A kind of collagen tripeptide and its production method and application

A collagen and production method technology, applied in the field of collagen tripeptide, can solve the problems of low enzymatic hydrolysis efficiency, complicated operation, acid and alkali resistance, etc., and achieve low free amino acid content, simplified process steps, and not easy to absorb moisture and agglomerate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

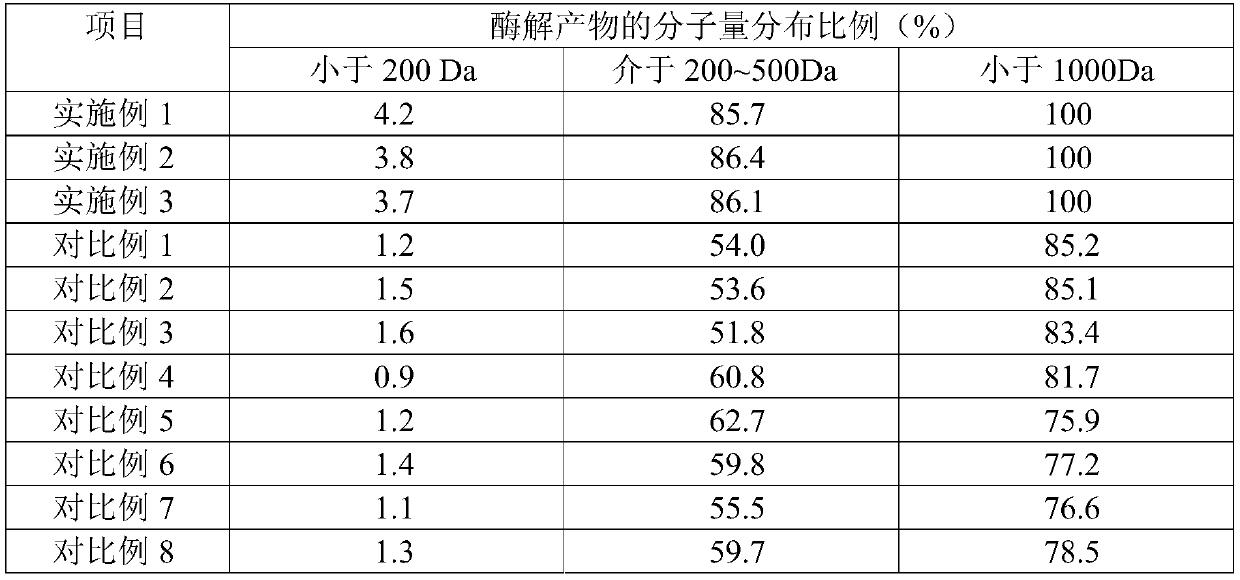

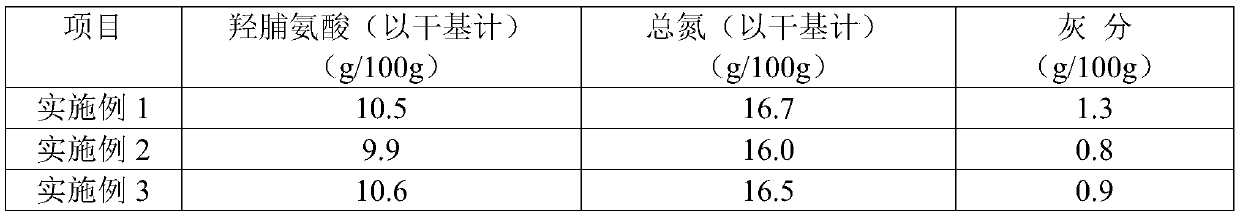

Examples

Embodiment 1

[0045] (1) Raw material pre-treatment: put marine fish (large yellow croaker) scales into the reaction kettle, add an alkali solution (sodium hydroxide solution, the same below) twice the weight of fish scales, stir and wash for 12 hours, to remove the fat and Wash other impurities with water, then add an acid solution (hydrochloric acid solution, the same below) twice the weight of fish scales, stir and wash for 12 hours, then wash with deionized water, add water 3 times the weight of fish scales and grind to prepare a crude collagen solution. Wherein, the mass volume concentration of the alkali solution is 4%, and the mass volume concentration of the acid solution is 3%.

[0046] (2) Heat treatment: heat the crude collagen solution in hot water at 100° C. for 30 minutes, and then lower the temperature to 50-55° C. to obtain a denatured collagen solution.

[0047] (3) Enzymolysis: Add 0.1% (w / w) high-efficiency compound enzyme preparation of raw material weight to the denatur...

Embodiment 2

[0053] (1) Raw material pre-treatment: put freshwater fish (grass carp) scales into the reaction kettle, add an alkali solution 10 times the weight of the scales, stir and wash for 1 hour to remove the fat and other impurities of the scales, wash them with water, and then add the scales 10 times the weight of the acid solution, stirred and washed for 1 hour, then washed with deionized water, added with water 4 times the weight of fish scales and ground to prepare a crude collagen solution. Wherein, the mass volume concentration of the alkali solution is 1%, and the mass volume concentration of the acid solution is 8%.

[0054] (2) Heat treatment: heat the crude collagen solution in hot water at 100°C for 30 minutes, then cool down to 50-55°C to obtain a denatured collagen solution;

[0055] (3) Enzymolysis: Add 0.1% (w / w) high-efficiency compound enzyme preparation of raw material weight to the denatured collagen solution, mix evenly, and enzymolyze for 1 hour to prepare a col...

Embodiment 3

[0061] (1) Raw material pre-treatment: Put freshwater fish (crucian carp) fish scales into the reaction kettle, add an alkali solution 6 times the weight of the fish scales, stir and wash for 6 hours to remove the fat and other impurities of the fish scales, wash them with water, and then add the fish scales Acid solution 6 times the weight was stirred and washed for 6 hours, then washed with deionized water, added with water 5 times the weight of fish scales and ground to prepare a crude collagen solution. Wherein, the mass volume concentration of the alkali solution is 2%, and the mass volume concentration of the acid solution is 5%.

[0062] (2) Heat treatment: heat the crude collagen solution in hot water at 100°C for 30 minutes, then cool down to 50-55°C to obtain a denatured collagen solution;

[0063] (3) Enzymolysis: Add 0.1% (w / w) high-efficiency compound enzyme preparation of raw material weight to the denatured collagen solution, mix evenly, and enzymolyze for 1 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com