Spinning method and apparatus

A heating device and liquid medium technology, applied in the field of spinning and devices, can solve the problems of fiber quality damage in the oil bath, insufficient utilization of heating medium, etc., to avoid high temperature loss, avoid transport instability and cavitation, The effect that the heating temperature is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] Hereinafter, examples are given to describe the present invention more specifically, but the present invention is not limited to these examples.

[0088] The volume of the oil bath is set to 300L, and the solvent used is set to water.

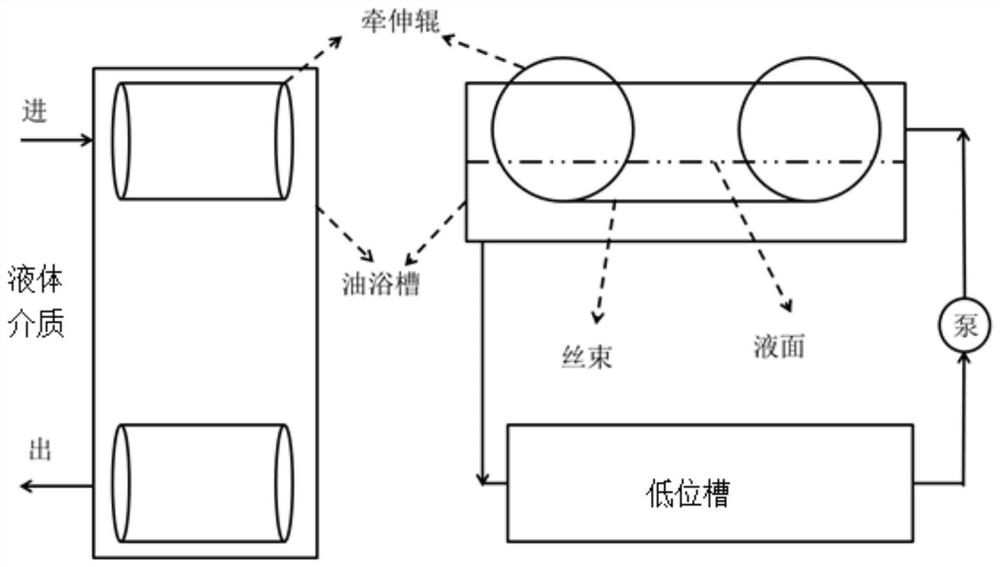

[0089] In the control group, the figure 1 In the way shown, add liquid medium (a mixture of water and finishing agent) into the lower tank and heat it directly. After the temperature of the liquid medium in the lower tank reaches 98°C, the liquid medium is pumped to the oil bath tank through a water pump. Inside, the maximum flow rate of the pump is 16m 3 / h, power 4Kw, and maintain the stability of the temperature of the liquid medium in the oil bath through circulation.

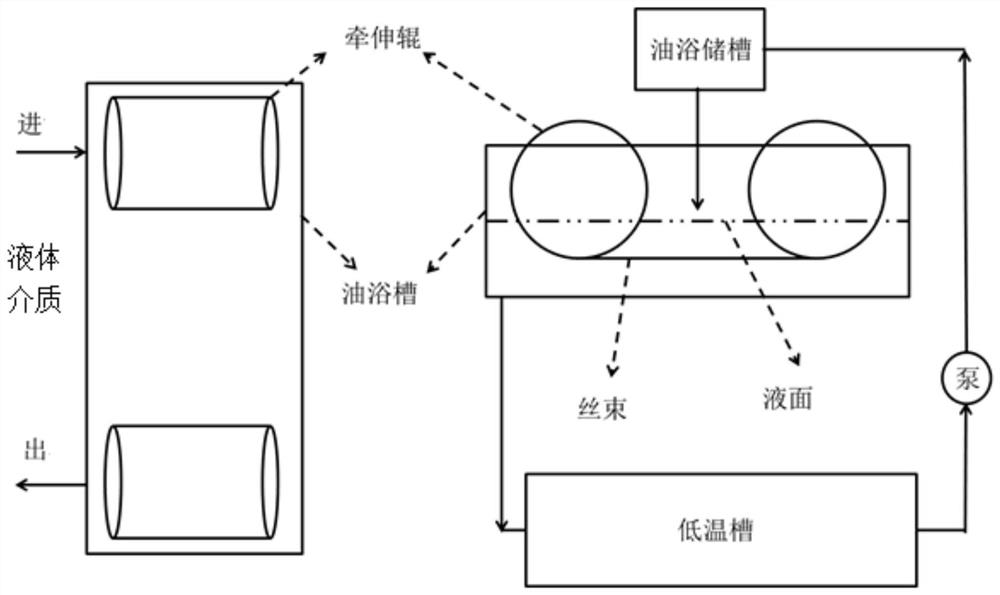

[0090] In the experimental group, the figure 2 In the way shown, the temperature of the liquid medium in the low-temperature tank (composition of the liquid medium in the control group is the same) is controlled at 70°C, while the temperature of the liquid medium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com