Novel automatically-degradable material of meal boxes and preparation method of novel automatically-degradable material of meal boxes

An automatic degradation and new material technology, applied in the field of environmental protection materials, can solve the problems of expensive equipment, not easy to obtain, and immature full degradation technology, and achieve the effect of protecting the ecological environment, reducing the use, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

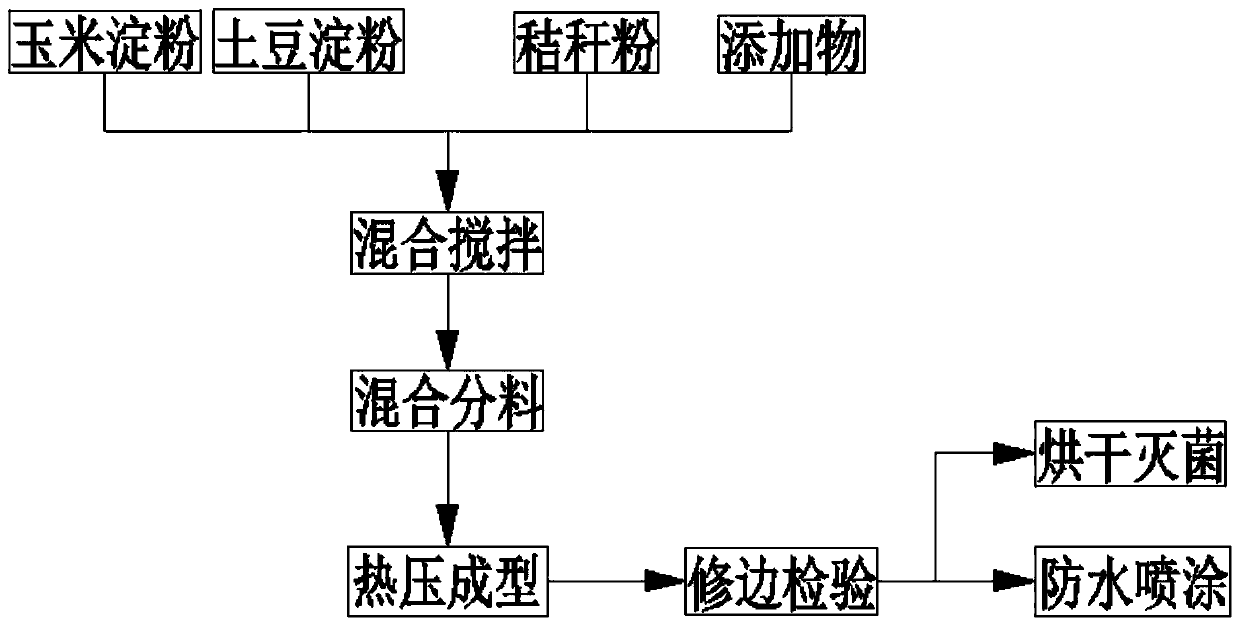

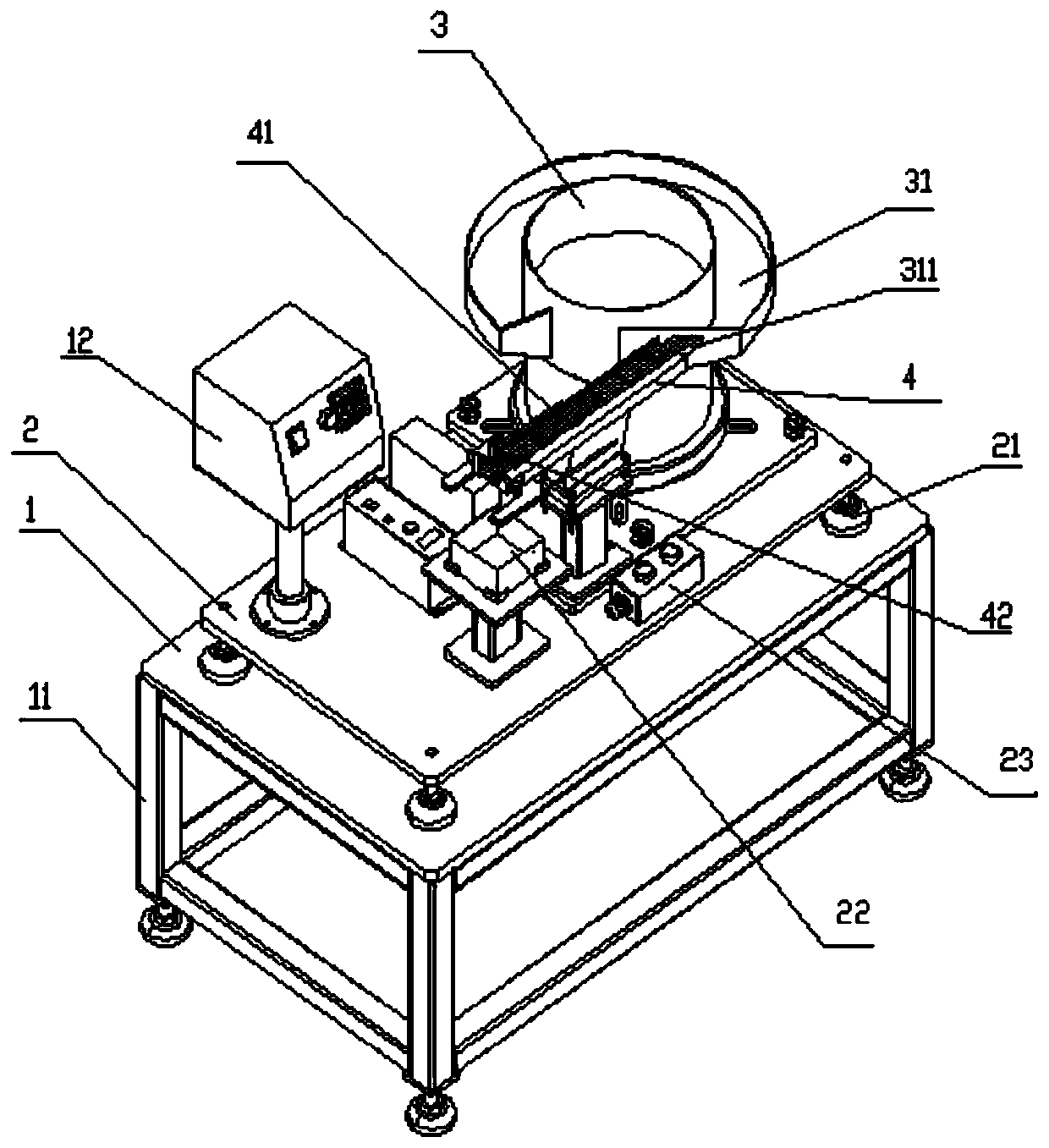

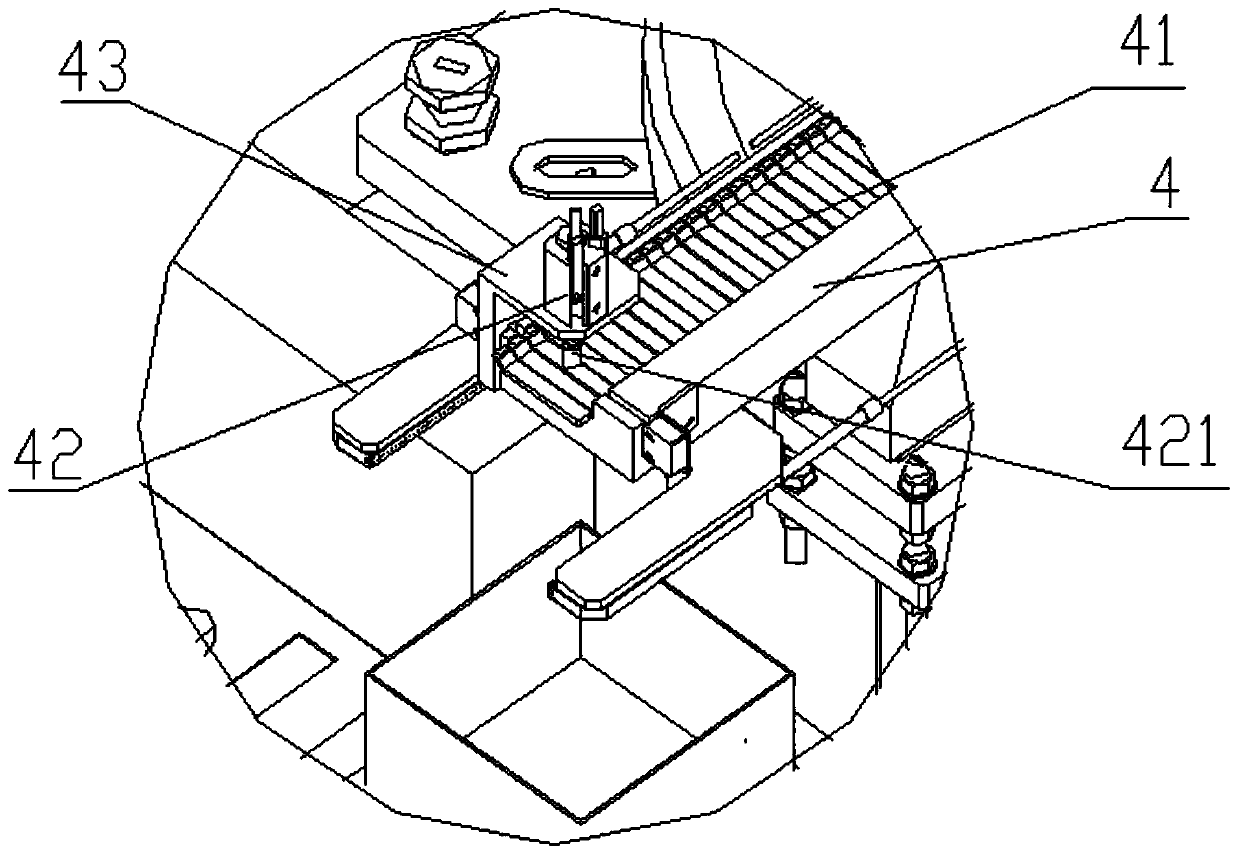

[0041] A new material for lunch boxes that can be automatically degraded, such as Figure 1-Figure 4 It consists of the following parts by weight, 60 parts of corn starch, 10 parts of potato starch, 20 parts of straw powder, 2 parts of fusion agent, 15 parts of polyglycolic fat, 15 parts of polylactic acid, and 10 parts of additives; the preparation method of the new material includes The following steps:

[0042] Step 1. Raw materials are mixed and stirred:

[0043] S1. Grind cornstarch and potato starch on a ball mill. The ground cornstarch and potato starch are vibrated and screened on a 200-mesh vibrating sieve respectively. The cornstarch and potato starch that have not passed the screening continue to be ground and screened again, and so on; The powder is ground on a ball mill, and the ground straw powder is vibrated and screened on a 100-mesh vibrating sieve, and the straw powder that has not passed the screen continues to be ground and screened, and this is repeated; ...

Embodiment 2

[0062] A new material for a lunch box that can be automatically degraded, consisting of the following parts by weight: 55 parts of corn starch, 8 parts of potato starch, 15 parts of straw powder, 1 part of fusion agent, 10 parts of polyethylene glycol fat, 10 parts of polylactic acid, and 5 parts of additives ; The preparation method of this automatically degradable lunch box new material is as in Example 1.

Embodiment 3

[0064] A new self-degradable lunch box material, which consists of the following parts by weight: 60 parts of corn starch, 5 parts of potato starch, 10 parts of straw powder, 1.5 parts of fusion agent, 10 parts of polyethylene glycol fat, 15 parts of polylactic acid, and 10 parts of additives ; The preparation method of this automatically degradable lunch box new material is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com