Hot-rolled strip steel head molding rolling machine and molding method thereof

A forming method and hot-rolled strip technology, applied to presses, presses using rotating pressure members, manufacturing tools, etc., can solve the problems that ordinary cutting machines cannot complete continuous cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

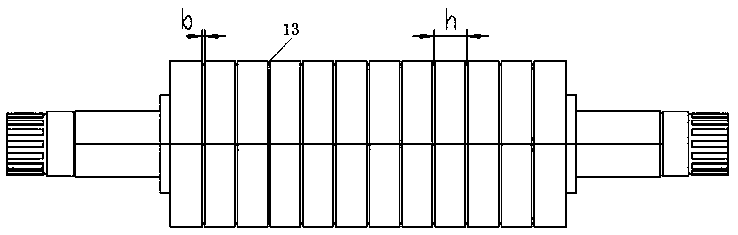

[0027] In this example, refer to the attached figure 2 , 4 The roller surface of the female roller 9 is provided with a plurality of U-shaped grooves 13 along the circumferential direction of the female roller 9, the width of the grooves 13 is b, and the distance between two adjacent grooves 13 is h, namely The width of the hot rolled strip head.

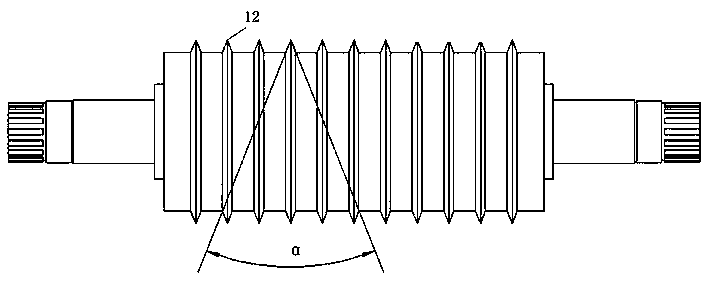

[0028] Refer to attached image 3 , 4 , The roller surface of the male roller 10 is provided with a plurality of roller ring shears 12 along the circumferential direction of the male roller 10, and the angle α of the section of the roller ring shears 12 is an acute angle.

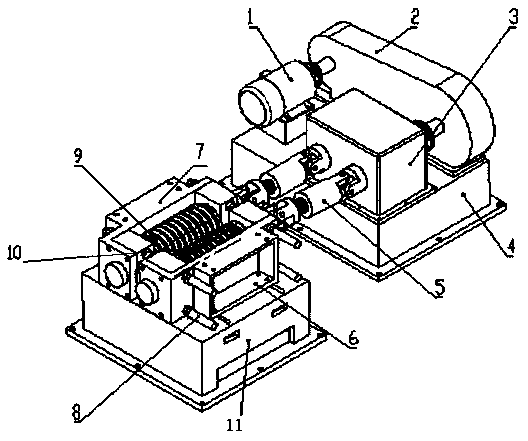

[0029] Refer to attached figure 1 , the speed of the motor 1 is 1450r / min, and the speed after being decelerated by the reducer 2 is 30-60r / min. The output end of the reducer 2 is connected to the power splitter 3, which is a common gear transmission mechanism. The power splitter 3 divides the power into two shafts with the same speed but opposite direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com