Method for partially regenerating catalyst of methanol to olefin and method of methanol to olefin

A technology for producing olefins from methanol and regenerating catalysts, which is applied in molecular sieve catalysts, chemical instruments and methods, catalyst regeneration/reactivation, etc., can solve problems such as unfavorable environmental protection, reduce the utilization rate of carbon atoms of methanol, and achieve the effect of improving the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

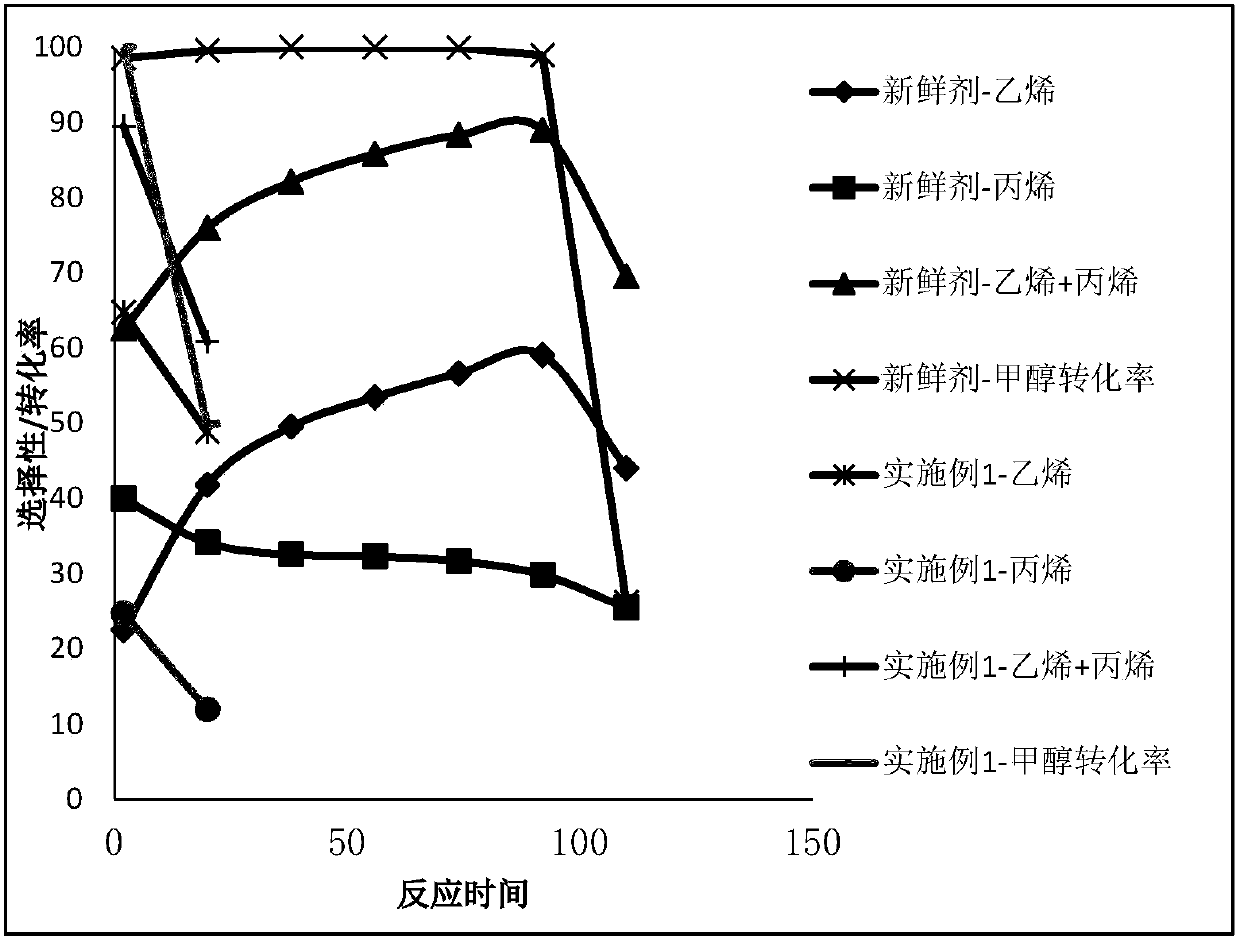

Embodiment 1

[0053] Pack 4g of commercially used methanol-to-olefins catalyst SAPO-34 into a fixed fluidized bed reactor to carry out the reaction of methanol to olefins. The reaction raw material is an aqueous methanol solution with a concentration of 80wt%, the reaction temperature is 490°C, and the pressure is 0.1MPa. The speed is 2.1h -1 . After the catalyst was deactivated, the amount of carbon deposited on the deactivated catalyst was measured and found to be 9.18%.

[0054] After the catalyst is deactivated, nitrogen gas with a flow rate of 100mL / min is introduced into the reactor for purging, and the temperature of the reactor heating furnace is set; speed is 6h -1 , constant temperature for 15 minutes. After steam gasification, take a small amount of catalyst and measure the amount of carbon deposition. The amount of carbon deposition is 5.95%. After the temperature program is completed, the regeneration is stopped, and the regeneration gas is switched to nitrogen gas. When the...

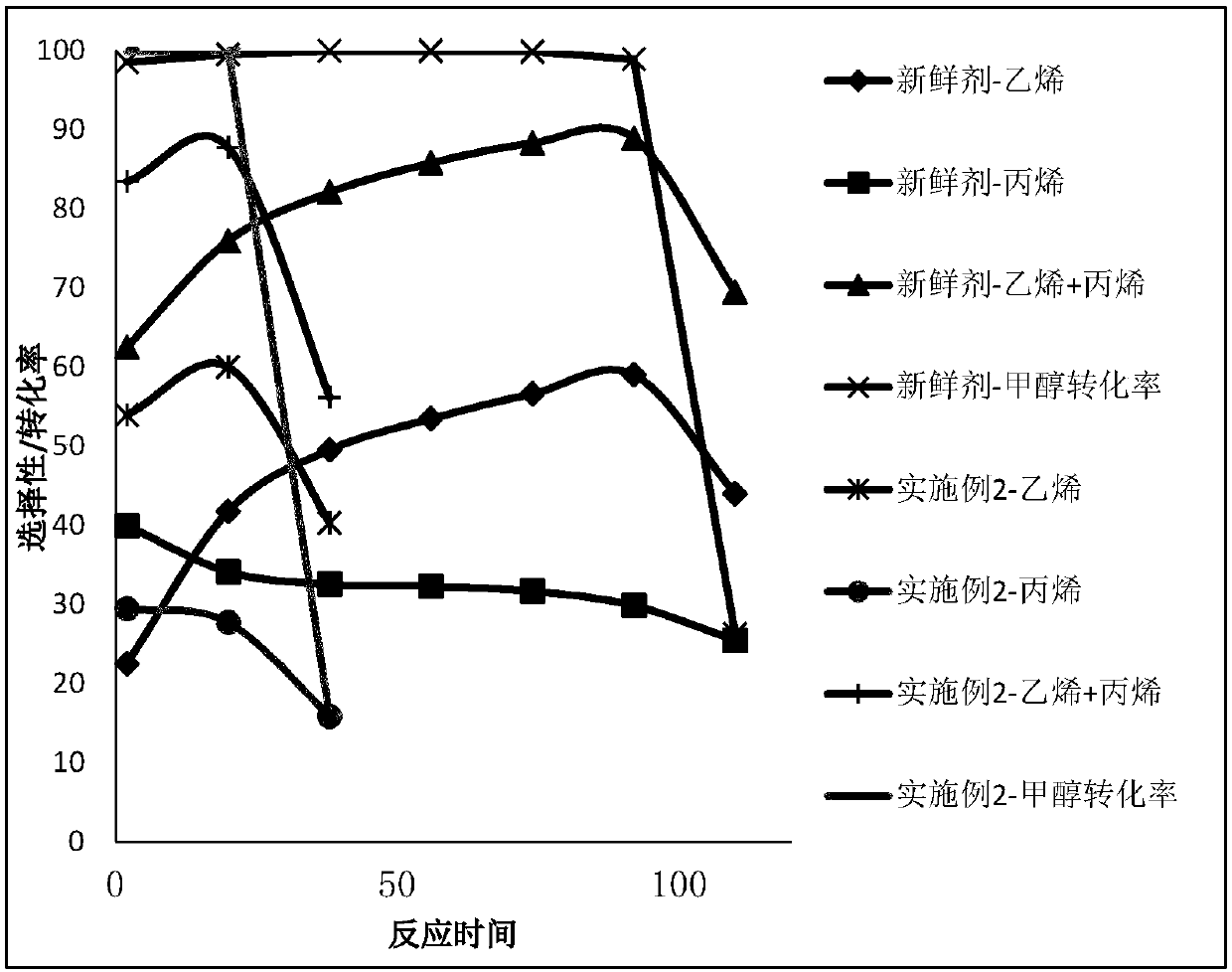

Embodiment 2

[0056] Pack 4g of commercially used methanol-to-olefins catalyst SAPO-34 into a fixed fluidized bed reactor to carry out the reaction of methanol to olefins. The reaction raw material is an aqueous methanol solution with a concentration of 80wt%, the reaction temperature is 490°C, and the pressure is 0.1MPa. The speed is 2.1h -1 . After the catalyst was deactivated, the amount of carbon deposited on the deactivated catalyst was measured and found to be 11.88%.

[0057] After the catalyst is deactivated, nitrogen gas with a flow rate of 100mL / min is introduced into the reactor for purging, and the temperature of the reactor heating furnace is set; speed is 6h -1 , constant temperature for 30min. After the steam gasification is completed, take a small amount of catalyst and measure the amount of carbon deposition. The amount of carbon deposition is 4.82%. After the temperature program is completed, the regeneration is stopped, and the regeneration gas is switched to nitrogen ...

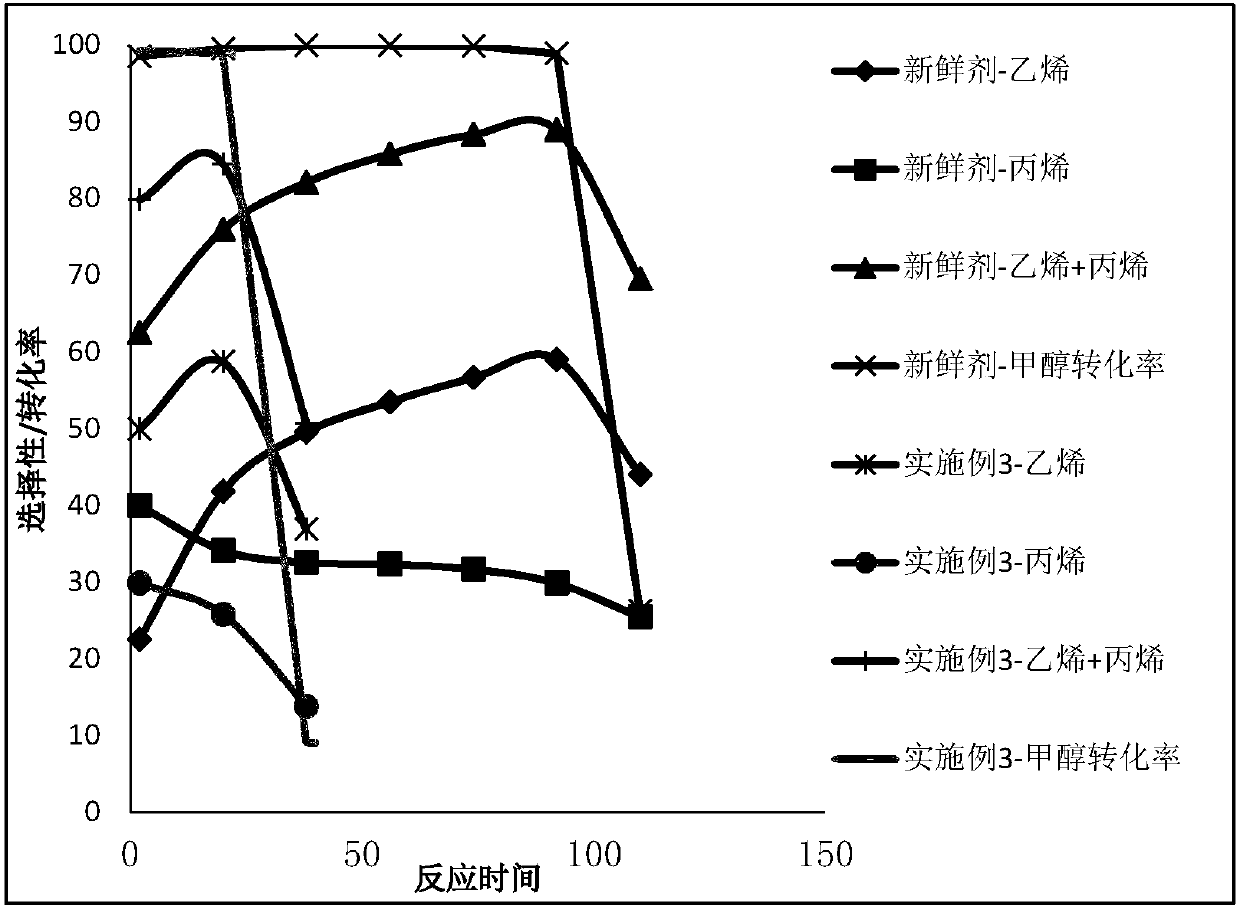

Embodiment 3

[0059] Pack 4g of commercially used methanol-to-olefins catalyst SAPO-34 into a fixed fluidized bed reactor to carry out the reaction of methanol to olefins. The reaction raw material is an aqueous methanol solution with a concentration of 80wt%, the reaction temperature is 490°C, and the pressure is 0.1MPa. The speed is 2.1h -1 . After the catalyst is deactivated, the amount of carbon deposited on the deactivated catalyst is measured, which is 7.08%

[0060] After the catalyst is deactivated, nitrogen gas with a flow rate of 100mL / min is introduced into the reactor for purging, and the temperature of the reactor heating furnace is set; speed is 6h -1 , constant temperature for 10 minutes. After the steam gasification is completed, take a small amount of catalyst and measure the amount of carbon deposition. The amount of carbon deposition is 5.16%. After the temperature program is completed, the regeneration is stopped, and the regeneration gas is switched to nitrogen gas. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com