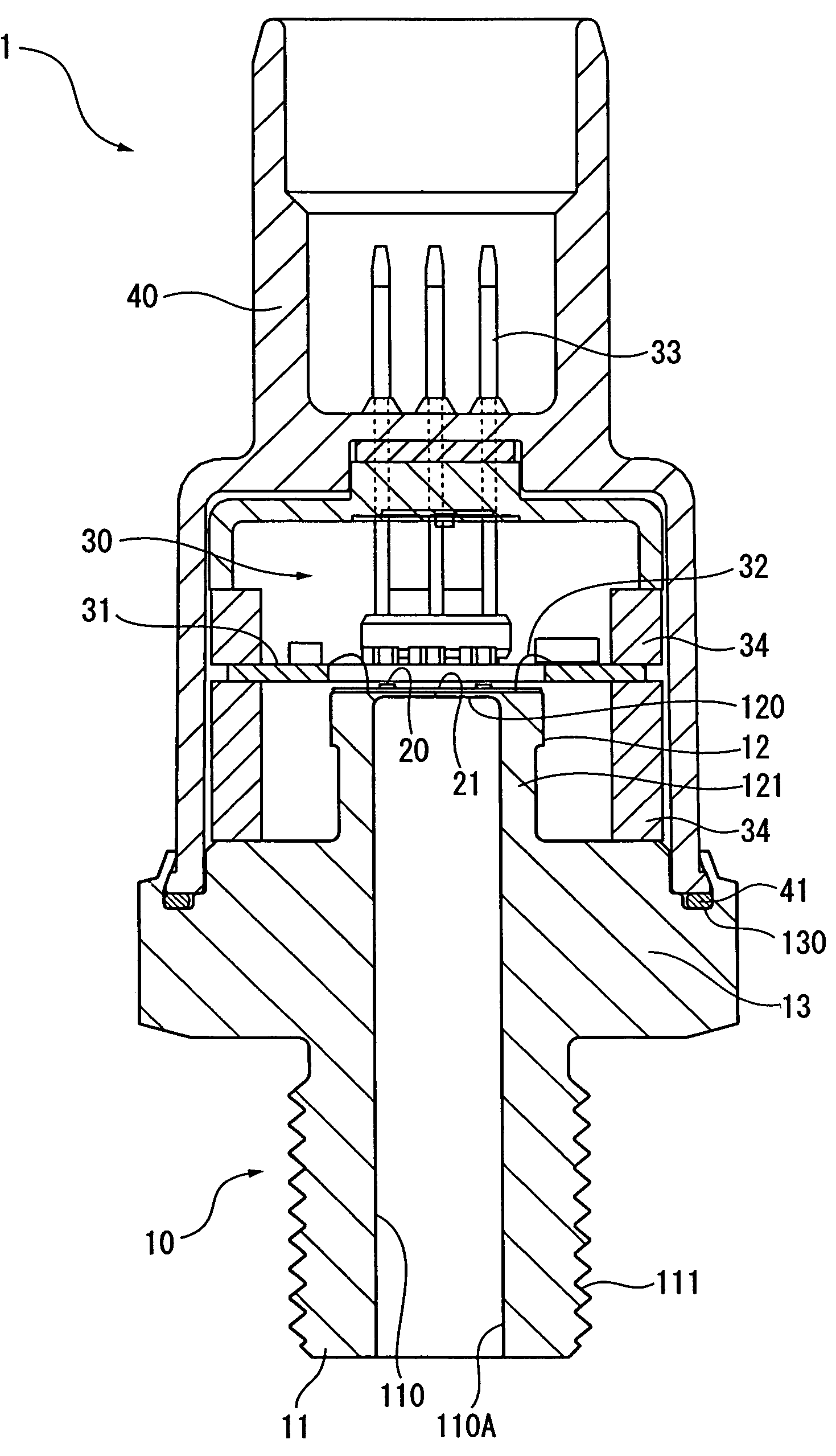

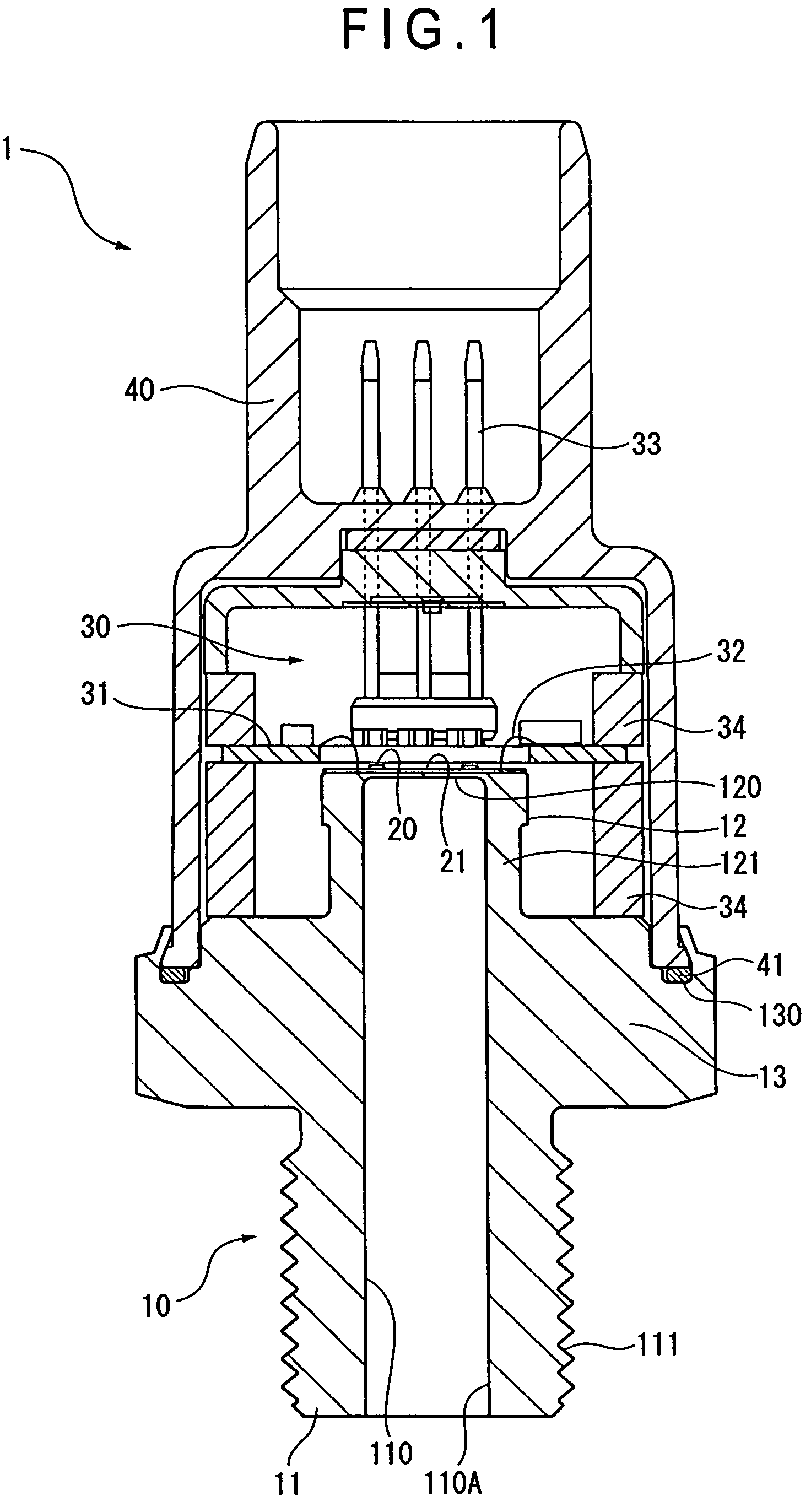

Strain detector and method of manufacturing the same

ActiveUS20060016268A1High precisionImprove reliabilityFluid pressure measurement using ohmic-resistance variationForce measurement using counterbalancing forcesSilicon oxideStrain gauge

A fluid pressure sensor (1) for measuring the pressure of a fluid comprises a diaphragm portion (12) which is a strain generating body, a silicon oxide film (21) as an insulating film, and a strain gauge (20) made of crystalline silicon, and austenitic precipitation hardening type Fe—Ni heat-resisting steel excellent in mechanical strength and corrosion resistance is used for the diaphragm portion (12). The silicon oxide film (21) is formed with the internal stress thereof adjusted to the range from −150 to 130 MPa. With this feature, the fluid pressure sensor (1) ensures high precision and reliability, and may be used even for measurement of a highly corrosive fluid.

Owner:NAGANO KEIKI

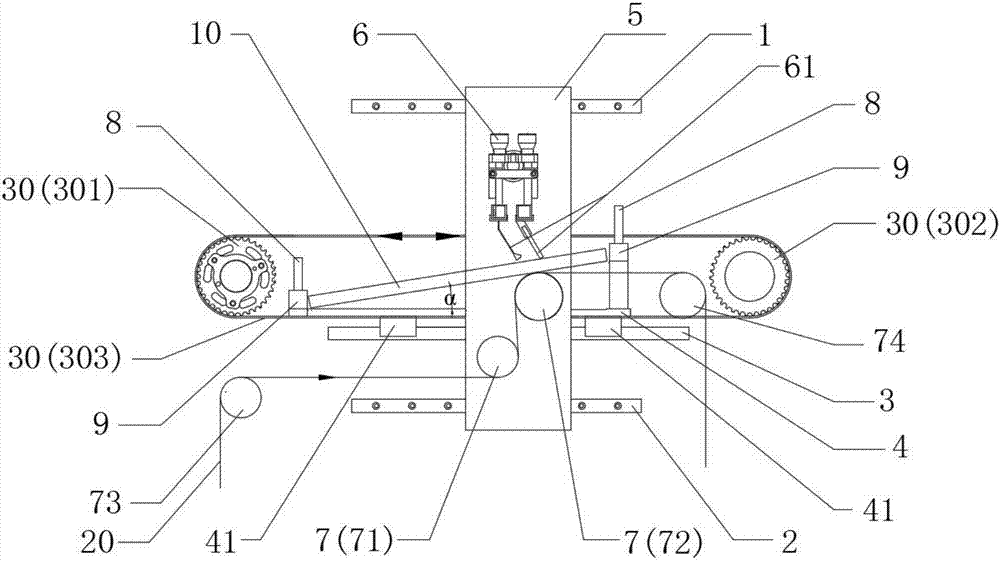

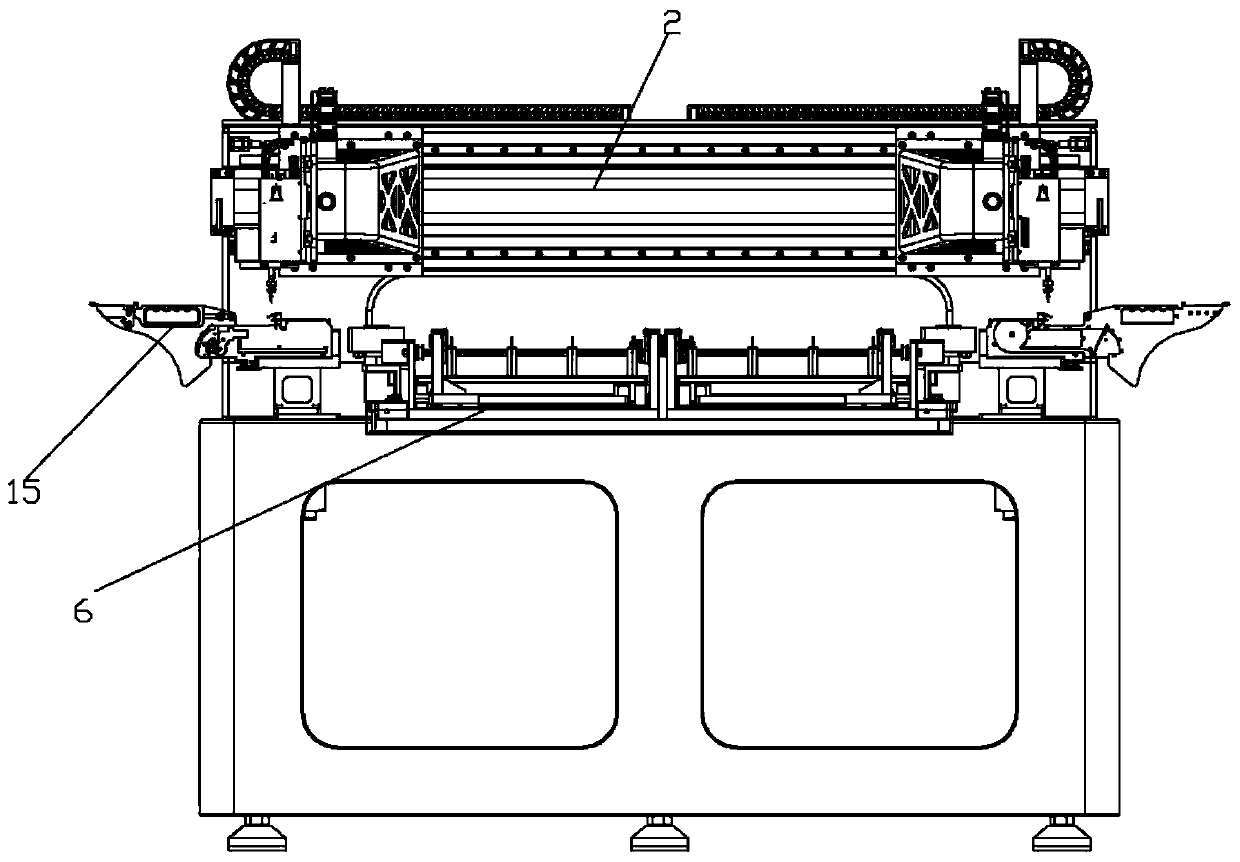

Coiled material flat screen silk-screen printing method and coiled material flat screen silk-screen printing machine

ActiveCN107053826AMeet production requirementsReasonable structural designFinal product manufactureScreen printersEngineeringPrinting ink

The invention discloses a coiled material flat screen silk-screen printing method. The coiled material flat screen silk-screen printing method comprises the following steps that (1), a coiled material printed object is wound on a roller shaft assembly and uniformly moves forward with the speed v1, a screen frame uniformly and horizontally moves with the speed v2 in the same direction with printed object moving, the screen frame uniformly and vertically moves upward with the speed v3 along a guiding column, therefore the screen frame operates with the overall speed v4 in the inclined direction, and a scraper structure and the roller shaft assembly move uniformly and horizontally with the same speed as the screen frame and in the reverse direction with the screen frame; (2), when the screen frame and the coiled material printed object are in a relatively static state, the scraper structure moves downward to squeeze printing inks on the screen frame, and the printing inks leak onto the coiled material printed object through meshes; (3), after the screen frame and the scraper structure move oppositely and horizontally by a half length of a screen frame graph, one time of graphic printing is completed; and (4), the coiled material printed object continues to move uniformly, the screen frame, the scraper structure and the roller shaft assembly return to the initial positions, and the actions are repeated. The invention further discloses a coiled material flat screen silk-screen printing machine

Owner:东莞市汇樾科技有限公司

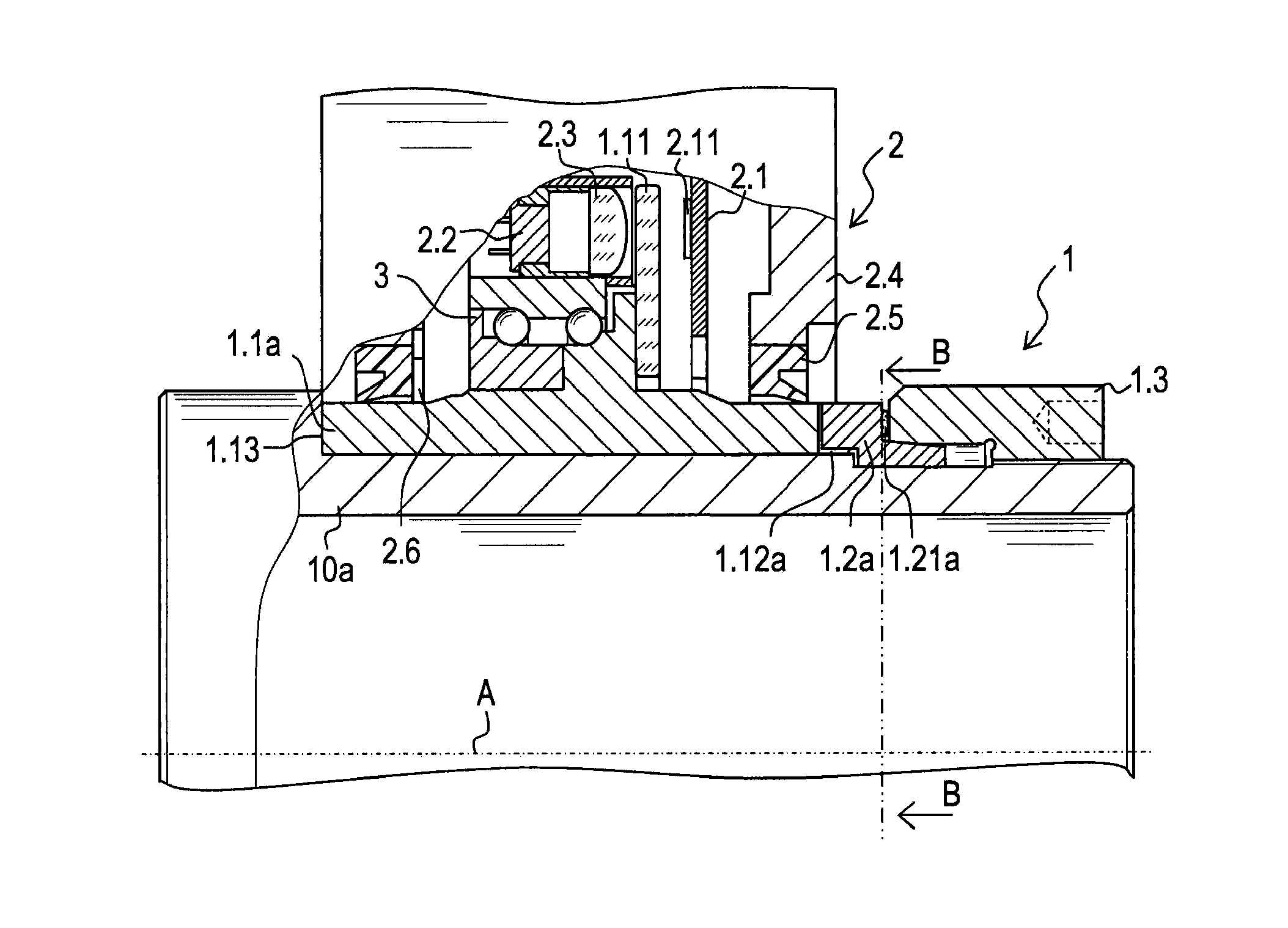

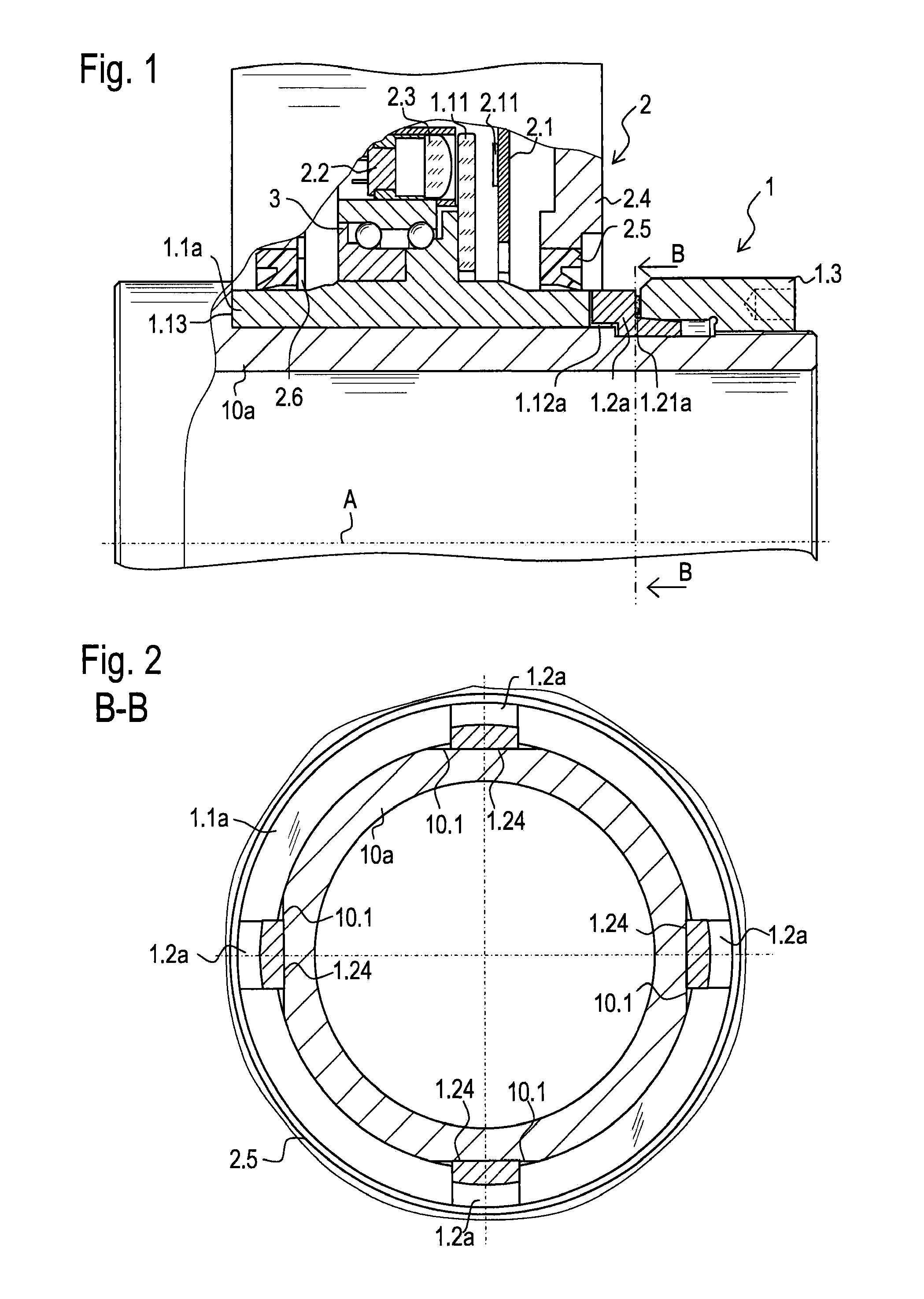

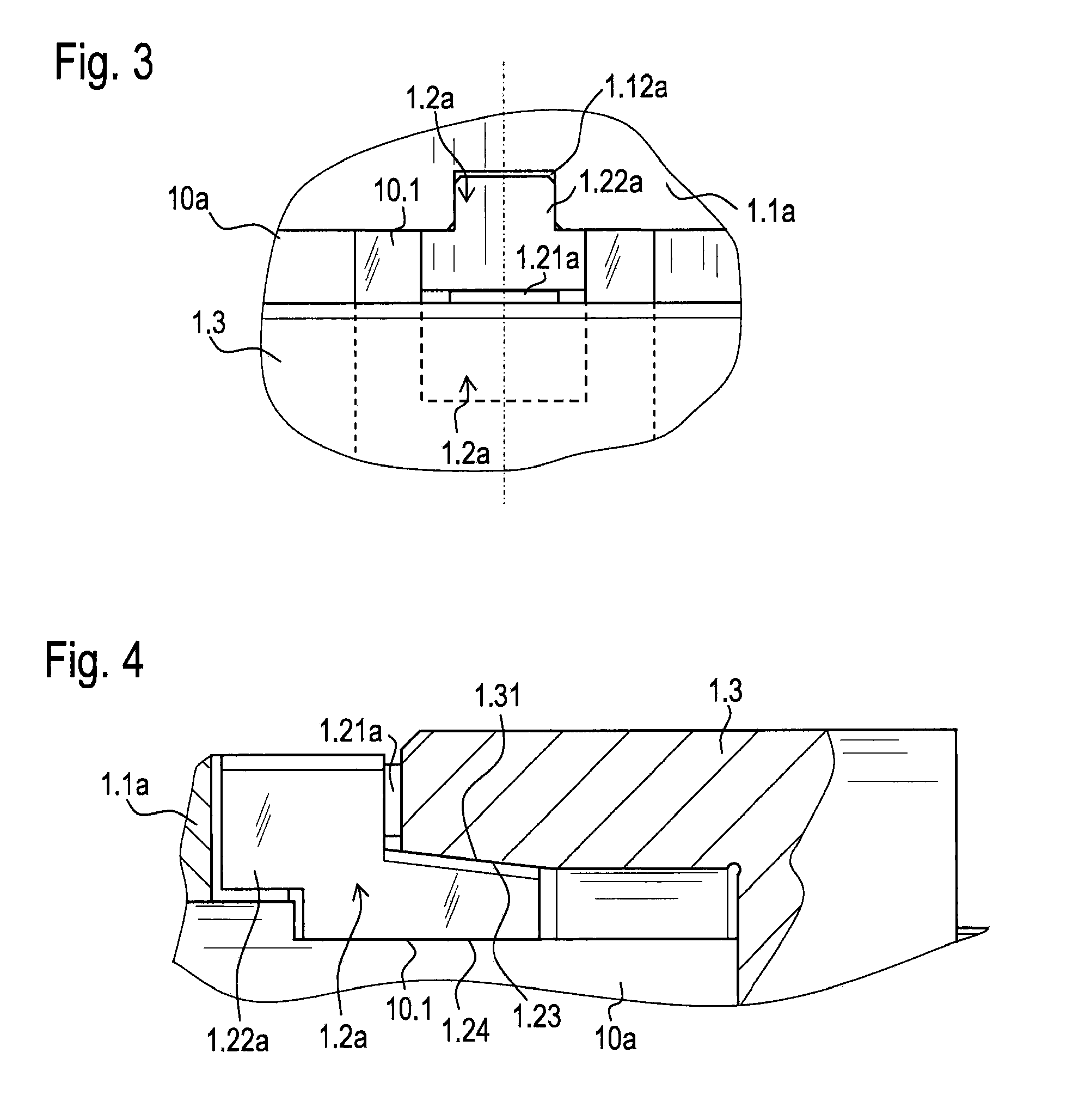

Angle-Measuring Device

ActiveUS20120188534A1High precision and reliabilityImprove accuracyAngle measurementMeasurement apparatus componentsEngineeringAxial displacement

An angle-measuring device includes a first group of components and a second group of components that are rotatable relative to each other about an axis. The first group includes a carrier element for enclosing a shaft and on which a graduation disk is secured, a connecting element, and a device for affixing the connecting element relative to the carrier element. The second group includes a sensor element for scanning the graduation disk. The carrier element and the connecting element are arranged such that the connecting element is able to be brought into operative connection with the carrier element so that torque is transmittable with positive locking between the connecting element and the carrier element about the axis. The connecting element is able to be brought into a positive-locking position by axial displacement by the device for affixing the connecting element, and is able to be prestressed radially against the shaft.

Owner:DR JOHANNES HEIDENHAIN GMBH

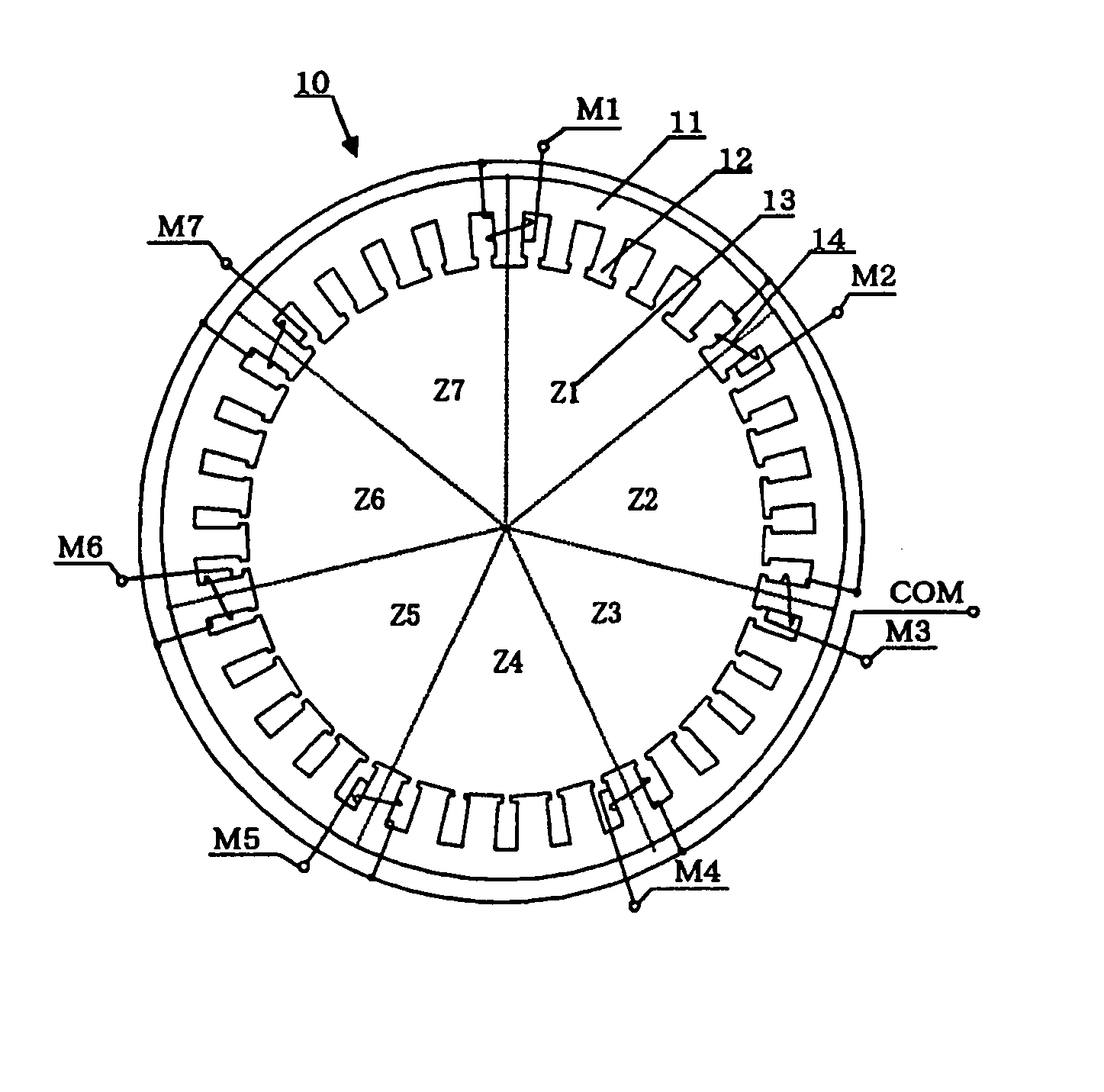

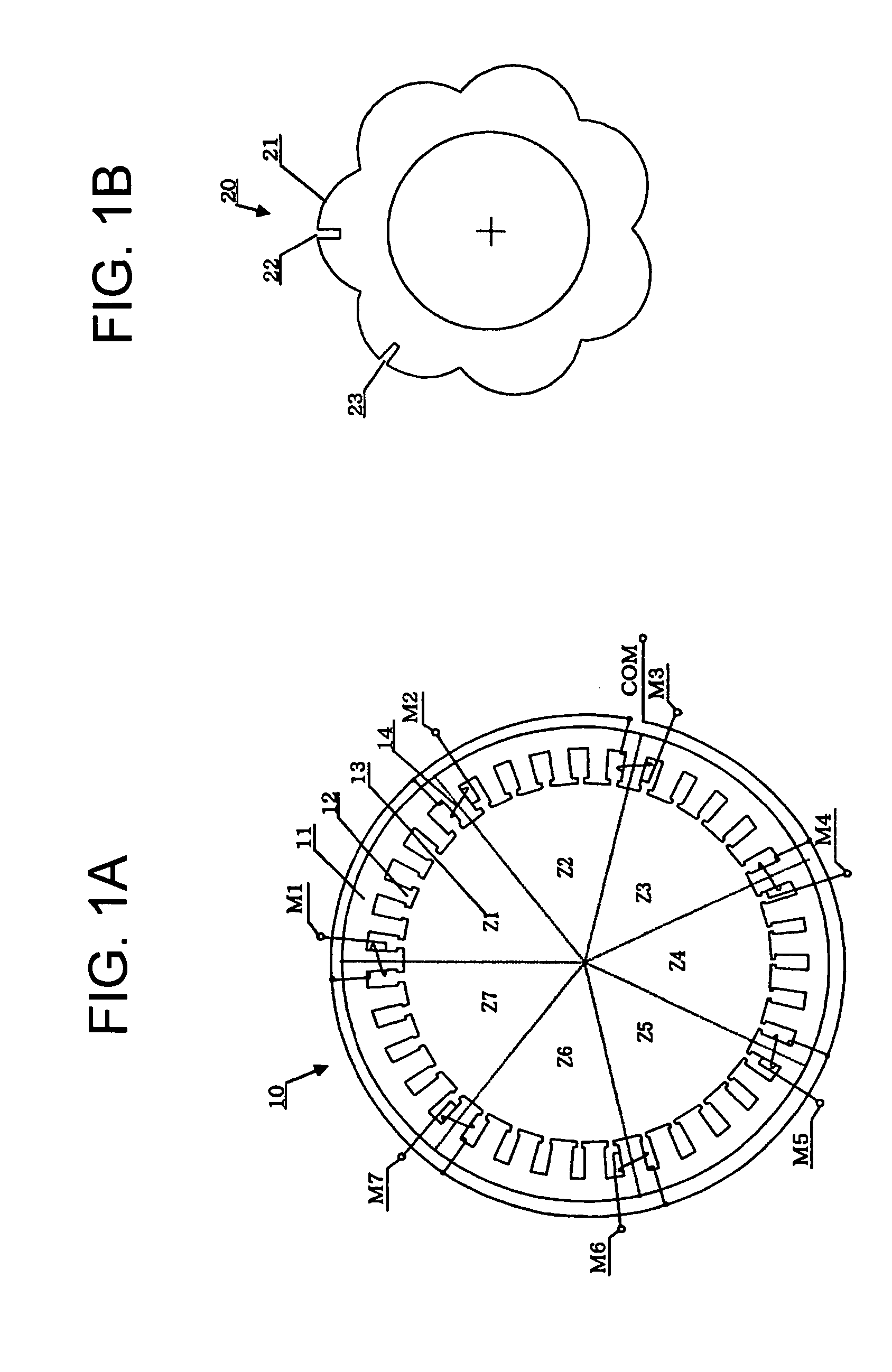

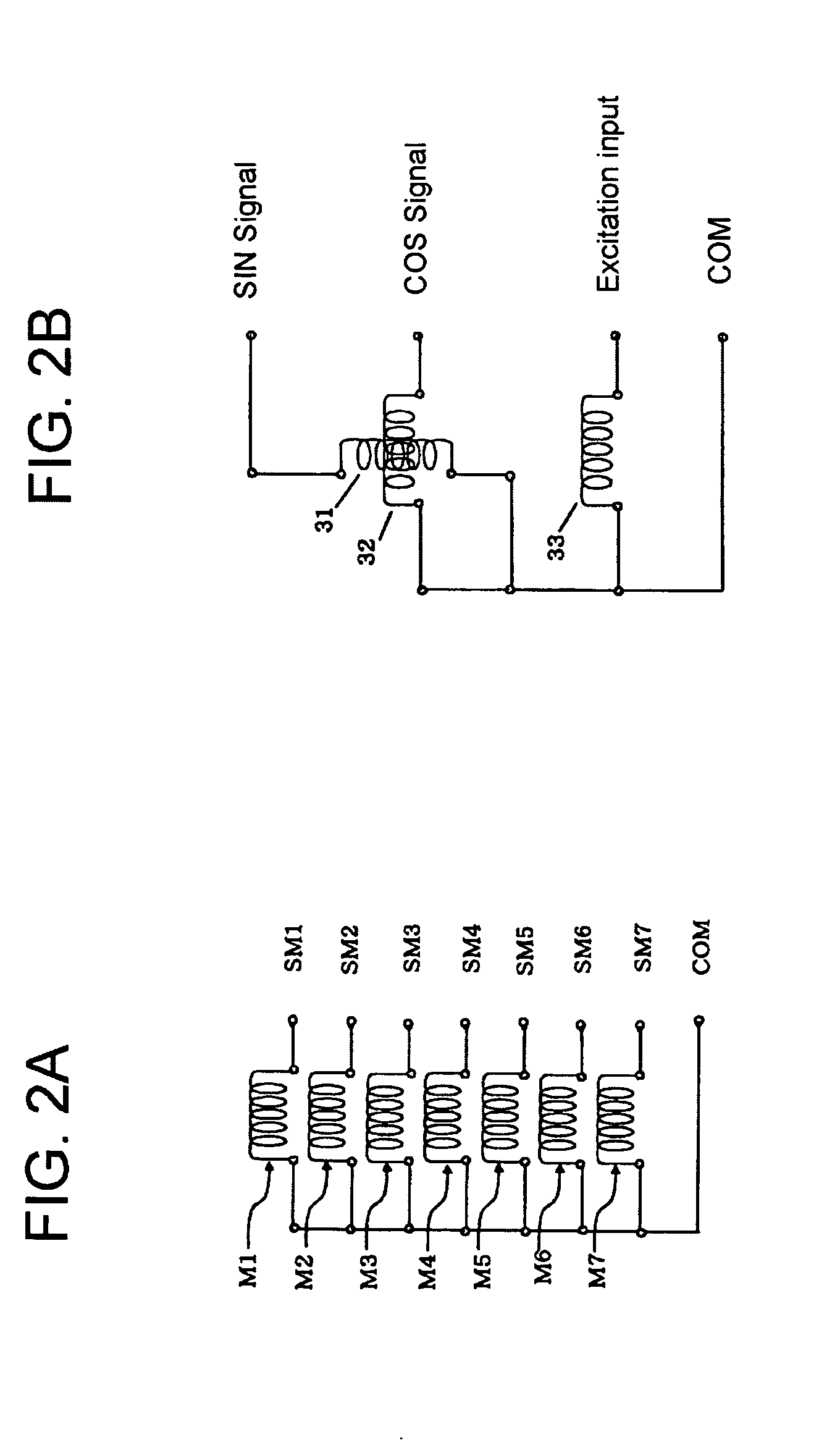

Variable reluctance resolver including rotor with multiple detection portions

InactiveUS20050035760A1High precision and reliabilityHigh precisionSynchronous generatorsMagnetic measurementsPhysicsStator

A variable reluctance resolver has a rotor with magnetic poles with 2× or greater axis combination angles, and is structured so that reliable and accurate zero point detection can be carried out. Concave and convex portions are provided on at least two, but fewer than all, of the magnetic poles of the rotor, and the zero point detection winding is provided on a plurality of electrical poles of the stator. Two or more zero point detection signals are generated simultaneously by a plurality of zero point detection windings. Therefore, even if a portion of the zero point detection signals is lost, the zero point can still be identified based on the correlation between the two or more zero point detection signals.

Owner:MINEBEA CO LTD

Strain detector and method of manufacturing the same

ActiveUS7263895B2High precision and reliabilityImprove corrosion resistanceForce measurement using counterbalancing forcesFluid pressure measurement using ohmic-resistance variationSilicon oxideStrain gauge

A fluid pressure sensor (1) for measuring the pressure of a fluid comprises a diaphragm portion (12) which is a strain generating body, a silicon oxide film (21) as an insulating film, and a strain gauge (20) made of crystalline silicon, and austenitic precipitation hardening type Fe—Ni heat-resisting steel excellent in mechanical strength and corrosion resistance is used for the diaphragm portion (12). The silicon oxide film (21) is formed with the internal stress thereof adjusted to the range from −150 to 130 MPa. With this feature, the fluid pressure sensor (1) ensures high precision and reliability, and may be used even for measurement of a highly corrosive fluid.

Owner:NAGANO KEIKI

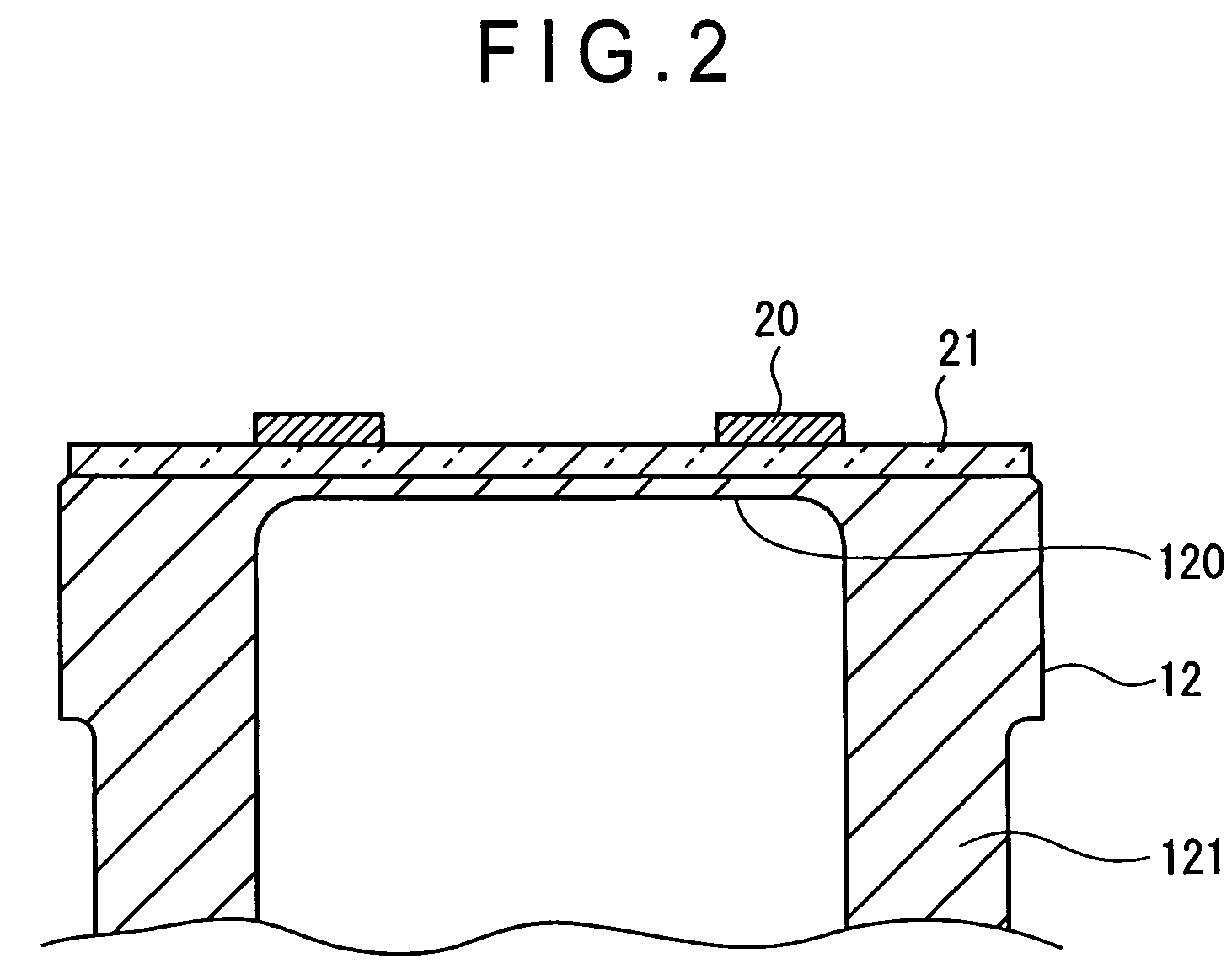

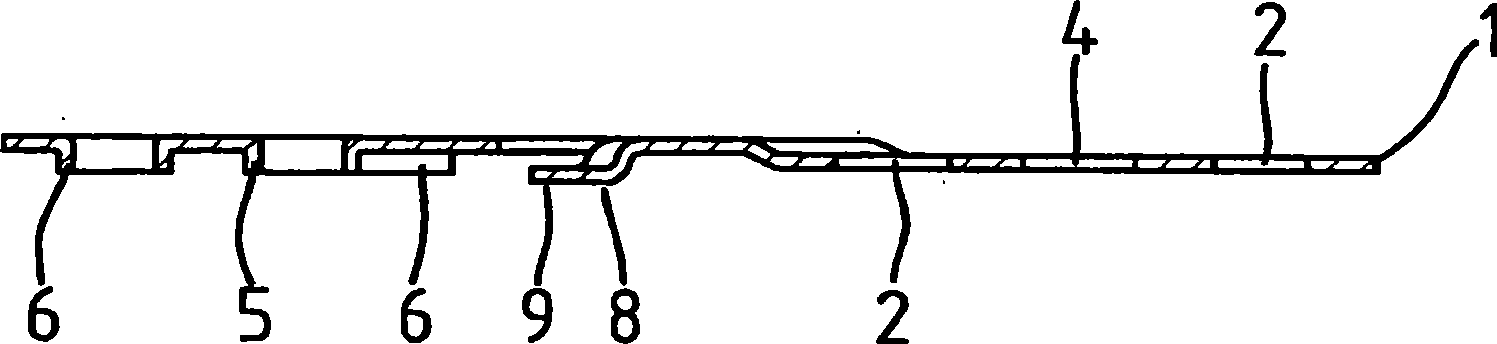

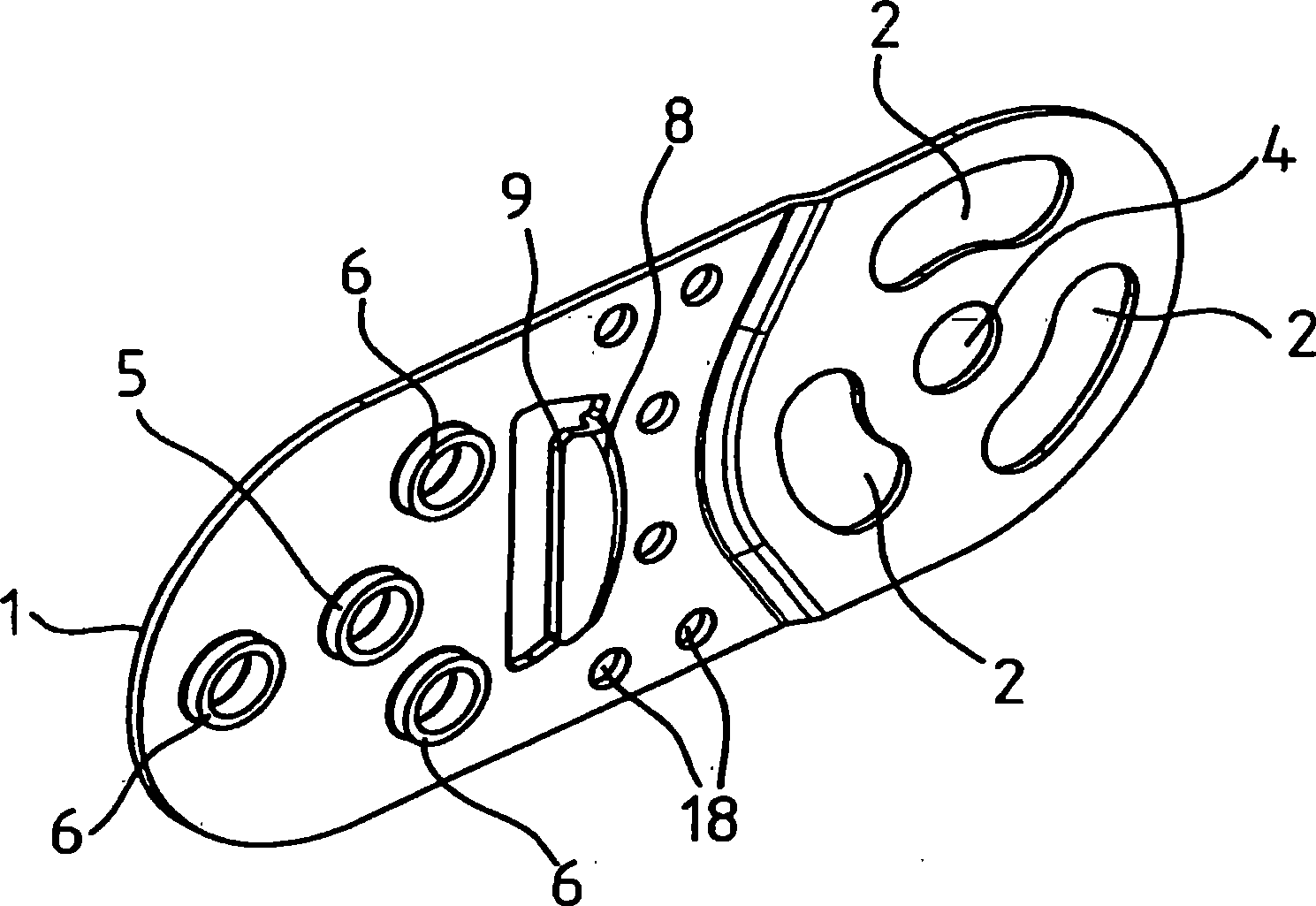

Power transmission chain made from metal

ActiveCN101421537AQuality improvementLarge expansion rateHauling chainsHoisting chainsEngineeringMechanical engineering

For the construction of an energy drag chain a design of a metal bracket is proposed, in which the bracket incorporates a first end-region and a second end-region, the first end-region having at least two cut-outs (2, 4). The second end-region of the metal bracket incorporates a number of elements (5, 6) corresponding to the number of cut-outs (2, 4), which elements when forming an energy drag chain at least partially extend into the respective cut-out of another bracket, whereby the elements (5, 6), shaped by a reforming process, in particular collar forming, protrude from the plane of the bracket.

Owner:椿本缆线牵引有限公司

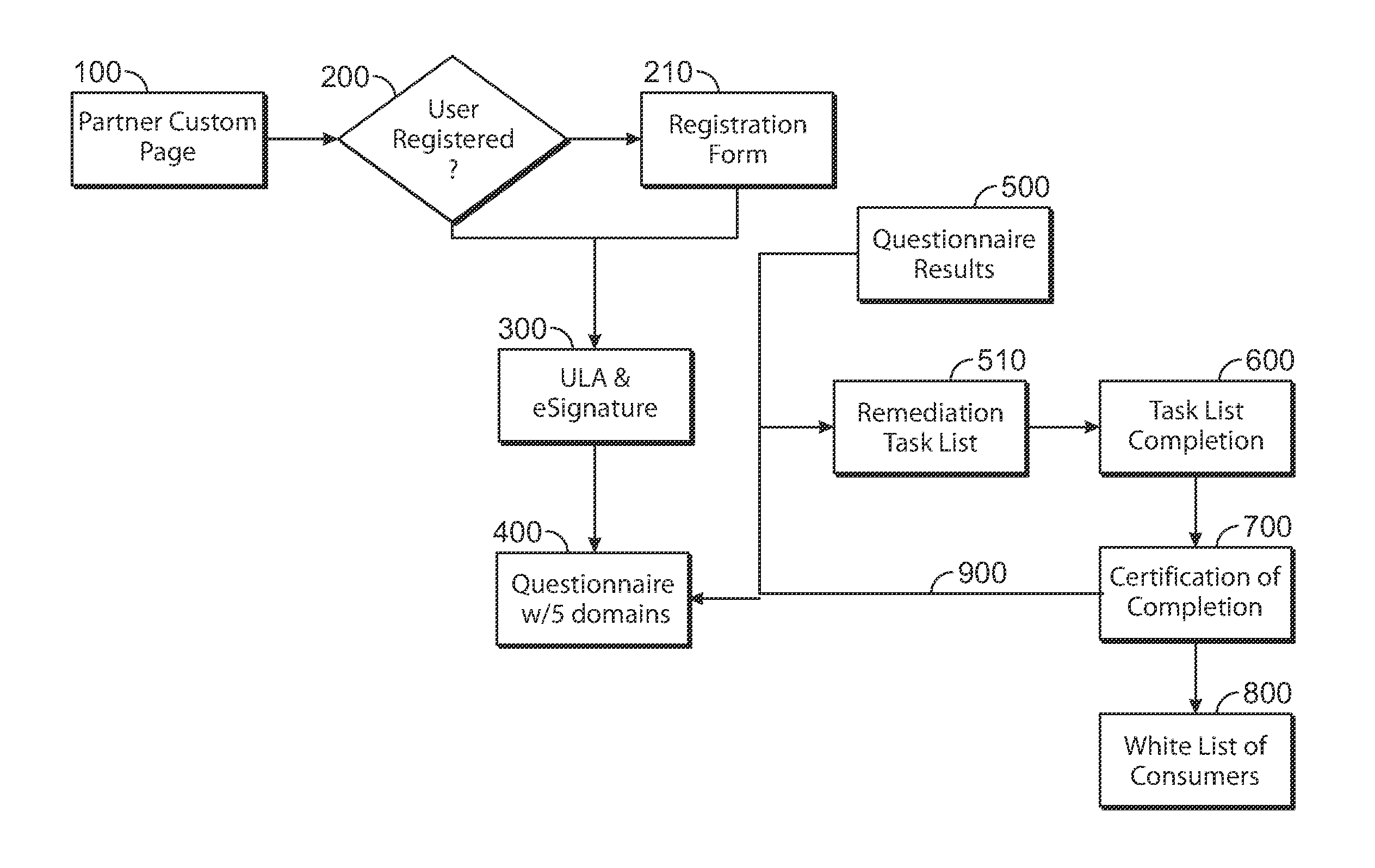

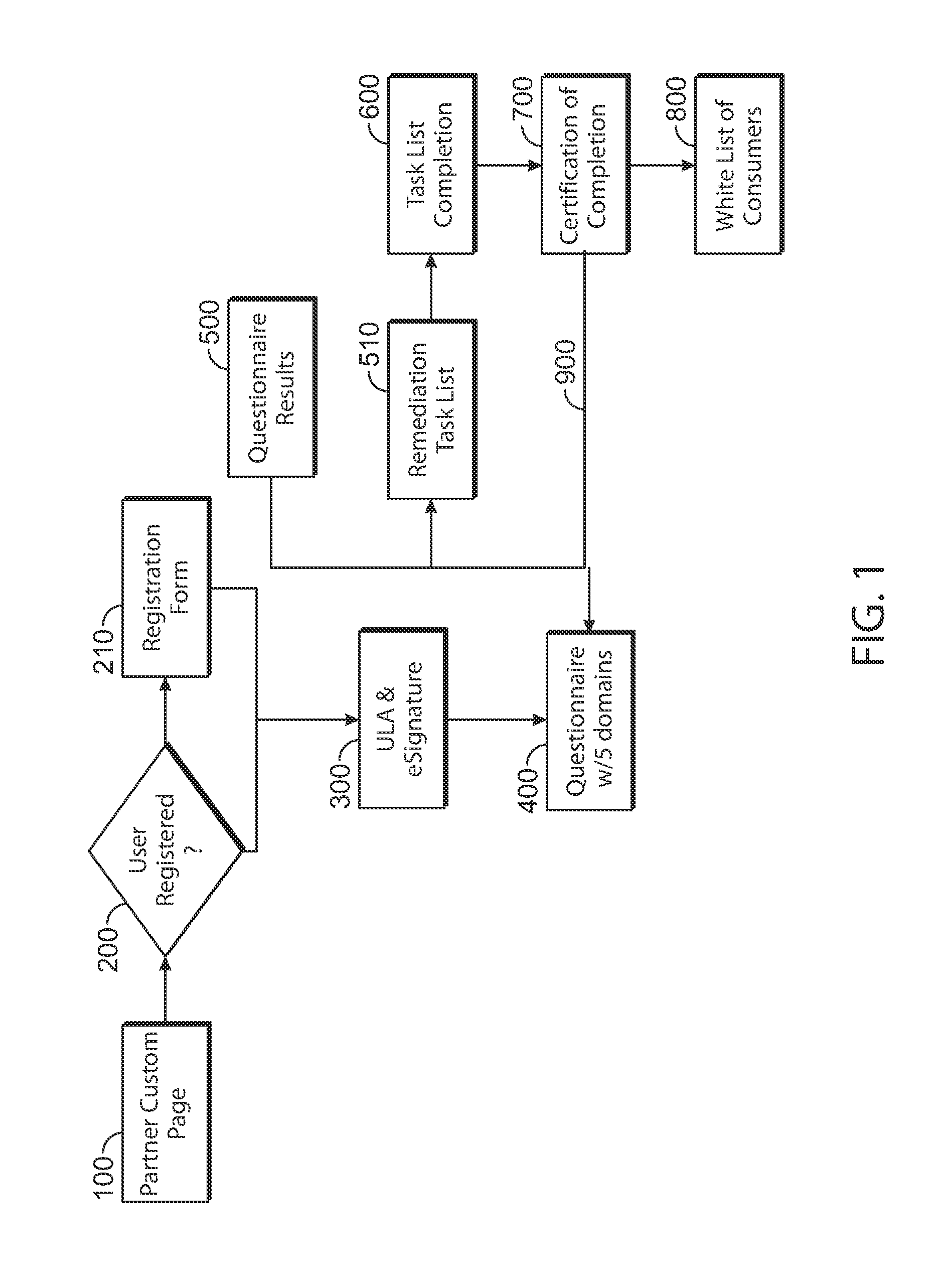

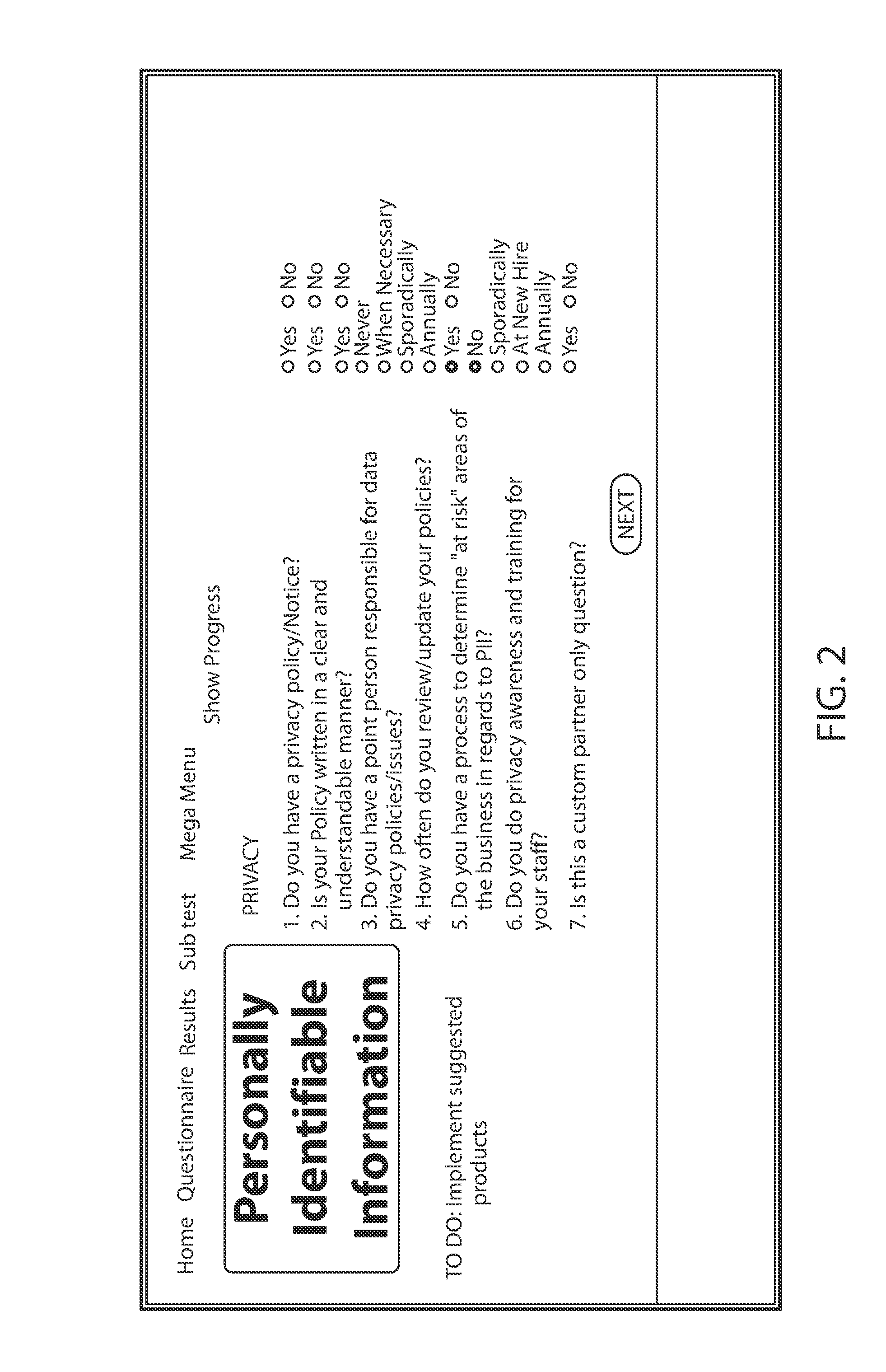

System and method for data breach readiness and prediction

InactiveUS20160140572A1Same of flexibilitySame levelDigital data protectionPlatform integrity maintainanceComputer scienceUser interface

A system for data breach readiness comprising computer executable code for presenting a questionnaire relating to data security practices; grading the answers to the questionnaire to determine a readiness score; presenting a task list comprising a list of tasks to be accomplished before a thresh hold readiness score is achieved; and presenting a user interface to update the task list to show that an entry in the task list has been completed.

Owner:CSR PROFESSIONAL SERVICES

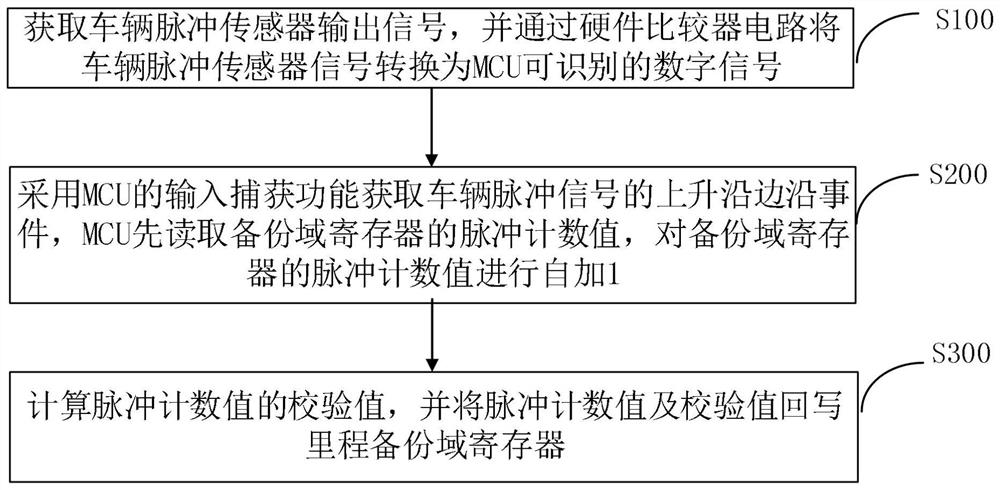

Vehicle mileage statistics method based on pulse counting

PendingCN114116296AHigh precision and reliabilityFast reading and writingRedundant data error correctionRedundant operation error correctionVehicle miles of travelComparators circuits

A vehicle mileage statistics method based on pulse counting comprises the following steps: acquiring an output signal of a vehicle pulse sensor, and converting the signal of the vehicle pulse sensor into a digital signal which can be identified by an MCU (Microprogrammed Control Unit) through a hardware comparator circuit; the method comprises the following steps: acquiring a rising edge event of a vehicle pulse signal by adopting an input capture function of an MCU (Microprogrammed Control Unit), firstly reading a pulse count value of a backup domain register by the MCU, and then automatically adding 1 to the pulse count value of the backup domain register; and calculating a check value of the pulse count value, and writing the pulse count value and the check value back to the mileage backup domain register. According to the invention, the vehicle driving mileage counting can be updated and stored in real time, an additional memory is not needed, and the mileage counting is not lost when the equipment is restarted abnormally. And the vehicle driving mileage counting precision is high and reliable.

Owner:WUHAN SOUTH SAGITTARIUS INTEGRATION CO LTD

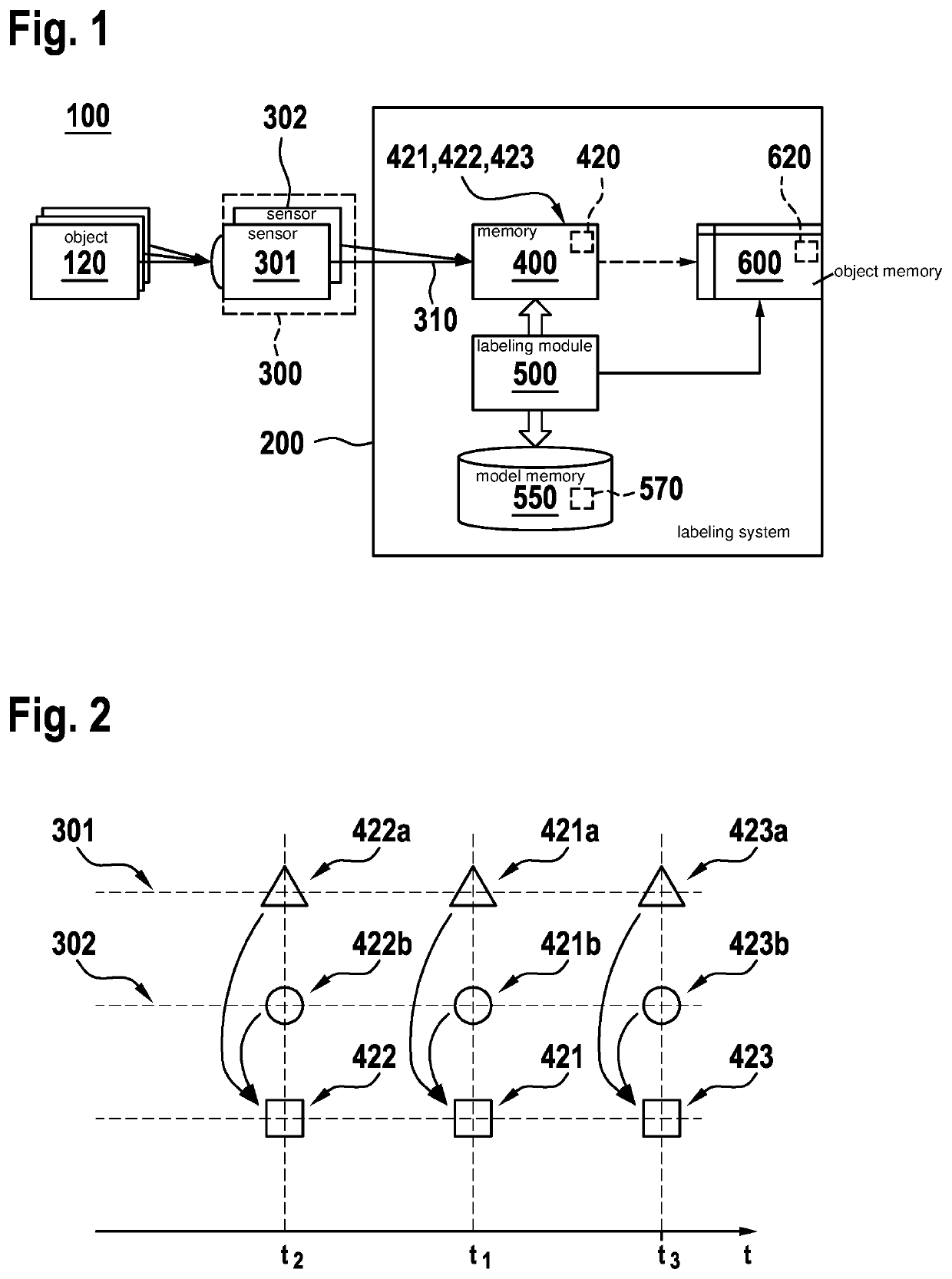

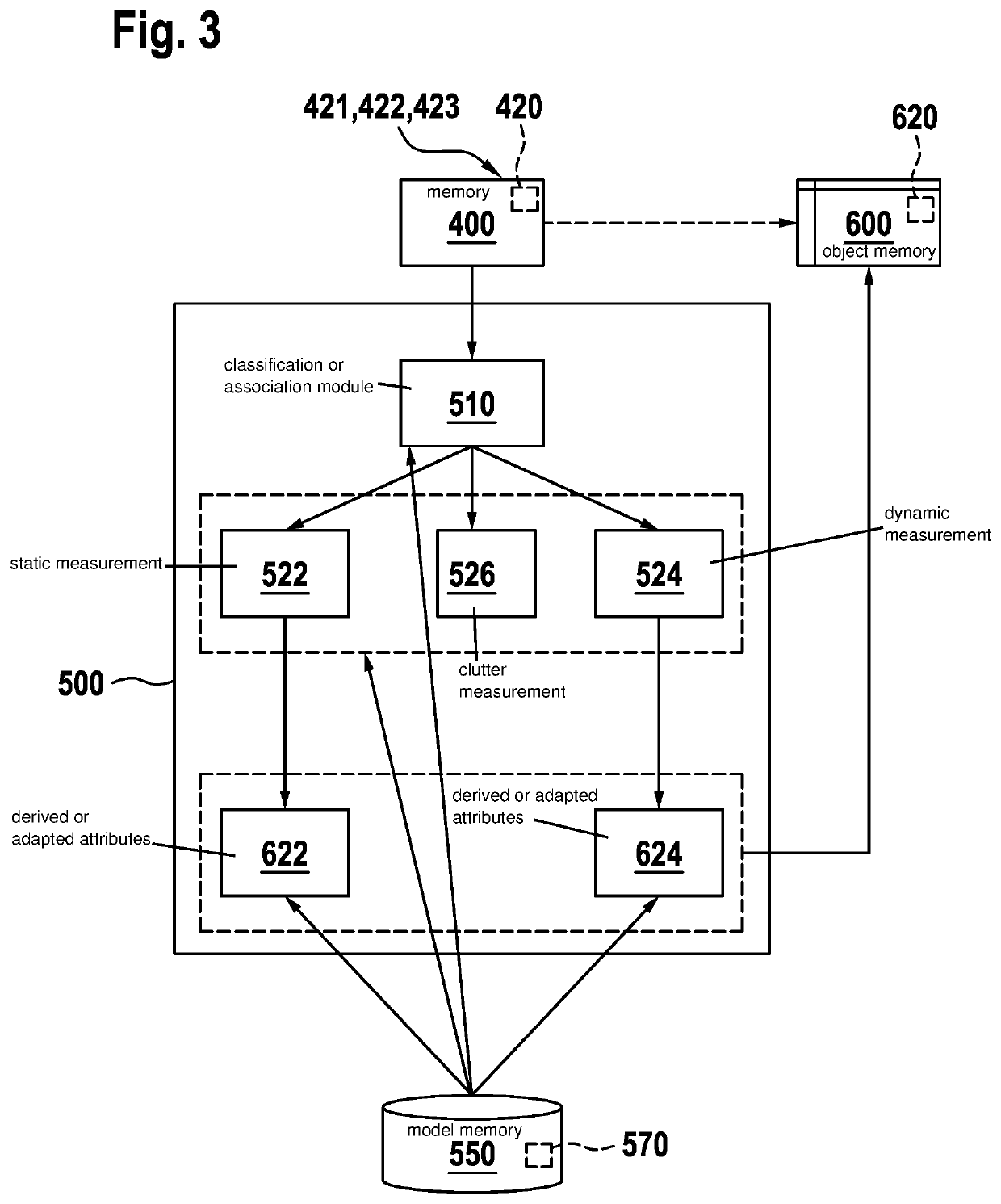

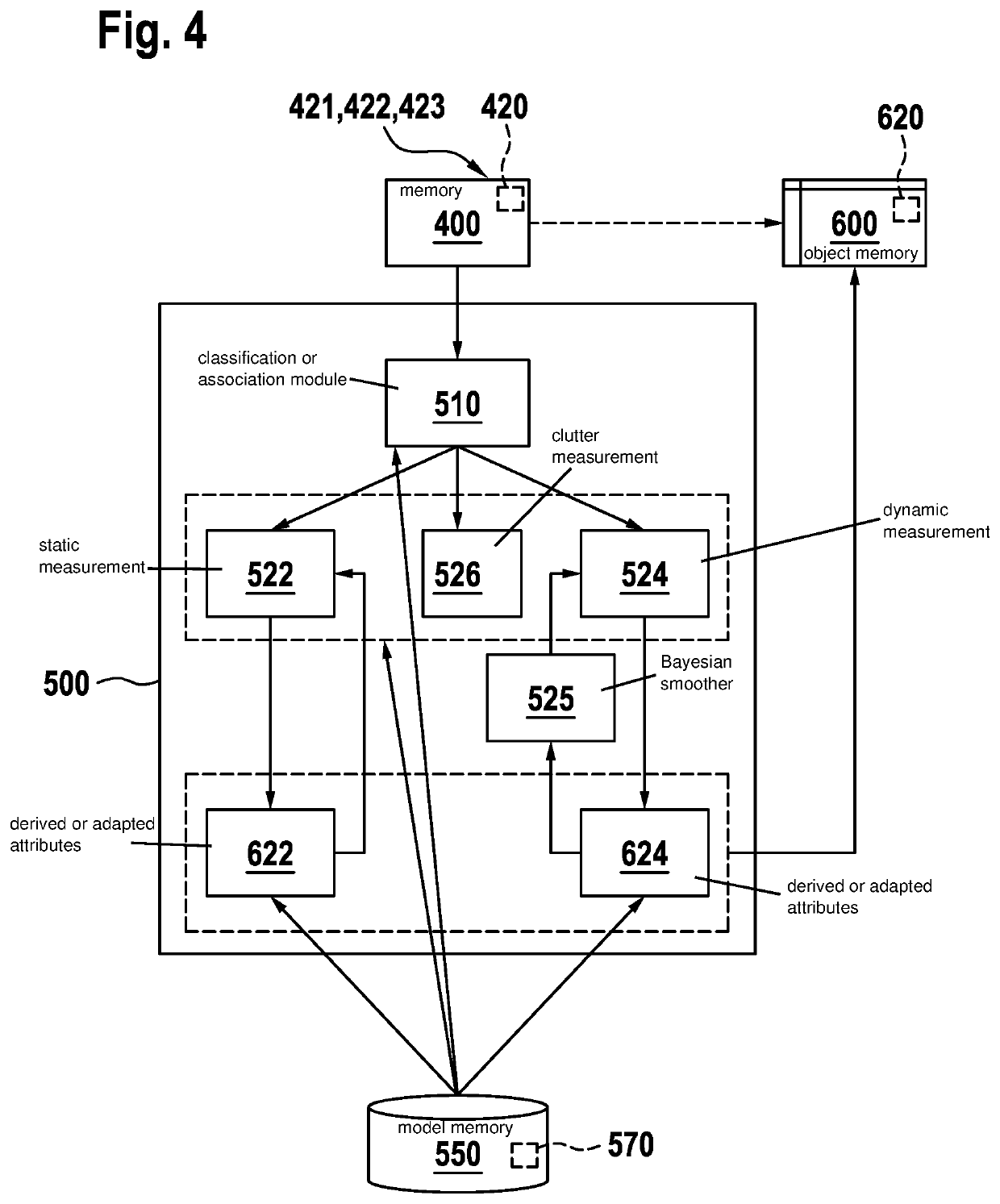

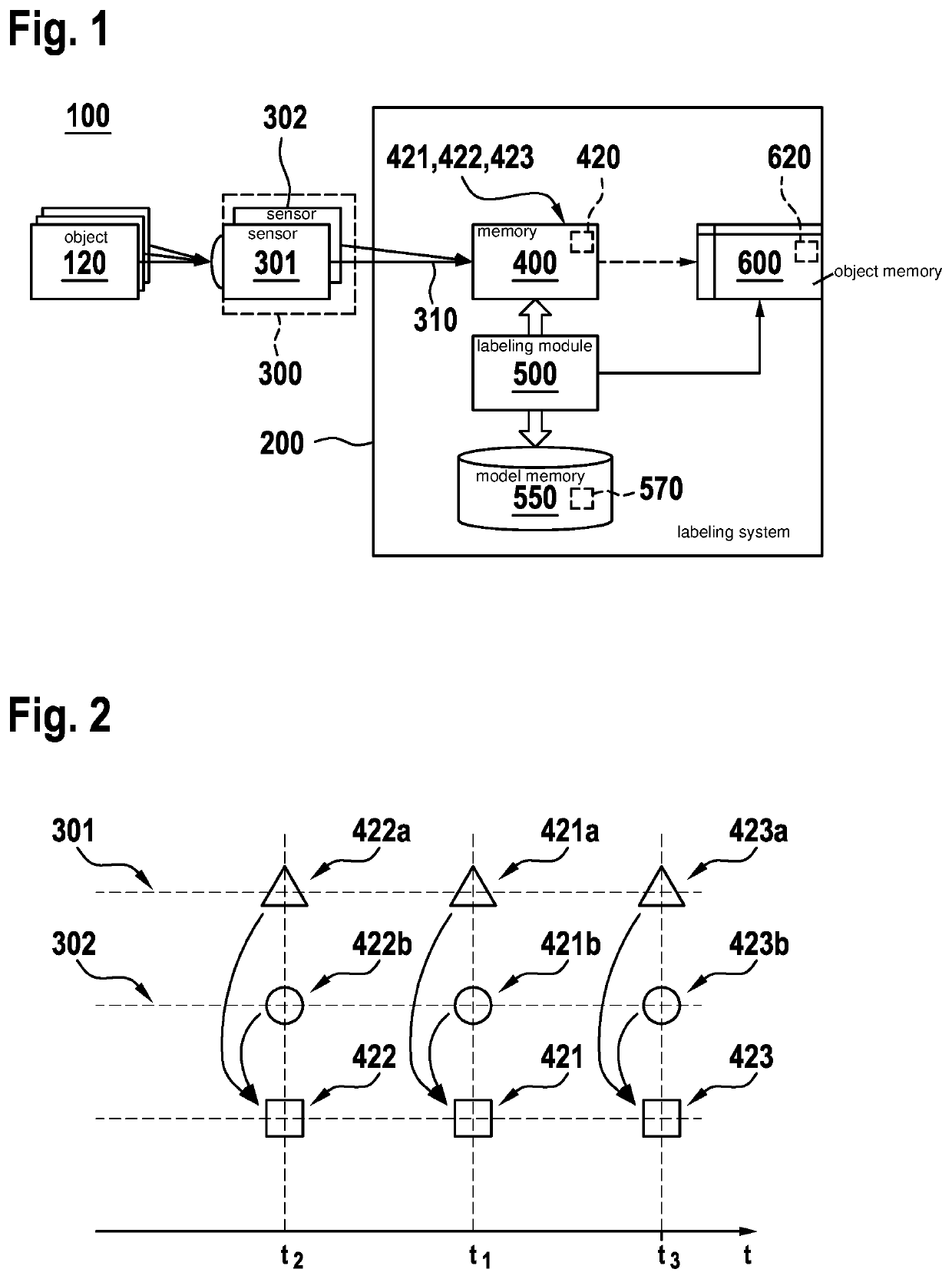

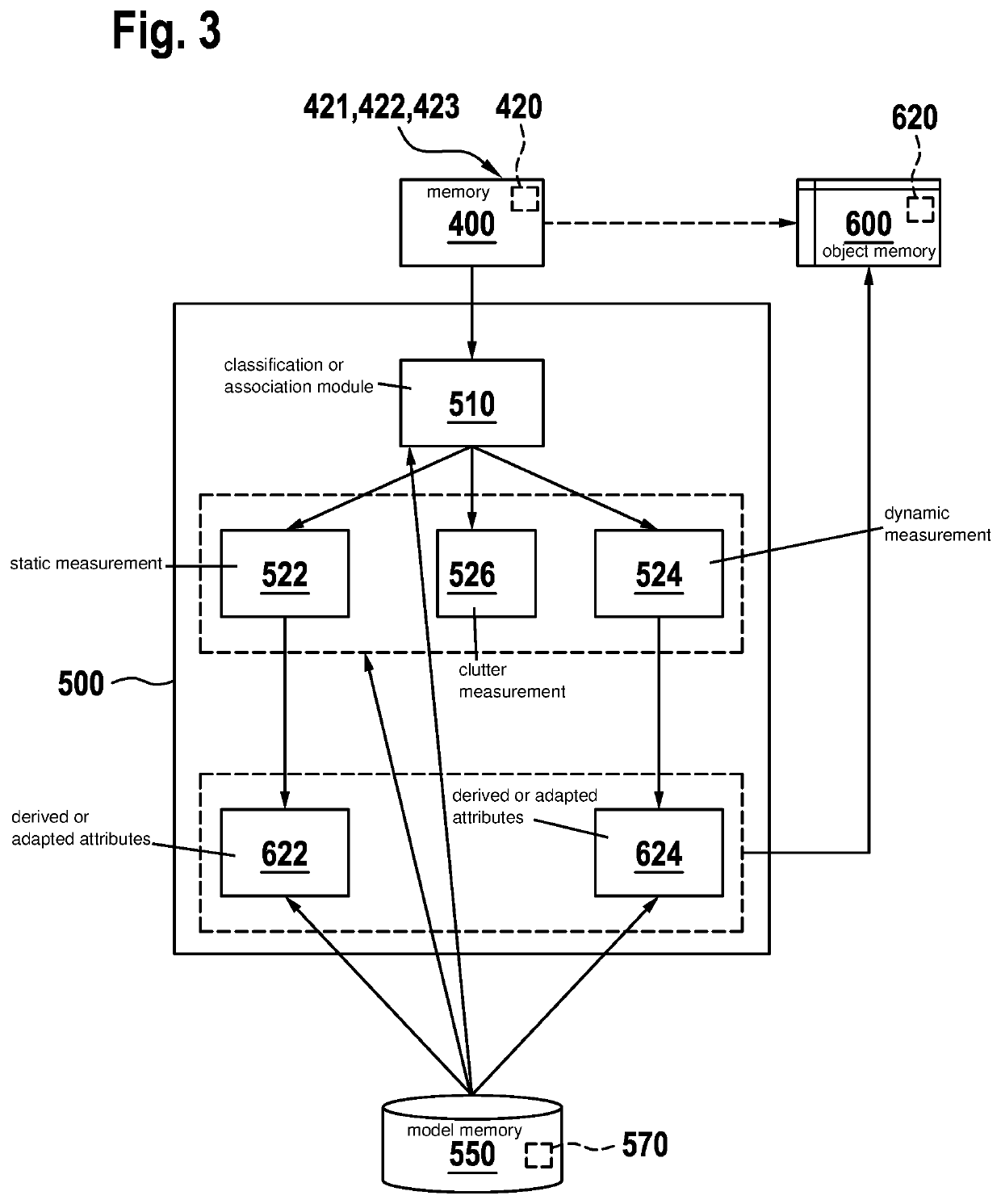

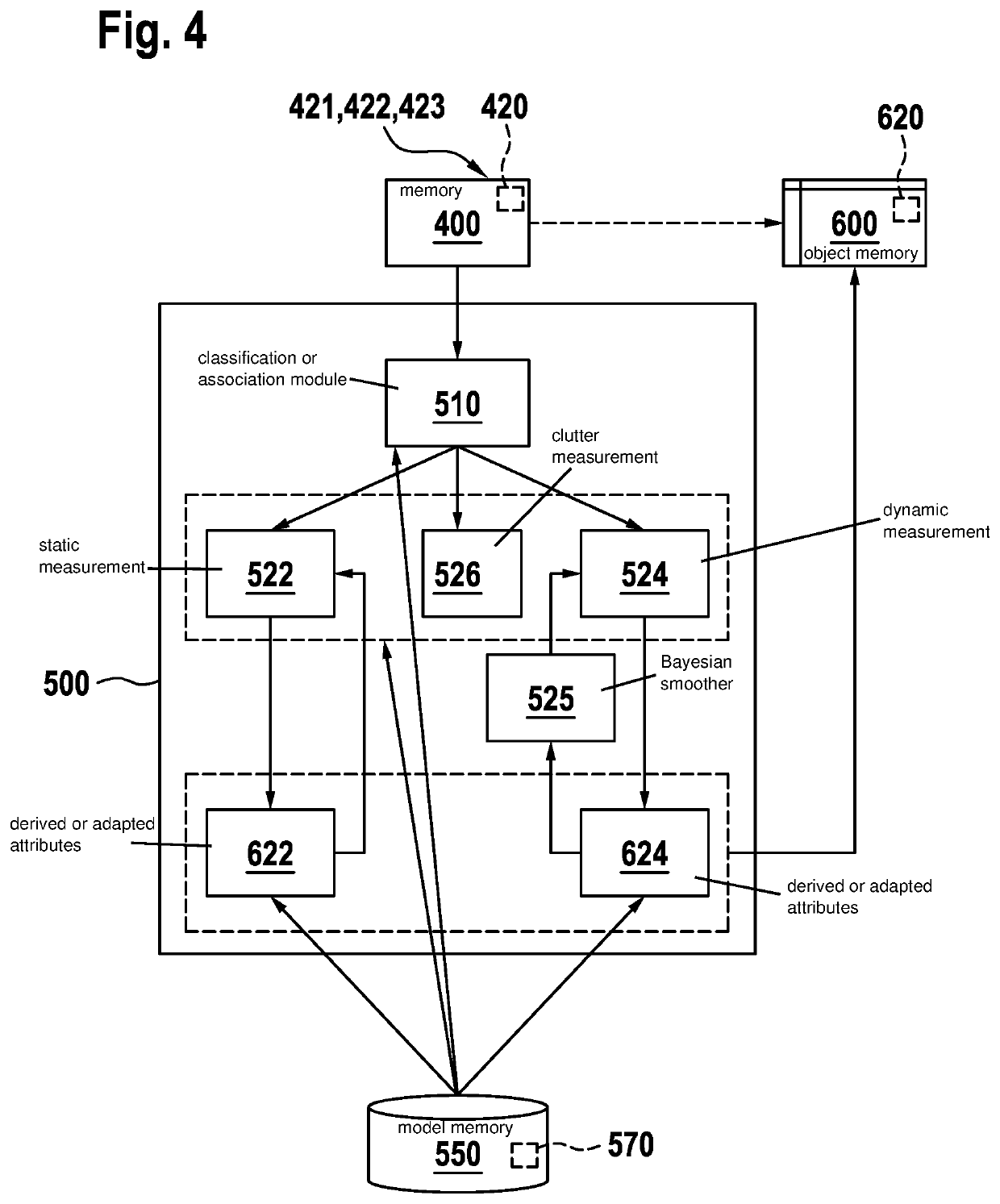

Device and method for generating label objects for the surroundings of a vehicle

ActiveUS11392804B2High precision and reliabilityImprove accuracyAutonomous decision making processScene recognitionComputer graphics (images)Engineering

A method and a labeling system for generating a label object for the symbolic description of an object of an environment of a mobile device, e.g., a robot or a vehicle. The label object includes at least one attribute of an object at a first point in time, from observations of this object. The method includes selecting, from the observations, a first observation recorded at a first point in time, a second observation recorded at a second point in time, the second point in time being a point in time before the first point in time, as well as a third observation recorded at a third point in time, the third point in time being a point in time after the first point in time; and ascertaining, by using the selected observations, the at least one attribute of the object.

Owner:ROBERT BOSCH GMBH

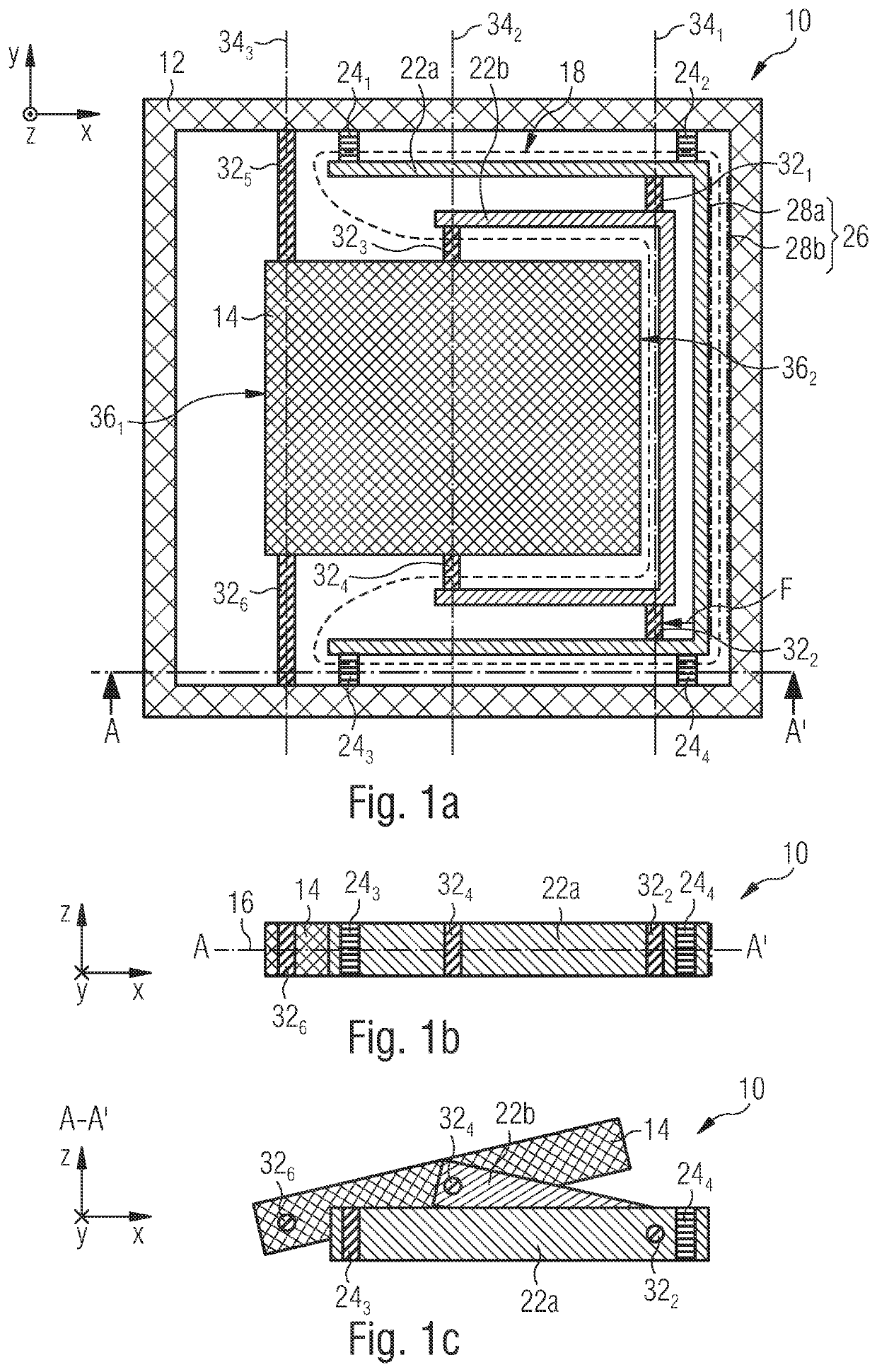

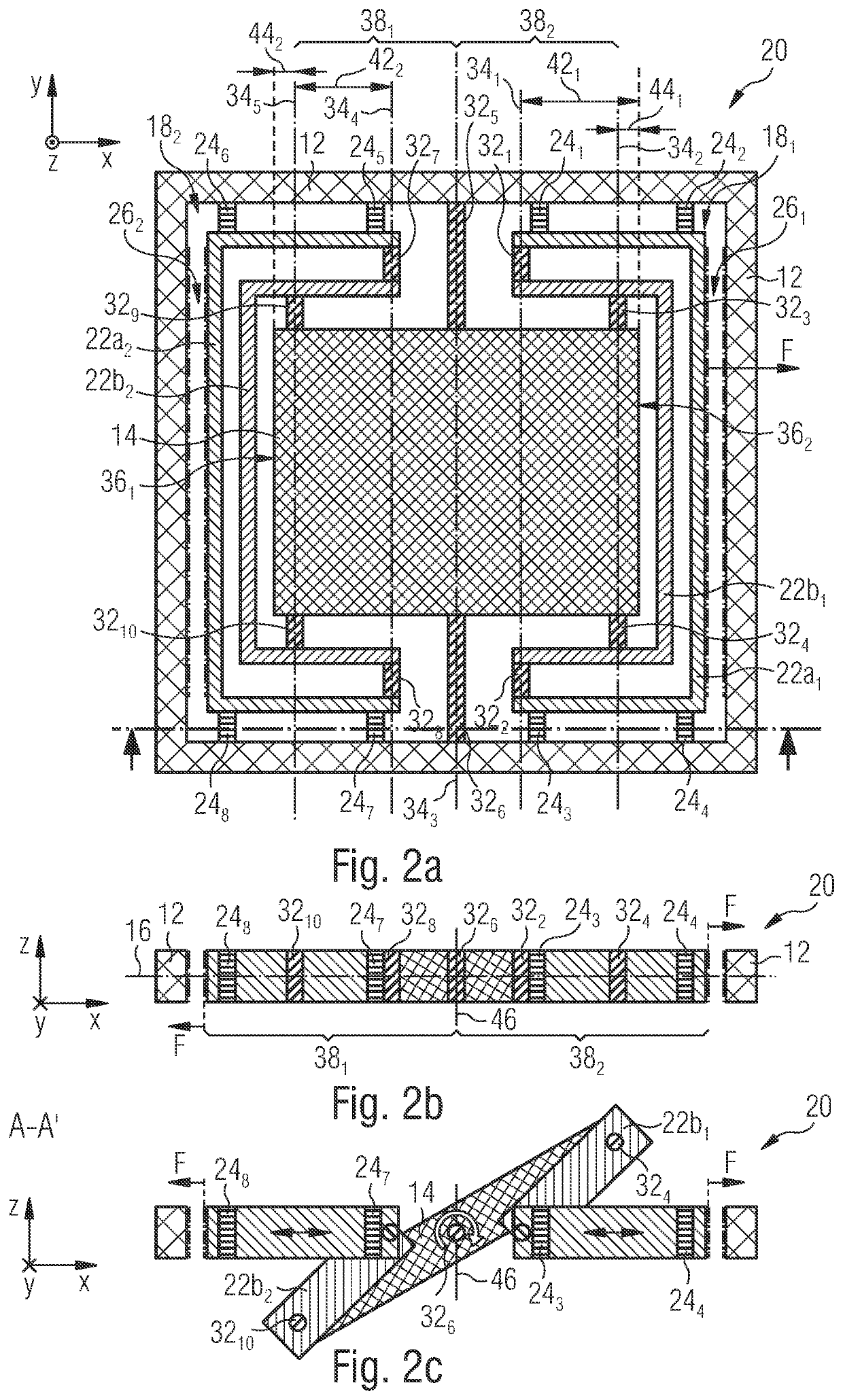

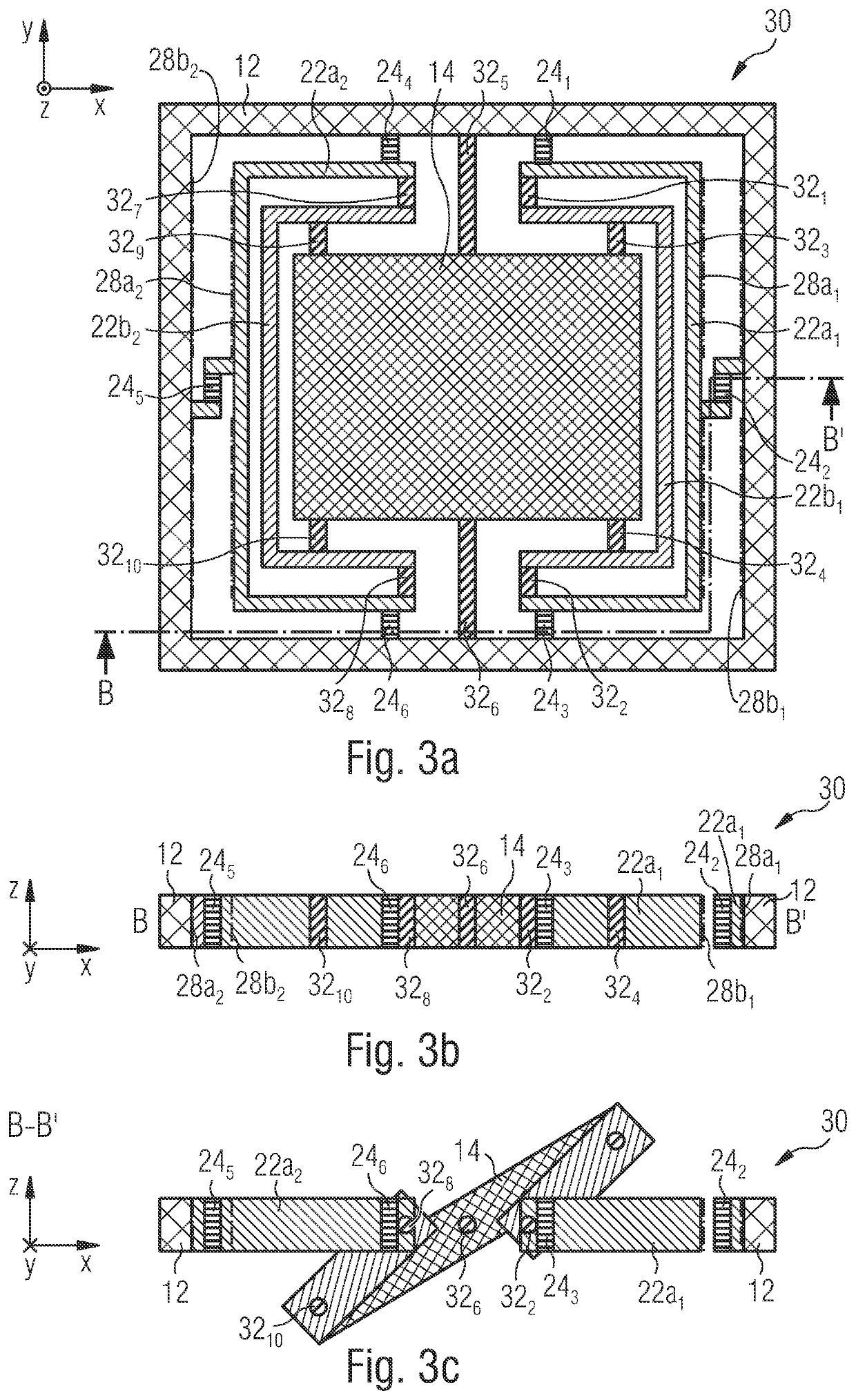

Micromechanical structure, micromechanical system and method of providing a micromechanical structure

PendingUS20210380401A1High precisionEasy to manufacturePiezoelectric/electrostrictive devicesFlexible microstructural devicesPhysicsEngineering

A micromechanical apparatus includes a substrate, a movable element disposed in a reference plane in an undeflected state, a transmission structure having a first transmission side coupled to the substrate, and a second transmission side coupled to the movable element, and an actuator configured to provide a force along a force direction parallel to the reference plane and apply the same to the first transmission side. The transmission structure is configured to transfer the force along the force direction to a movement of the movable element out of the reference plane.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

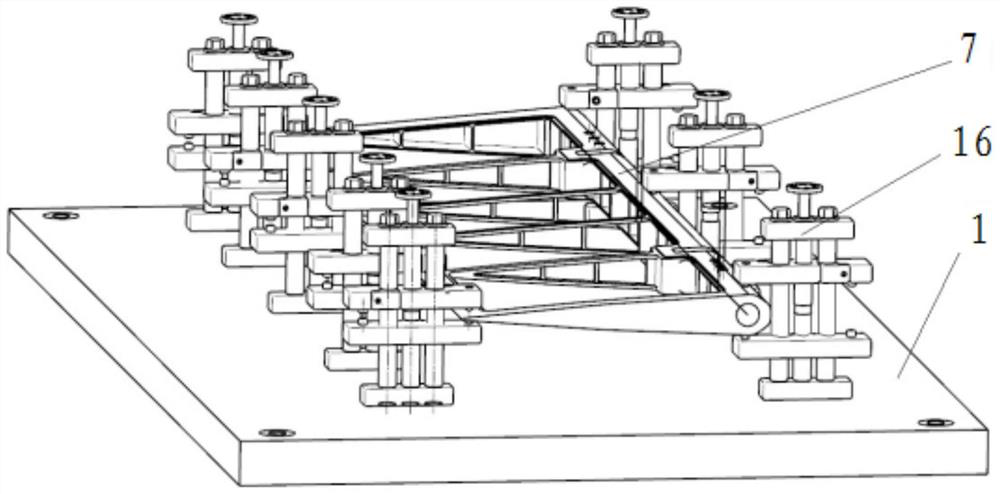

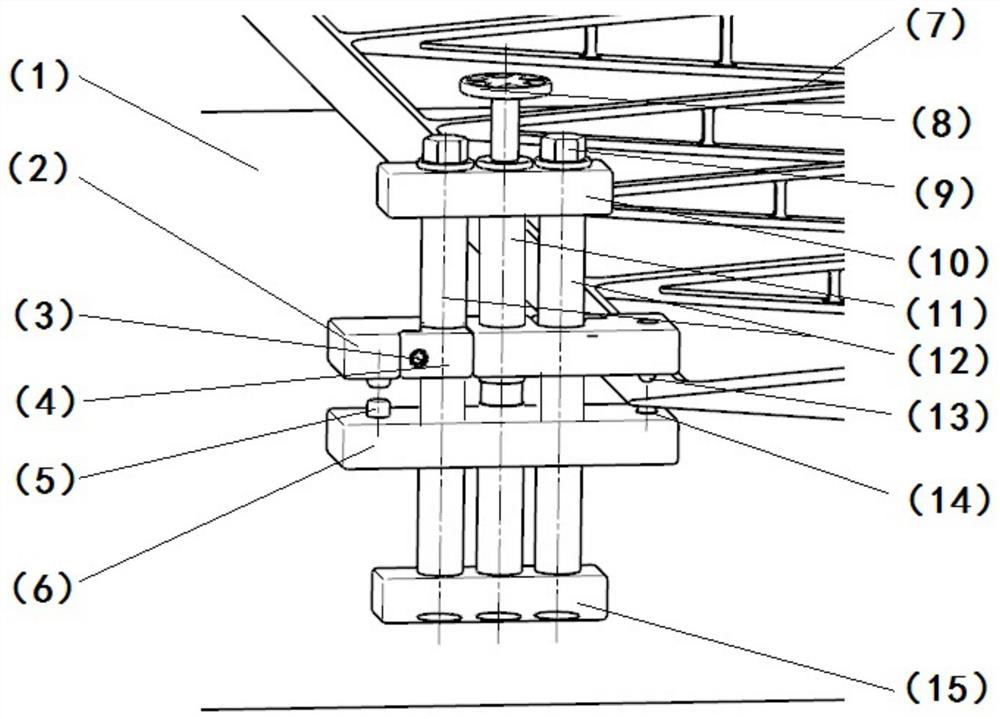

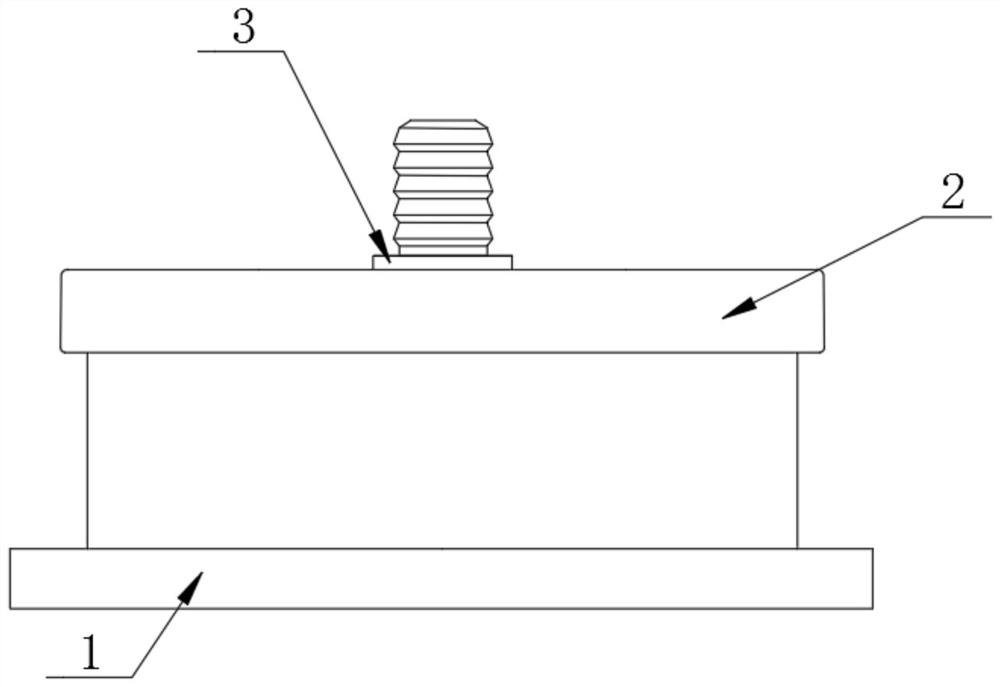

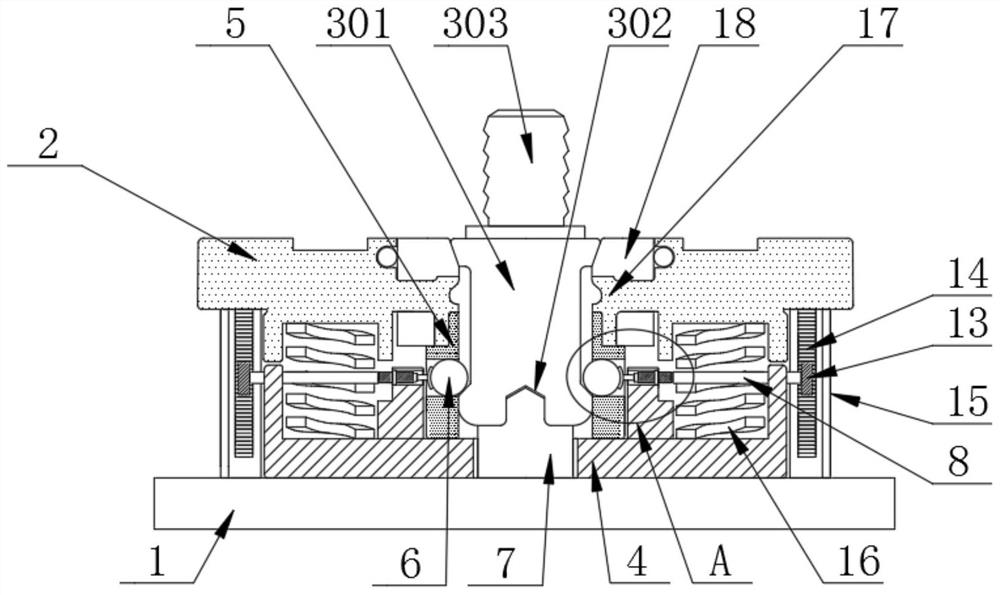

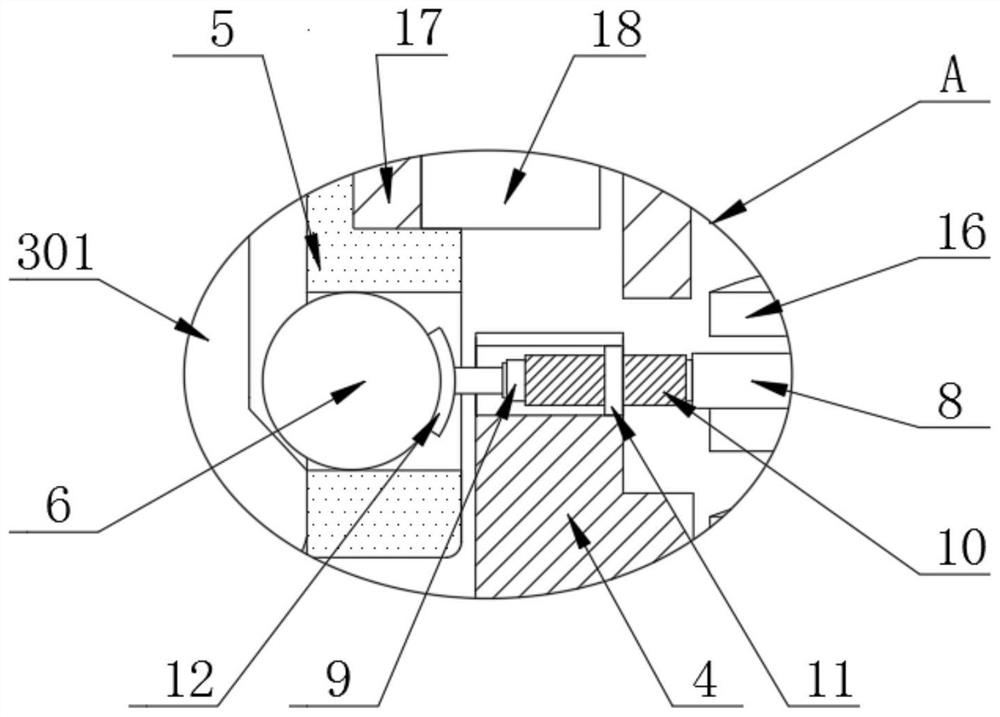

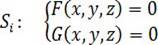

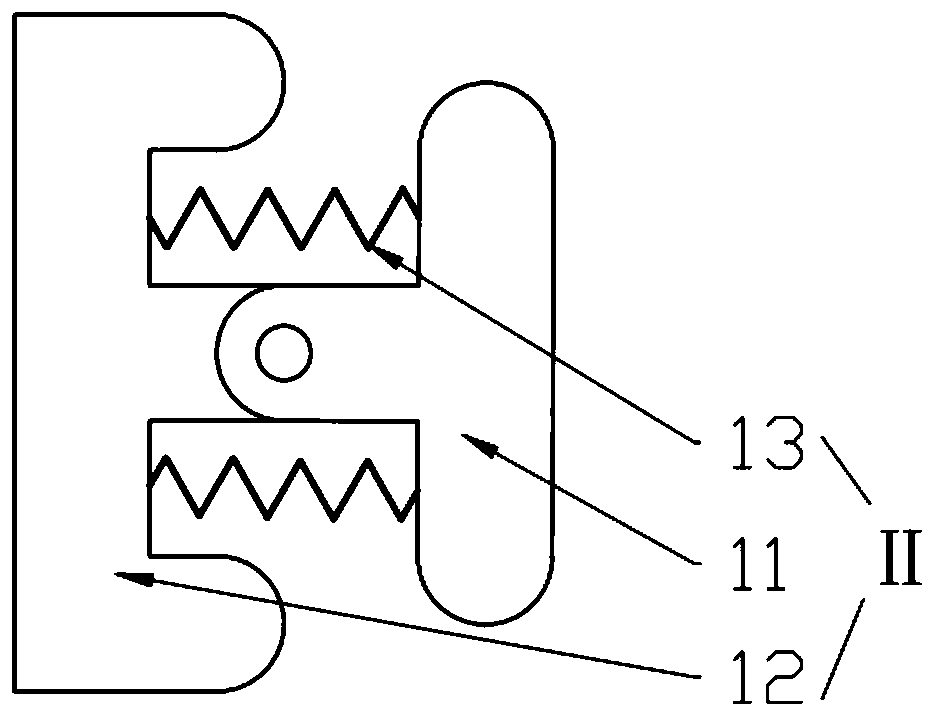

Self-centering adjustable machining clamping device and clamping method

ActiveCN112643367ASolve the problem of too long preparation time for clamping and processingReduce processing costsPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention relates to a self-centering adjustable machining clamping device comprising a base plate (1) and a plurality of sets of clamping tools arranged on the base plate. Each set of clamping tools comprises an upper pressing plate (2), a lower pressing plate (6), an upper positioning block (10), a forward and reverse screw rod (11), polish rods (12) and a lower positioning block (15); and the forward and reverse screw rod (11) and the polish rods (12) are arranged in parallel and penetrate through the upper positioning block (10), the upper pressing plate (2), the lower pressing plate (6) and the lower positioning block (15) from top to bottom respectively. By the adoption of the self-centering adjustable machining clamping device, the problem that the clamping machining preparation time of wing rudder type parts is too long is effectively solved, the problems of great difficulties in clamping and no way of guaranteeing the centering precision caused by part deformation are solved, the clamping efficiency is greatly improved, meanwhile, clamping is firmer, and the precision reliability is further improved.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Zero-point rapid positioning reference clamp of cylinder cover machining tool

PendingCN113478251AHigh precision and reliabilityImprove securityPositioning apparatusMetal-working holdersButt jointEngineering

The invention relates to the technical field of cylinder cover machining, in particular to a zero-point rapid positioning reference clamp of a cylinder cover machining tool. The zero-point rapid positioning reference clamp comprises an upper end clamping disc, a lower end clamping disc, a positioning connector arranged on the upper end clamping disc and a locking piece arranged at the top end of the lower end clamping disc, and the upper end clamping disc and the lower end clamping disc are oppositely arranged; and the positioning connector movably penetrates through the upper end clamping disc and extends into the locking piece, and the upper end clamping disc and the lower end clamping disc are in butt joint and drive the locking piece to lock the zero point position of the positioning connector. Compared with an air pressure or hydraulic pressure manner, the zero-point rapid positioning reference clamp is not easily influenced by the size of a pressure source, multi-directional zero-point positioning of the positioning connector is completed in the installation process of all parts of the clamp, the repeated positioning precision is only influenced by structural factors of all parts of the clamp, and the precision reliability is high.

Owner:ANQING CSSC MATING POWER

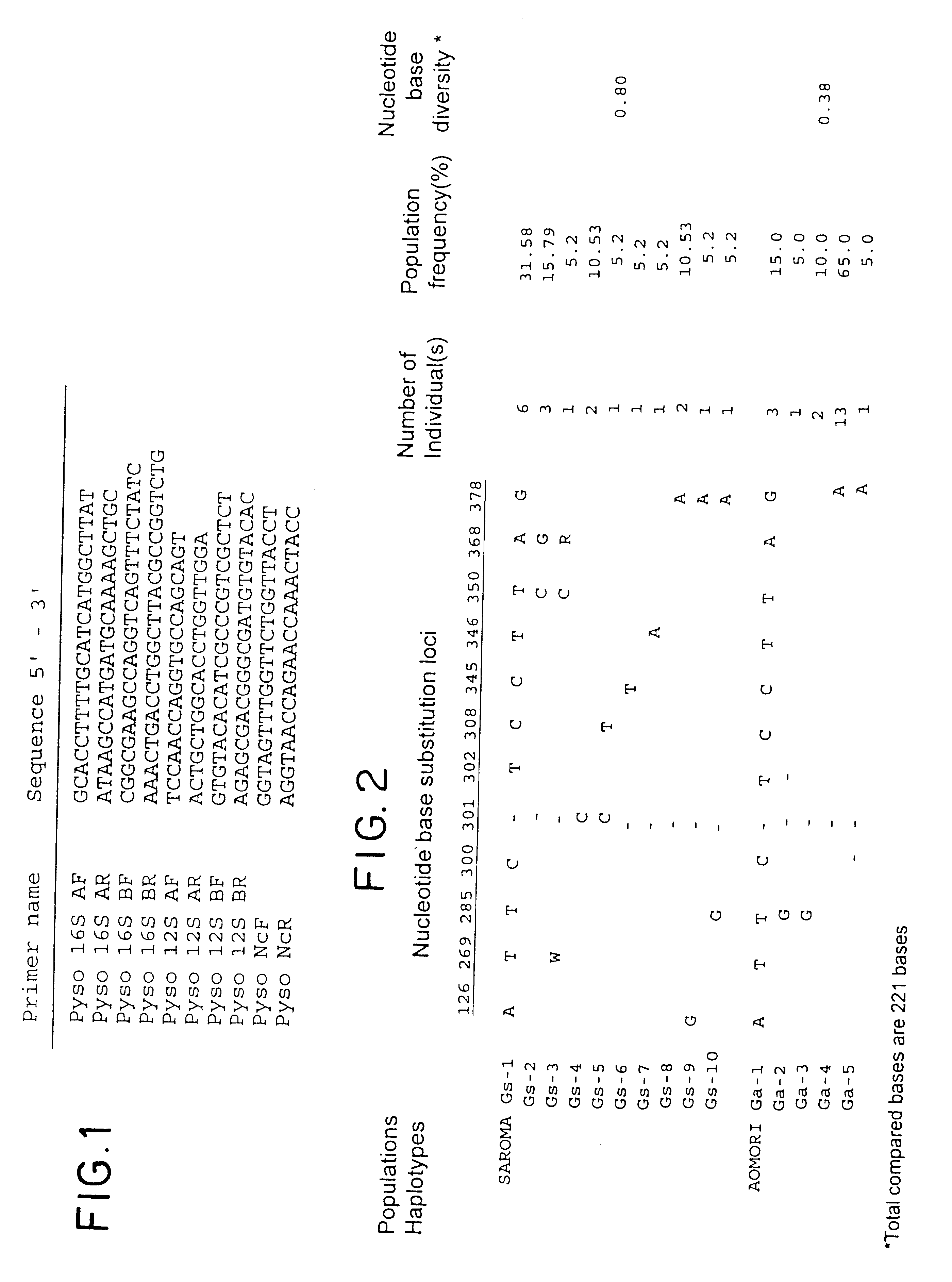

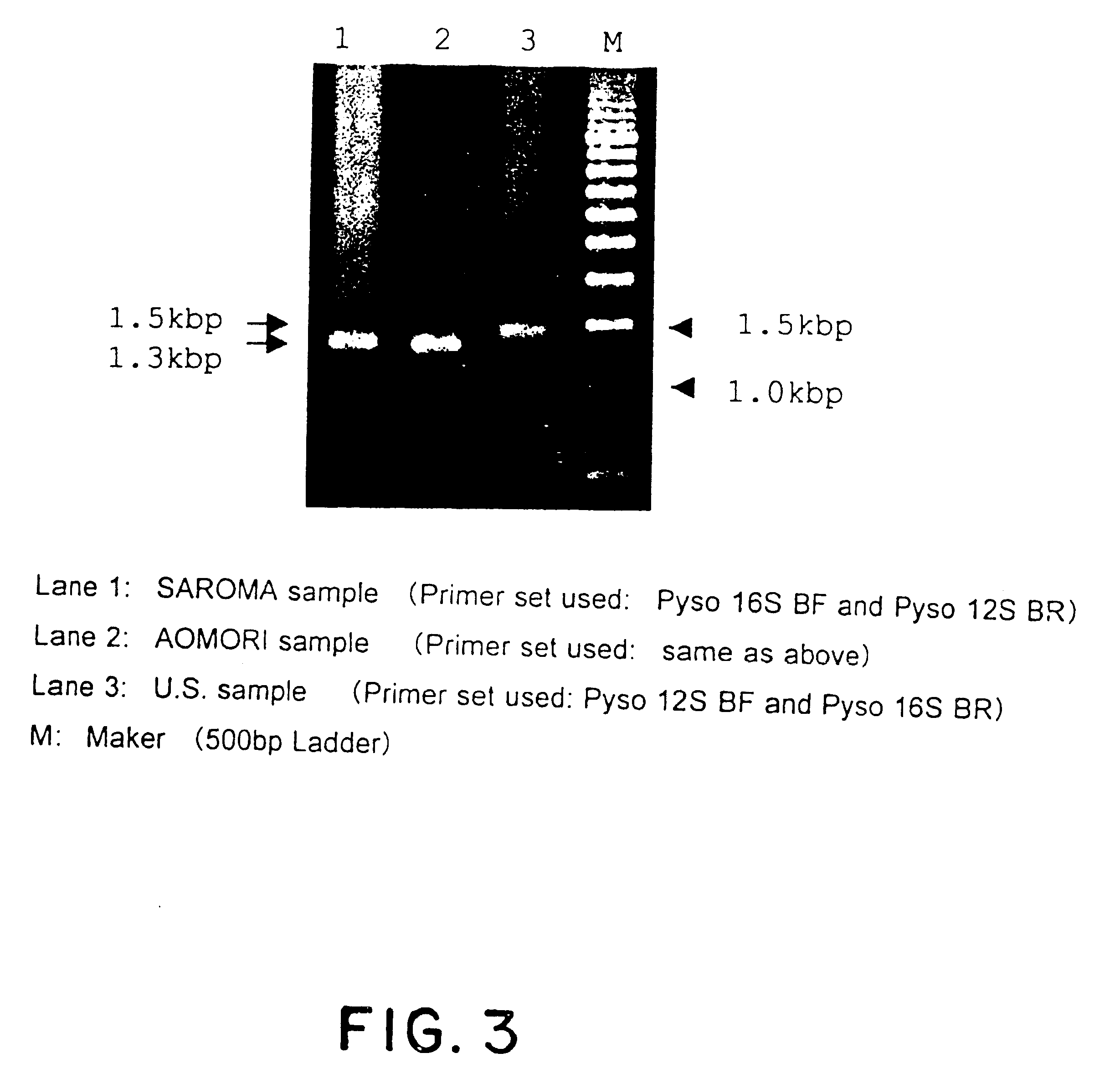

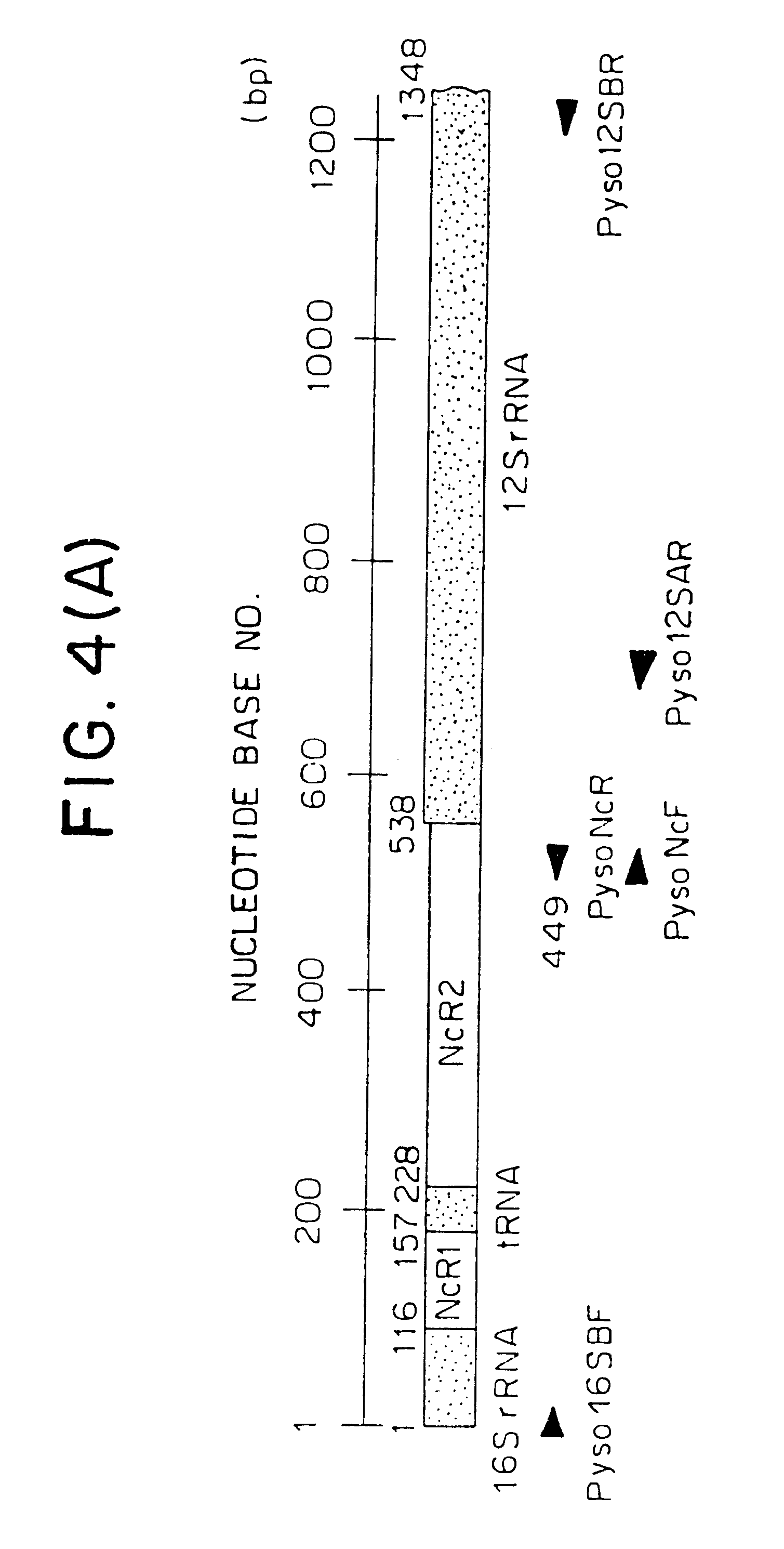

Method for analyzing phyletic lineage of scallop

InactiveUS6514705B2High precision and reliabilityEfficient analysisSugar derivativesMicrobiological testing/measurementPatinopecten yessoensisCoding region

Method for analyzing a phyletic lineage of scallop, which comprises the steps of sequencing a mitochondrial DNA of the scallop to determine a nucleotide base sequence of the mitochondrial DNA, wherein the nucleotide base sequence includes a non-coding region containing a nucleotide base substitution locus which shows a sequence polymorphism indicative of a particular lineage of the scallop. Mitochondrial DNA of the scallop is amplified by PCR, using a suitable primer set designed on the basis of nucleotide base sequences conserved among known shellfish mitochondrial 16S rRNA and 12S rRNA genes, followed by sequencing to determine a non-coding region therein. In such non-coding region, a nucleotide base substitution locus is located, whereby a particular lineage of the scallop is determined. Based on those steps, a Japanese scallop, Patinopecten yessoensis, is analyzed as to the nucleotide base sequence and lineage thereof.

Owner:HOKKAIDO FEDERATION OF FISHERIES COOP ASSOCS

Device and method for generating label objects for the surroundings of a vehicle

ActiveUS20200175342A1High precision and reliabilityImprove accuracyAutonomous decision making processScene recognitionComputer graphics (images)Engineering

A method and a labeling system for generating a label object for the symbolic description of an object of an environment of a mobile device, e.g., a robot or a vehicle. The label object includes at least one attribute of an object at a first point in time, from observations of this object. The method includes selecting, from the observations, a first observation recorded at a first point in time, a second observation recorded at a second point in time, the second point in time being a point in time before the first point in time, as well as a third observation recorded at a third point in time, the third point in time being a point in time after the first point in time; and ascertaining, by using the selected observations, the at least one attribute of the object.

Owner:ROBERT BOSCH GMBH

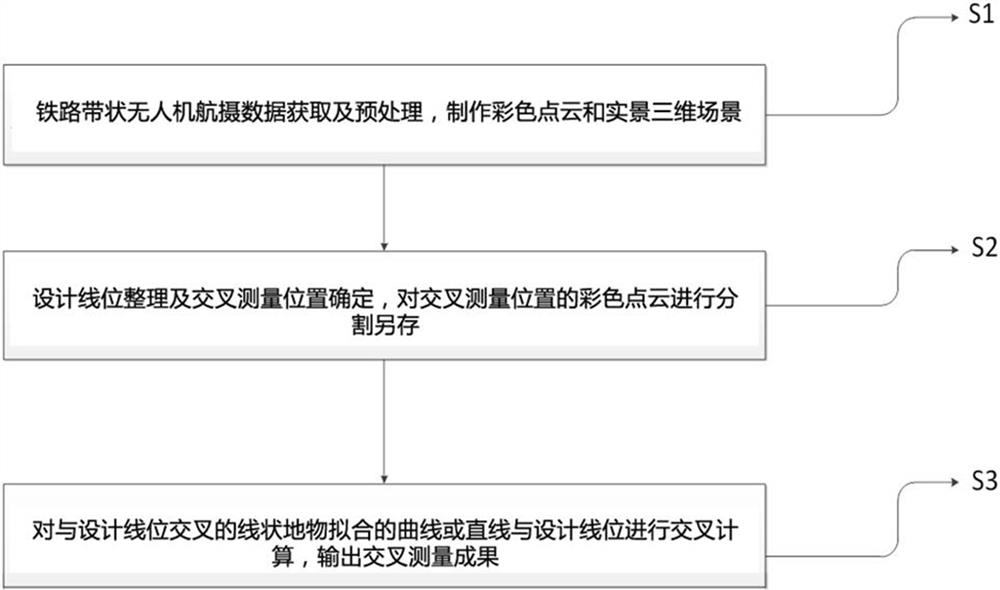

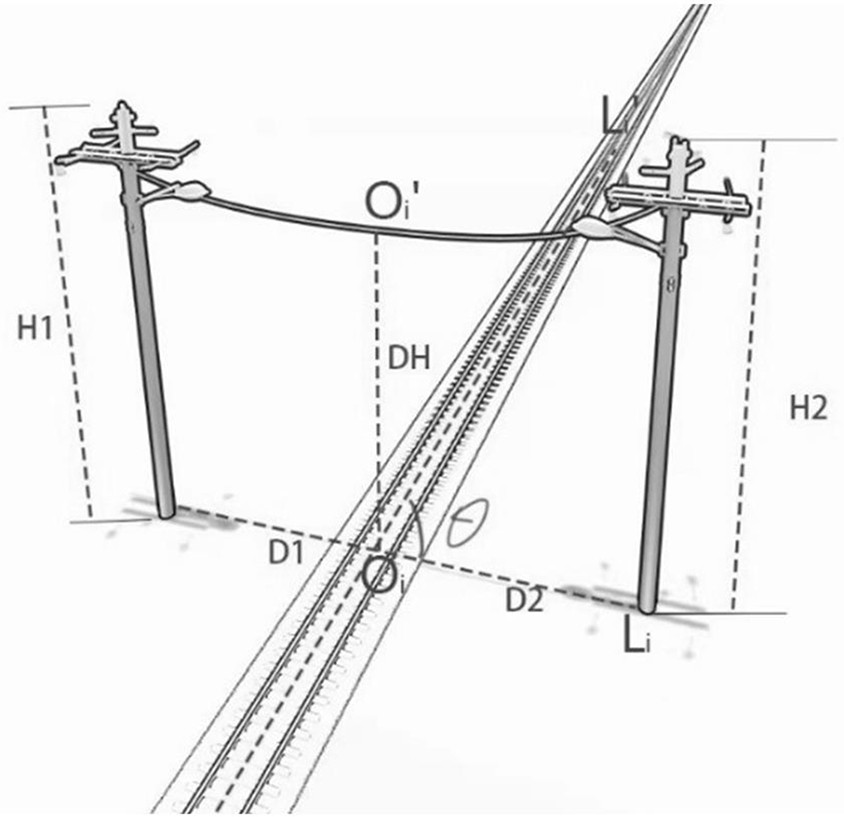

Newly-built railway cross measurement method based on unmanned aerial vehicle laser point cloud and image fusion

ActiveCN114859374AGood for checkingConducive to archive managementInternal combustion piston enginesPicture interpretationPoint cloudUncrewed vehicle

The invention relates to a newly-built railway cross measurement method based on unmanned aerial vehicle laser point cloud and image fusion, and belongs to the technical field of newly-built railway engineering survey and construction, and the method comprises the following steps: S1, obtaining and preprocessing railway band-shaped unmanned aerial vehicle aerial photography data, and making a color point cloud and a live-action three-dimensional scene; s2, design line position arrangement and cross measurement position determination are carried out, and color point clouds at the cross measurement positions are segmented and saved; and S3, performing crossover calculation on the curve or straight line fitted by the linear ground feature crossed with the design line position and the design line position, and outputting a crossover measurement result. According to the invention, laser point cloud and image data are obtained at the same time in a way that the unmanned aerial vehicle carries out strip-shaped aerial photography along the line, and the aerial photography data can be reused, thereby facilitating checking and archiving management of achievements; according to the invention, unmanned aerial vehicle laser point cloud and image fusion processing is adopted, so that the precision and reliability of cross measurement are greatly improved; according to the invention, a non-contact measurement mode is adopted, so that the cross measurement field workload of the traditional newly-built railway is effectively reduced.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

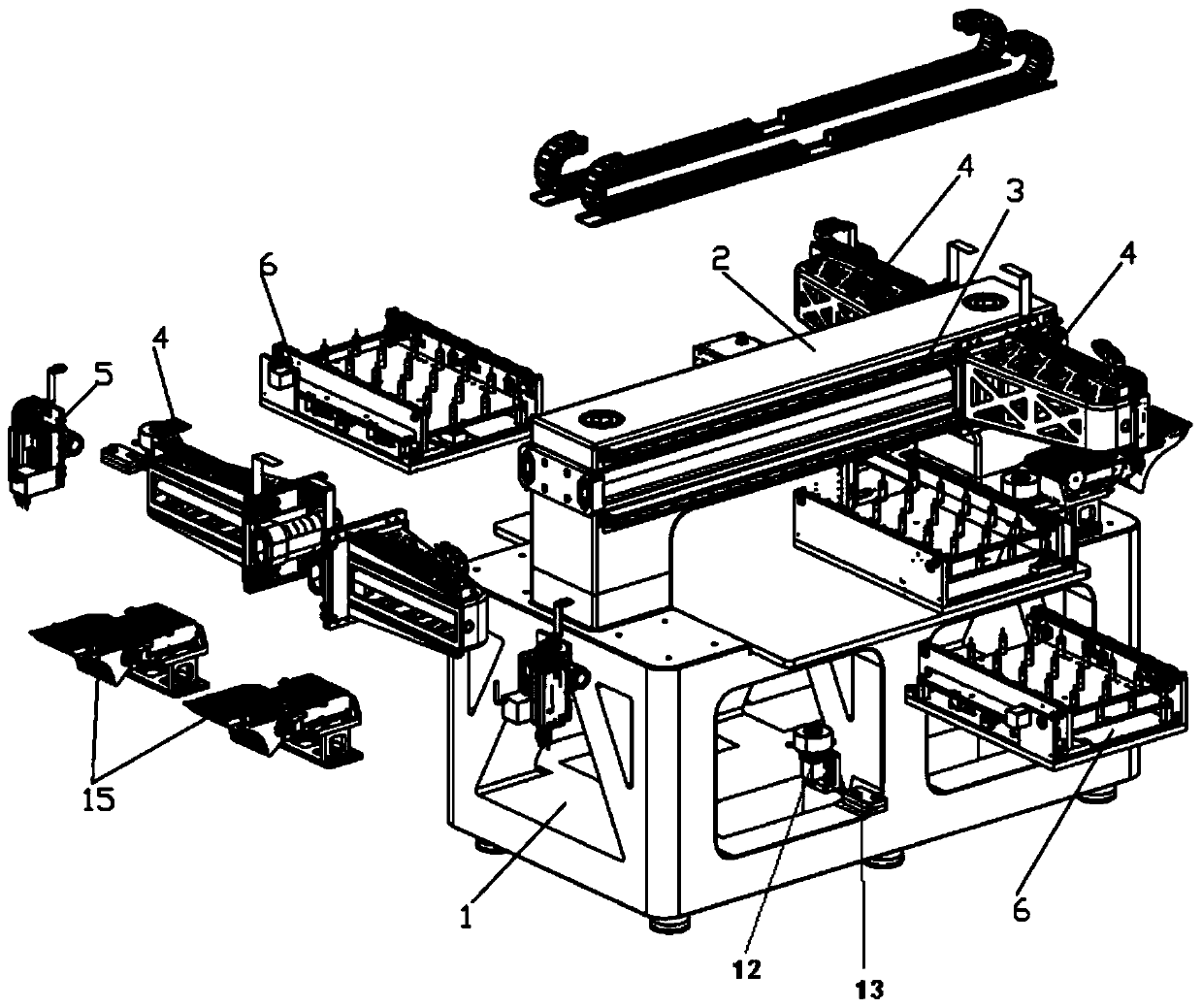

3C industry orientated modular multi-cantilever multifunctional device

ActiveCN109850565ACompact structureReduce volumeConveyor partsElectrical componentsModularityEngineering

The invention discloses a 3C industry orientated modular multi-cantilever multifunctional device. The 3C industry orientated modular multi-cantilever multifunctional device comprises a main module, adetachable cross beam module is fixedly mounted on the main module, X-axis linear motor driving modules are symmetrically arranged on the two sides of the cross beam module, the X-axis linear motor driving modules are each provided with at least one Y axis cantilever module, at least one Z axis submodule is arranged on each Y axis cantilever module, at least one jig feeding module is arranged at the position, below the cross beam module, of the upper end of the main module, the upper end of the main module is further provided with at least one feeding submodule, composition components are in modular design, according to production needs, assembling matching is carried out, the structure is compact, and the size is smaller. According to production needs, the kind of Z axis submodules can bereplaced, the Z axis submodules can be replaced with carrying functions, machining functions, pasting functions, chip mounting functions and the like, and when the Z axis submodules are replaced, other modules do not need to be detached and replaced, and time and labor are saved.

Owner:杭州正向智能装备有限公司

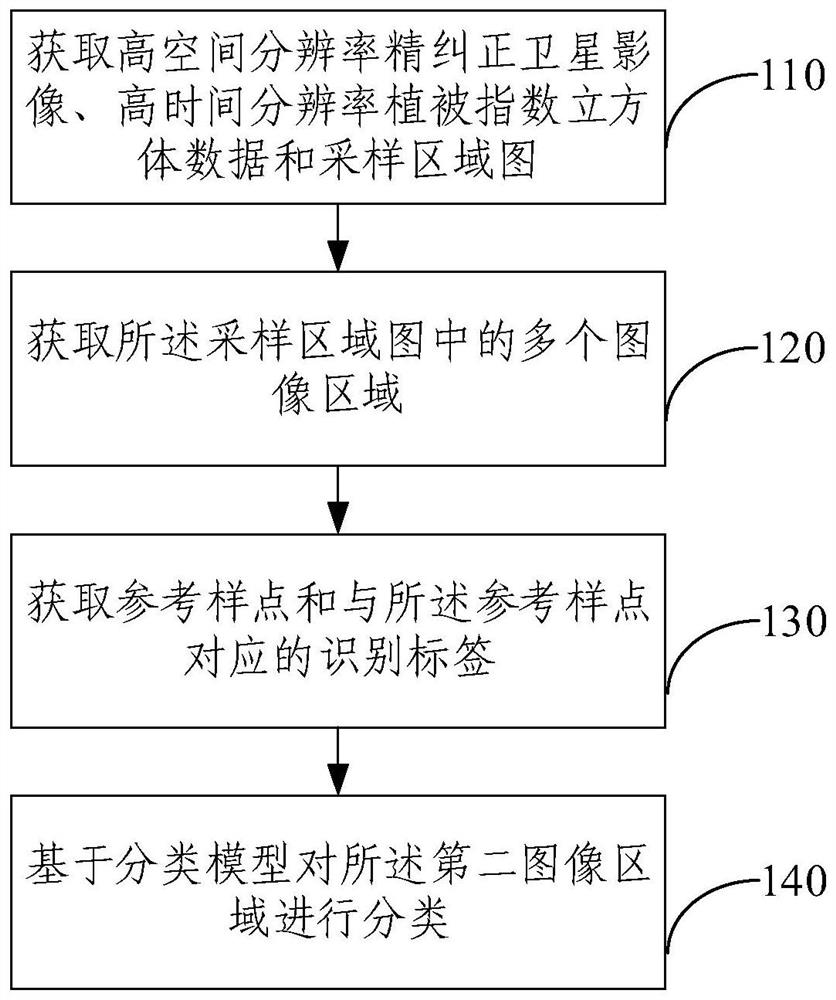

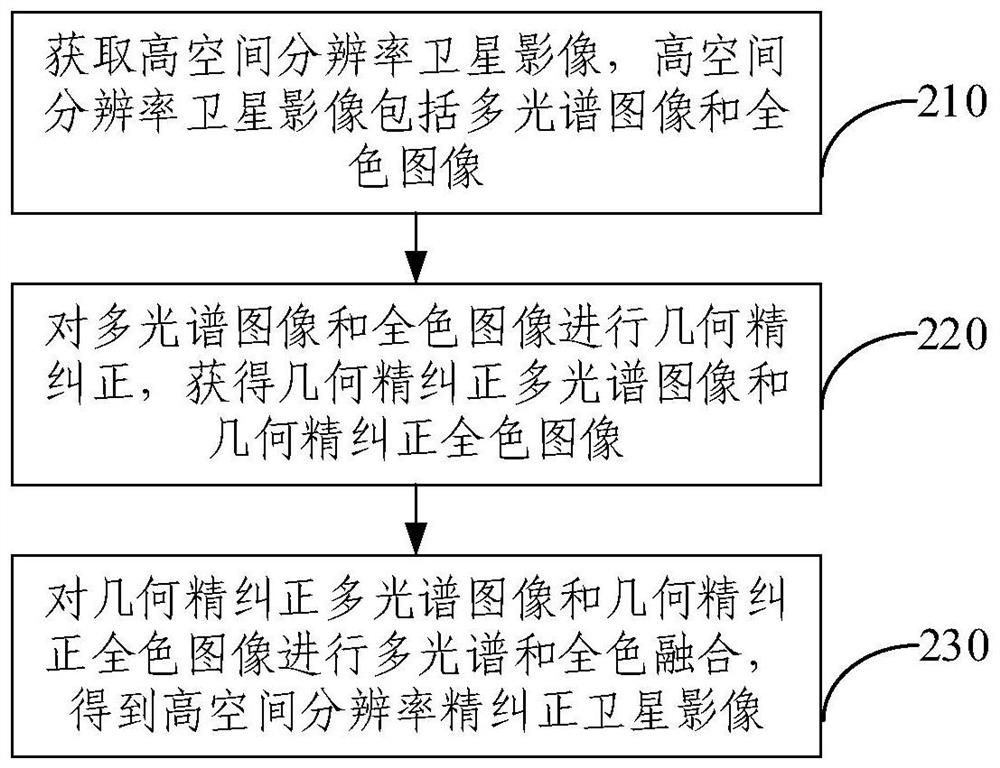

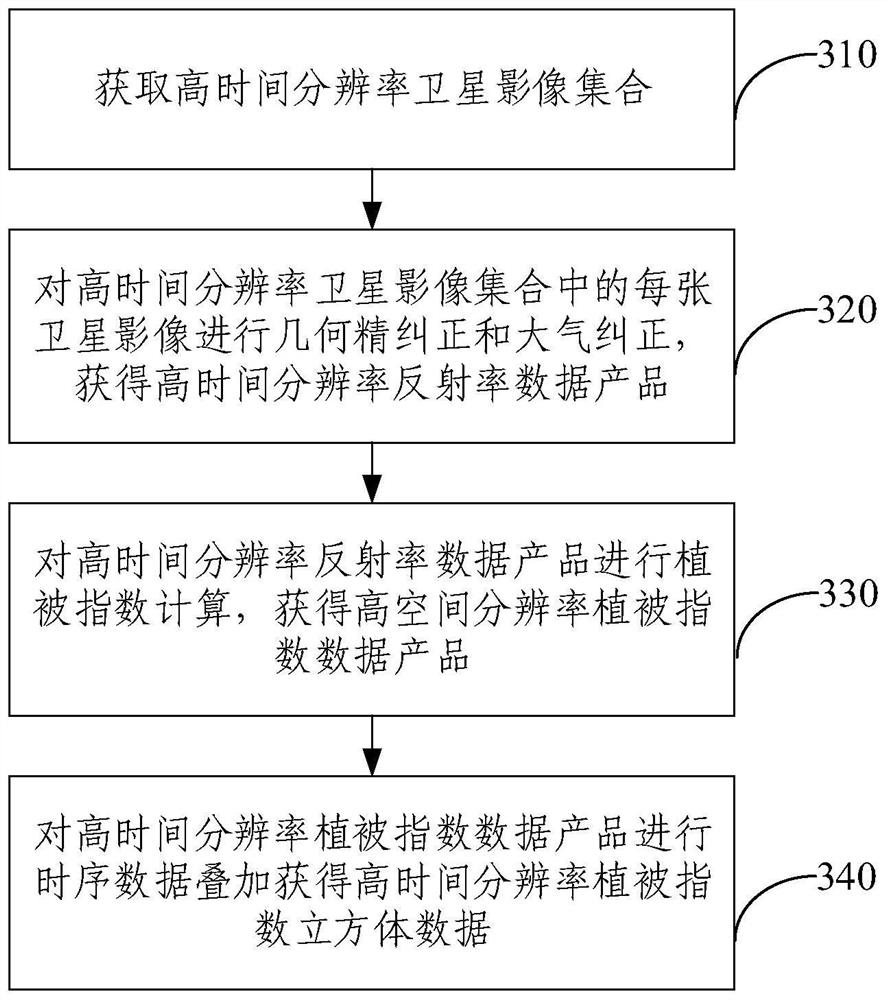

Remote sensing information sample selection method and system

PendingCN114220018AHigh precision and reliabilityImprove selection efficiencyScene recognitionReference sampleTemporal resolution

The invention provides a remote sensing information sample selection method and system. The method comprises the following steps: acquiring a high-spatial-resolution fine correction satellite image, high-temporal-resolution vegetation index cube data and a sampling area map; acquiring a plurality of image areas in the sampling area map, wherein the image areas comprise a first image area and a second image area; obtaining a reference sample point and an identification tag corresponding to the reference sample point; and classifying the second image area based on a classification model, the classification model being obtained after training based on the reference sample point and an identification tag corresponding to the reference sample point, and the identification tag being predetermined according to the sample type. According to the remote sensing information sample selection method and system provided by the invention, the precision and reliability of sample selection and the sample selection efficiency can be improved.

Owner:AEROSPACE INFORMATION RES INST CAS

Method and device for obtaining parasitic mismatch capacitance of mems accelerometer

ActiveCN108008152BHigh precision and reliabilitySolve the low measurement accuracyAcceleration measurementTesting/calibration of speed/acceleration/shock measurement devicesCapacitanceAccelerometer

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

A Method for Determining the Supply Channel and Intensity of Large Karst Springs

ActiveCN108020649BComprehensive index factorsImprove scienceRainfall/precipitation gaugesEarth material testingStream flowWater quality

The invention discloses a method for determining the large karst spring replenishment channel and intensity. The method comprises the following steps of 1, using a spring water position to judge the sensitivity of a rainfall station; 2, determining the main runoff zone depth and distribution thereof; 3, verifying the main runoff zone depth and distribution thereof determined in the step 2 througha temperature and conductivity tracer technique; 4, calculating the intensities of different runoff replenishment sources. By means of the method for determining the large karst spring replenishment channel and intensity, on the basis of the nature of a regional hydrogeological condition, through the four elements of the relevance of the rainfall station and the spring water position, the karst fissure rate, the temperature tracer and the water chemical mixing ratio, the outdoor large-scale karst spring replenishment channel is precisely identified, a scientific basis is provided for protection of large karst spring water flow and water quality, and decision-making support is provided for related government departments to manage groundwater resources.

Owner:UNIV OF JINAN

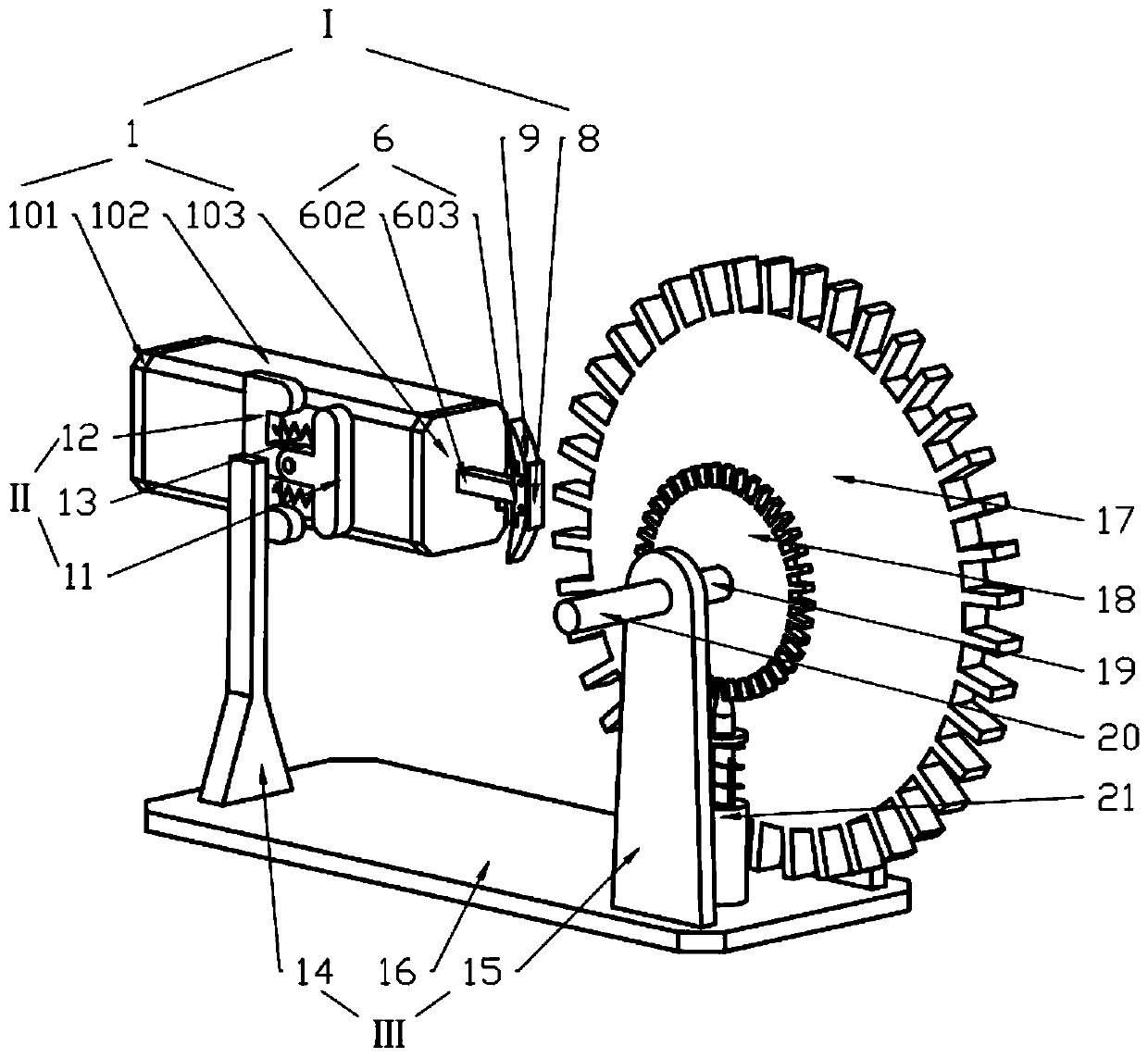

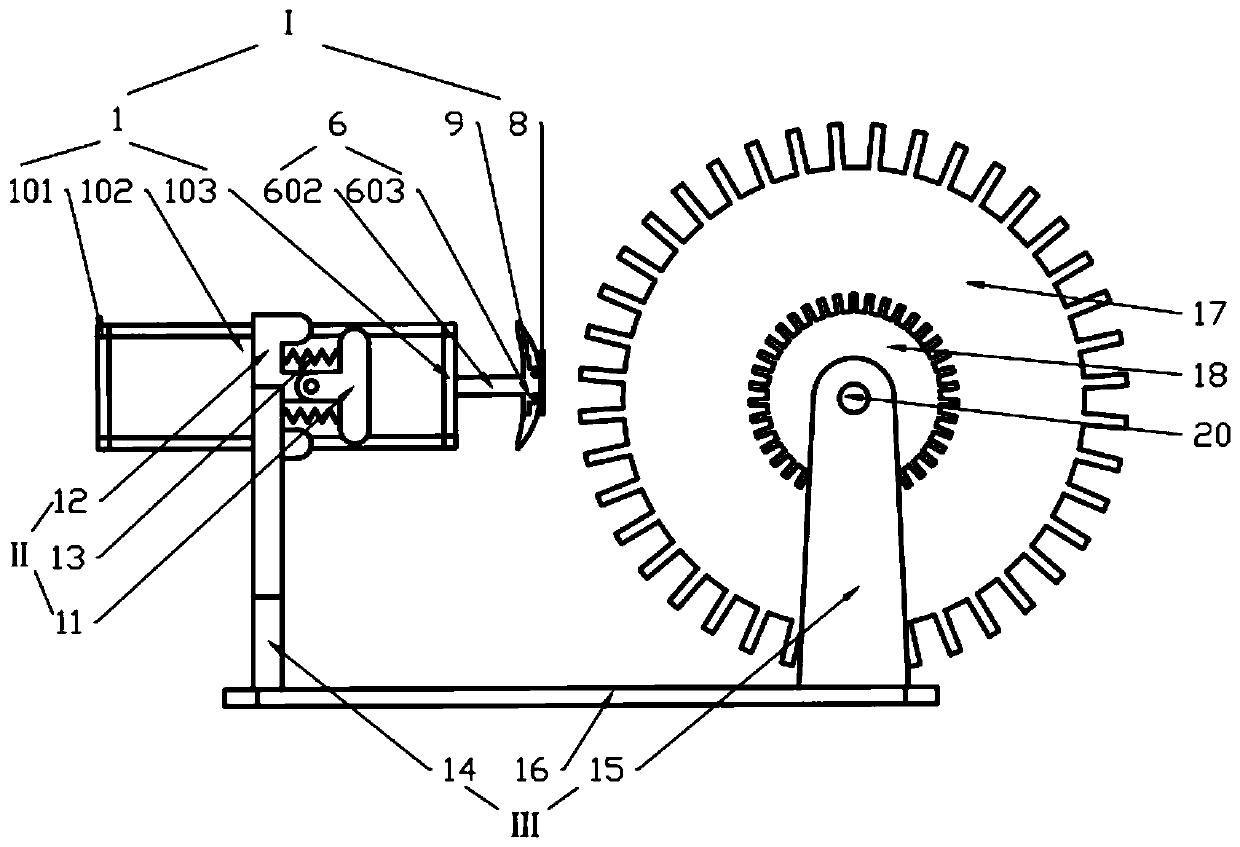

A rotating mechanism driven by shape memory alloy

ActiveCN108386329BRealize idling functionSolve travel problemsMachines/enginesMechanical power devicesShape-memory alloyAlloy

The invention discloses a shape memory alloy driven rotating mechanism which comprises a rotating mechanism fixed to a base III, an SMA oscillator II fixed to the base III for controlling the rotatingdirection of the rotating mechanism and an SMA driver I connected to the SMA oscillator II for pushing a fluted disc of the rotating mechanism to rotate, wherein the SMA fluted disc II comprises twooscillating racks; electrified SMA springs are separately connected between the oscillating racks; the SMA driver comprises an SMA elastic telescopic mechanism; the electrified SMA spring shrinks to drive the SMA oscillator II to oscillate while the SMA elastic telescopic mechanism of the electrified SMA driver I shrinks to push the fluted disc to rotate intermittently through a push rod claw on apush rod. The structure taking an SMA wire as a power source is very high in the ratio of output power and weight, small in driving voltage, small in size, simple in structure, noise-free, magnetism-free and convenient to control and is of very high popularization.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com