High temperature and high pressure resistant petroleum instrument

A technology of high temperature resistance and instrumentation, applied in the field of high temperature and high pressure petroleum instruments, can solve the problems of instrumentation burnout, shortening the service life, affecting the accuracy of instrument measurement, etc., achieving convenient use, improving high temperature resistance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

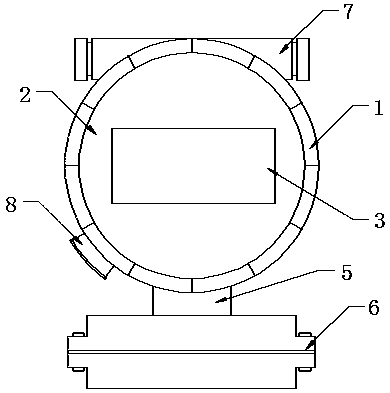

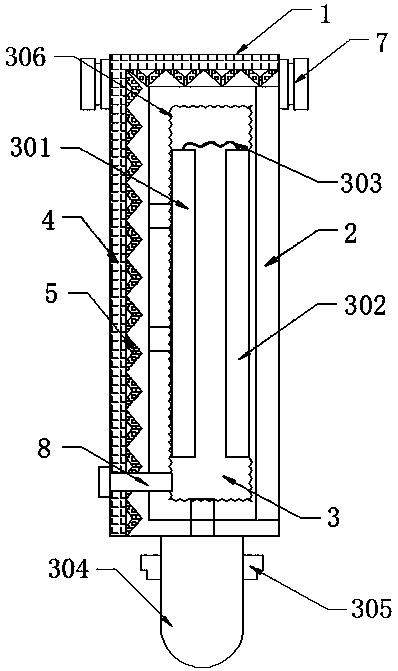

[0020] Example: such as Figure 1-2 As shown, the present invention provides a high-temperature and high-pressure resistant petroleum instrument, including an instrument body 3, and the instrument body 3 includes a detection probe 304 for detecting various indicators of petroleum, a display screen 302 for displaying various indicators, and a detection control center. The chip 301 and the detection chip 301 are respectively connected to the detection probe 304 and the display screen 302 through the cable 303. The detection probe 304 is sealed and connected to the flange 6 through the sealing cushion 305, and is connected to the oil pipeline through the flange 6; Toughened glass 2, tempered glass 2 is fixed on the front of the protective cover 1 by buckles; the back of the protective cover 1 is fixedly connected to the instrument body 3 through bolt mounting columns, and the outer peripheral surface of the instrument body 3 is composed of a number of heat dissipation fins 306, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com