Lithium battery tab and preparation method thereof

A lithium battery and tab technology, which is applied in the field of lithium battery tabs and its preparation, can solve the problems of increased battery internal resistance, reduced battery energy density, and decreased battery power performance, achieving cost savings, easy operation, and battery protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

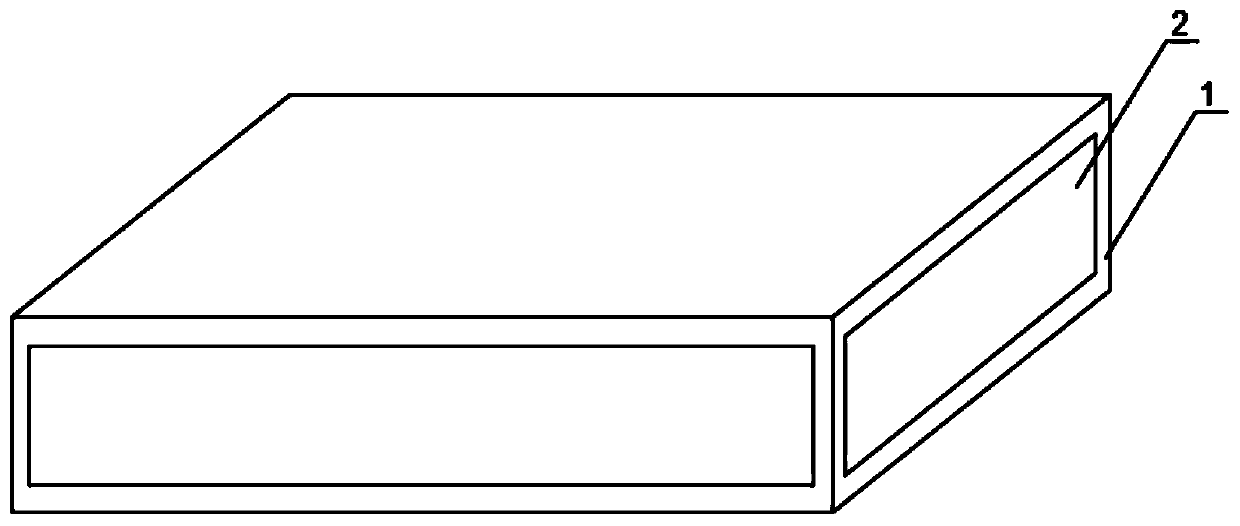

[0051] Embodiment 1: as Figure 1-2 As shown, a lithium battery tab is coated with a PVDF coating 1 on the surface of the tab itself. The thickness of the PVDF coating 1 is 1 micron, and the PVDF coating 1 is made of PVDF, CNT, graphene, and NMP materials. ,

[0052] Wherein, the ratio by weight: PVDF, graphene, and CNT are 50%:10%:10% by weight. The addition of NMP is 14.5 times of PVDF weight;

[0053] The preparation method of the above-mentioned lithium battery tab is the following steps:

[0054] S1: Mix graphene, CNT, NMP and PVDF to make slurry;

[0055] The steps of making slurry are:

[0056] 1. PVDF baking: Baking PVDF for 10 hours at 75°C and vacuum less than -0.095Mpa.

[0057] 2. PVDF and NMP are made into glue: PVDF is baked and mixed with NMP, and PVDF glue is made after three times of stirring;

[0058] Mix three times using a blender for:

[0059] Stirring for the first time: NMP is 14 times the weight of PVDF, add baked PVDF to NMP, and stir for the fi...

Embodiment 2

[0073] Embodiment 2: as Figure 1-2 As shown, a lithium battery tab is coated with a PVDF coating 1 on the surface of the tab itself. The thickness of the PVDF coating 1 is 10 microns, and the PVDF coating 1 is made of PVDF, CNT, graphene, and NMP materials. ,

[0074] Wherein, the ratio by weight: PVDF, graphene, and CNT is 90%:25%:25% by weight. The addition amount of NMP is 23 times of PVDF weight.

[0075] The preparation method of the above-mentioned lithium battery tab is the following steps:

[0076] S1: Mix graphene, CNT, NMP and PVDF to make slurry;

[0077] The steps of making slurry are:

[0078] 1. PVDF baking: Baking PVDF for 13 hours at 85°C and vacuum less than -0.095Mpa.

[0079] 2. PVDF and NMP are made into glue: PVDF is baked and mixed with NMP, and PVDF glue is made after three times of stirring;

[0080] Mix three times using a blender for:

[0081] Stirring for the first time: NMP is 18 times the weight of PVDF, add baked PVDF to NMP, and stir for ...

Embodiment 3

[0095] Embodiment 3: as Figure 1-2 As shown, a lithium battery tab is coated with a PVDF coating 1 on the surface of the tab itself. The thickness of the PVDF coating 1 is 5 microns, and the PVDF coating 1 is made of PVDF, CNT, graphene, and NMP materials. ,

[0096] Wherein, the ratio by weight: PVDF, graphene, and CNT is 80%:18%:20% by weight. The addition amount of NMP is 19 times of PVDF weight.

[0097] The preparation method of the above-mentioned lithium battery tab is the following steps:

[0098] S1: Mix graphene, CNT, NMP and PVDF to make slurry;

[0099] The steps of making slurry are:

[0100] 1. PVDF baking: Baking PVDF for 12 hours at 80°C and vacuum less than -0.095Mpa.

[0101] 2. PVDF and NMP are made into glue: PVDF is baked and mixed with NMP, and PVDF glue is made after three times of stirring;

[0102] Mix three times using a blender for:

[0103] Stirring for the first time: NMP is 16 times the weight of PVDF, add baked PVDF to NMP, and stir for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com