An ultra-low specific speed centrifugal pump device

A technology of specific speed and centrifugal pumps, which is applied in the direction of pump devices, components of pumping devices for elastic fluids, jet propulsion devices, etc., and can solve the problem of uneven circumferential velocity components at the front edge of the induction wheel and centrifugal wheel inlet, and unfavorable rockets. The stability of the engine system, the head and efficiency drop in small flow areas, etc., achieve the effects of light weight, reduced manufacturing process difficulty, and small structural size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

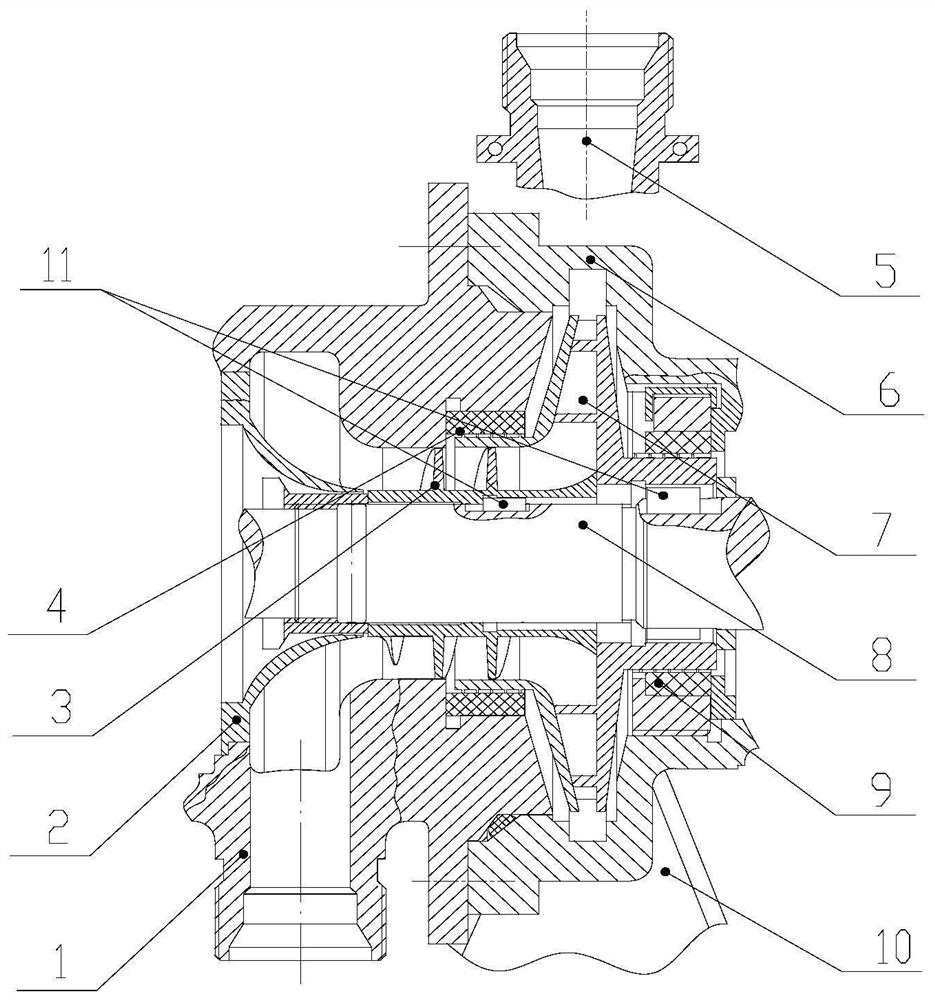

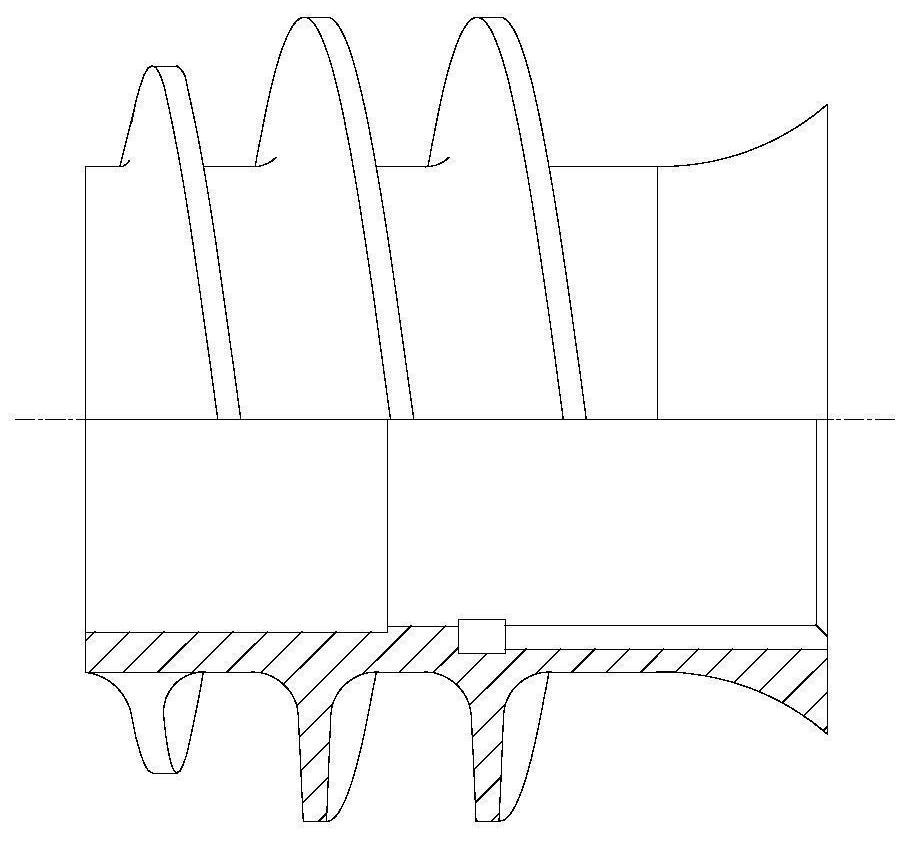

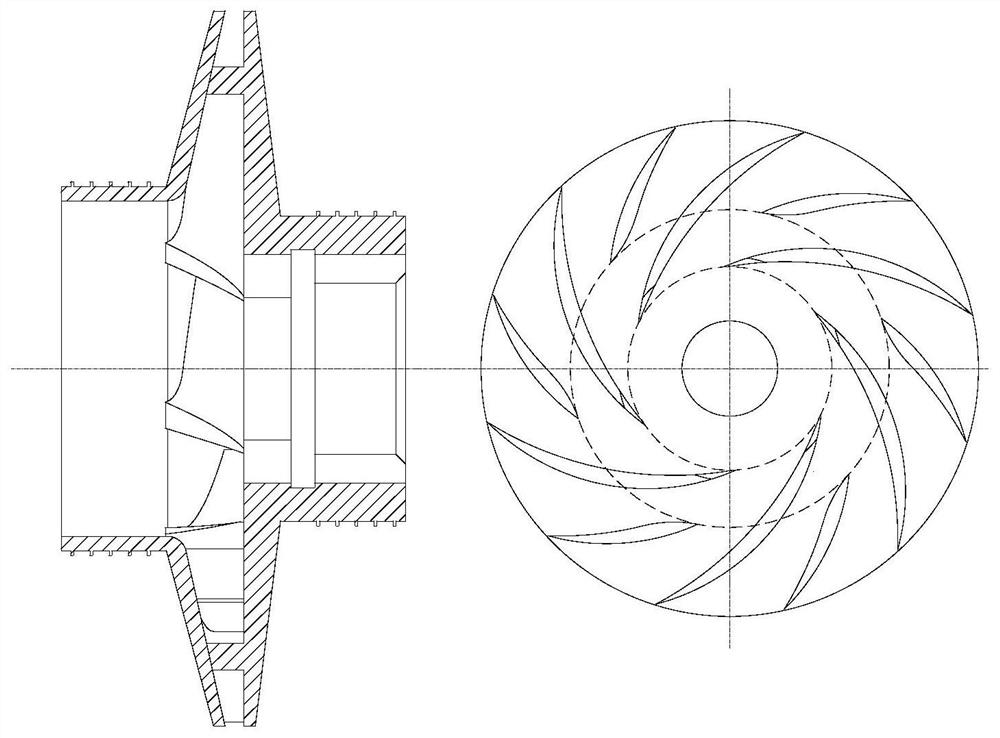

[0029] The invention utilizes the rotation of the impeller to generate high-speed fluid, and then converts the kinetic energy of the flowing liquid into pressure energy through the diffusion effect of the pump casing 6 and the outlet pipe 5, thereby generating high-pressure liquid to ensure the fuel supply of the engine and the combustion inlet pressure requirements. The specific speed of the pump device designed by adopting the invention is only 24, which belongs to the special type pump with ultra-low specific speed. The working medium is unsymmetrical dimethylhydrazine. Under the design flow rate, the medium head can reach 12.6MPa. The structure size of the present invention is light in weight. This type of fuel pump device has passed the test of the engine test and fully meets the system and structure requirements of the upper engine.

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com