Surface emitting laser and surface emitting laser array

A technology of surface-emitting lasers and doped layers, which is applied in the laser field and can solve problems such as the difficulty in growing DBR structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

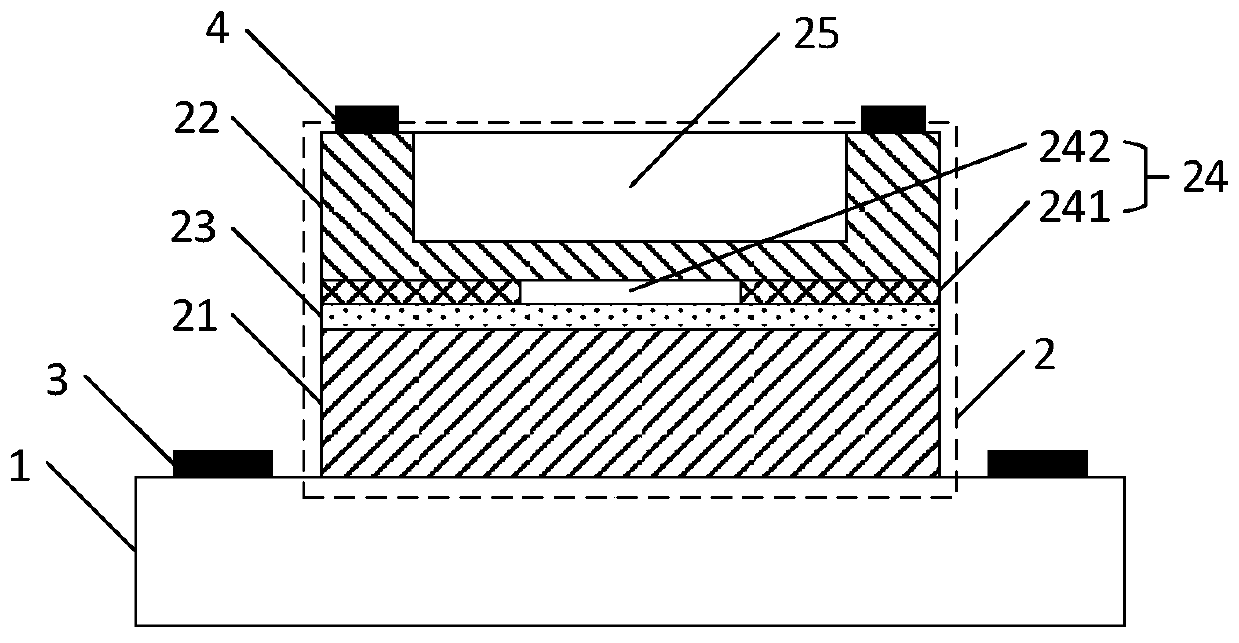

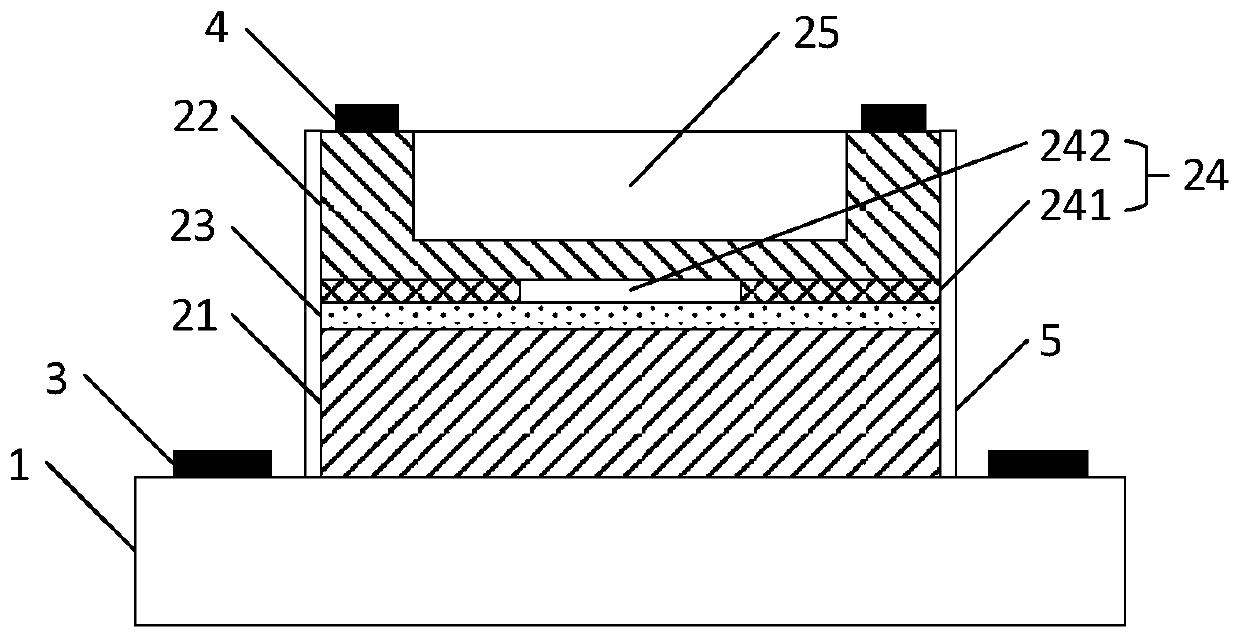

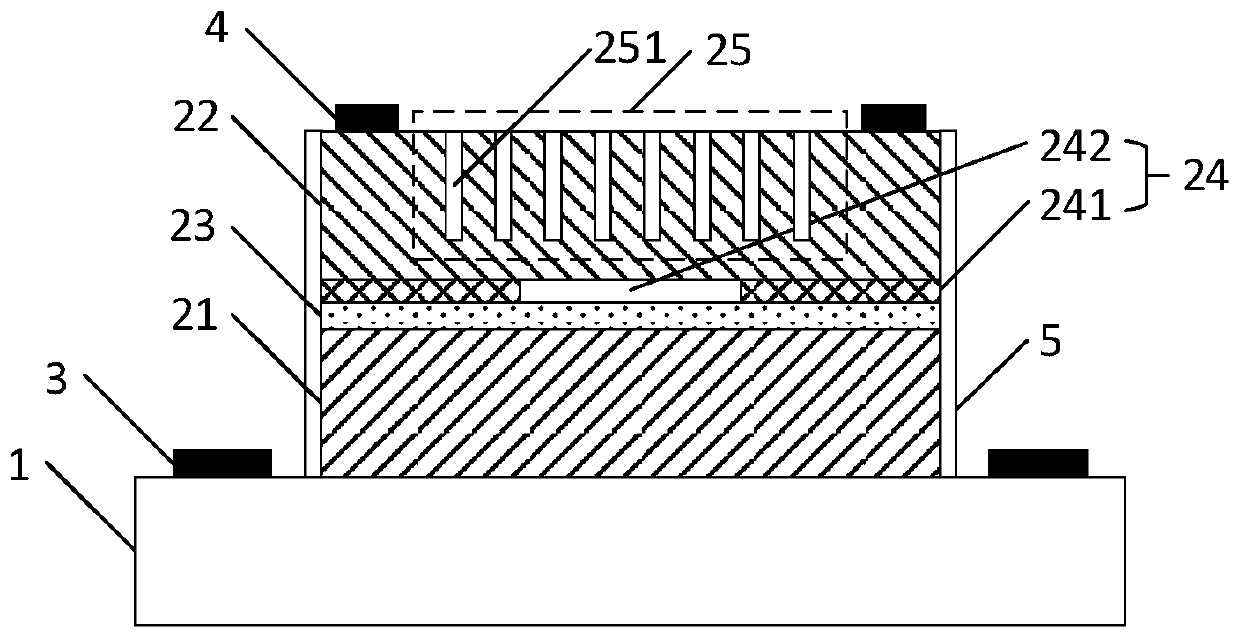

[0029] The core of the present invention is to provide a surface emitting laser. In the prior art, usually the entire active layer is used to emit laser light, and the carrier injection area at this time is the entire surface area of the active layer, resulting in an excessively large carrier injection area. When the same injection current is applied to the outside world, the carrier density is lower, resulting in a larger threshold current required for the active layer to excite photons.

[0030] However, a surface-emitting laser provided by the present invention includes a substrate and a functional layer of a sandwich structure, and the functional layer includes a first doped layer, an active layer, a confinement layer and a second doped layer, wherein the active layer And the confinement layer is located between the first doped layer and the second doped layer. The first doped layer and the second doped layer are used to transport carriers to the active layer, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com