Layered elastomer, manufacturing method thereof and special spinneret

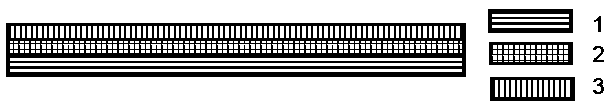

An elastomer and spinneret technology, which is used in spinneret assemblies, non-woven fabrics, textiles and papermaking, etc., can solve the problem of not being able to significantly improve the support factor, and achieve high resilience, good comfort, and optimal softness. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

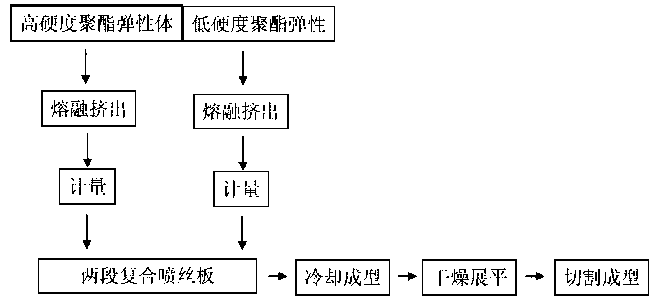

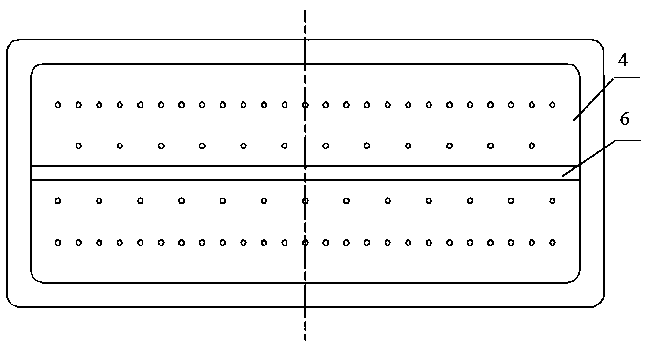

[0042] The raw material of low hardness polyester elastomer B-1 accounting for 40% by mass of the total amount is fed into the first component extruder, heated to a molten state of 220°C, and 60% by mass of high hardness polyester elastomer A-2 Raw materials are heated to a molten state of 230°C in the second component extruder; after metering, they are extruded into the die head and distributed through the partition of the distribution plate. Raw materials A-2 and B-1 are respectively located in the spinneret On both sides of the partition, the pulling speed is 0.4 m / min. During the process of the filamentous fibers falling and falling into 30°C cold water cooling and curling, the adjacent high-hardness fiber filaments and low-hardness fiber filaments on both sides of the separator are interlaced and bonded to each other, and finally in the The layered elastomer is formed in the mold, and the layered elastomer is tested by the above method, and the physical parameters obtained...

Embodiment 2

[0044] Feed the raw material of low hardness polyester elastomer B-2 accounting for 40% by mass of the total amount into the first component extruder and heat it to a molten state of 220°C, and 60% by mass of high hardness polyester elastomer A-1 The raw materials are heated to a molten state of 240°C in the second component extruder; after metering, they are extruded into the die head and distributed through the partition of the distribution plate. The raw materials A-1 and B-2 are respectively located in the spinneret On both sides of the partition, the pulling speed is 0.4 m / min. During the process of the filamentous fibers falling and falling into 30°C cold water cooling and curling, the adjacent high-hardness fiber filaments and low-hardness fiber filaments on both sides of the separator are interlaced and bonded to each other, and finally in the The layered elastomer is formed in the mold, and the layered elastomer is tested by the above method, and the physical parameter...

Embodiment 3

[0046] Feed the low-hardness polyester elastomer B-2 raw material accounting for 40% by mass of the total amount into the first component extruder, heat it to a molten state at 220°C, and 60% by mass of high-hardness polyester elastomer A-2 The raw materials are heated to a molten state of 230°C in the second component extruder; after metering, they are extruded into the die head and distributed through the partition of the distribution plate. The A-2 raw material and B-2 raw material are located in the spinneret On both sides of the partition, the pulling speed is 0.4 m / min. During the process of the filamentous fibers falling and falling into 30°C cold water cooling and curling, the adjacent high-hardness fiber filaments and low-hardness fiber filaments on both sides of the separator are interlaced and bonded to each other, and finally in the The layered elastomer is formed in the mold, and the layered elastomer is tested by the above method, and the physical parameters obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com