Device for executing thermoelectric power generation through memory metal

A technology of memory metal and thermoelectric power generation, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of no possibility of realization, no consideration of the implementation method of heating and cooling memory metal, and power consumption, etc., to achieve high plasticity and bending The effect of large amount and reduction of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

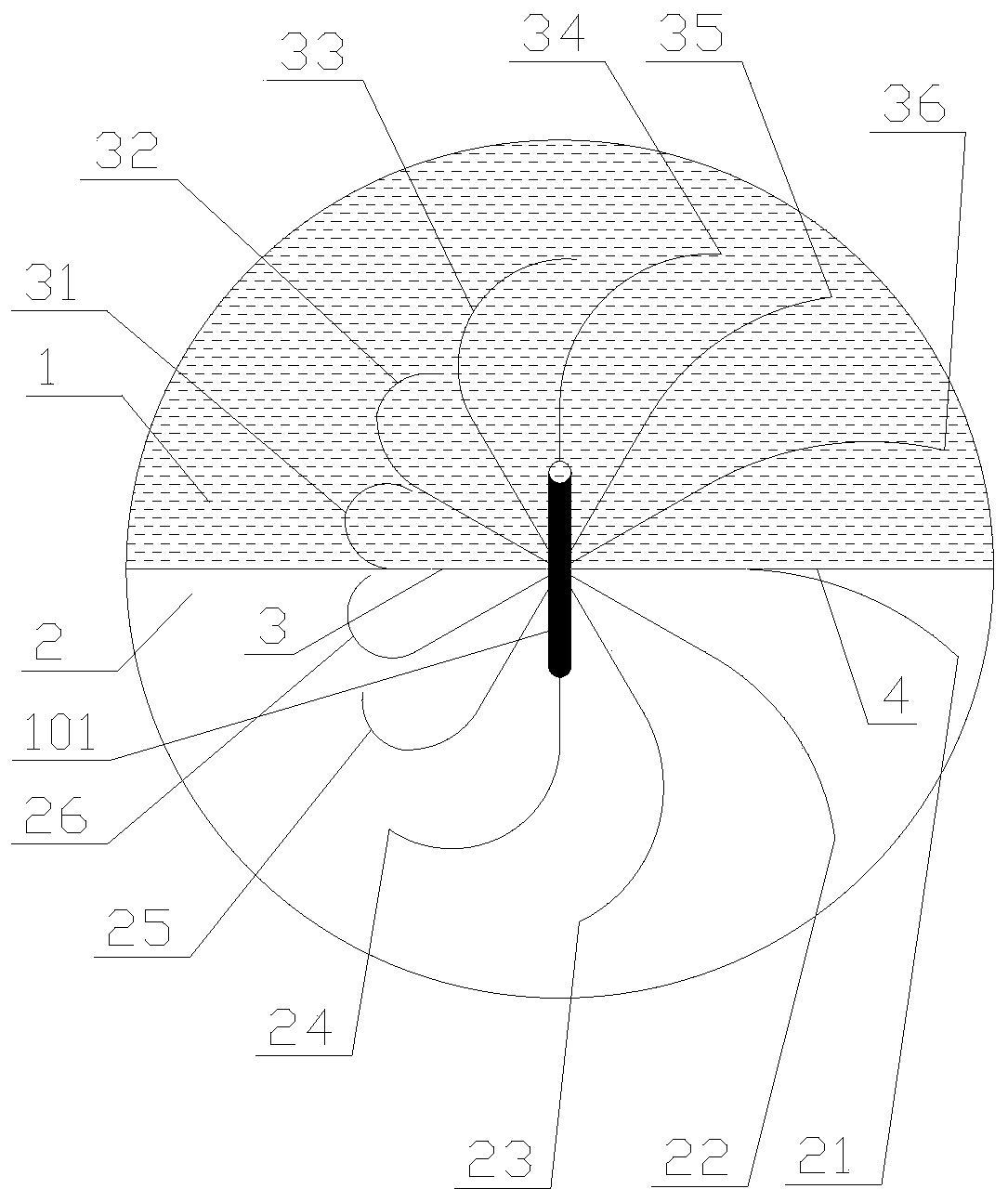

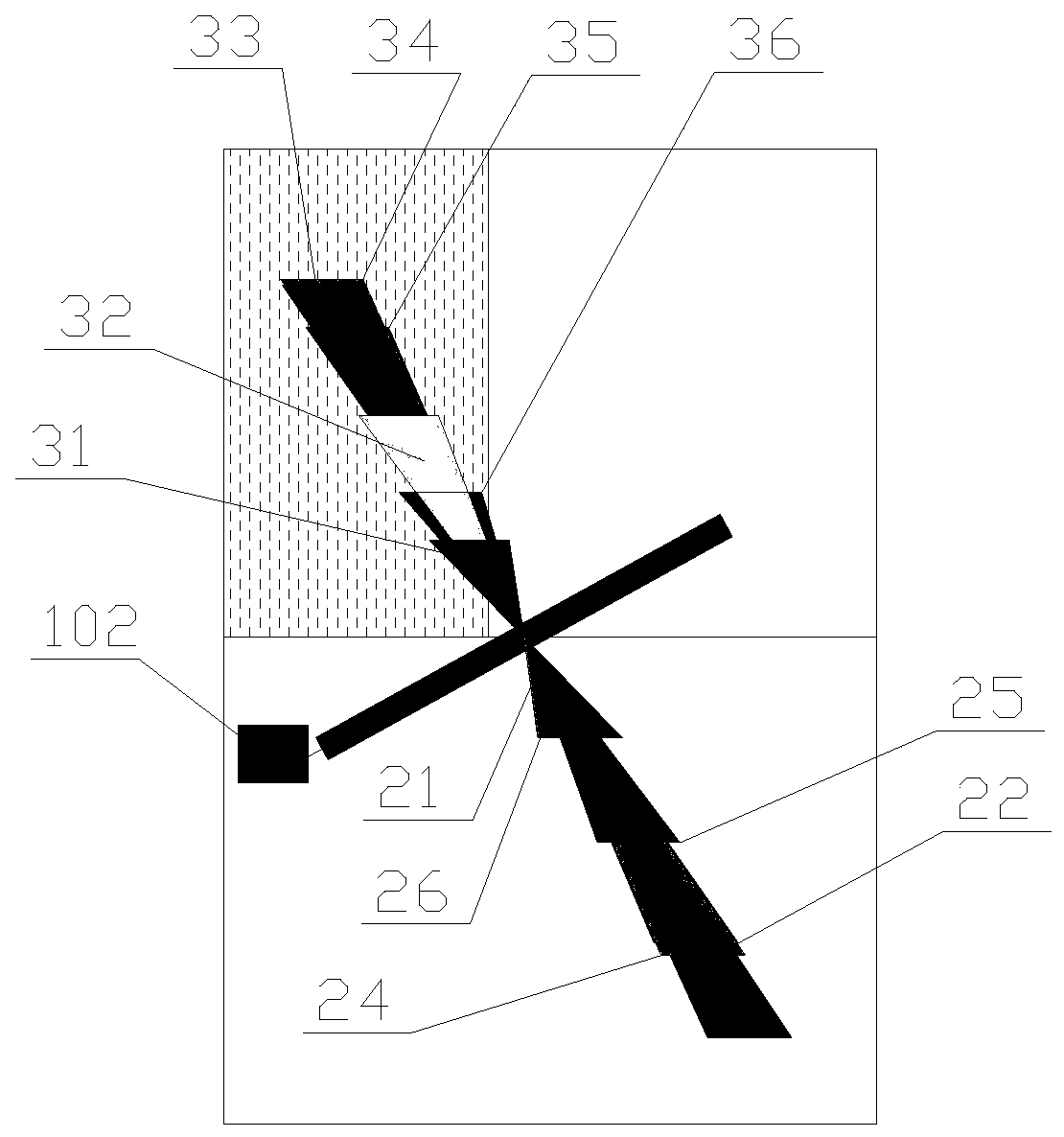

[0036] Such as figure 1 , figure 2 shown. At this time, the cooling source is gas such as cold air.

[0037]The blade made of memory metal has different deformations at high temperature and low temperature. The blade becomes contracted at low temperature and stretches at high temperature. The blade 26 in the shrinking state enters the hot water section 1 through the 3-elastic opening A, is heated by the hot water, and deforms into a memory stretching state, and its gradual stretching process is as blade 31, blade 32, blade 33, blade 34, blade 35, blade 36, During the process of stretching and deformation, the hot water produces a resistance much greater than that of the air, and the counteraction of this resistance relative to the blade becomes hydraulic force to push the blade to rotate around the central axis 101 . After turning to the state and position of the blade 36, continue to rotate to 4-the elastic opening B enters the cooling source area 2, the blade is cooled b...

Embodiment 2

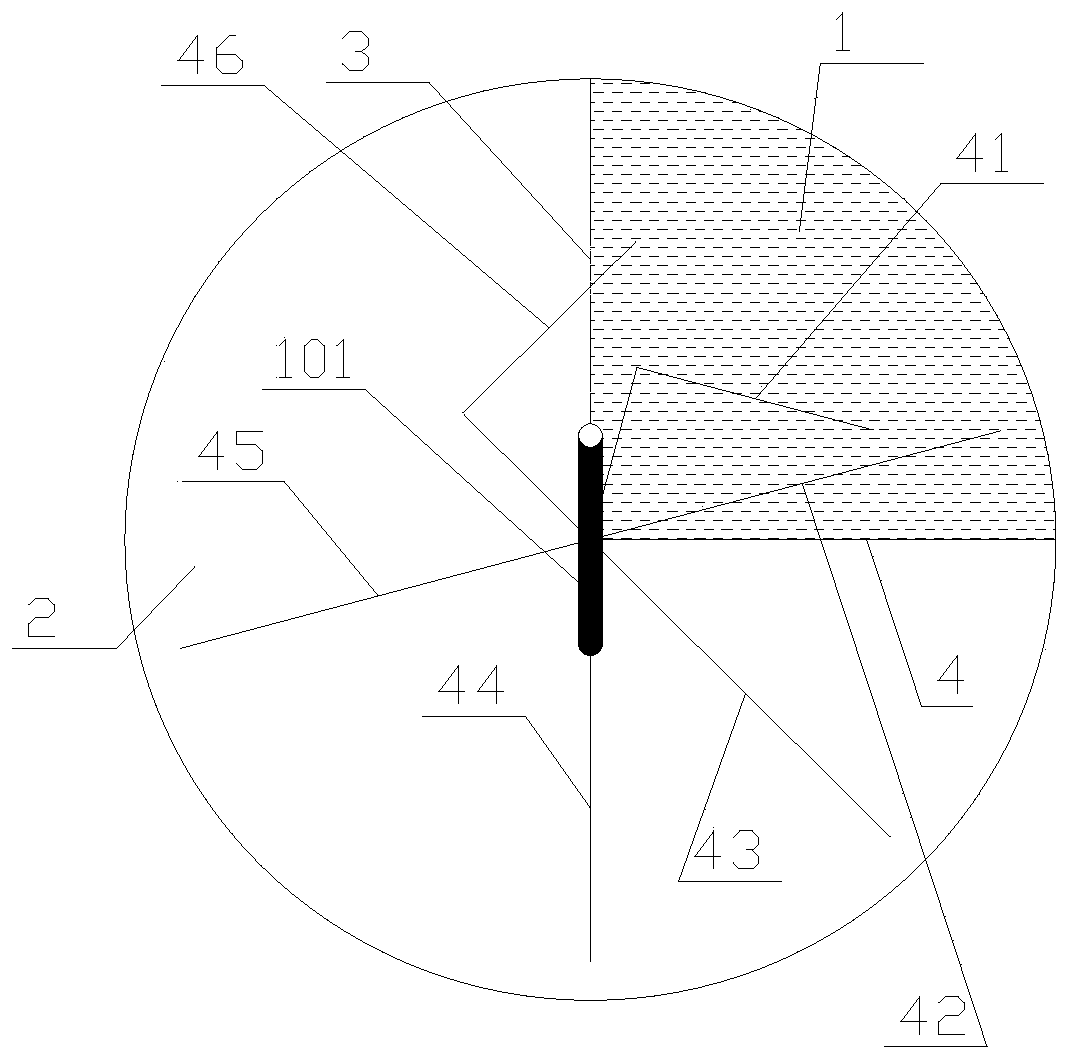

[0039] Such as image 3 shown. At this time, the cooling source is gas such as cold air.

[0040] Considering that the heat transfer coefficient between hot water and memory metal blades is much greater than that between gas and memory metal blades, the space occupied by the heat source is reduced, and the heat exchange area of cold air and the number of blades in cold air are increased. Proportion.

[0041] The deformation of the blade is bending and stretching, and the deformation process of the memory metal blade is short, so its force to push the hydraulic force is greater, and the power generation effect driven by the hydraulic reaction is better.

Embodiment 3

[0043] Such as Figure 4 , Figure 5 As shown, the cold source 2 is cold water or air, and the central axis is placed vertically.

[0044] The level change of the blade in the hot water heating process is the same as that in Embodiment 1 or Embodiment 2. The blade consists of two sections, including a fan-shaped shaft connected to the central axis and a deformable blade. Take one fan-shaped circumference 41 and blade 23 as an example for illustration. The fan-shaped shaft 41 can follow the rotation of the central shaft 101 and move up and down relatively. The support part at the lower part of the shaft is in rolling connection with the fan-shaped shaft at the upper part. When the blade 23 rotates to the interface between the cold and heat sources, it will move up and pass through the 3-elastic opening A and 4-elastic opening B away from the water surface to avoid mixing of cold and hot water. Or in hot water, cooling / heating deforms, and is driven by hydraulic power to gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com