Preparation method of environmental-friendly rubber asphalt

An environmentally friendly rubber and rubber asphalt technology, used in building thermal insulation materials, building components, buildings, etc., can solve problems such as environmental protection, achieve excellent cost performance, good durability, and improve rutting resistance and construction stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention discloses a preparation method for producing environmentally friendly rubber asphalt, comprising: 70-100 parts of 90# petroleum asphalt, 20-40 parts of rubber powder, and 0.2-5 parts of deodorant. First, heat and melt the petroleum asphalt at 180°C, add deodorant, and stir for 0.5h through high-speed shearing (shear rate: 2000-4500r / min). After shearing for 40 minutes, the volatilized alkanes, mercaptans, olefins and other gases are recovered through condensation treatment to obtain environmentally friendly rubber asphalt.

[0021] Further, the petroleum asphalt is a conventional product, which can be purchased from the market.

[0022] Further, the rubber powder is any one or two in any ratio of ground automobile tires, rubber products, etc.

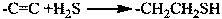

[0023] Further, the deodorant is a mixture of one or more of zinc ricinoleate, ricinoleate, long-chain acids containing -C=C groups, and organic acid soap compounds in any proportion;

[0024] Further, the specifi...

Embodiment 1

[0026] 1#: Take 100 parts of road 90# petroleum asphalt and 40 parts of rubber powder. First, heat and melt the petroleum asphalt at 180°C, then add rubber powder, shear at a high speed of 4500r / min, stir for 0.5h, and then mix it with 5000r / min speed shearing at high speed for 40min, volatilized alkanes, mercaptans, olefins and other gases are recovered through condensation treatment to obtain environmentally friendly rubber asphalt. Invert the sample and test various indicators of environmentally friendly rubber asphalt;

Embodiment 2

[0028] 2#: Take 100 parts of road 90# petroleum asphalt, 40 parts of rubber powder, and 0.2 parts of deodorant, heat and melt the petroleum asphalt at 185°C, add deodorant, and shear at 4500r / min at high speed, stir for 0.5h, and mix well Finally, add rubber powder and shear at a high speed of 5000r / min for 40 minutes. The volatilized alkanes, mercaptans, olefins and other gases are recovered through condensation treatment to obtain environmentally friendly rubber asphalt. Invert the sample and test various indicators of environmentally friendly rubber asphalt;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com