Indexable and variable-cutting-width milling cutter for blisk high-efficiency machining

An integral blisk and high-efficiency technology, applied in milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of fixed cutting width, increased chip space, and low cutting efficiency, and achieve reduced machining accuracy and simple positioning Accurate, the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

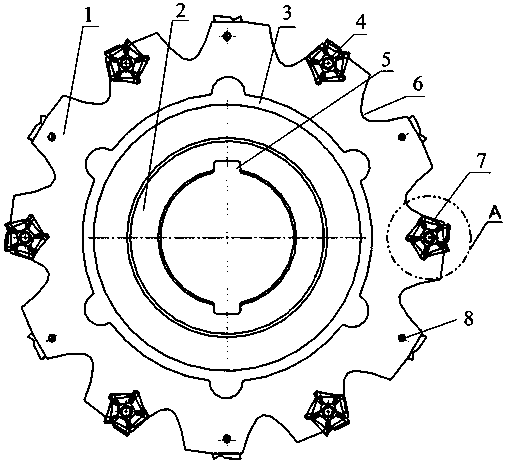

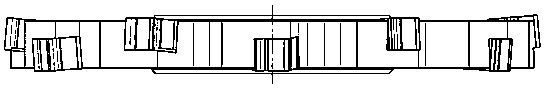

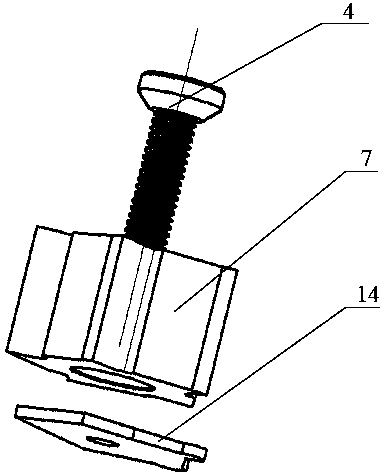

[0023] Specific implementation mode one: combine Figure 1-Figure 7 Description, an indexable variable cutting width milling cutter for efficient machining of integral blisks, including a cutter body 1, a central bush 2, a cutter body cooling groove 3, a keyway 5 and a plurality of blades 7, the outer peripheral surface of the cutter body There are a plurality of chip removal grooves 6, threaded holes 8, positioning grooves 9, knife grooves 10, gaskets 14 evenly distributed on the top, the blade 7 is provided with chip removal grooves 13 and a fastening screw hole 11 is provided in the center, and the tip of the blade is provided with Convex 12.

specific Embodiment approach 2

[0024] Specific implementation mode two: as figure 1 and image 3 As shown, the cutter body 1 needs to have higher rigidity and shock resistance, so that it can meet the working conditions of large cutting amount, and the material of the cutter body is determined to be 42CrMo; the center of the cutter body 1 is designed with a central bushing 2, The key grooves 5 exist in pairs, and the circumferential positioning through the key grooves 5 can effectively avoid damage to the tool due to uneven force and excessive torque during machining.

specific Embodiment approach 3

[0025] Specific implementation mode three: as image 3 and Figure 5 As shown, the spacer 14 is a variable cutting width structure. When the blade 7 is offset by 1 mm, the variable cutting width on one side increases by 1 mm, thereby realizing the variable cutting width of the cutter. The variable cutting width on one side is 1- 2mm, can realize the processing of groove width within the range of 18mm-22mm, and the gasket 14 is provided with internal thread, high installation accuracy, simple and flexible operation, and good economy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com