P-type PERC double-side solar cell alignment printing method, preparation method and battery

A solar cell and alignment printing technology, applied in the field of solar cells, can solve the problems of affecting the performance of the cell, unable to realize the accurate connection and separation of the back aluminum grid line and the back electrode bus line, etc., so as to reduce the defect rate, effectively connect, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

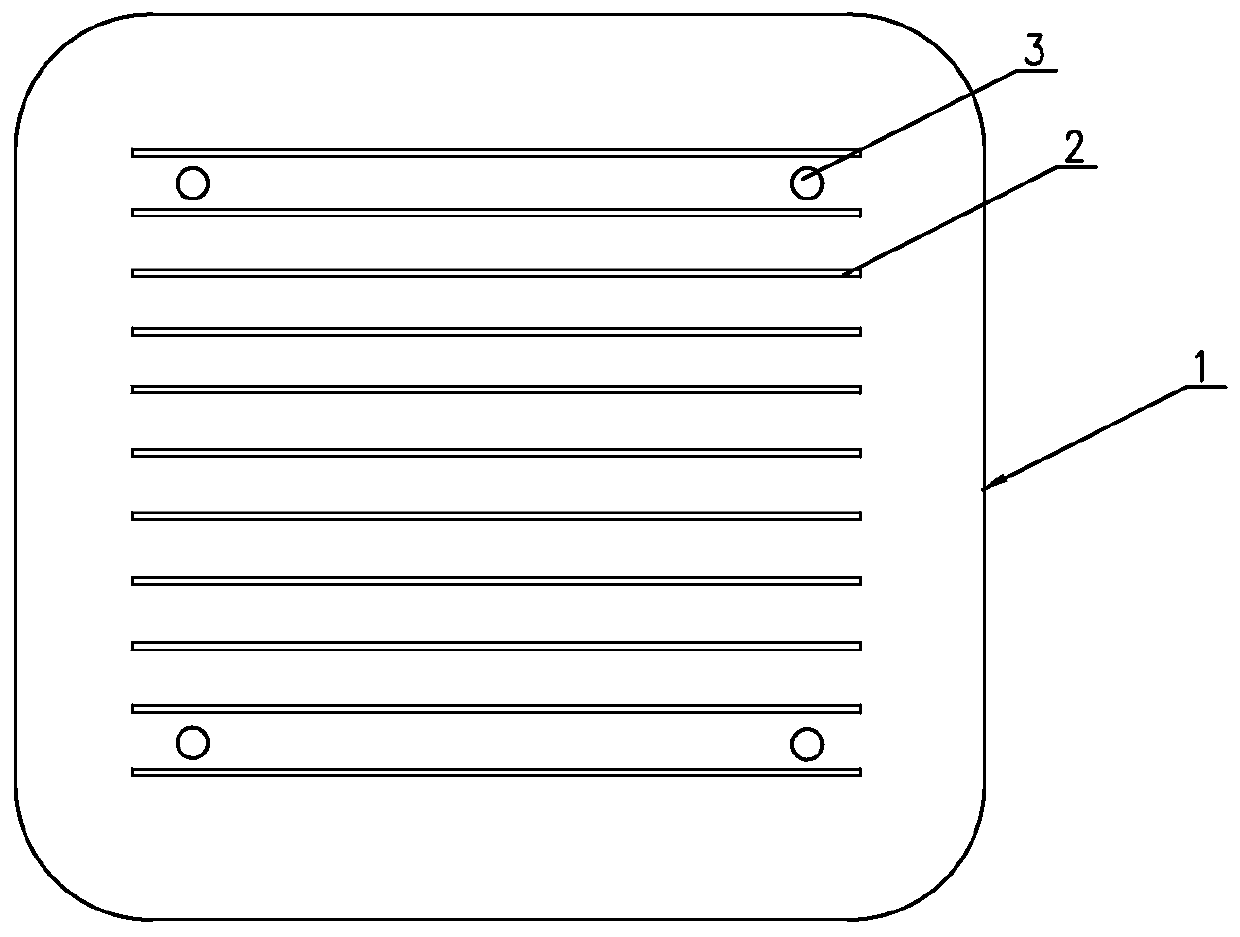

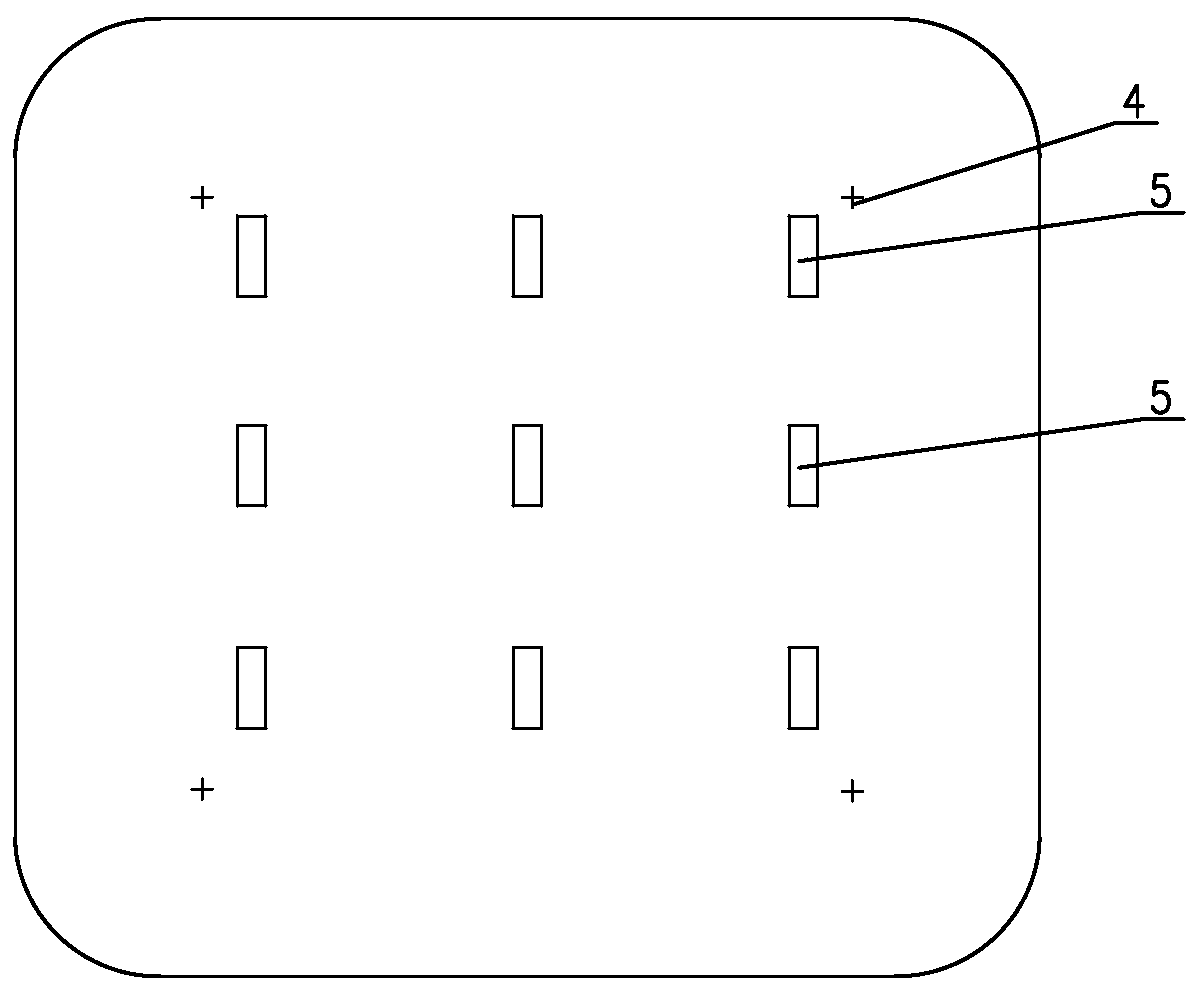

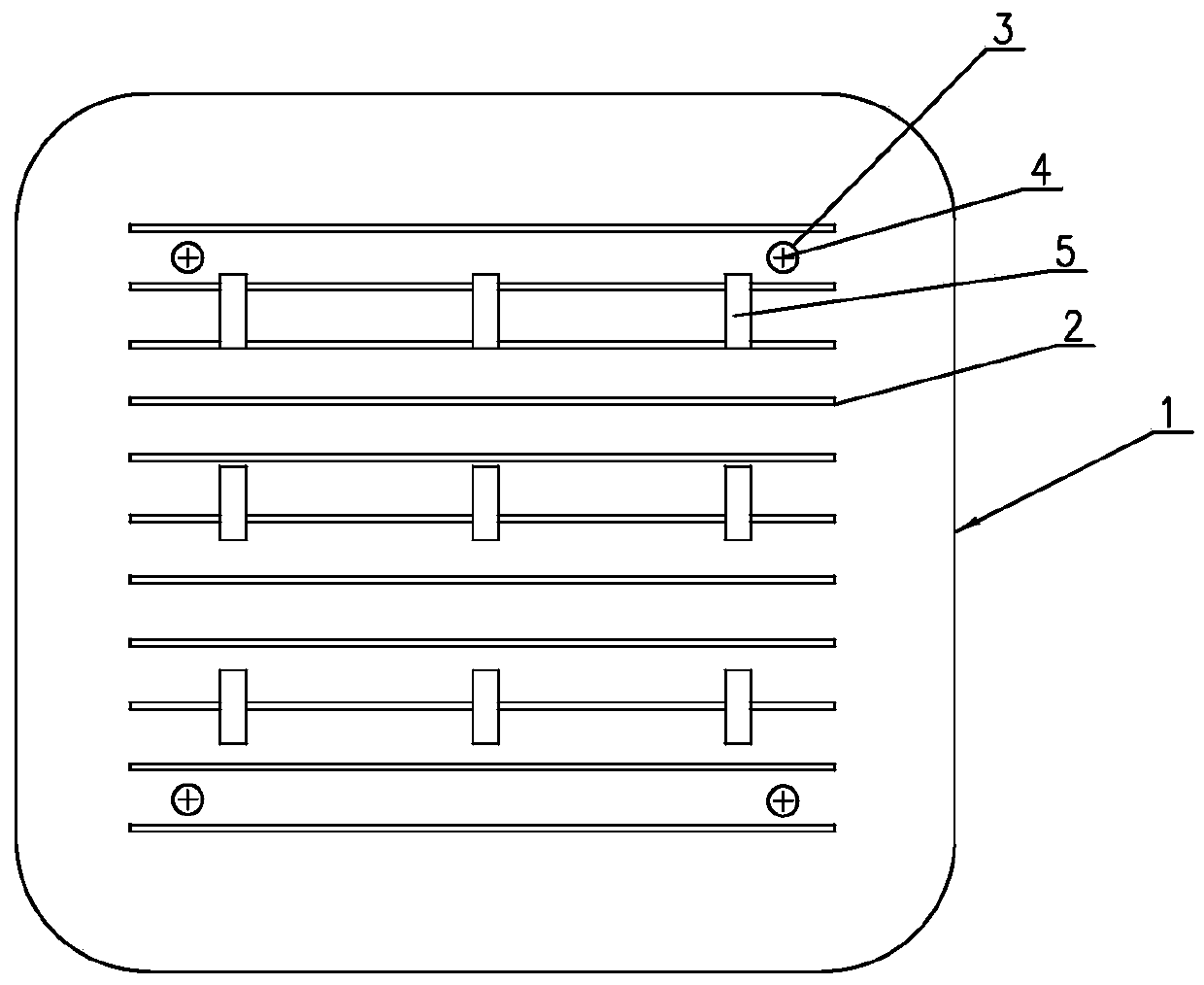

[0045] The invention relates to a P-type PERC double-sided solar cell alignment printing method. In the process of sequentially manufacturing the back laser grooved area, the back electrode main grid line and the back aluminum grid line on the silicon wafer, firstly on the back laser groove pattern Set the Mark1 point, and make the backside laser groove area with the Mark1 point on the silicon wafer, then set the Mark2 point on the back busbar screen, and print the back pole busbar with the Mark2 point on the silicon wafer line; then, use the Mark1 point on the silicon wafer to adjust the position of the silicon wafer through the three parameters of X (horizontal axis), Y (vertical axis), and θ (angle), so that the laser grooved area on the back is aligned with the back aluminum grid line Align the back aluminum grid line on the screen plate with the back aluminum grid line on the back aluminum grid line screen plate and the back electrode main grid line by adjusting the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com