Underwater gravel base bed laying method

A laying method and foundation bed technology, applied to underwater structures, water conservancy projects, infrastructure projects, etc., can solve the problems of correcting riprap pipes, slow positioning speed, and difficult control of leveling accuracy, so as to ensure accuracy and facilitate Migration, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

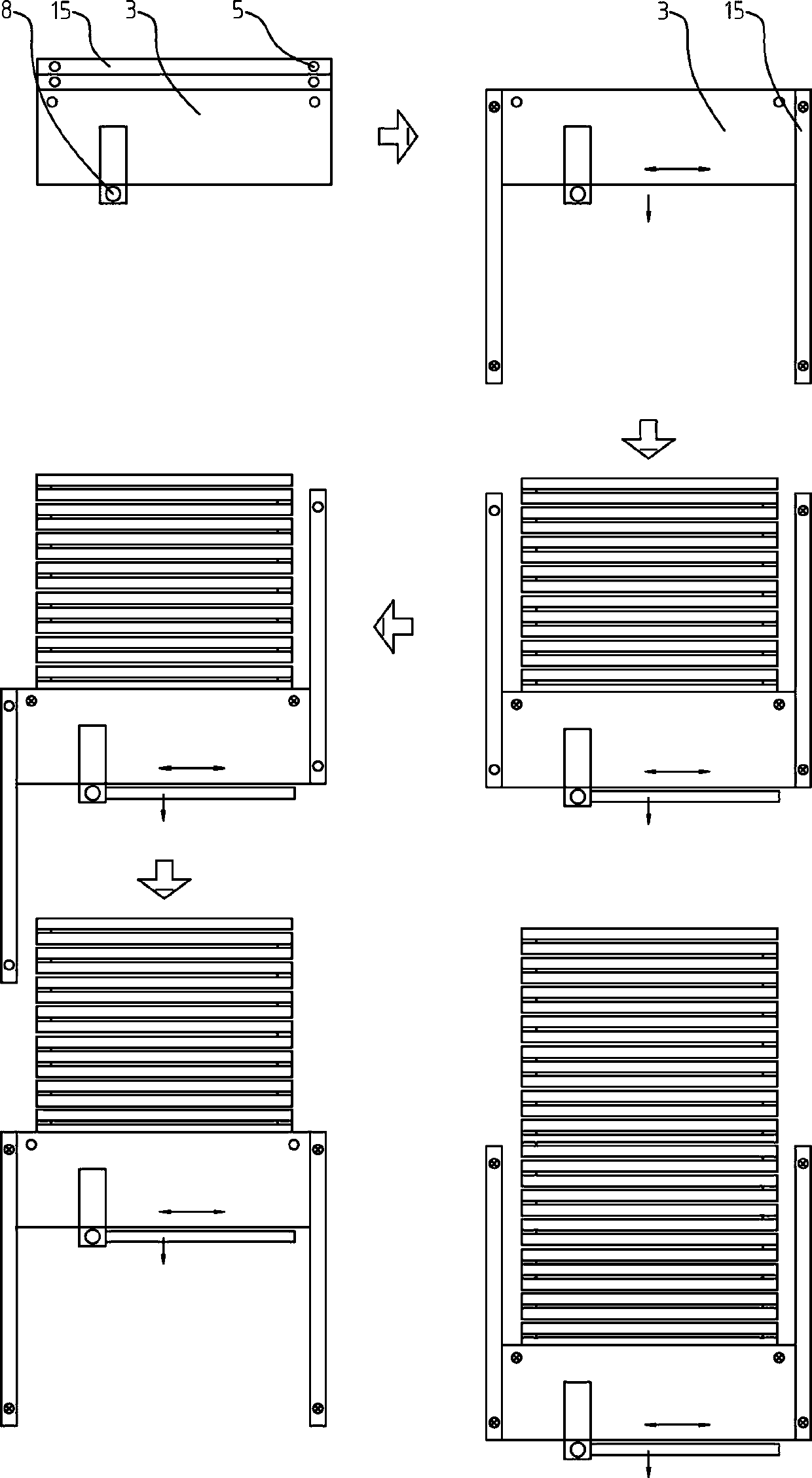

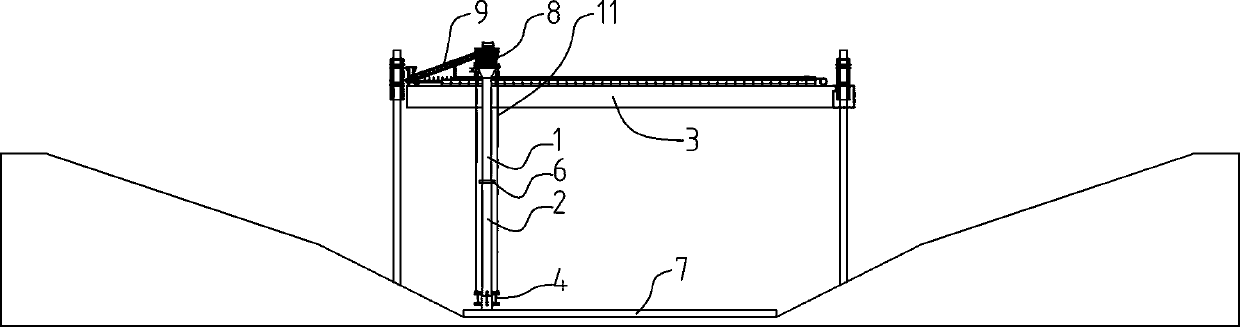

[0063] Such as Figure 2~4 Among them, a method for laying an underwater crushed stone bed, comprising the following steps:

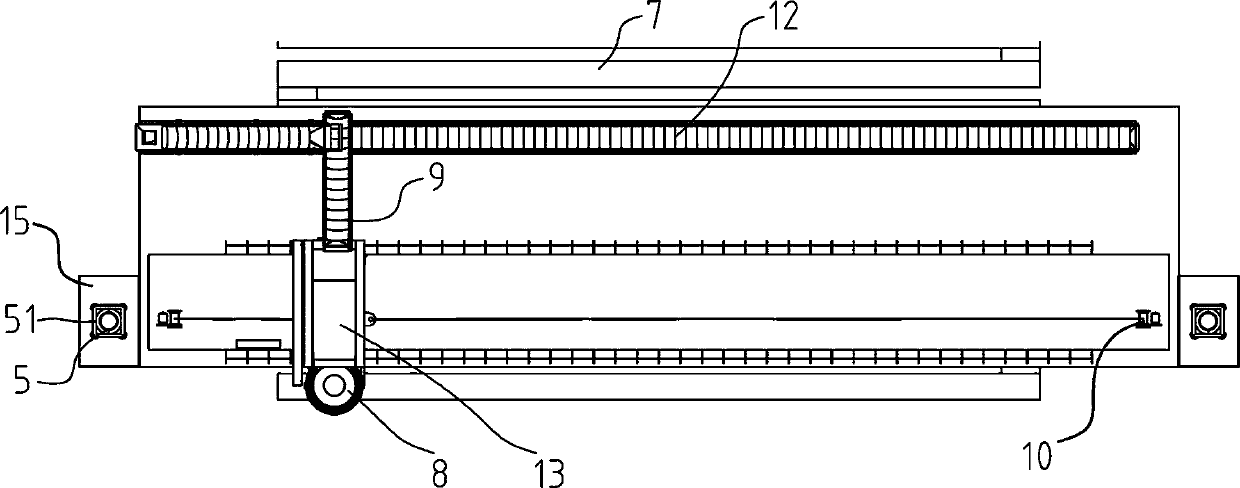

[0064] S1, the hull 3 is provided with a transport trolley 13, the transport trolley 13 is driven by the driving device to slide along the length direction of the hull 3, the transport trolley 13 is provided with a slide pipe, the top of the slide pipe is provided with a feeding port 8, and the slide pipe The bottom is close to the bottom of the water; there is also at least one conveyor belt for feeding the trolley 13;

[0065] S2. The hull moves to the design position through the winch, and uses GPS or Beidou system to locate the position of the chute on the horizontal plane;

[0066] S3, by adjusting the lifting of the chute, control the elevation position of the discharge port at the bottom of the chute;

[0067] S4, the bottom of the chute is provided with a discharge opening adjustment device 4, and an inclination adjustment oil cylinder 42 is a...

Embodiment 2

[0072] On the basis of Example 1, the preferred scheme is as figure 2 In step S1, a liftable positioning pile 5 is provided at the bow and stern of the hull 3, and the positioning pile 5 is slidably connected with the hull 3;

[0073] In step S2, the positioning pile 5 is driven into the bottom of the water;

[0074] In step S6, after the construction of one row of crushed stone bed 7 is completed, the hull 3 moves to the position of the next row through the guidance of the positioning pile 5, and then the construction of the crushed stone foundation bed is carried out; relatively sliding.

[0075] After the hull 3 reaches the sliding limit position, the hull 3 is fixed, the spuds 5 are pulled out, and the spuds 5 are slid back to the initial position;

[0076] The continuous laying construction of the underwater crushed stone bed is realized through the above steps. According to this scheme, the winch 10 drives the transport trolley 13 to reciprocate to complete the ripra...

Embodiment 3

[0078] On the basis of Example 2, the preferred scheme is as figure 1 , 5 In ~7, in step S1, the positioning pile 5 is arranged on the floating tank slide rail 15, and at least two positioning pile locking devices 51 are arranged at the positions near the two ends of the floating tank sliding rail 15, and the positioning pile 5 can be lifted and lowered to be arranged on the positioning In the pile locking device 51; the cross section of the positioning pile locking device 51 is a circular structure, an opening is provided on the ring, and a hinged compression block is arranged at the position of the opening. One end of the locking cylinder is hinged with the compression block, and the other end Connected with the ring structure, the first chute 1 is loosened or compressed by the expansion and contraction of the piston rod of the locking cylinder. The construction method of lifting the positioning pile 5 and driving into the bottom of the water belongs to the technology commo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap