Electric core, electrochemical device and manufacturing method thereof

An electrochemical and battery technology, applied in the manufacture of electrolyte batteries, electrochemical generators, secondary batteries, etc., can solve the problems of positive and negative contact short circuit, edge wrinkling and deformation of the diaphragm, etc., to avoid contact short circuit, Overall enhancement, not easy to loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

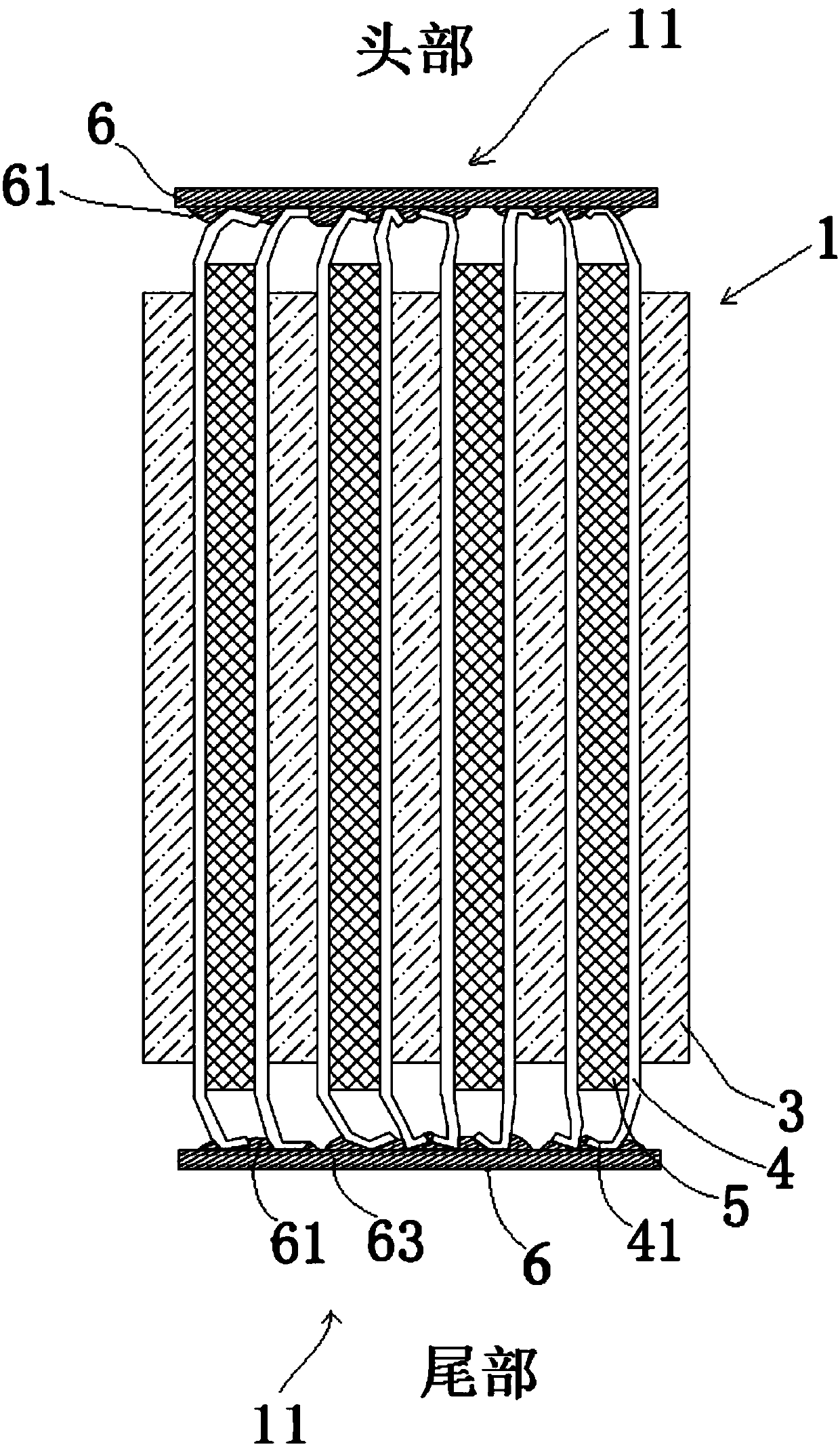

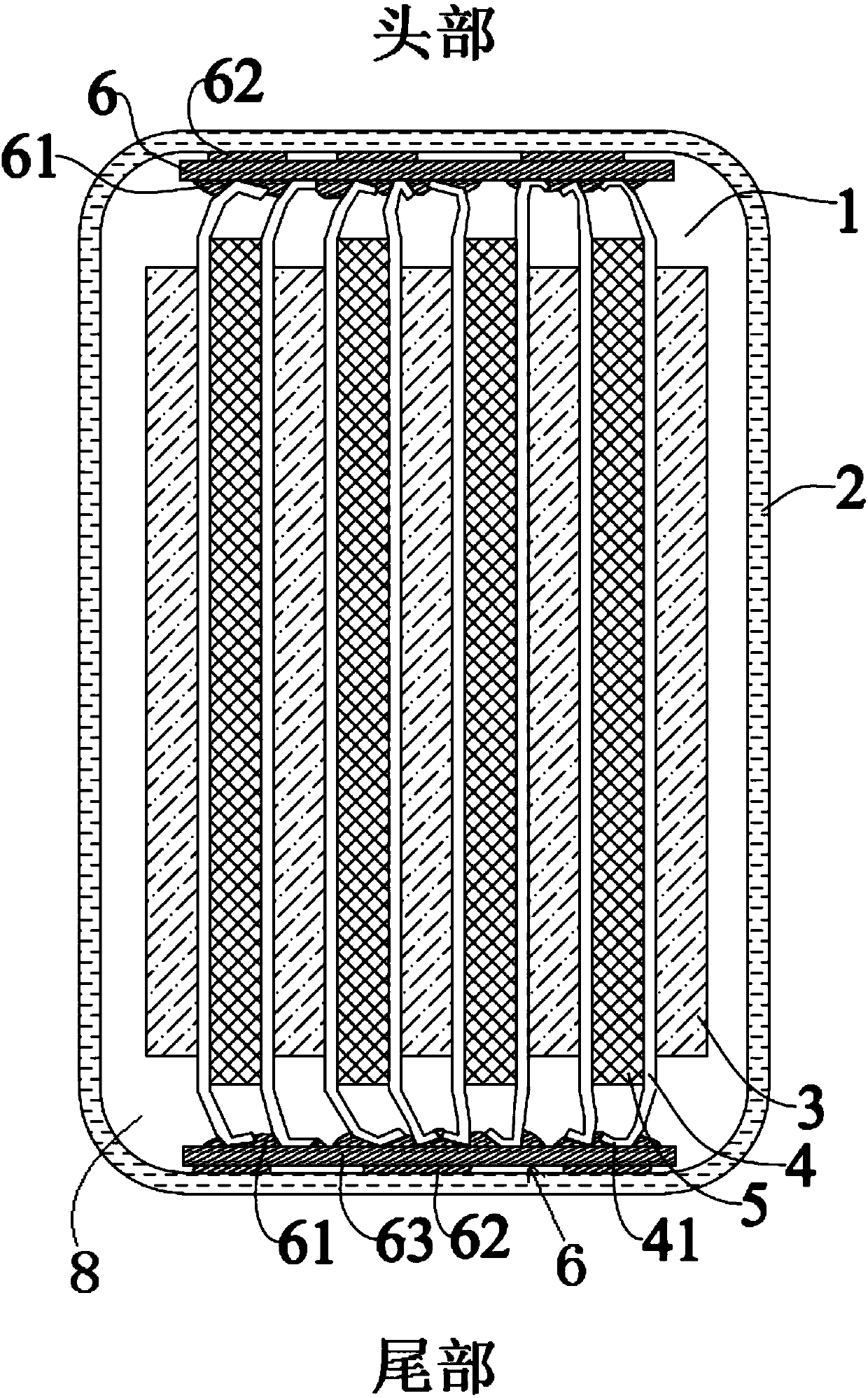

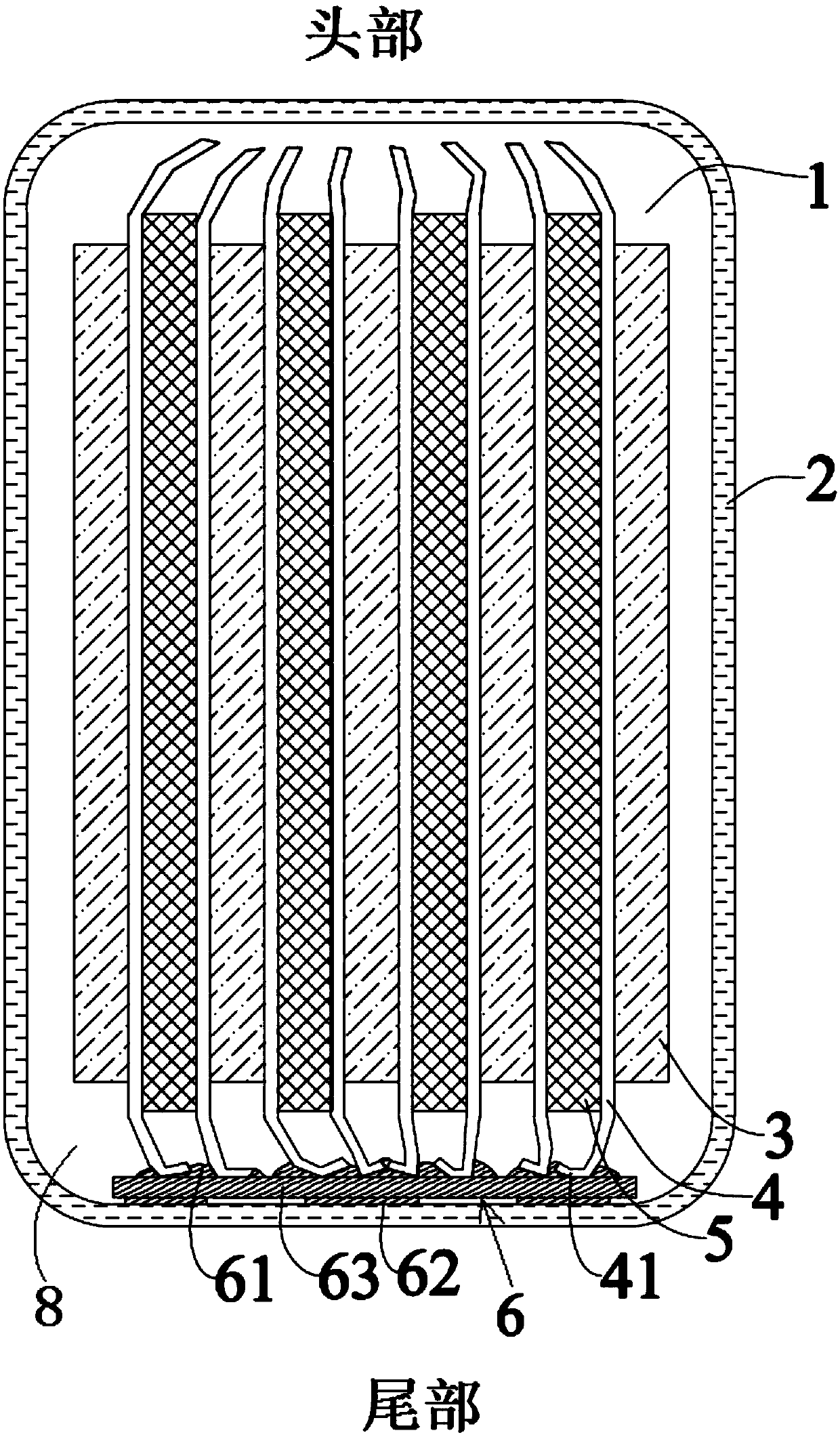

[0053] refer to figure 2 The electric core 1 is obtained by winding or stacking, the positive electrode sheets 5 and the negative electrode sheets 3 are alternately arranged, and both ends of the positive electrode sheets are 0.2-1mm beyond the negative electrode sheets. A separator 4 made of polyolefin material is included between the two pole pieces, and both ends of the membrane 4 protrude from the positive pole piece by 0.2-2 mm. The adhesive film 6 is cut into long and thin strips, the length is close to but not exceeding the width of the battery cell 1 , and the width is close to but not exceeding the thickness of the battery cell 1 . Adhesive film 6 is pasted on both ends of the battery cell 1 by manual operation or automatic equipment, and is in direct contact with the edge of the diaphragm exposed at the end. The position of the adhesive film 6 needs to be controlled more accurately, and try not to exceed the area range of the cell end face. Before pasting the adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com