Floor radiation air conditioner system, air conditioner floor assembly, heat preservation module and pavement method

A thermal insulation module and floor technology, which is applied in the field of floor radiant air-conditioning systems and air-conditioning floor components, and thermal insulation modules, which can solve the problems that the good use status of the floor heating system cannot be effectively ensured, it is difficult to find the correct leak point, and the operation convenience is low, etc. problems, to achieve the effect of reducing the ineffective loss of heat, improving the efficiency of laying operations, and improving the efficiency of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

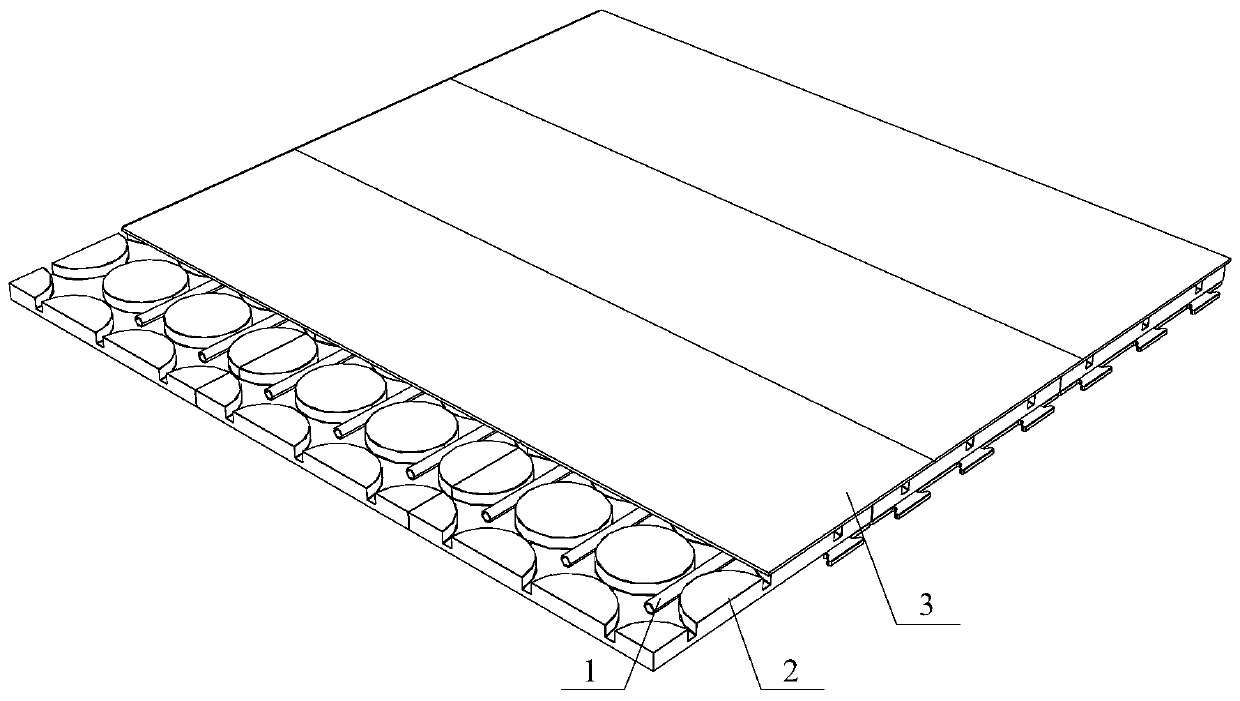

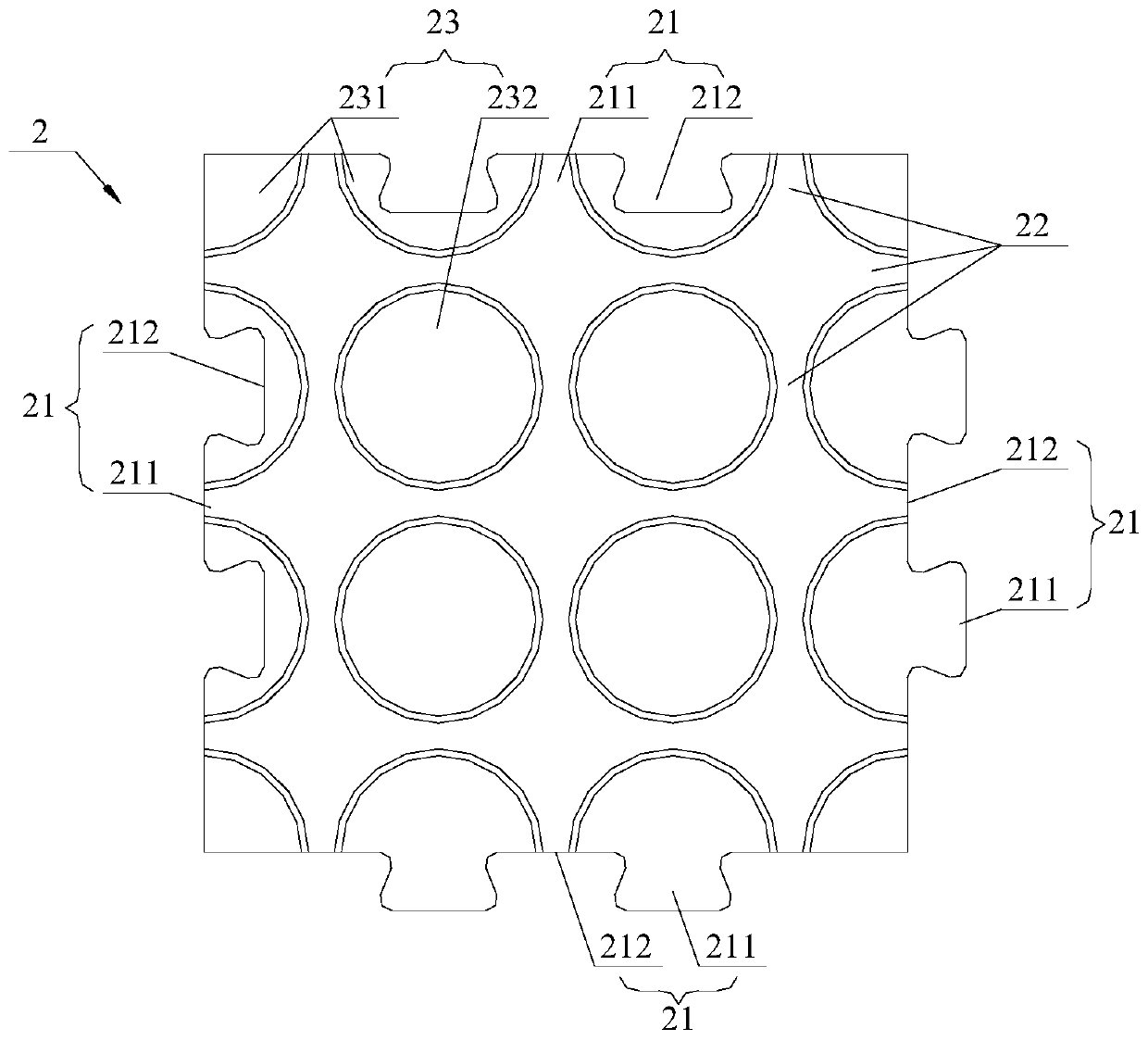

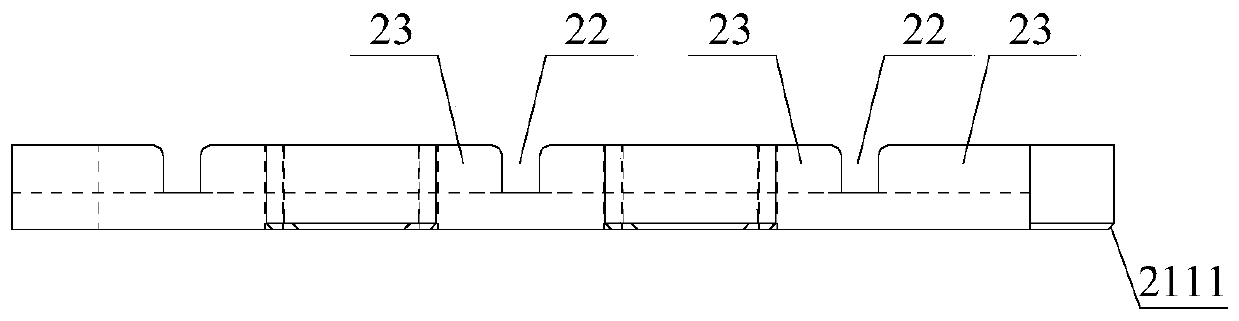

[0054] Please also see Figure 2-4 ,in, figure 2 is the front view of the insulation module, Figure 4 is the bottom view of the insulation module, Figure 5 It is the rear view of the insulation module.

[0055] In this solution, the outer periphery of the thermal insulation module 2 is provided with an assembly interface portion 21, so that the adjacent thermal insulation modules 2 can be assembled sequentially according to the laying space; here, the assembly interface portion 21 includes an outer convex insertion structure 211 and an inner concave accommodation structure. 212, the shape and size of the two are consistent, so that they can be assembled.

[0056] As shown in the figure, the protruding insertion structure 211 on one side of the thermal insulation module 2 is matched with the concave accommodation structure 212 on the opposite side. The accommodating structure 212 and the protruding insertion structure 211 are fitted together, so that they can be arranged...

Embodiment 2

[0069] See Figure 7 and Figure 8 ,in, Figure 7 A schematic diagram of the air-conditioning floor assembly described in Embodiment 2 is shown, Figure 8 for Figure 7 A schematic diagram of the typical assembly relationship of the thermal insulation module shown in .

[0070] The core idea of this embodiment is the same as that of Embodiment 1. The difference is that the heat preservation module 2 provided by this solution is not provided with an assembly interface. mark to indicate.

[0071] combine Figure 8 As shown, the heat preservation module 2 is provided with pipe slots 22, and is configured as follows: after the heat preservation modules 2 are assembled sequentially according to the laying space, the pipe slots 22 on the adjacent heat preservation modules 2 can be connected to form the heat pipe installation path of the air-conditioning floor assembly; And after the assembly is completed, the gap between adjacent insulation modules 2 is 0.05 mm to 0.3 mm, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com