Heat shield for stove and stove using heat shield for stove

A technology for heat shields and stoves, applied in the field of stoves, can solve the problems of sliding pans, overflowing of cooking soup, swinging of combustion flames of gas stoves, flameout of gas stoves, etc., achieving ingenious structure, protecting flames and preventing radiation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

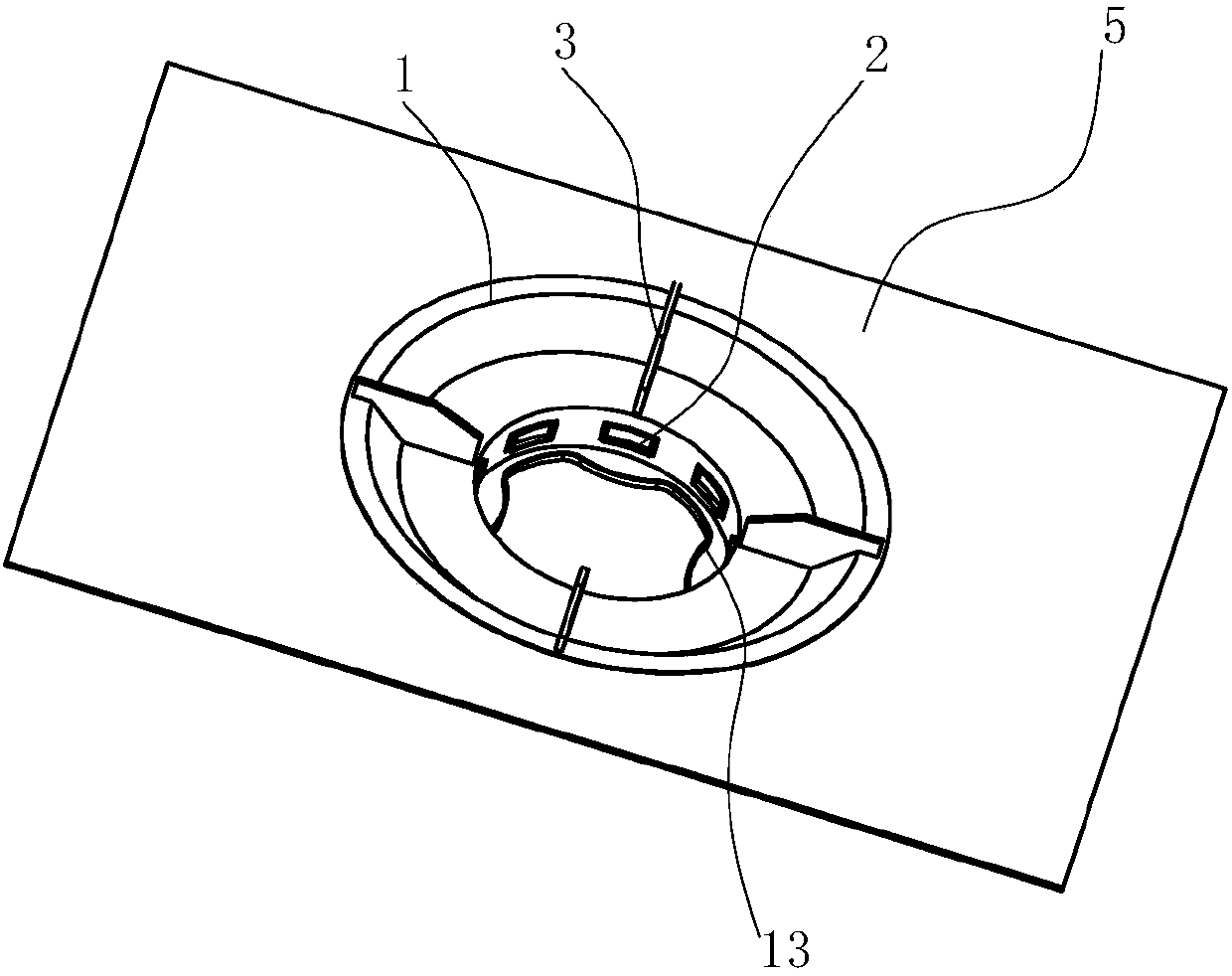

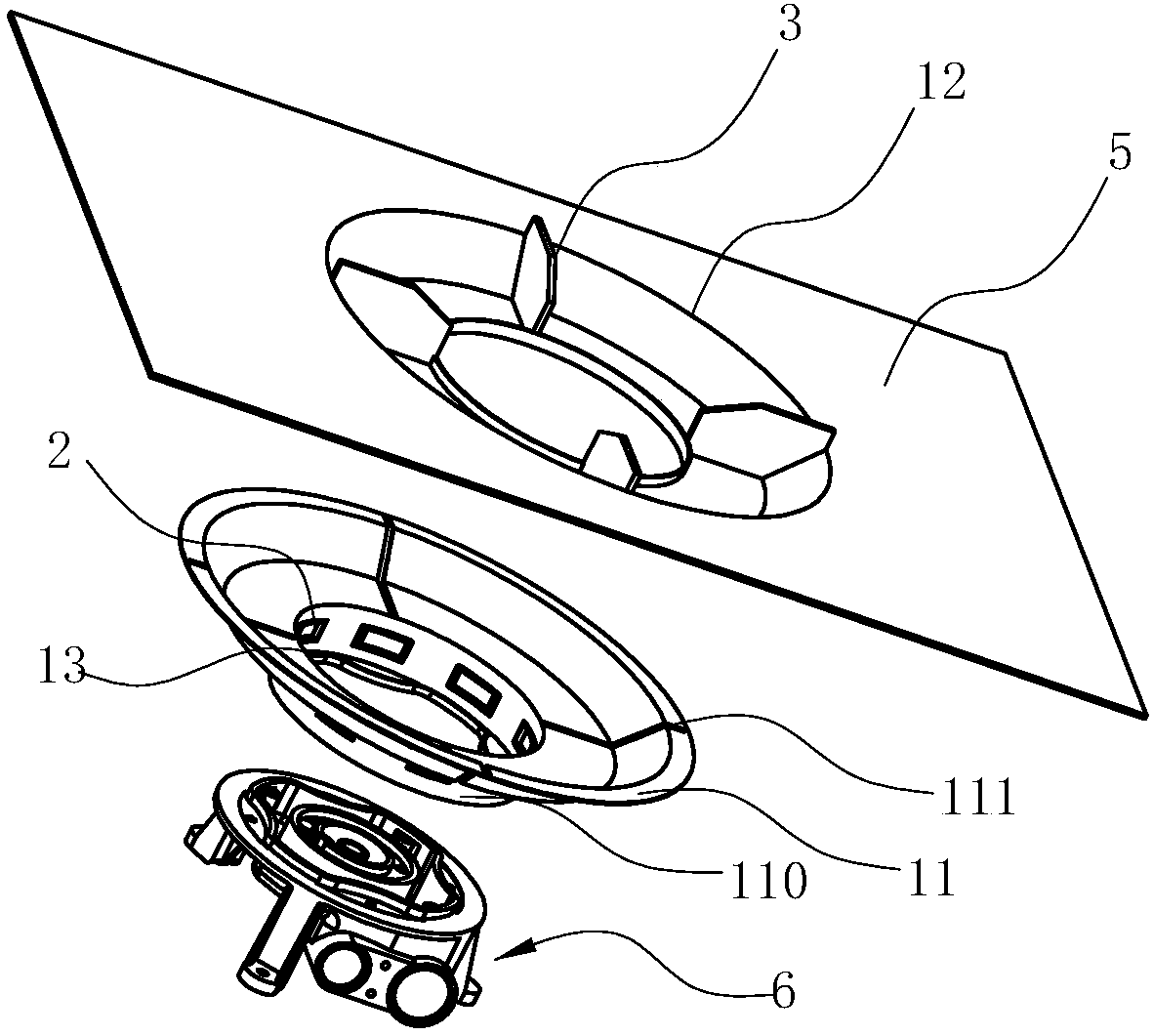

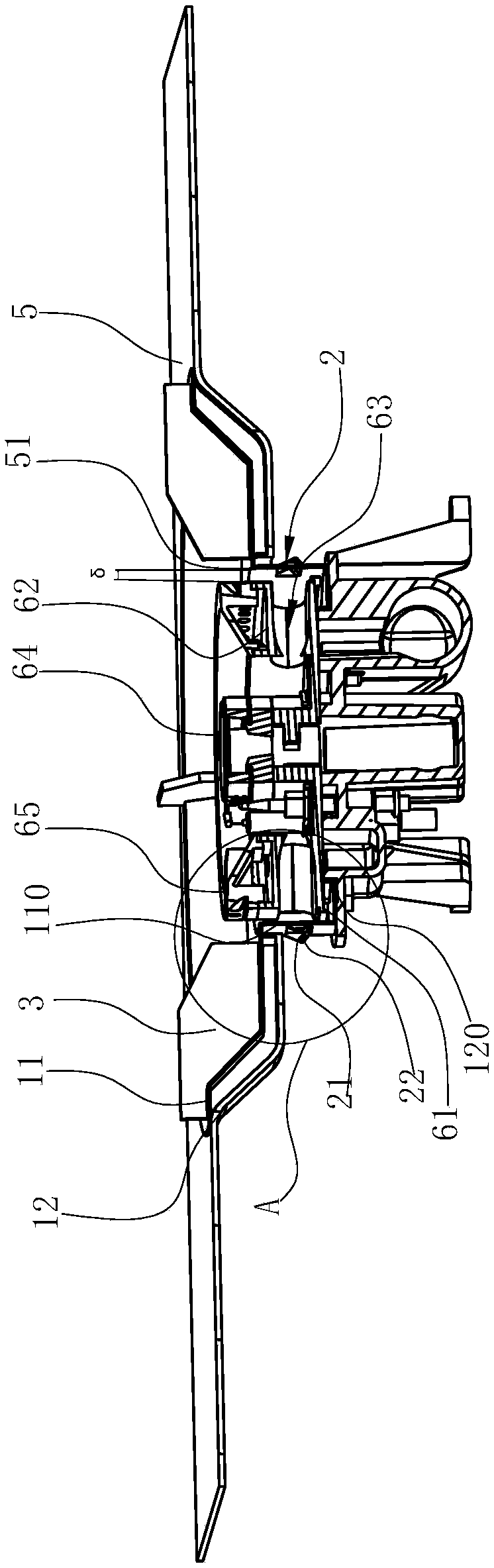

[0024] Such as Figure 1~4 As shown, the stove heat shield in this embodiment includes an annular cover body 1, the cover body 1 is a double-layer structure and has a cavity 4, the cavity 4 is filled with air, and the excellent thermal insulation properties of air are used to Reduce the heat transfer from the cover body 1 to the outside. The annular wall 110 of the central through hole of the cover body 1 protrudes downwards and has an upwardly protruding edge 120 extending horizontally to form a circle of an annular liquid collecting pan 13 for collecting spillage. In order to make the air outside the cover 1 flow into the area surrounded by the annular wall 110 of the cover 1 through the secondary air inlet hole 2, the annular wall 110 of the central through hole is provided with secondary air inlet holes 2 at intervals in the circumferential direction, wherein , in order to prevent the overflow from flowing out of the cover body 1, the secondary air inlet 2 is formed by pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com