Exhaust powder valve-free type air distribution two-way pneumatic down hole hammer applied to deep hole complex stratum

A technology of complex formation and down-the-hole hammer, which is applied to the drilling drive device, drilling equipment, earth-moving drilling and other directions in the wellbore, which can solve the problems of low efficiency, difficulty in hole formation, slow progress, etc. Impact energy, avoid the effect of supporting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] specific implementation plan

[0041] The present invention is described in detail below in conjunction with accompanying drawing:

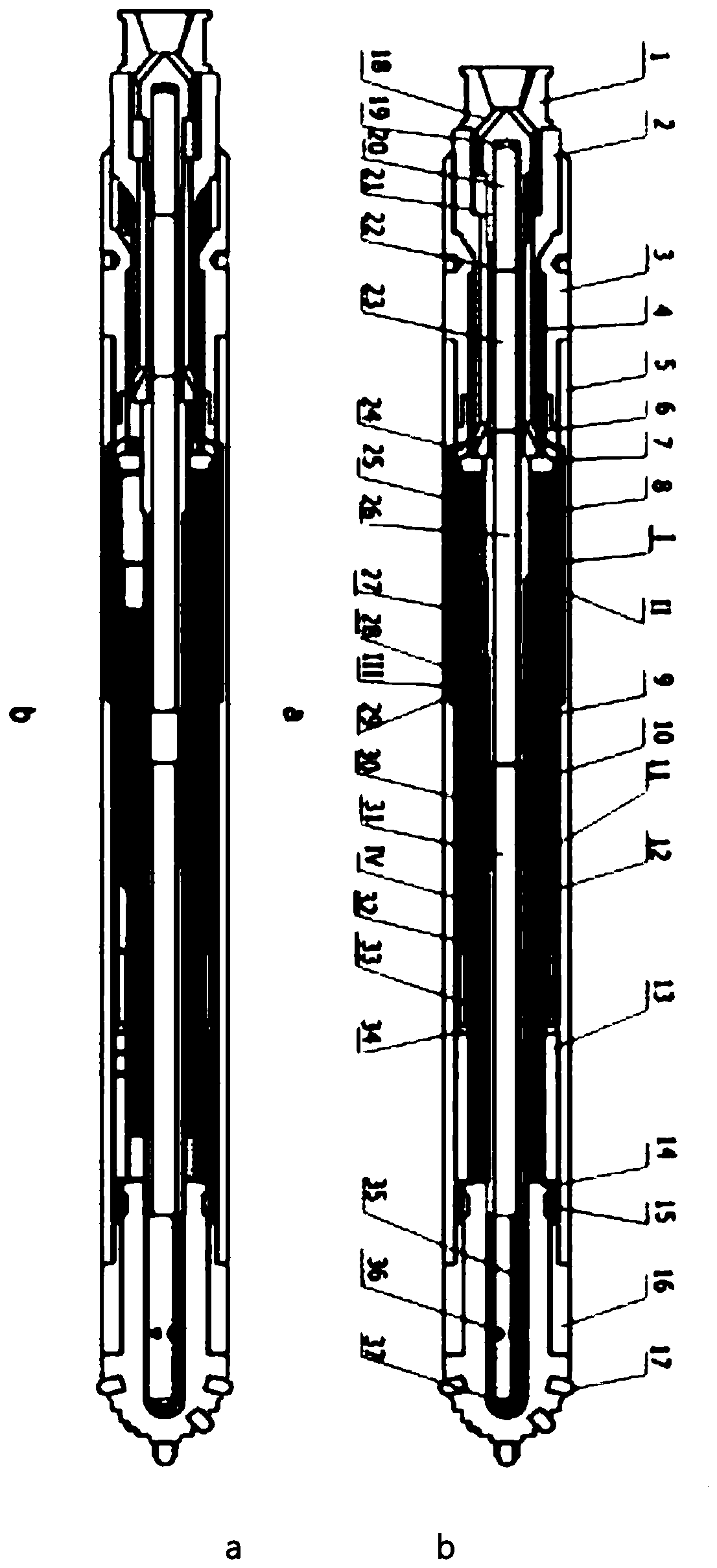

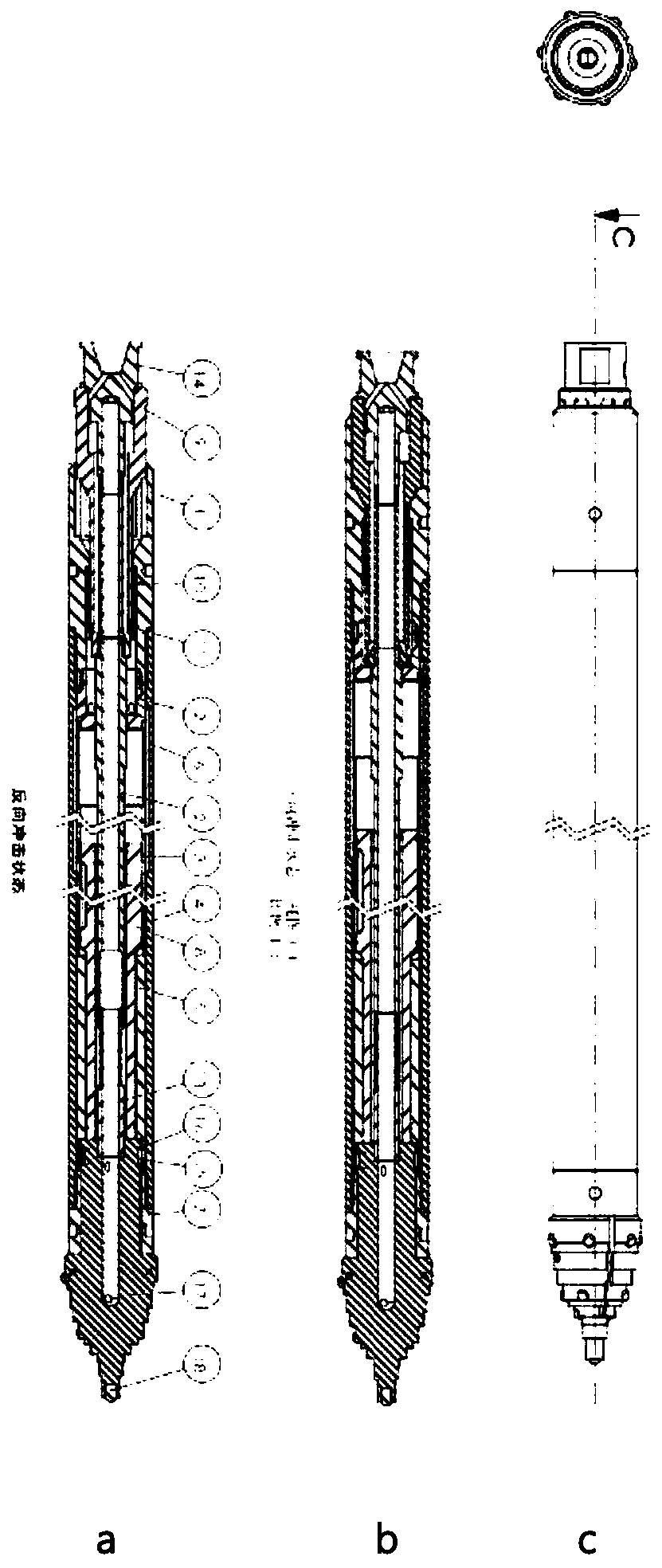

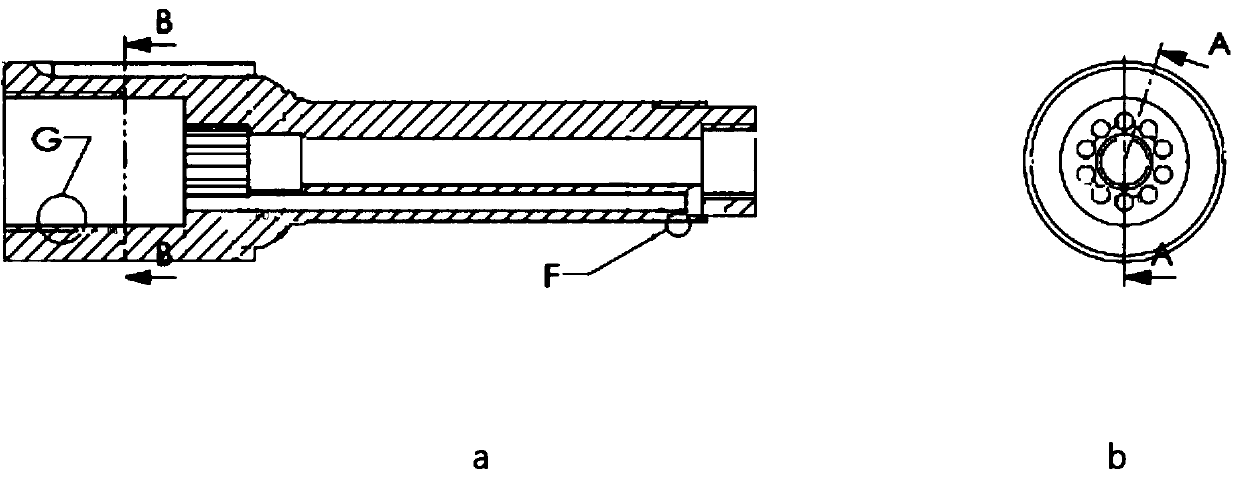

[0042] According to the present invention, a powder-discharging, valveless, gas-distributing, two-way pneumatic down-the-hole hammer suitable for complex formations with deep holes can realize rapid compaction and formation of holes in soil layers and loose sand and pebble formations, and the hole walls are dense and smooth. , It is not easy to cross the hole, and the drilling quality is high. At the same time, it can solve the problem that the two-way pneumatic DTH hammer is difficult to drill into complex formations such as hard rocks, broken zones, and weak and uneven formations.

[0043] refer to figure 1, the powder-discharging, valveless and valve-distributing two-way pneumatic down-the-hole hammer suitable for complex formations in deep holes includes a pressure transmission mechanism, a tail gas distribution mechanism, a cylinder-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com