Light source-side polarizing plate for liquid crystal display device, and liquid crystal display device comprising same

A technology of liquid crystal display device and polarizing plate, which can be used in polarizing elements, optics, optical elements, etc., and can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

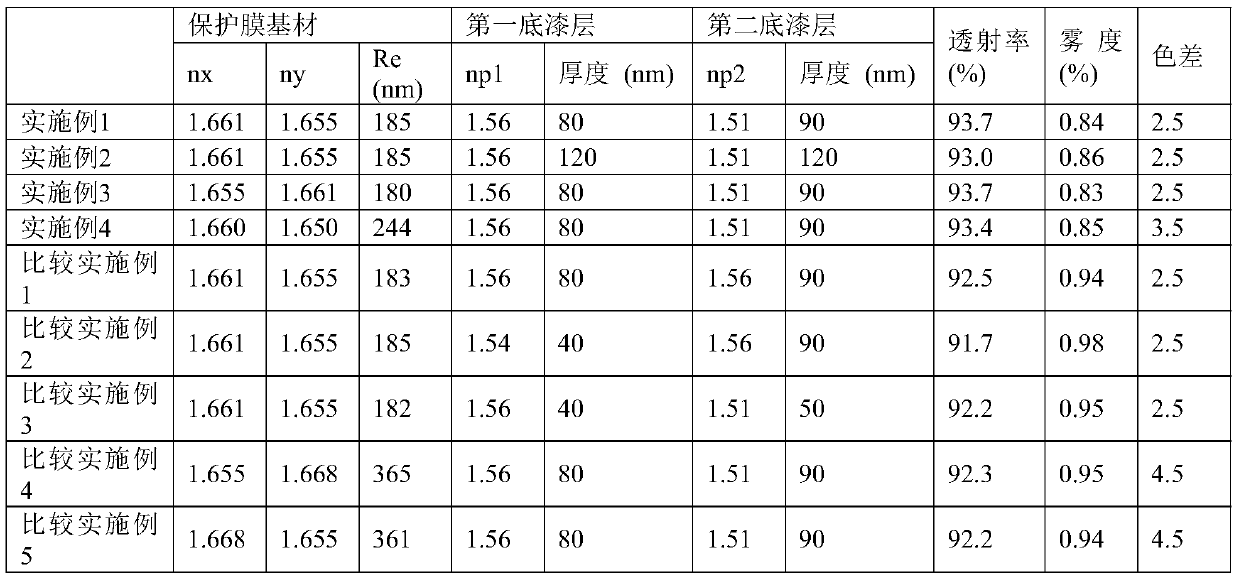

[0082]A polarizer was prepared by stretching a polyvinyl alcohol film (VF-PS6000, Kuraray Co., Ltd., thickness: 60 μm) to 3 times its original length at 60 °C, dyed the stretched film with iodine, and The dyed film was stretched to 2.5 times the length of the stretched film in a boric acid solution at °C to prepare a polarizing plate.

[0083] A film prepared by melt extrusion of polyethylene terephthalate (PET) resin was stretched in MD to 3 times its original length while mechanically moving the film in MD, and then the film was stretched in MD to three times its original length to prepare a polyethylene terephthalate film. At a wavelength of 550 nm, the thickness of the polyethylene terephthalate film was 40 μm, Re according to Formula 3 was 185 nm, Rth according to Formula 4 was 6,800 nm, and NZ according to Formula 5 was 19. The prepared polyethylene terephthalate film was used as a base material of the first protective film. Re, NZ and Rth were measured at a wavelength...

Embodiment 2 to 4

[0087] A polarizing plate was prepared by the same method as in Example 1, except that the refractive index and retardation of the polyethylene terephthalate film were changed as listed in Table 1, and the first primer layer and the second The refractive index or thickness of the primer layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Delay | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com