Saccharification process for producing rice-flavored baijiu

A rice-flavored and crafted technology, which is applied in the field of food processing, can solve the problems of complex realization process, high labor intensity, and high energy consumption, so as to reduce labor cost and energy consumption, meet market demand and quality requirements, and simplify process realization The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

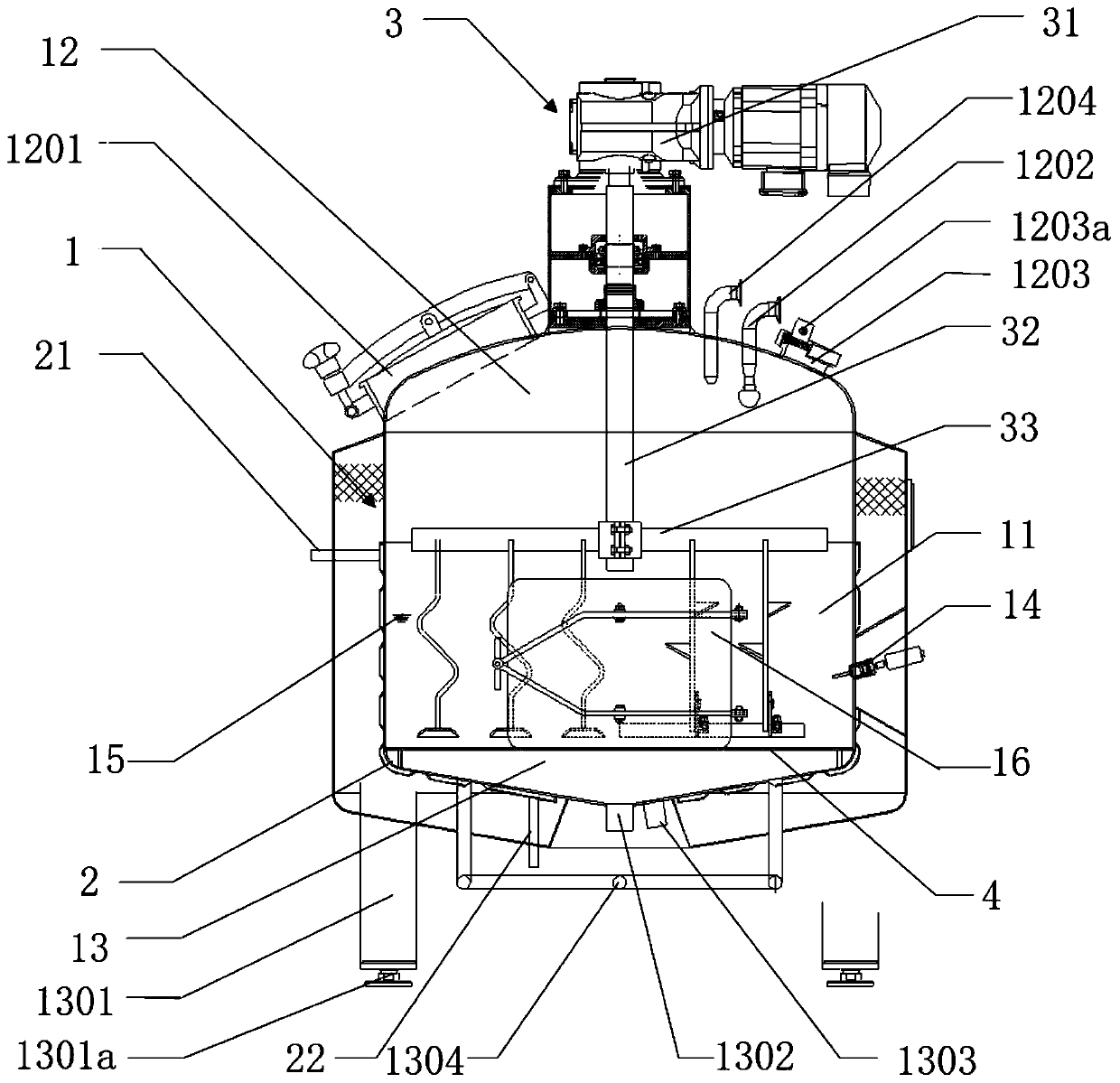

[0055] The saccharification process for the production of rice-flavored liquor of the present embodiment is used for the saccharification process of rice-flavored liquor production, comprising the following steps:

[0056] (1) Feeding: After the closed pot body 1 and related pipelines are effectively cleaned by the CIP cleaning device 1202, the finished 50KG rice is put into the closed pot body 1 from the pressure manhole 1201;

[0057] (2) Rice washing once: through the first nozzle 1204, the brewing water is evenly sprayed on the rice layer, and the stirring device 2 is turned on at the same time to stir the rice layer. Re-inject the material outlet 1303 into the closed pot body 1 through the water pump to circulate and clean for 10 minutes;

[0058] (3) Rice soaking: after washing the rice, close the sewage outlet 1302, the material outlet 1303 and the stirring device 2, continue to add brewing water through the first nozzle 1204, stop until the water surface is 10cm higher...

Embodiment 2

[0066] The saccharification process of rice-flavored liquor production of the present embodiment is used for the technology of rice-flavored liquor saccharification, comprises the following steps:

[0067] (1) Feeding: After the closed pot body 1 and related pipelines are effectively cleaned by the CIP cleaning device 1202, the finished product 100KG rice is dropped into the closed pot body 1 from the pressure manhole door 1201;

[0068] (2) Rice washing once: through the first nozzle 1204, the brewing water is evenly sprayed on the rice layer, and the stirring device 2 is turned on at the same time to stir the rice layer. Re-inject the material outlet 1303 into the closed pot body 1 through the water pump to circulate and clean for 10 minutes;

[0069] (3) Rice soaking: after washing the rice, close the sewage outlet 1302, the material outlet 1303 and the stirring device 2, continue to add brewing water through the first nozzle 1204, stop until the water surface is 10cm highe...

Embodiment 3

[0077] The saccharification process of rice-flavored liquor production of the present embodiment is used for the technology of rice-flavored liquor saccharification, comprises the following steps:

[0078] (1) Feeding: After the closed pot body 1 and related pipelines are effectively cleaned by the CIP cleaning device 1202, the finished product 150KG rice is dropped into the closed pot body 1 from the pressure manhole door 1201;

[0079] (2) Rice washing once: through the first nozzle 1204, the brewing water is evenly sprayed on the rice layer, and the stirring device 2 is turned on at the same time to stir the rice layer. Re-inject the material outlet 1303 into the closed pot body 1 through the water pump to circulate and clean for 10 minutes;

[0080] (3) Rice soaking: after washing the rice, close the sewage outlet 1302, the material outlet 1303 and the stirring device 2, continue to add brewing water through the first nozzle 1204, stop until the water surface is 10cm highe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com