Production and processing method of high-quality quartz boat

A processing method, quartz boat technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as easy deformation, poor product quality, affecting product quality and corporate reputation, etc., to prevent deformation and reduce manufacturing costs. Low cost, convenient operation and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This embodiment includes the following steps:

[0067] a. Incoming material inspection;

[0068] b. Cutting: Cut the qualified quartz rods in step a according to the specified size requirements;

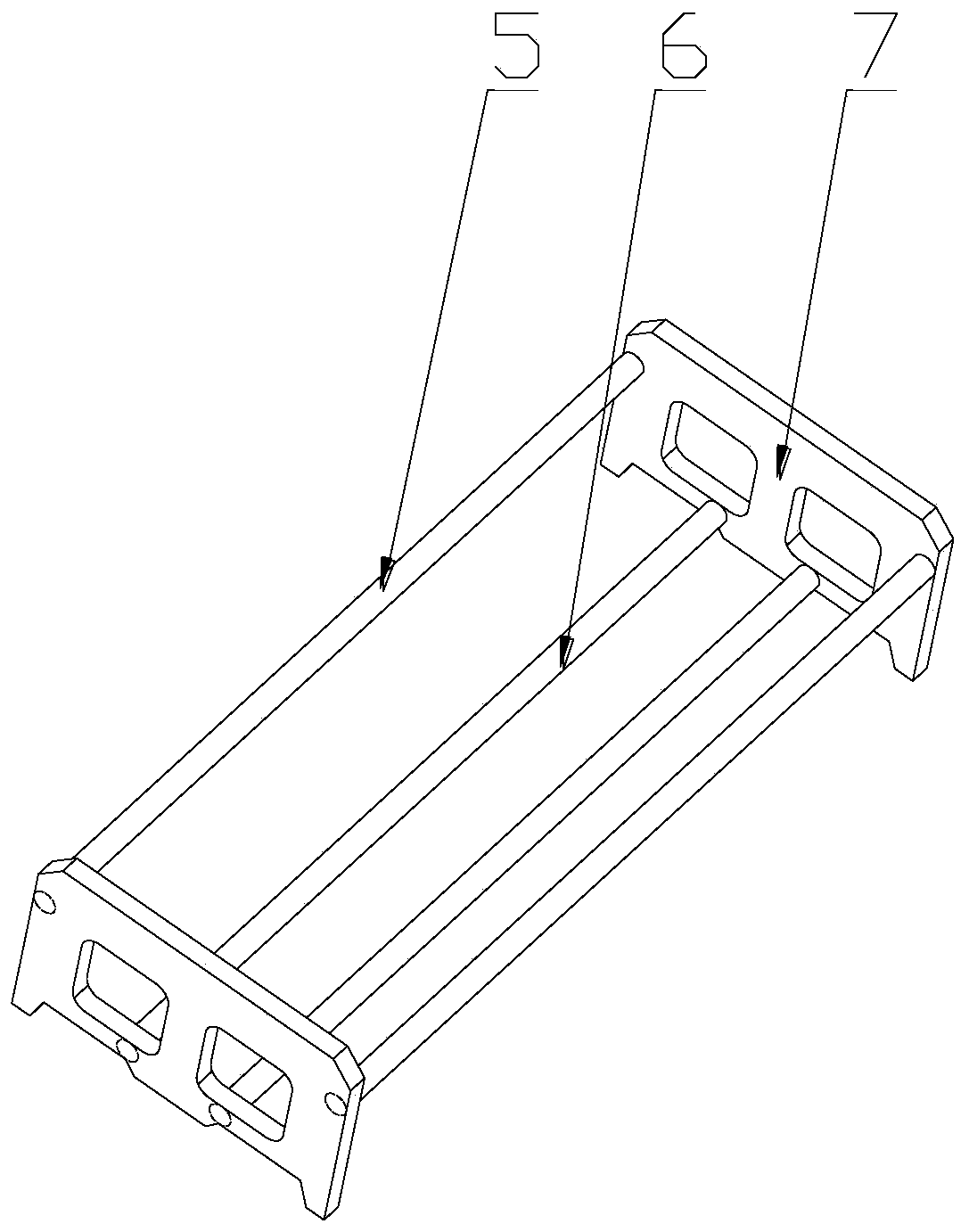

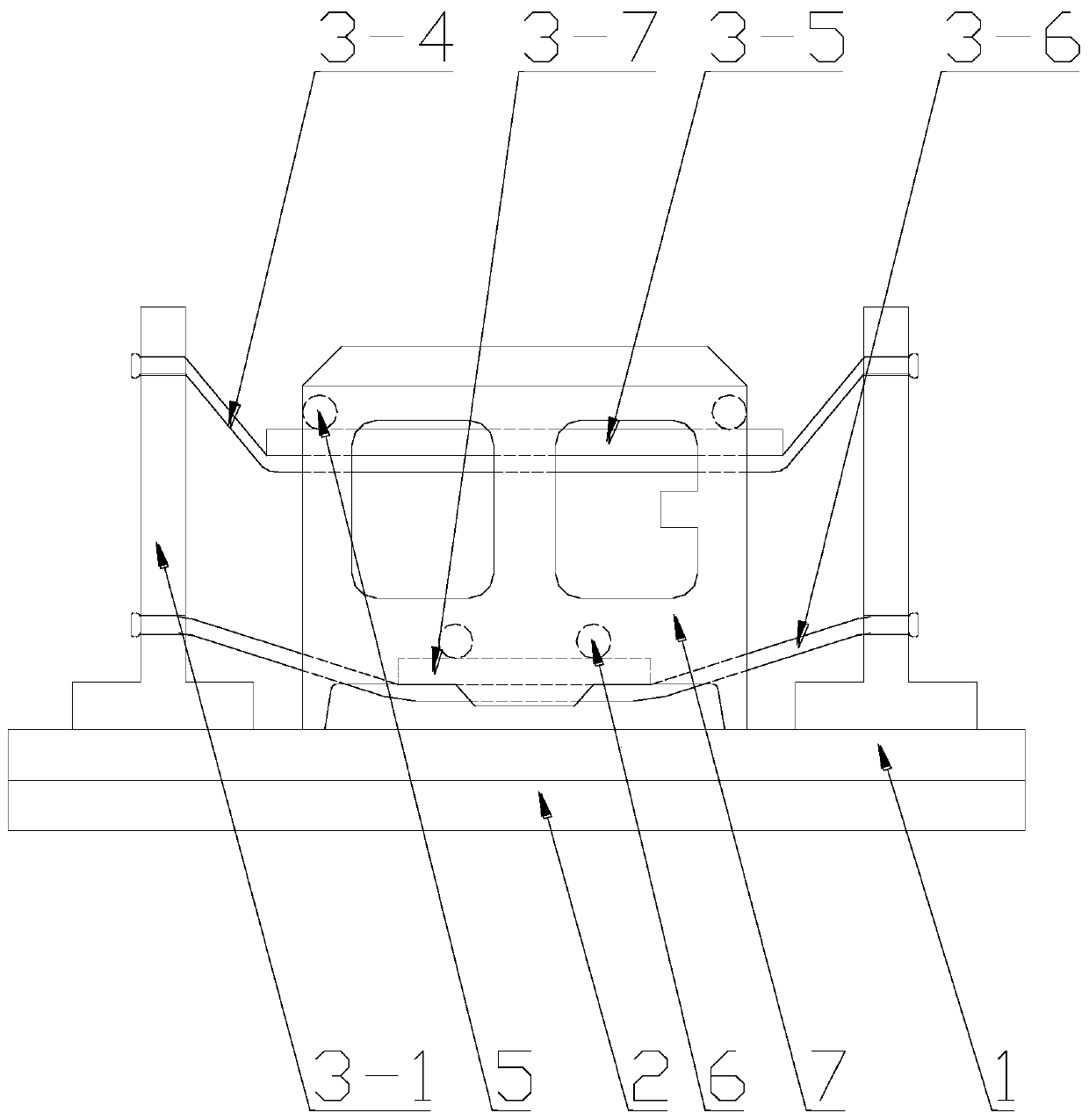

[0069] c. Machining center processing; use the machining center to process the insert groove of the quartz rod and the side plate 7 of the quartz boat;

[0070] d. pickling: using pickling solution to clean the product of step c;

[0071] e. Cleaning with pure water: put the product of step d into pure water for cleaning, and then dry naturally after cleaning;

[0072] f. Pyroprocessing: use a quartz torch to weld the product of step e, and after the quartz rod and the side plate 7 are fixed, the semi-finished quartz boat is formed;

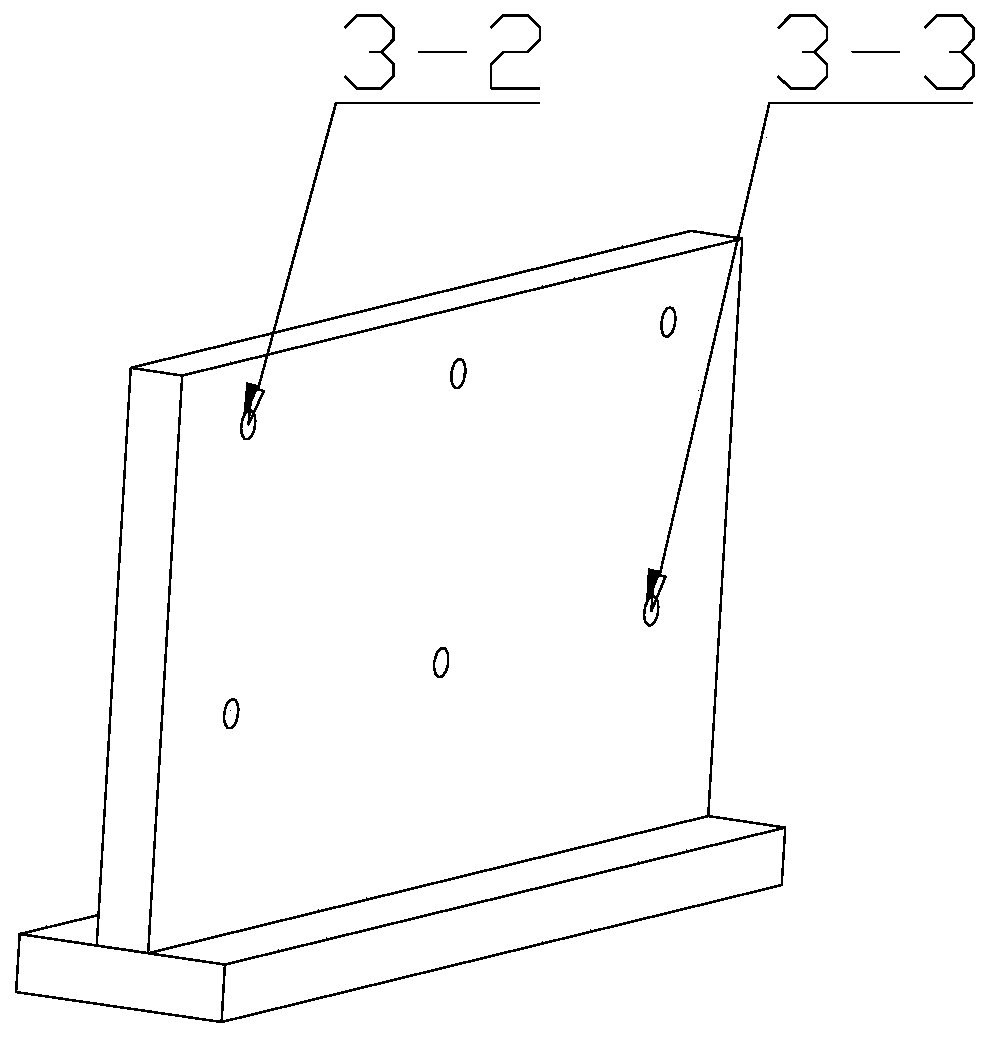

[0073] g. Support annealing: Push the semi-finished quartz boat in step f into the annealing furnace for annealing to relieve stress. The semi-finished quartz boat is supported by the annealing support platform in the furnace and placed on the...

Embodiment 2

[0081] This embodiment includes the following steps:

[0082] a. Incoming material inspection;

[0083] b. Cutting: Cut the qualified quartz rods in step a according to the specified size requirements;

[0084] c. Machining center processing; use the machining center to process the insert groove of the quartz rod and the side plate 7 of the quartz boat;

[0085] d. pickling: using pickling solution to clean the product of step c;

[0086] e. Cleaning with pure water: put the product of step d into pure water for cleaning, and then dry naturally after cleaning;

[0087] f. Pyroprocessing: use a quartz torch to weld the product of step e, and after the quartz rod and the side plate 7 are fixed, the semi-finished quartz boat is formed;

[0088] g. Support annealing: Push the semi-finished quartz boat in step f into the annealing furnace for annealing to relieve stress. The semi-finished quartz boat is supported by the annealing support platform in the furnace and placed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com