A control method for improving the flexibility of coal-fired units through condensate throttling

A technology for condensate throttling and coal-fired units, applied in mechanical equipment, steam engine installations, machines/engines, etc., can solve problems such as parameter fluctuations, achieve short recovery periods, increase variable load rates, and implement simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

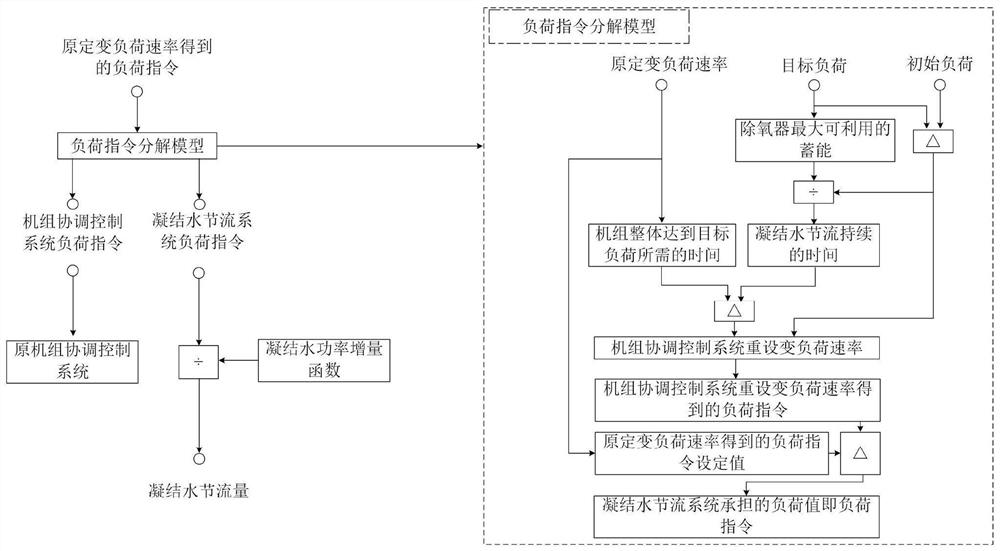

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

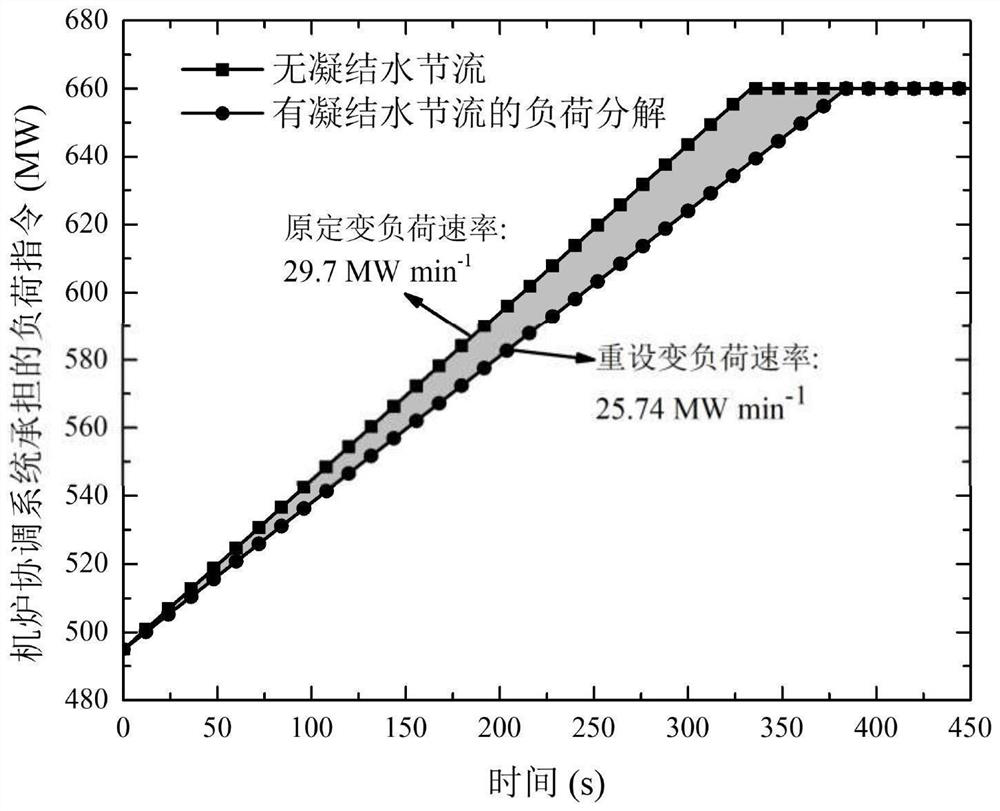

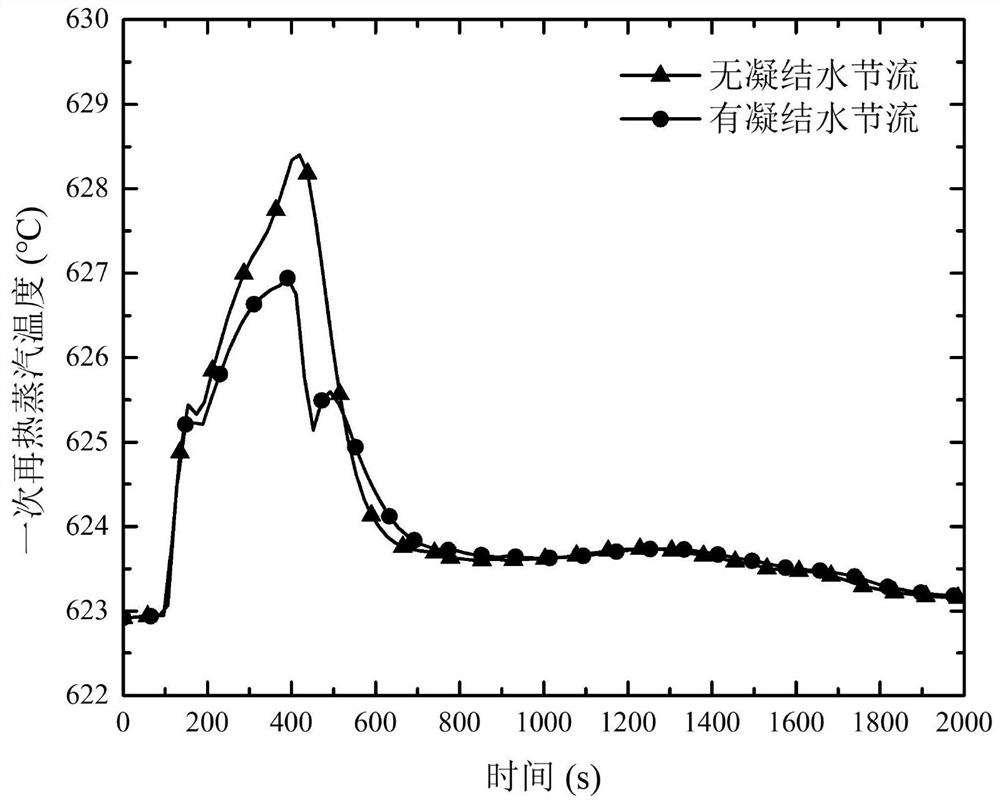

[0035] The present invention is a control method for improving the flexibility of a coal-fired unit by throttling condensate water, and a certain secondary reheat unit is selected as a research object. The specific implementation method is as follows:

[0036] 1. The maximum storage capacity available in the deaerator during variable load The amount and the time that the condensate throttling can last is calculated as follows:

[0037] After the unit is determined, the diameter of the deaerator head, the height of the deaerator head, the radius of the deaerator water storage tank, and the length of the deaerator water storage tank can be obtained according to the structural dimension diagram of the deaerator. According to the current operating state of the unit, the water level of the deaerator and the thermodynamic parameters of the working fluid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com