Combined wave-type recyclable prefabricated building retaining wall

A combined and prefabricated technology, applied in the direction of buildings, building types, fences, etc., can solve the problems of increased demolition and re-transportation costs, reduced stability, environmental pollution, etc., to improve building stability, reduce resistance, and upgrade structures The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

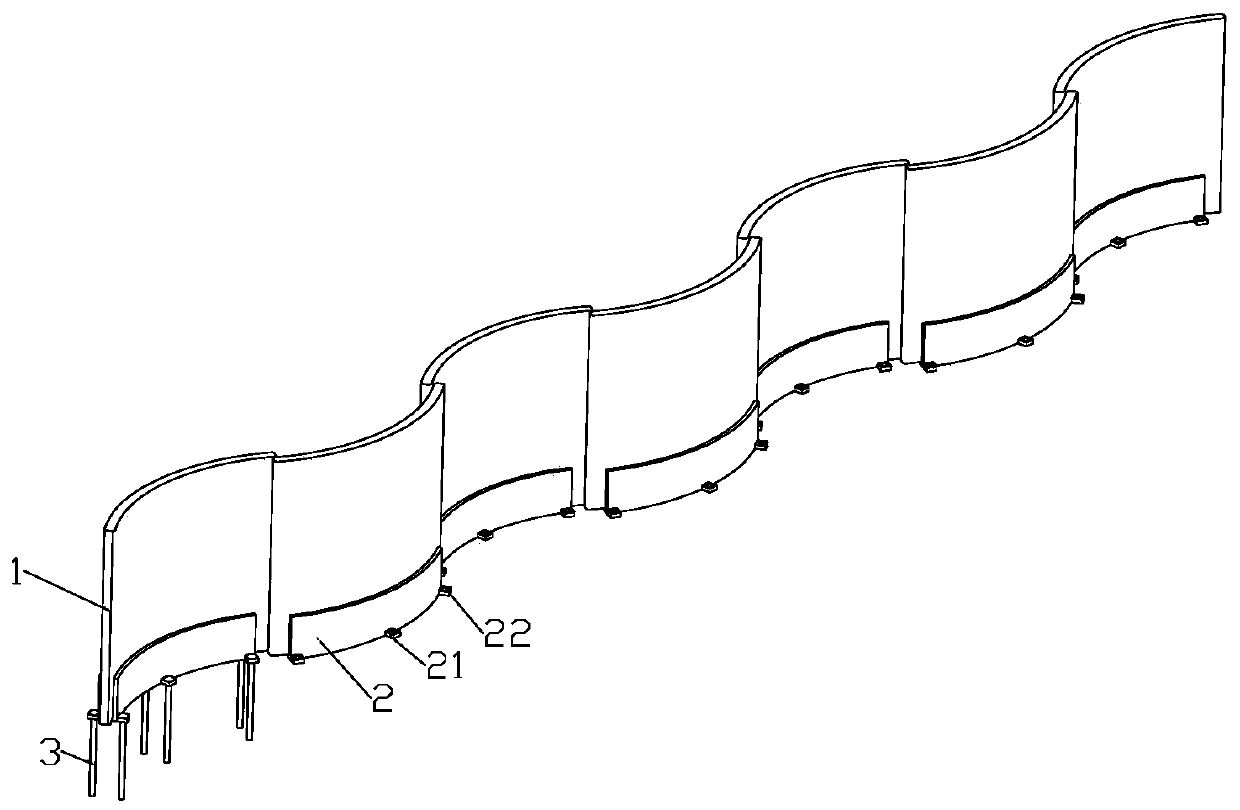

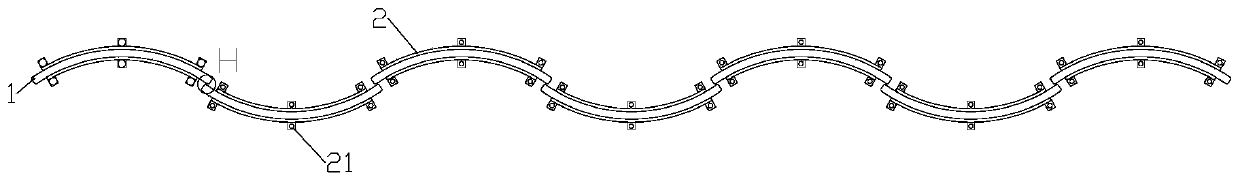

[0047] The combined wave-shaped recyclable assembly building enclosure wall is composed of several enclosure wall units installed vertically in sequence. There are gaps between the vertical ends of adjacent enclosure wall units for wind to pass through. figure 1 and 2 shown.

[0048] Specifically, the retaining wall unit includes a wall piece 1 and a base 2 , the wall piece 1 is installed vertically and its lower end is inserted into the base 2 .

[0049] Specifically, the wall sheet 1 is formed by integral pouring and maintenance of steel bars and concrete, and is in the shape of an arc sheet as a whole. The length, width, and height dimensions can be designed according to needs, and can be designed to be the same size or a combination of different sizes, or a combination of the two. ~10cm, preferably 4~6cm in thickness. In this implementation, the height of the wall piece 1 is 200cm, the arc length is 100cm, and the thickness is 5cm.

[0050] In this embodiment, in order ...

Embodiment 2

[0058] The difference between the combined wave-shaped recyclable assembled building enclosure wall and Embodiment 1 is that after the lower end of the wall sheet 1 is inserted into the base 2, several bolts 4 are used to penetrate the base 2 and the wall along the length direction of the base 2. Piece 1 is used for auxiliary fixation. In this implementation, 6 bolts 4 are used, which are divided into three groups for fixing, and each two bolts 3 are set in the upper and lower positions, as attached Figure 4 shown.

Embodiment 3

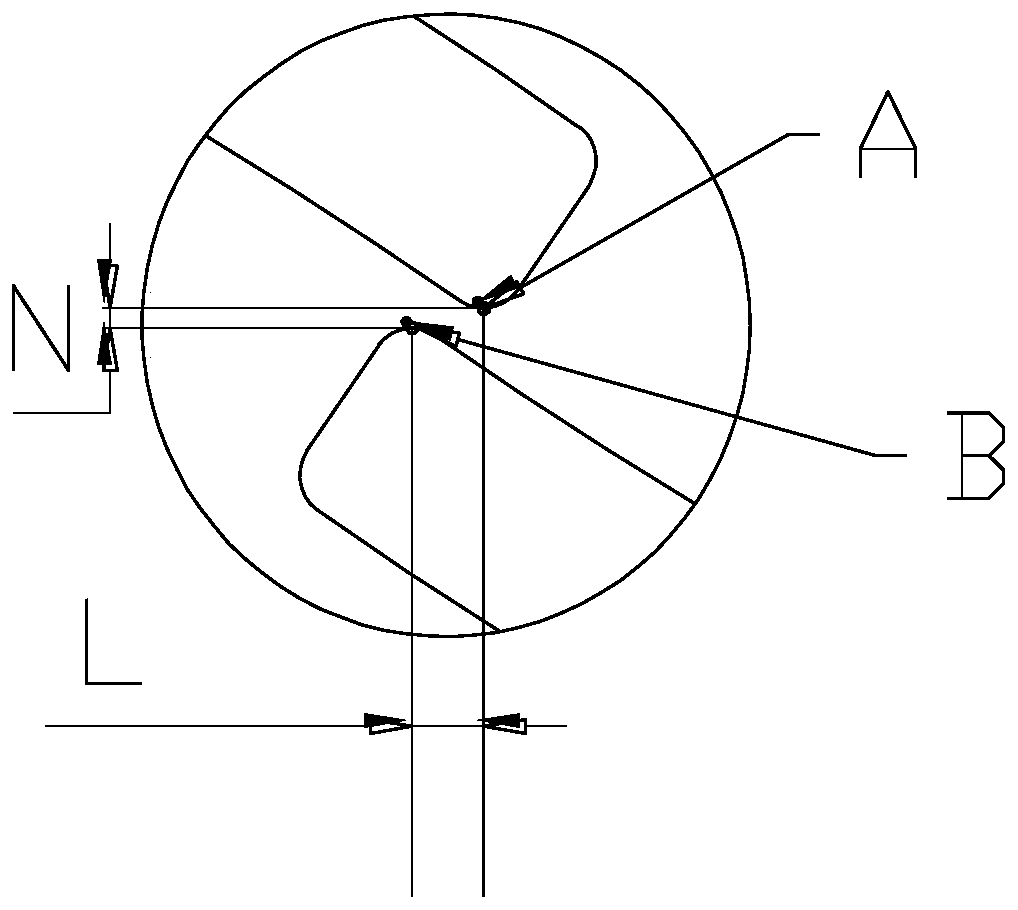

[0060] The difference between the combined wave-shaped recyclable assembled building enclosure wall and the embodiment 1 is that when the lower end of the wall piece 1 is inserted into the base 2, both sides of the wall piece 1 are located outside the two ends of the base 2 . Among the three adjacent wall pieces 1, one end of one wall piece 1 located in the middle extends to the inner side of the depression of the adjacent wall piece 1 and the adjacent ends are close to each other to form a gap overlapping structure. The extension distance L is along the arrangement direction of the enclosure , the distance between point A and point B is 0.5-3cm, the gap M is perpendicular to the layout direction of the enclosure, the distance between point A and point B is 0.5-2cm, and the other end extends to the outside of the depression of wall sheet 1 and is adjacent to The ends are close to each other to form a gap lap joint structure. The extension distance L is along the layout directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com