Thermoelectric unit combined control method and system

A technology of combined control and thermal power unit, applied in general control systems, control/regulation systems, adaptive control, etc., can solve the problems of not significantly improved load rate, large pipe diameter, no quick opening function, etc., to eliminate The effect of dynamic energy imbalance and improving variable load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

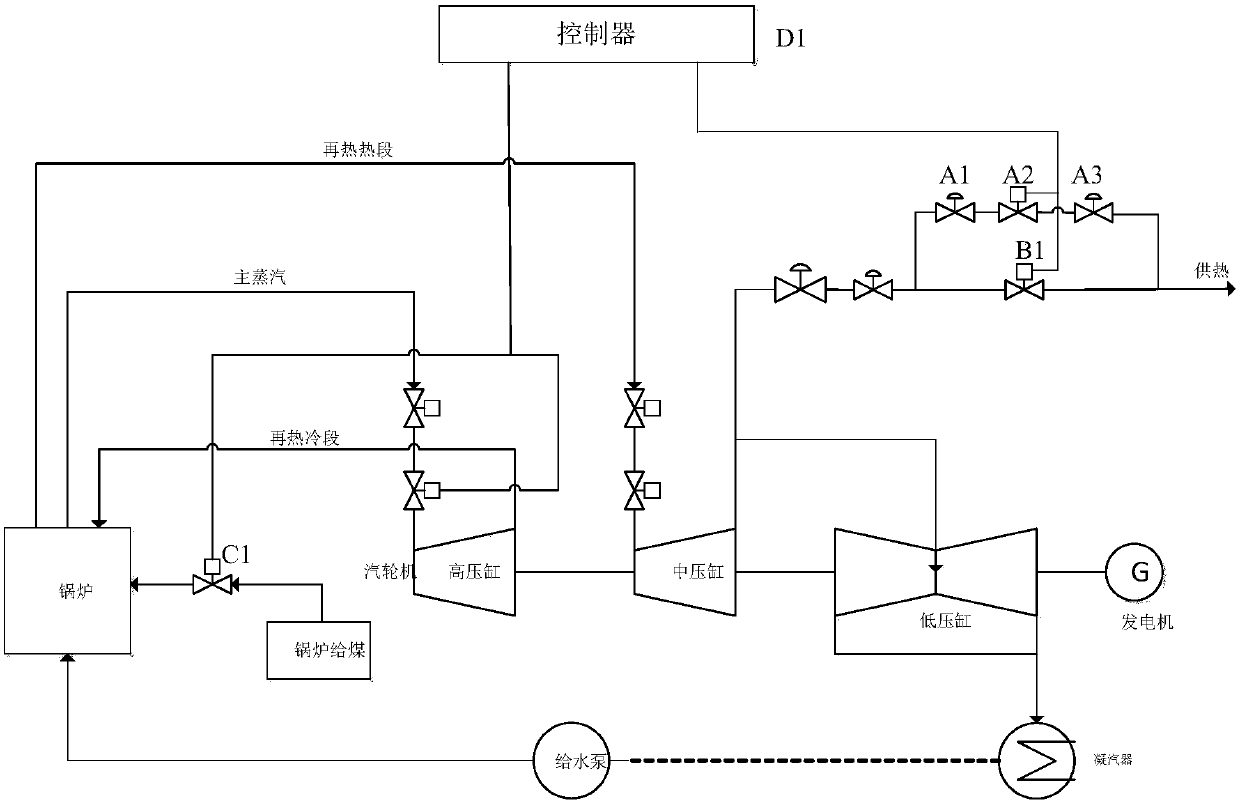

[0056] The core of the present invention is to disclose a combined control method and system of thermoelectric units to increase the load changing rate of thermoelectric units.

[0057] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

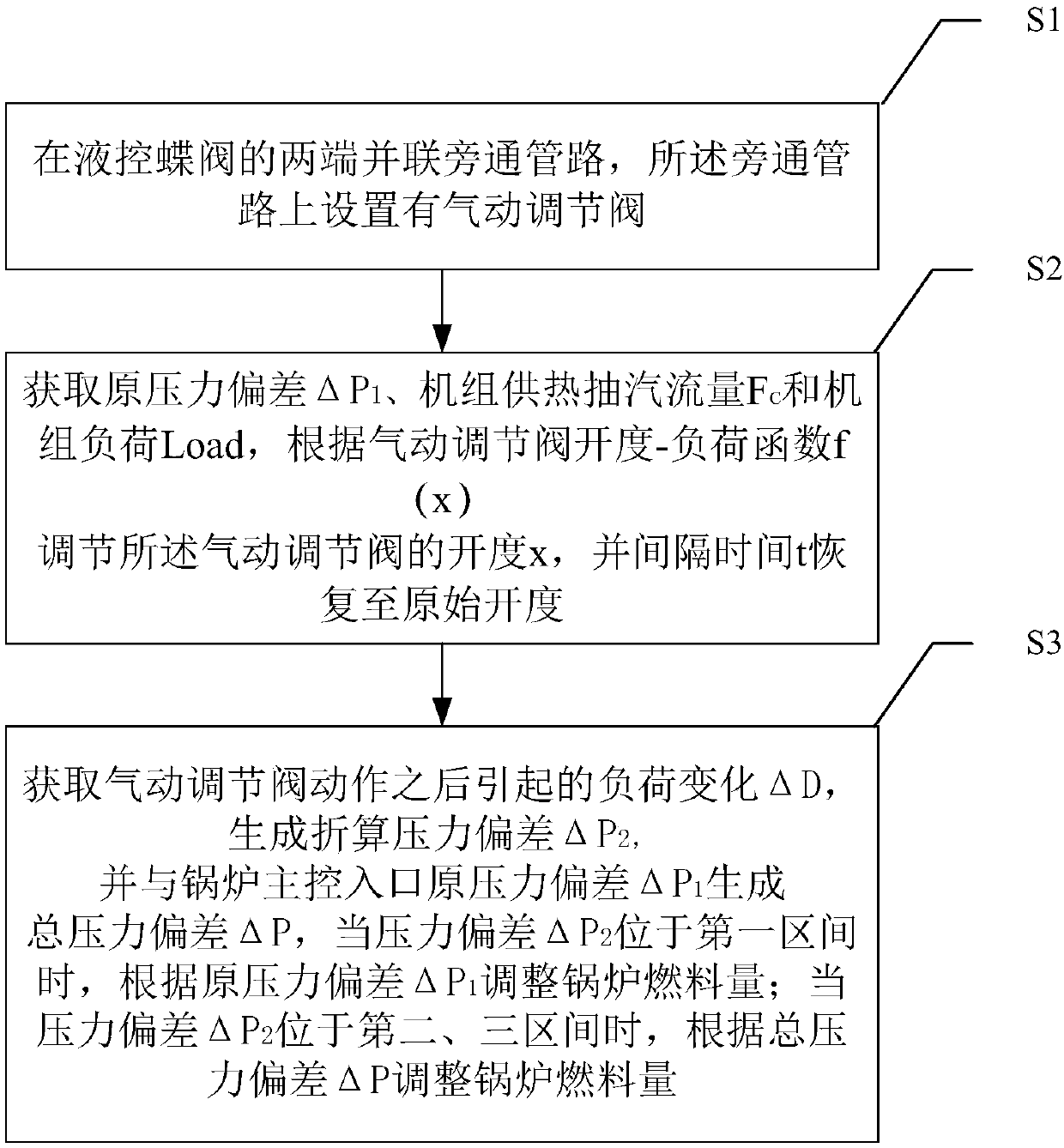

[0058] see figure 1 , the joint control method of the thermoelectric unit includes:

[0059] Step S1: Connect bypass pipelines in parallel at both ends of the hydraulic control butterfly valve, and the bypass pipeline is provided with a pneumatic regulating valve;

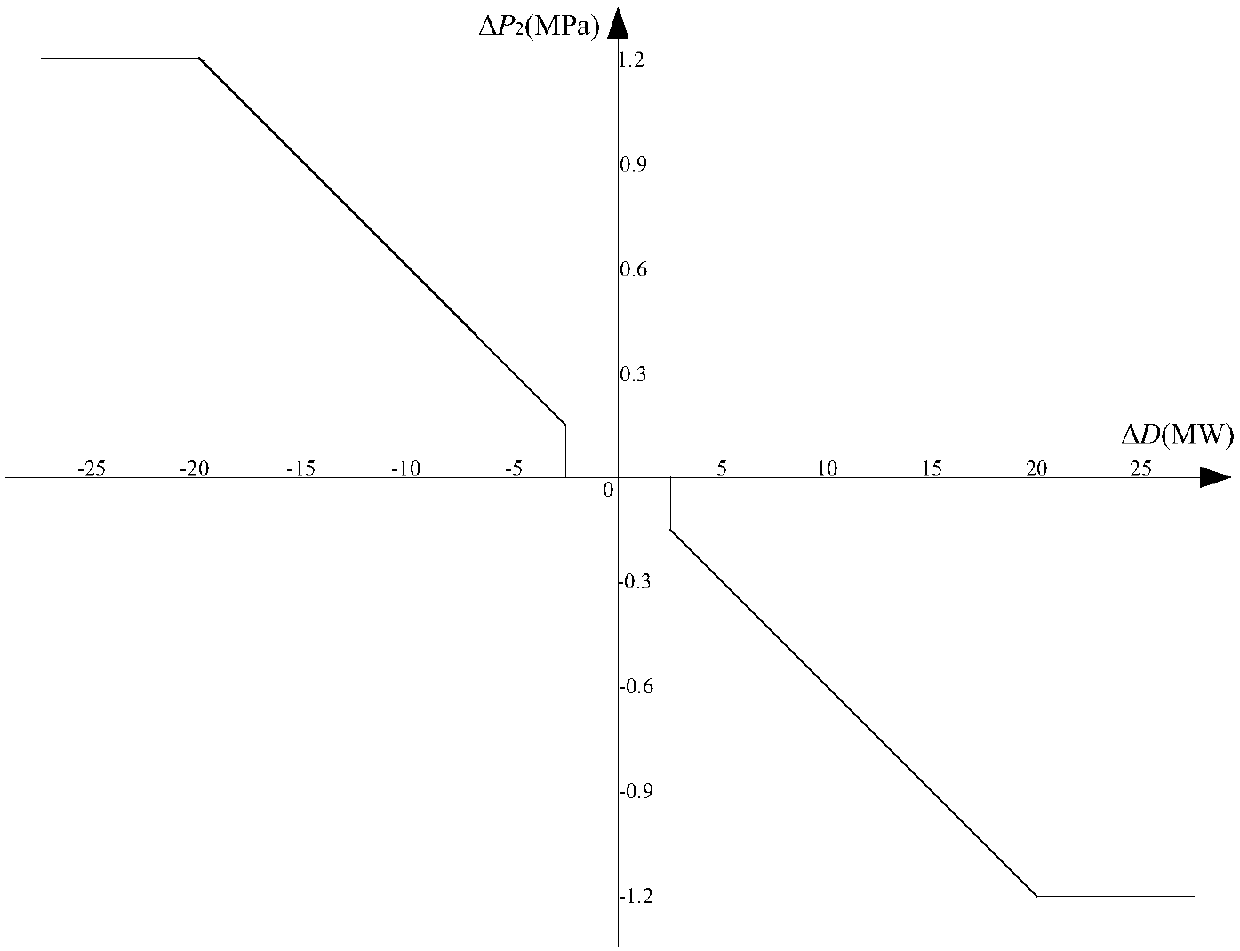

[0060] Step S2: Obtain the original pressure deviation ΔP 1 , Unit heating and extraction flow F c and unit load Load, adjust the opening x of the pneumatic regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com