Thrust bearing for submersible and oil-submerged motor

A thrust bearing, submersible motor technology, applied in the direction of bearings, bearing components, shafts and bearings, can solve the problems of difficult to check the use, loss of mechanical efficiency, non-reusable and other problems, to reduce the loss of parts and mechanical efficiency. High, maintenance-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

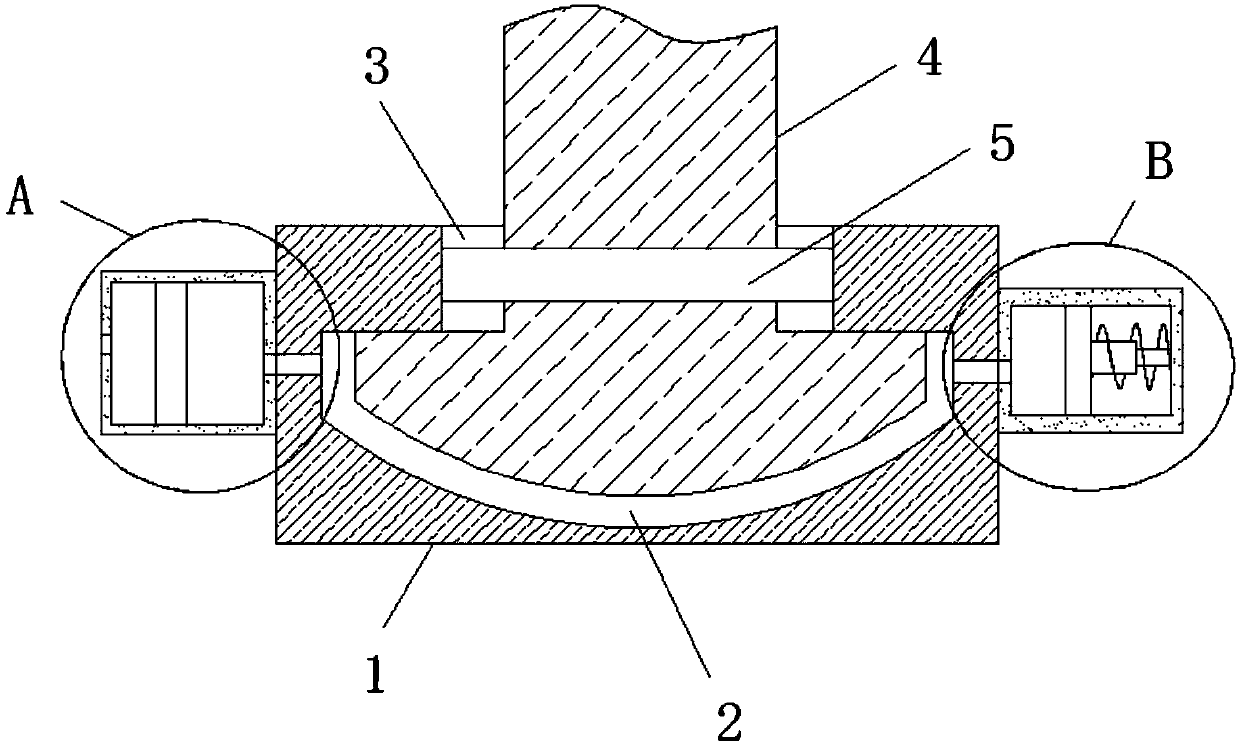

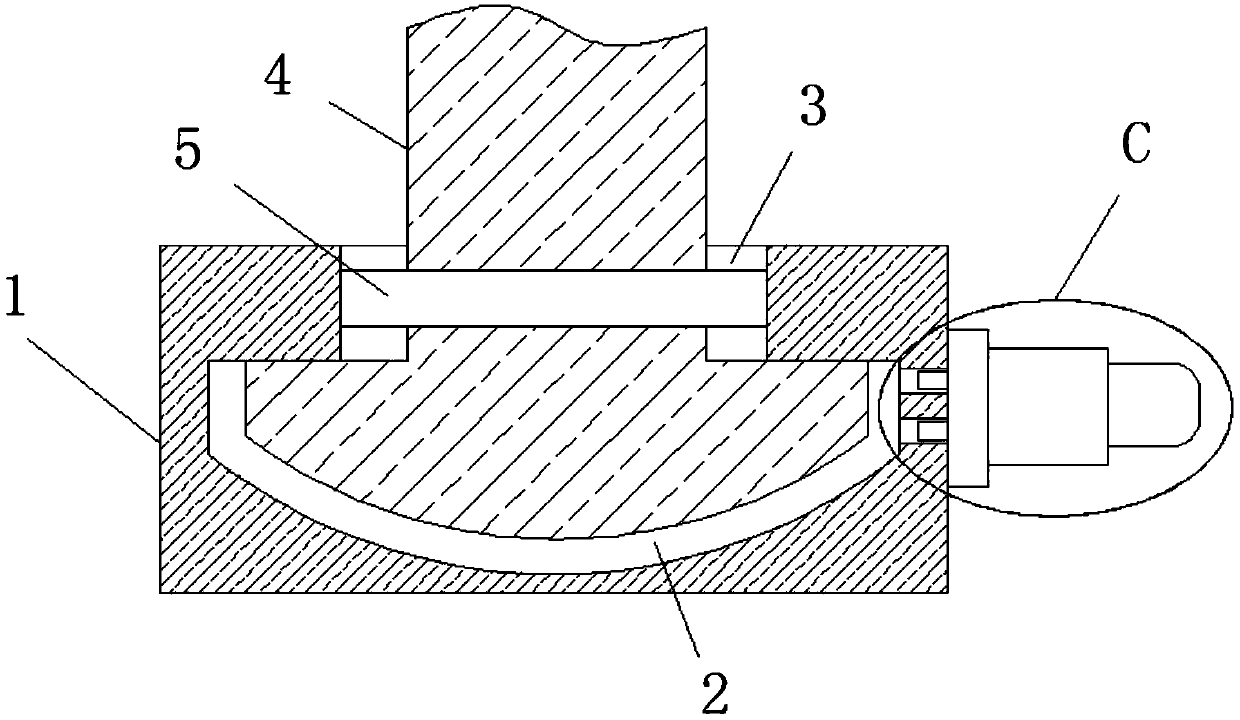

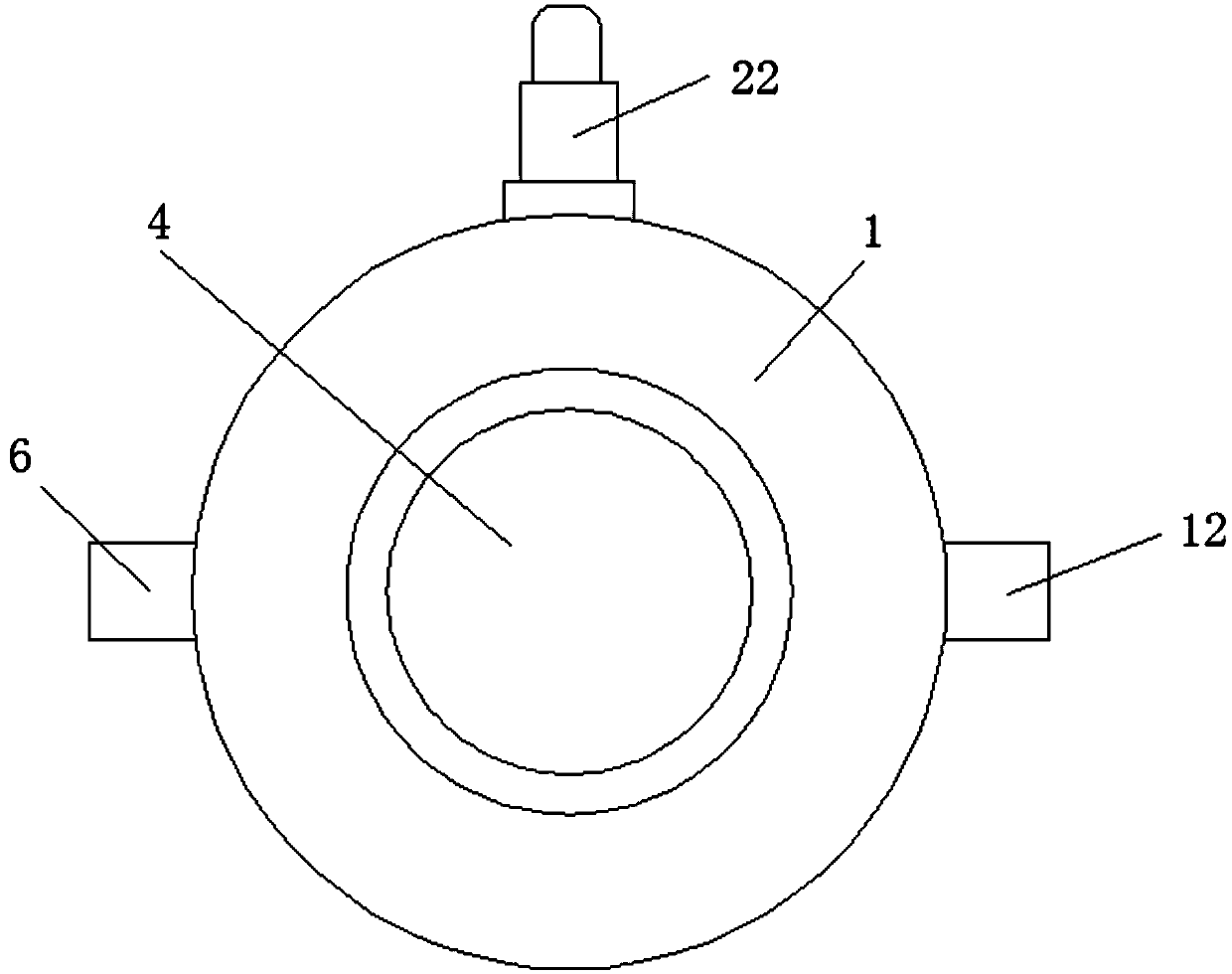

[0025] see Figure 1-6 , the present invention provides the following technical solutions: a thrust bearing for a submersible submersible motor, comprising an end cover 1, an oil chamber 2 is formed in a ring on the end cover 1, lubricating oil is housed in the oil chamber 2, and the top side of the oil chamber 2 A through hole 3 is opened on the inner wall, and a water floating shaft 4 is installed in the oil chamber 2. The top of the water floating shaft 4 penetrates the through hole 3 and extends to the outside of the through hole 3. During the use of the water pump, there is water pressure under water. The water pressure causes the pressure of the part of the first cavity 7 close to the air inlet 9 to increase, causing the first piston 8 to move closer to the end cover 1, so that the part of the first cavity 7 close to the end cover 1 is lubricated. The oil flows into the oil chamber 2, the lubricating oil pressure in the oil chamber 2 increases, and the lubricating oil en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com