Battery negative electrode coating, battery negative electrode sheet and manufacturing method thereof, and lithium ion battery

A lithium-ion battery and battery negative electrode technology, applied in the direction of electrode manufacturing, battery electrodes, electrode carriers/collectors, etc., can solve the problems of shortened cycle life of lithium-ion batteries, achieve improved cycle performance, good electrical conductivity, and prolong cycle life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

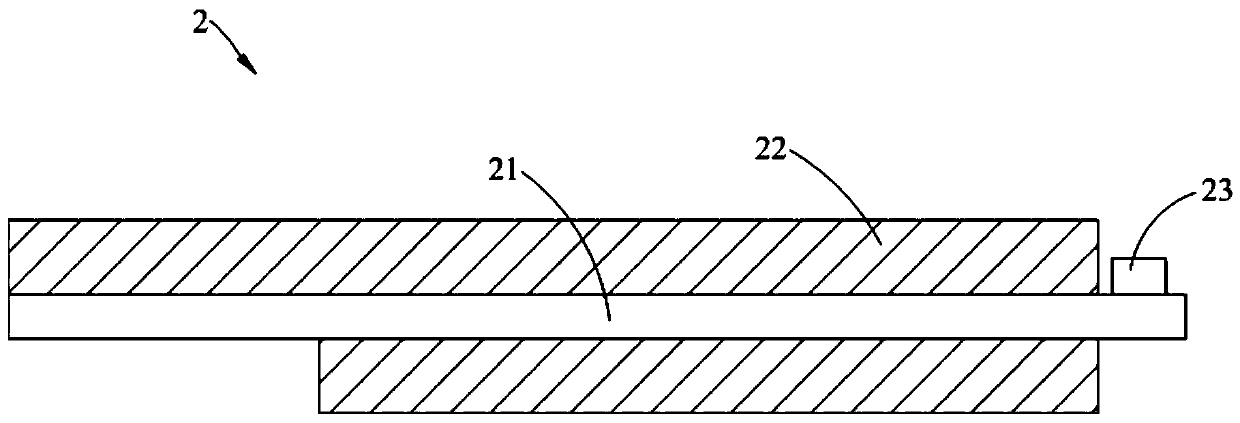

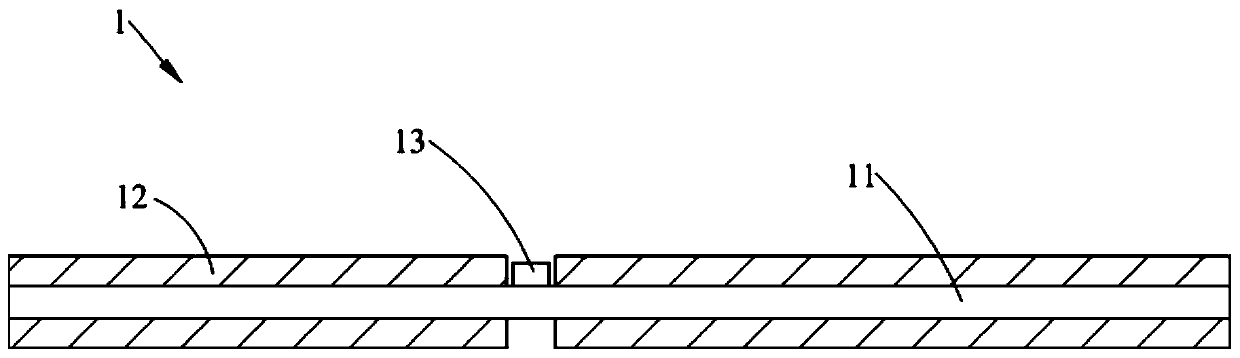

[0042] Such as Figure 1-2As shown, the negative electrode coating 22 of the battery provided by Embodiment 1 of the present invention includes a negative electrode active material, a negative electrode conductive agent, a suspending agent and a negative electrode binder. The negative electrode active material includes artificial graphite particles and is coated on artificial graphite particles. A layer of hard carbon material outside graphite particles. Artificial graphite using amorphous carbon materials in N 2 Obtained by high temperature graphitization (>2500°C) in the atmosphere. Hard carbon material is pyrolytic carbon formed after thermal decomposition of high molecular polymer, which is difficult to graphitize. It has good electrical conductivity, which is helpful for reducing the internal resistance of lithium-ion batteries and improving cycle performance, and can prevent the solvent molecules of the electrolyte from intercalating. into the graphite structure layer ...

Embodiment 2

[0114] The battery negative electrode coating 22, the battery negative electrode sheet 2, the manufacturing method of the battery negative electrode sheet 2, and the lithium-ion battery provided in this embodiment are mainly different from the first embodiment in that the positive electrode active material is different, and the details are as follows:

[0115] In this embodiment, the positive active material includes the ternary material LiNi x mn y co z o 2 Particles, doped in the ternary material LiNi x mn y co z o 2 The doping elements in the particles and the ternary material LiNi coated in the x mn y co z o 2 The coating layer outside the particle, wherein, 0.5≤x≤0.8, 0.1≤y≤0.3, 0.1≤z≤0.3, x+y+z=1.0;

[0116] The doping element includes at least one of Al and F;

[0117] The cladding layer includes MgO, Al 2 o 3 , ZrO 2 、TiO 2 , AlPO 4 , AlF 3 , LiAlO 2 , LiTiO 2 at least one of the

[0118] The battery anode coating 12 provided in this embodiment adop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com