Automatic magnesium chloride discharging and waste gas collecting device for titanium sponge production and production process thereof

A technology of waste gas collection and automatic discharge, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., to reduce the incidence, save power consumption, and reduce occupational diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

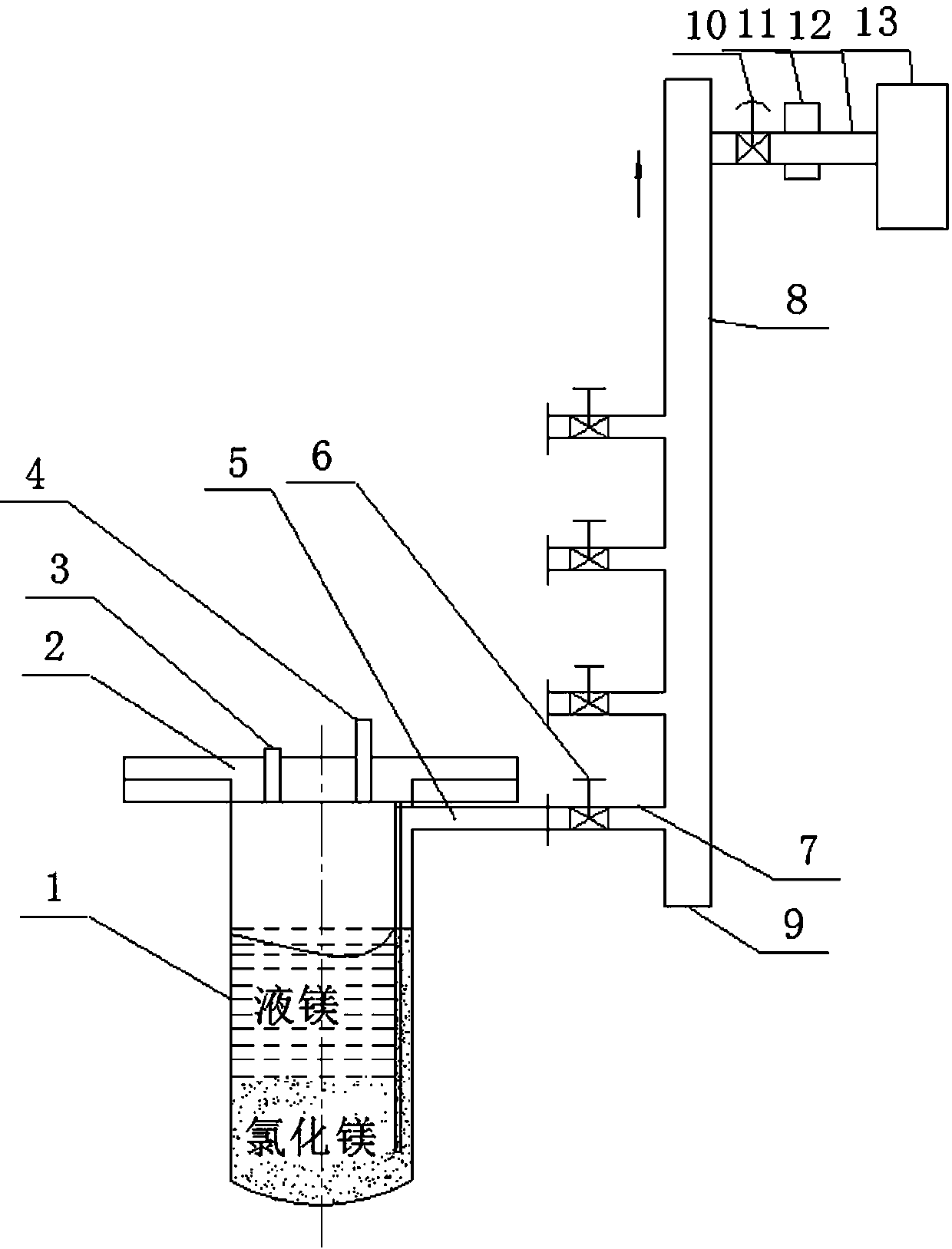

[0018] like figure 1 As shown, a magnesium chloride automatic discharge and waste gas collection device for sponge titanium production includes a reactor 1, a large cover 2, an argon filling tube 3, a pressure measuring tube 4, a magnesium chloride tube 5, a magnesium chloride delivery tube 8, a solenoid valve 10, and a water ring Vacuum pump 11, waste gas delivery pipe 12 and waste gas collection device 13; a waste gas delivery pipe 12 is provided on the side above the magnesium chloride delivery pipe 8, a solenoid valve 10 and a water ring vacuum pump 11 are arranged on the waste gas delivery pipe 12, and a waste gas delivery pipe 12 One end is provided with a waste gas collecting device 13;

[0019] The outlet end of the magnesium chloride pipe 5 on the reactor 1 links to each other with the magnesium chloride delivery pipe 8 by the magnesium chloride delivery branch pipe 7; Magnesium chloride flows into the electrolytic cell, and the flue gas is sucked away by the exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com