KEE three-level biochemical filter

A level filter and filter technology, applied in the field of KEE three-level biochemical filter, can solve the problems of unable to maintain the balance of filter digestion and degradation, unable to further remove organic matter, high energy consumption, etc., to achieve efficient and durable advanced treatment, replacement and maintenance Simple and easy to implement, satisfying the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

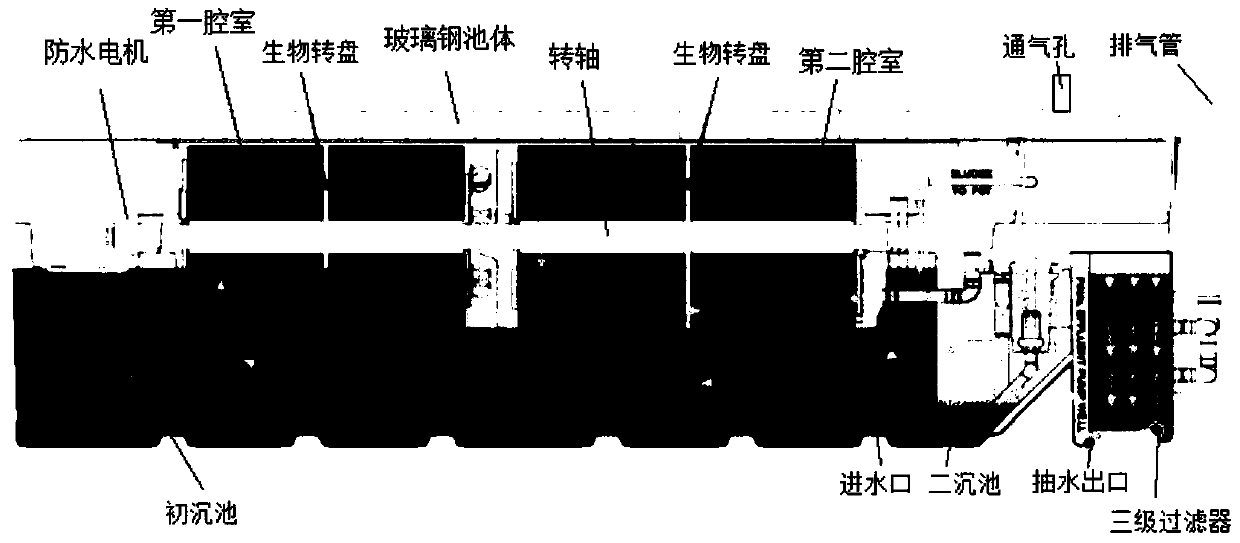

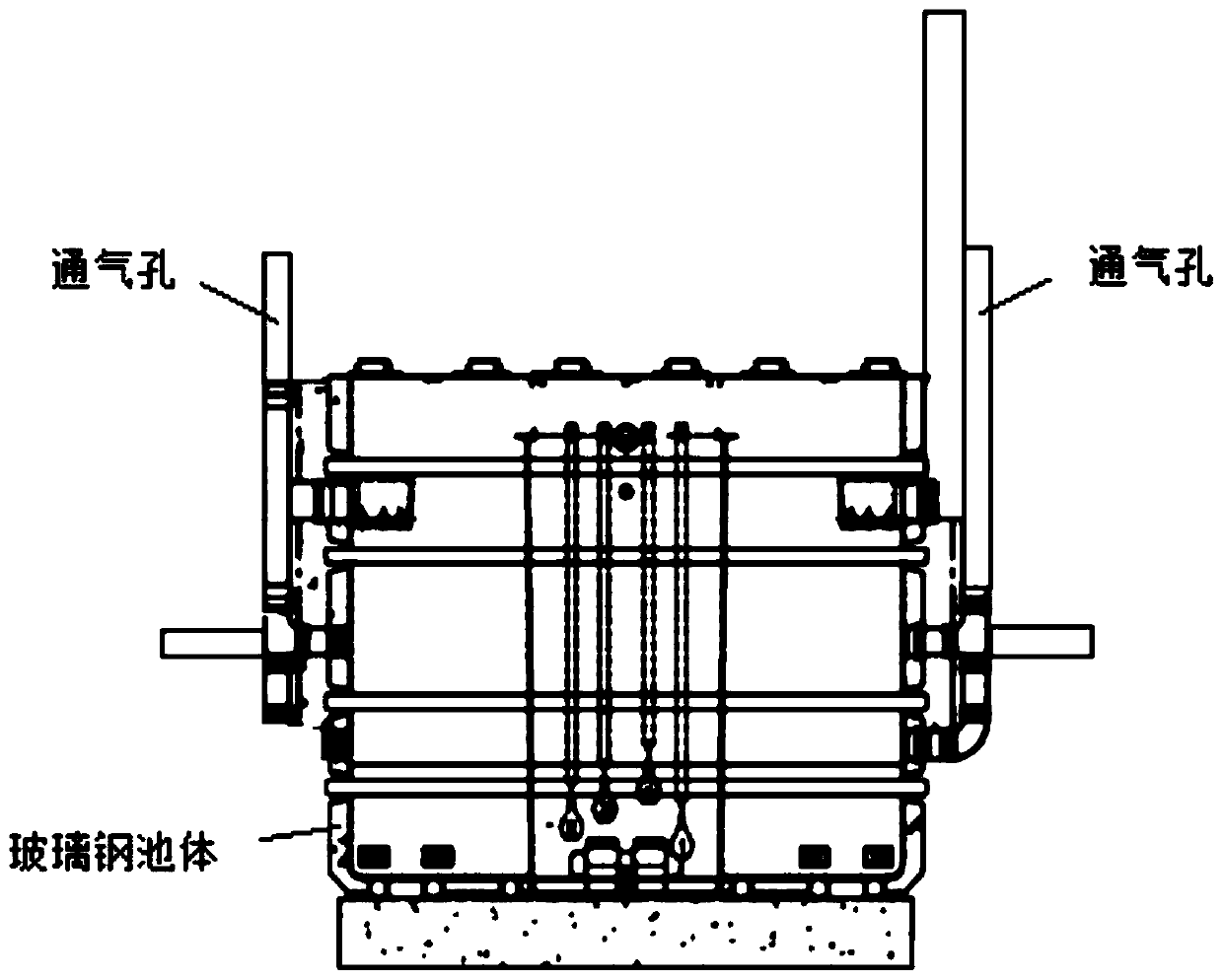

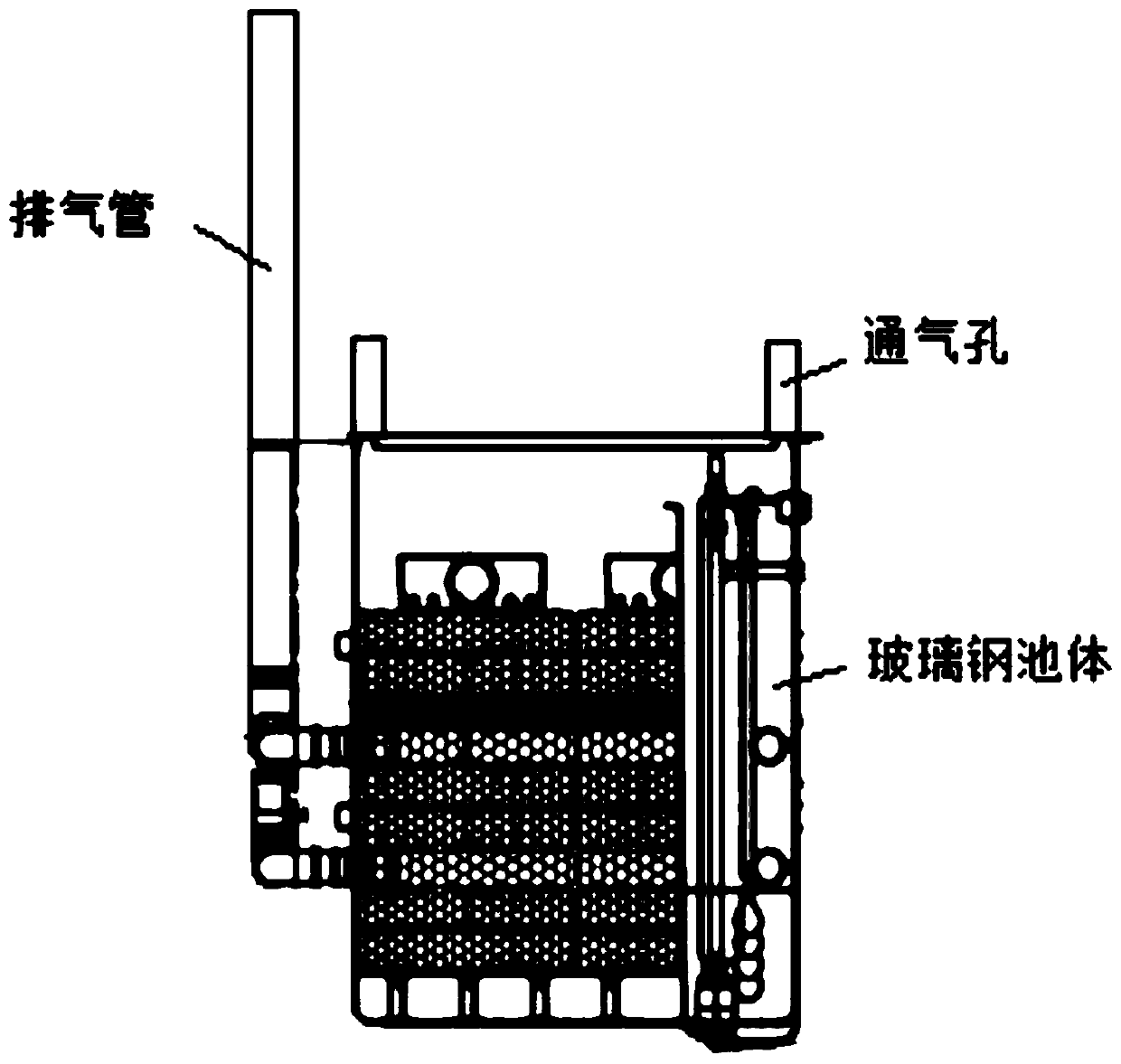

[0024] refer to Figure 1-4 , proposed KEE three-stage biochemical filter in the present embodiment, comprises glass fiber reinforced plastic pool body, is provided with first chamber on the glass fiber reinforced plastic pool body, and one side of the first chamber is provided with waterproof motor, and the output shaft of waterproof motor is fixedly installed There is a rotating shaft, and there is a second chamber on the glass fiber reinforced plastic pool body. The second chamber is located on the other side of the first chamber. The end of the rotating shaft away from the waterproof motor runs through the first chamber, the second chamber and extends to the second chamber. On the side of the chamber away from the first chamber, two biological turntables are fixedly installed on the outside of the rotating shaft, and the two biological turntables are respectively located in the first chamber and the second chamber; The tank is located on the side of the second chamber away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com