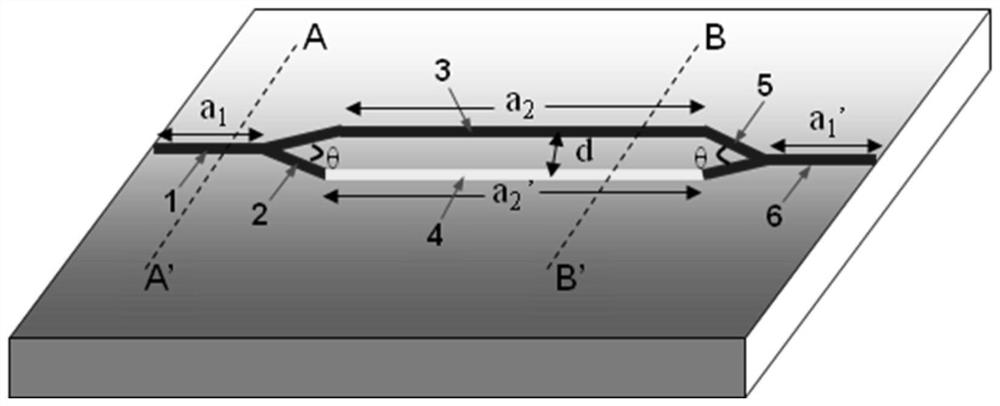

A temperature sensor based on asymmetric MZI optical waveguide and its preparation method

A technology of temperature sensor and optical waveguide, applied in the direction of physical/chemical change thermometer, light guide, thermometer, etc., can solve the problems of losing temperature sensing function and limiting the practical application of temperature sensor with MZI optical waveguide structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

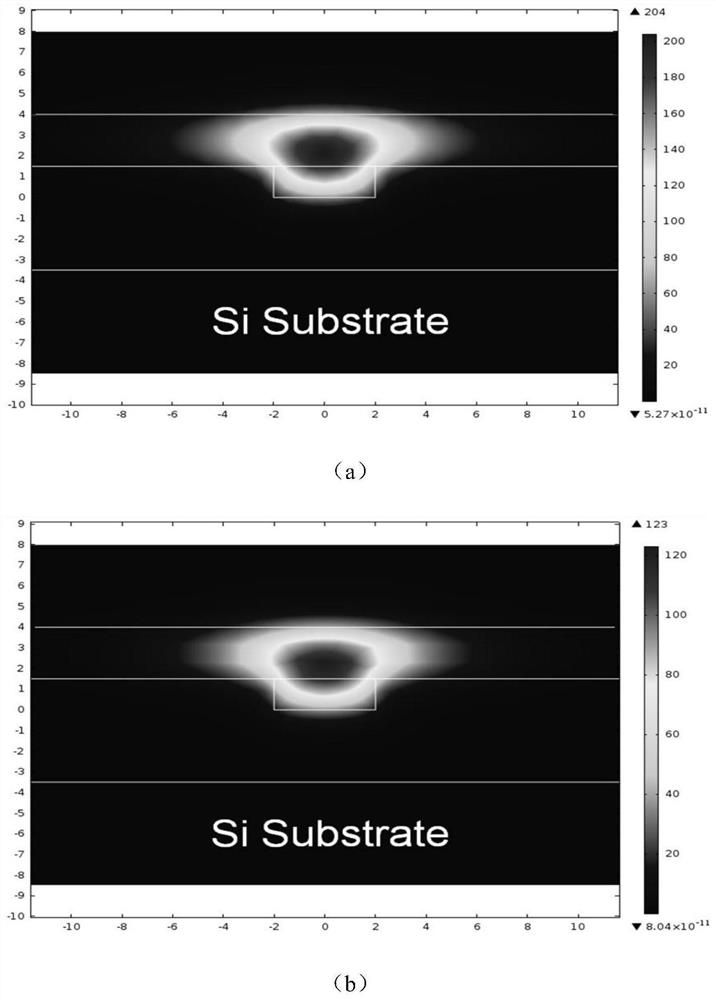

Method used

Image

Examples

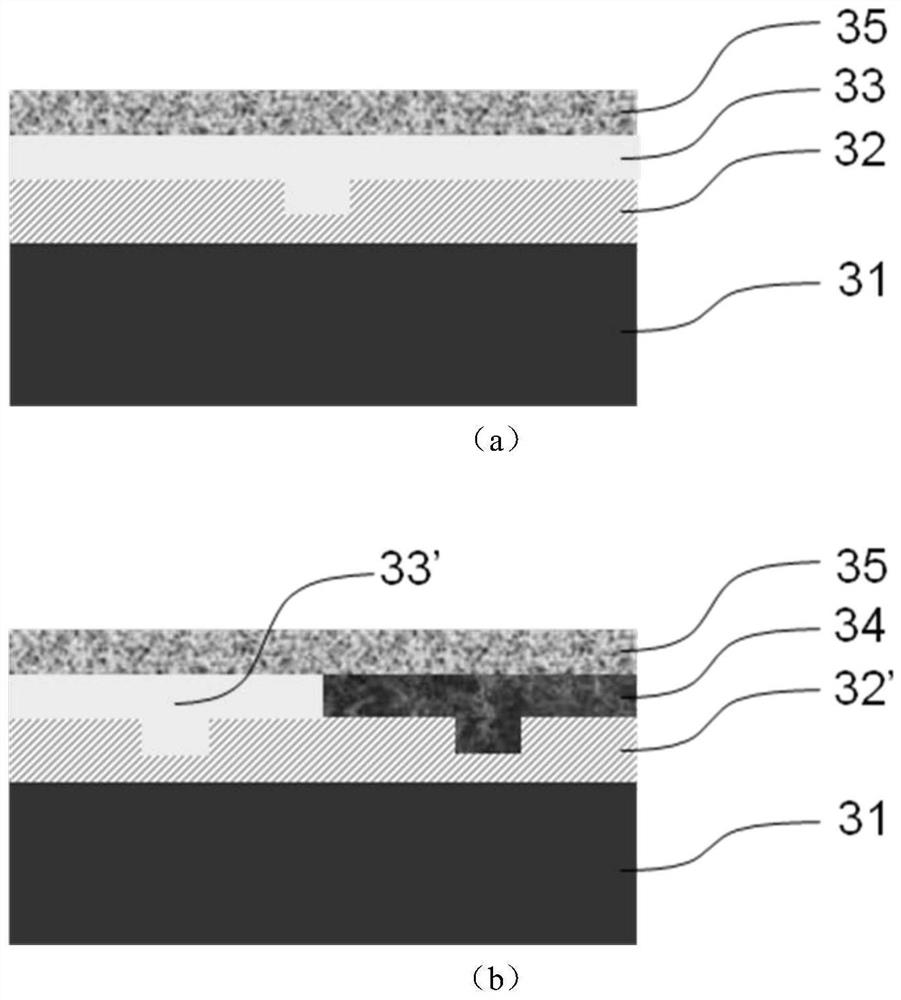

Embodiment 1

[0045] Cleaning treatment of silicon substrate: Soak the silicon substrate in acetone solution and ultrasonically clean it for 8 minutes, then repeatedly wipe it with acetone and ethanol cotton balls in sequence, rinse it with deionized water, dry it with nitrogen, and finally put it under the condition of 110°C Bake for 1.5 hours to remove moisture.

[0046] The lower cladding of the polymer waveguide was prepared by spin-coating: the polymer material PMMA was spin-coated on the cleaned silicon substrate, the spin-coating speed was controlled at 3000 rpm, and then the film was baked at 120°C for 2.5 hours , to obtain a waveguide lower cladding with a thickness of 4 μm.

[0047]The waveguide groove was prepared by standard photolithography and dry etching process: first, a layer of Al mask with a thickness of 100nm was evaporated on the prepared polymer lower cladding layer, and the Al film was spin-coated by spin-coating process. A layer of positive photoresist BP212 with a ...

Embodiment 2

[0053] Cleaning treatment of silicon substrate: Soak the silicon substrate in acetone solution and ultrasonically clean it for 8 minutes, then repeatedly wipe it with acetone and ethanol cotton balls in sequence, rinse it with deionized water, dry it with nitrogen, and finally put it under the condition of 110°C Bake for 1.5 hours to remove moisture.

[0054] The lower cladding of the polymer waveguide was prepared by spin-coating: the polymer material PMMA was spin-coated on the cleaned silicon substrate, the spin-coating speed was controlled at 3000 rpm, and then the film was baked at 120°C for 2.5 hours , to obtain a waveguide lower cladding with a thickness of 4 μm.

[0055] The waveguide groove was prepared by standard photolithography and dry etching process: first, a layer of Al mask with a thickness of 100nm was evaporated on the prepared polymer lower cladding layer, and the Al film was spin-coated by spin-coating process. A layer of positive photoresist BP212 with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com