Steam heat supply network energy storage auxiliary peak regulation control method and system, equipment and medium

A control method and technology of heating network, applied in control systems, lighting and heating equipment, steam generation, etc., can solve problems such as difficult to use effectively, waste of resources, and large steam energy storage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A steam heating network energy storage-assisted peak shaving control method, comprising the following steps:

[0050] Step 1) Obtain the operation data of the steam heating network;

[0051] Step 2) Based on the operation data of the steam heating network, the variation of the flow rate of heating and extracting steam is calculated;

[0052] Based on the variation of heating extraction steam flow, a nonlinear model of the heating extraction throttling system in the steam heating network is established, and the power increment estimate of the steam heating network is obtained based on the nonlinear model;

[0053] Step 3) Establishing a power increment generating loop based on the operating data of the steam heating network;

[0054] The specific method of the power increment generating loop is as follows: the power that the steam heating network can bear is obtained from the current safety limit of the steam heating network, which is recorded as the power increment, an...

Embodiment 2

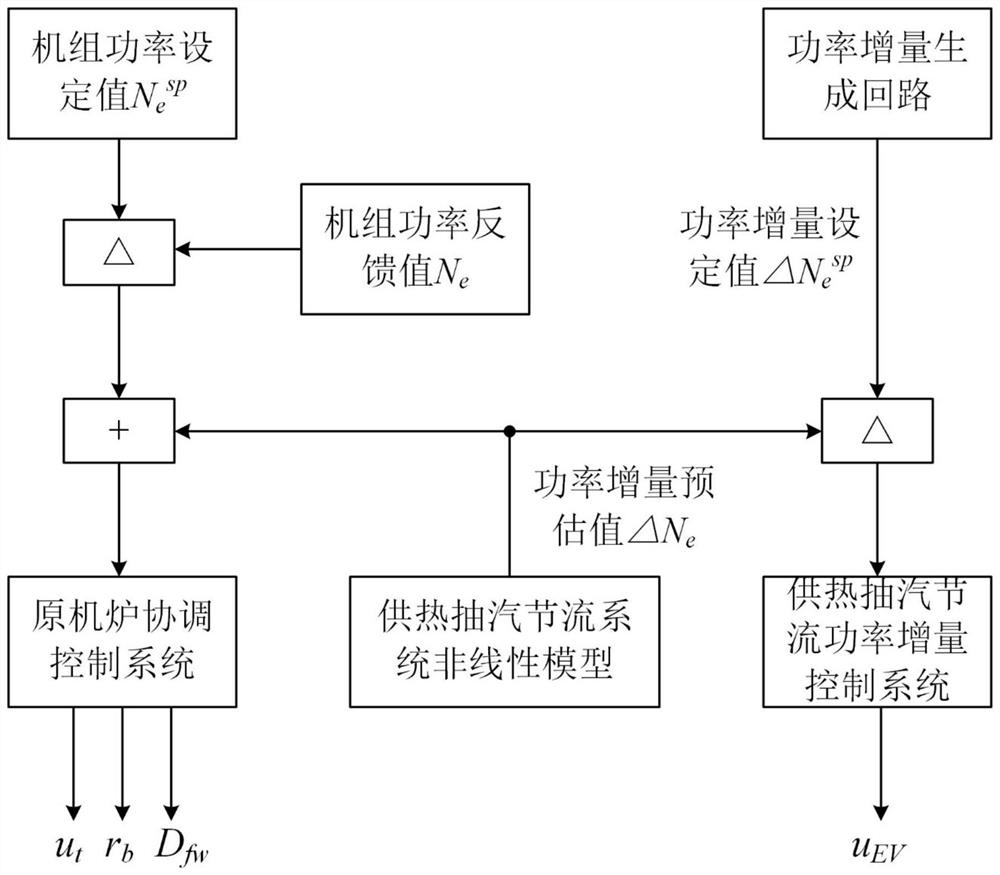

[0058] A steam heating network energy storage-assisted peak-shaving control method, the power control system of the unit is divided into two parts: the original machine furnace coordination control system and the power increment control system; the power increment control system makes the setting of the power increment through PID control The value is equal to the estimated value. In this system, the predicted value of the power increment is obtained by the nonlinear model of the heating extraction throttling system, and the difference between the set value of the power increment obtained by the power increment generation loop is used as the power increment The input value of the control system; the input value in the coordinated control system of the original furnace is the difference between the power difference and the power increment estimate;

[0059] The nonlinear model of the heat extraction throttling system is:

[0060] ΔN e =ΔG e ·(h j -h n ) (1)

[0061] In for...

Embodiment 3

[0074] Except for the following content, all the other contents are the same as in Example 1.

[0075] The regulation of step 4) is specifically:

[0076] Calculate the difference between the predicted value of the power increment and the set value of the power increment to obtain the difference of the power increment;

[0077] The power increment difference is used as the input variable of the power increment control system, and the power increment difference is made to be zero through the PID control method.

[0078] The regulation of step 5) is specifically:

[0079] The difference between the power feedback value of the computer group and the estimated value of the power increment is used as the actual generating power of the original unit coordination control system, and the difference between the unit power setting value and the actual generating power of the original unit coordination control system is calculated. This difference is made zero by the PID control method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com