Temperature-regulation liner and preparation method and application thereof

A pad and temperature-regulating technology, applied in the field of temperature-regulating pads, can solve the problems of increasing the risk of injury, cumbersome use, and reducing the thermal comfort of the head, so as to maintain the comfort of the head, improve thermal comfort, and maintain time lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

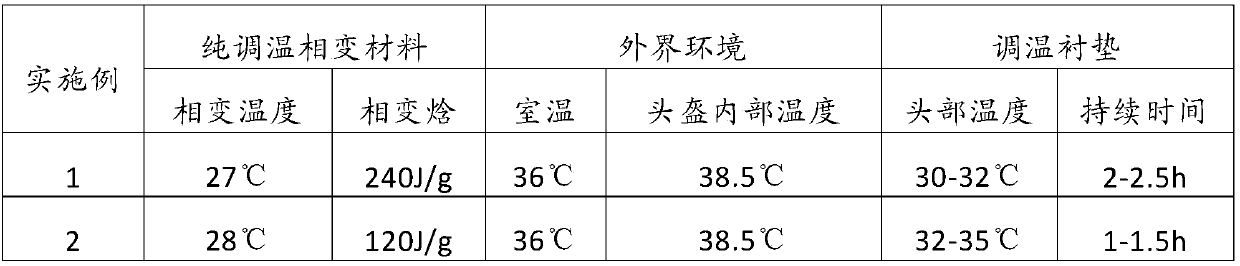

Embodiment 1

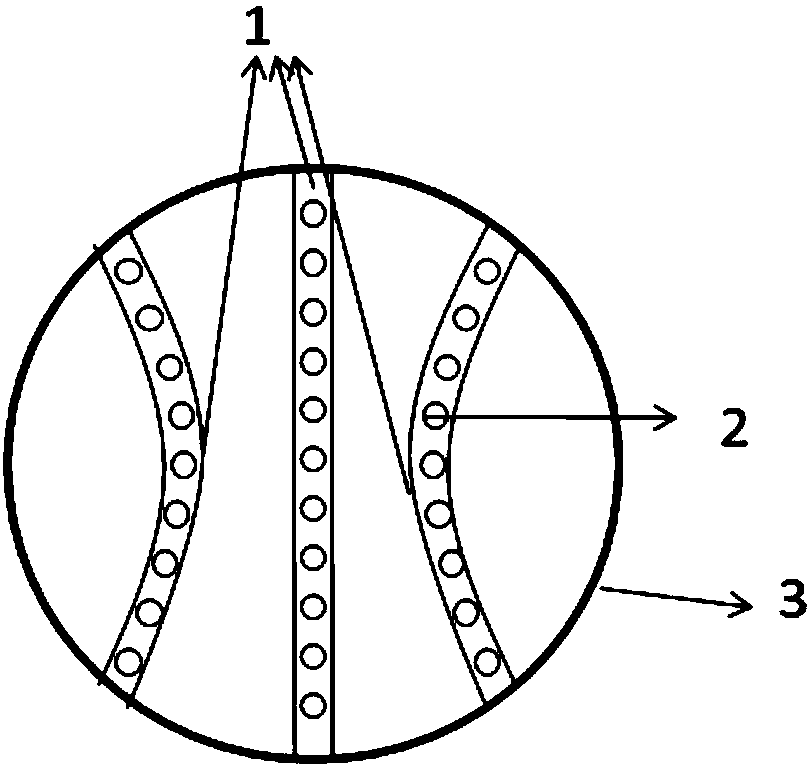

[0041] Lay the periphery of the upper and lower PVC composite fabrics, the straight line passing through the center of the circle, and the symmetrical curve together through high-frequency hot pressing (reserve a channel for phase change material filling); open a 30-degree gap in the inner hot-pressing compound gap of the circular temperature-regulating liner. vent holes;

[0042] Phase-change temperature-regulating material preparation: use 200 parts of sodium sulfate inorganic salt as a phase-change material, add 120 parts of water, stir at a speed of 40r / min for 60 minutes, then add 2 parts of glycerin, 2 parts of borax, 1 part of gelatin and 0.2 parts of chlorine NaCl, continue to stir at a speed of 40r / min until uniform and form a mixed solution. Heat the mixed solution to 80°C, let it basically melt, and set aside.

[0043] Pour the heat-absorbed mixed solution into the circular gasket with a reserved channel through a small funnel, and seal it with a high-frequency hea...

Embodiment 2

[0046] Laminate the periphery of the upper and lower PVC composite fabrics, the straight line passing through the center of the circle, and the symmetrical curve through high-frequency heat pressing (reserve a channel for phase change material filling); open a 20-degree gap in the inner heat-pressing compound gap of the circular temperature-regulating liner. vent holes;

[0047] Preparation of phase-change temperature-regulating materials: 150 parts of organic microcapsule phase-change materials were used as phase-change materials, 100 parts of ethanol was added, stirred at a speed of 50 r / min for 50 minutes, and then 1 part of glycerin, 1 part of borax and Li 2 B 4 o 7 10H 2 O (weight ratio is 1:1), 1 part of sodium polyacrylate and 0.1 part of sodium chloride, continue to stir at a speed of 60r / min until uniform, forming a mixed solution. Heat the mixed solution to 80°C, let it basically melt, and set aside.

[0048] Pour the heat-absorbed mixed solution into the circula...

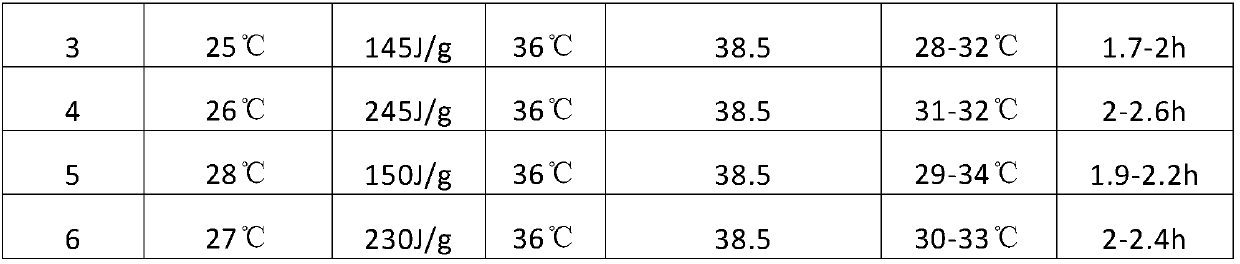

Embodiment 3

[0051] Combine the upper and lower PVC composite fabrics in a circle, the straight line passing through the center of the circle, and the symmetrical curve together by high-frequency hot pressing (reserve a channel for phase change material filling); open a 40-degree gap in the inner hot-pressing compound gap of the circular temperature-regulating liner. vent holes;

[0052] Phase-change temperature-regulating material preparation: 250 parts of inorganic microcapsule phase-change materials were used as phase-change materials, 150 parts of ethanol was added, stirred at a speed of 60 r / min for 30 minutes, and then 5 parts of glycerin and sodium silicate (weight ratio of 1: 1), 5 parts of borax, 3 parts of gelatin and polyacrylamide (1:1 by weight) and 0.5 parts of sodium chloride, continue to stir at a speed of 50r / min until uniform, forming a mixed solution. Heat the mixed solution to 80°C, let it basically melt, and set aside.

[0053] Pour the heat-absorbed mixed solution in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com