Multi-connected single lithium battery pack packaging technology

A lithium battery pack and lithium battery technology, applied in battery pack components, secondary batteries, circuits, etc., can solve design difficulties, battery pack cycle life and safety requirements that cannot meet the mileage and safety requirements of electric vehicles, etc. problems, to achieve the effect of eliminating hidden dangers of fire accidents, improving reliability and satisfying safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following describes the manufacturing process of each component of the battery pack, the installation structure and the implementation principle in conjunction with the accompanying drawings.

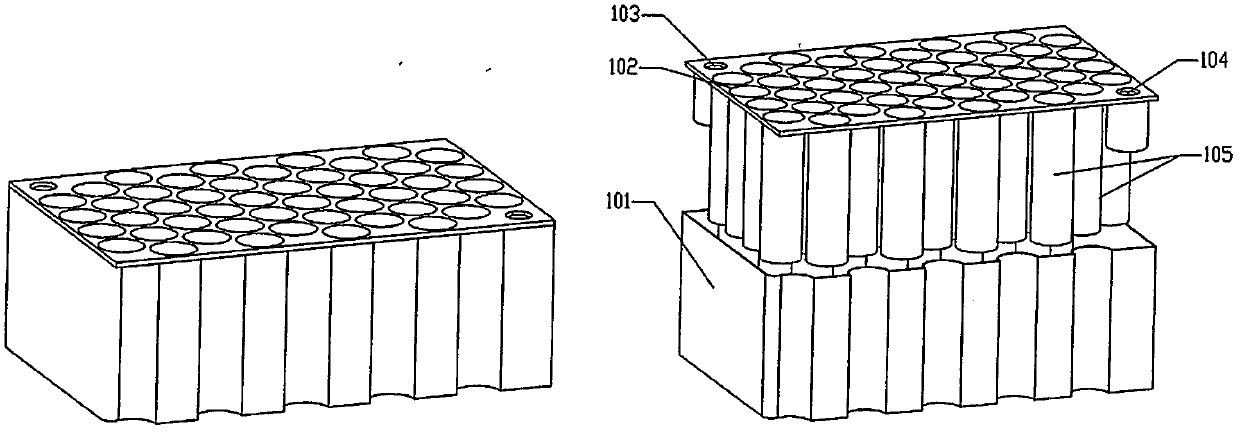

[0023] as attached figure 1 As shown, the double-layer casing of the multi-cell lithium battery is composed of an outer shell 101 and an inner shell 102 of the multi-cell lithium battery. The outer shell 101 and the inner shell 102 are socketed and assembled together. The shells are layered, and coolant is injected between the shells. The inner shell 102 is formed with a cooling liquid inlet hole 103 , a cooling liquid drain hole 104 and a cylindrical lithium battery casing 105 densely arranged in a honeycomb shape by a stamping process. The liquid inlet and discharge holes 103, 104 and the airtight double-layer casing can be connected with a liquid cooling circulation pipe to form a heat management system of the battery pack. The honeycomb-shaped cylindrical lithium batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com