Water-cooled wall assembling tool and water-cooled wall assembling method

An assembly tool and assembly method technology, applied in the direction of combustion methods, manufacturing tools, auxiliary devices, etc., can solve the problems of high production cost, low production precision, and long production cycle of membrane water-cooled walls, and achieve time-saving and labor-saving assembly and disassembly. Achieve standardization and facilitate repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

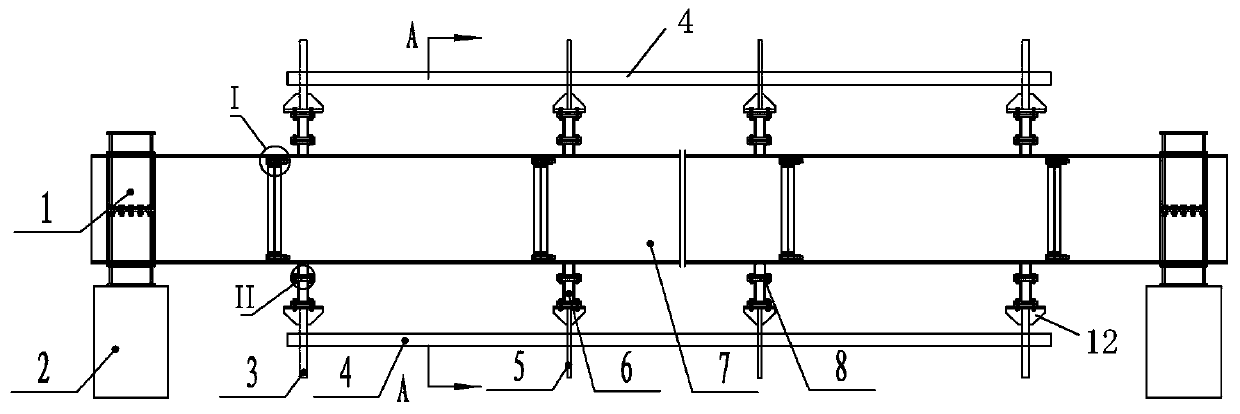

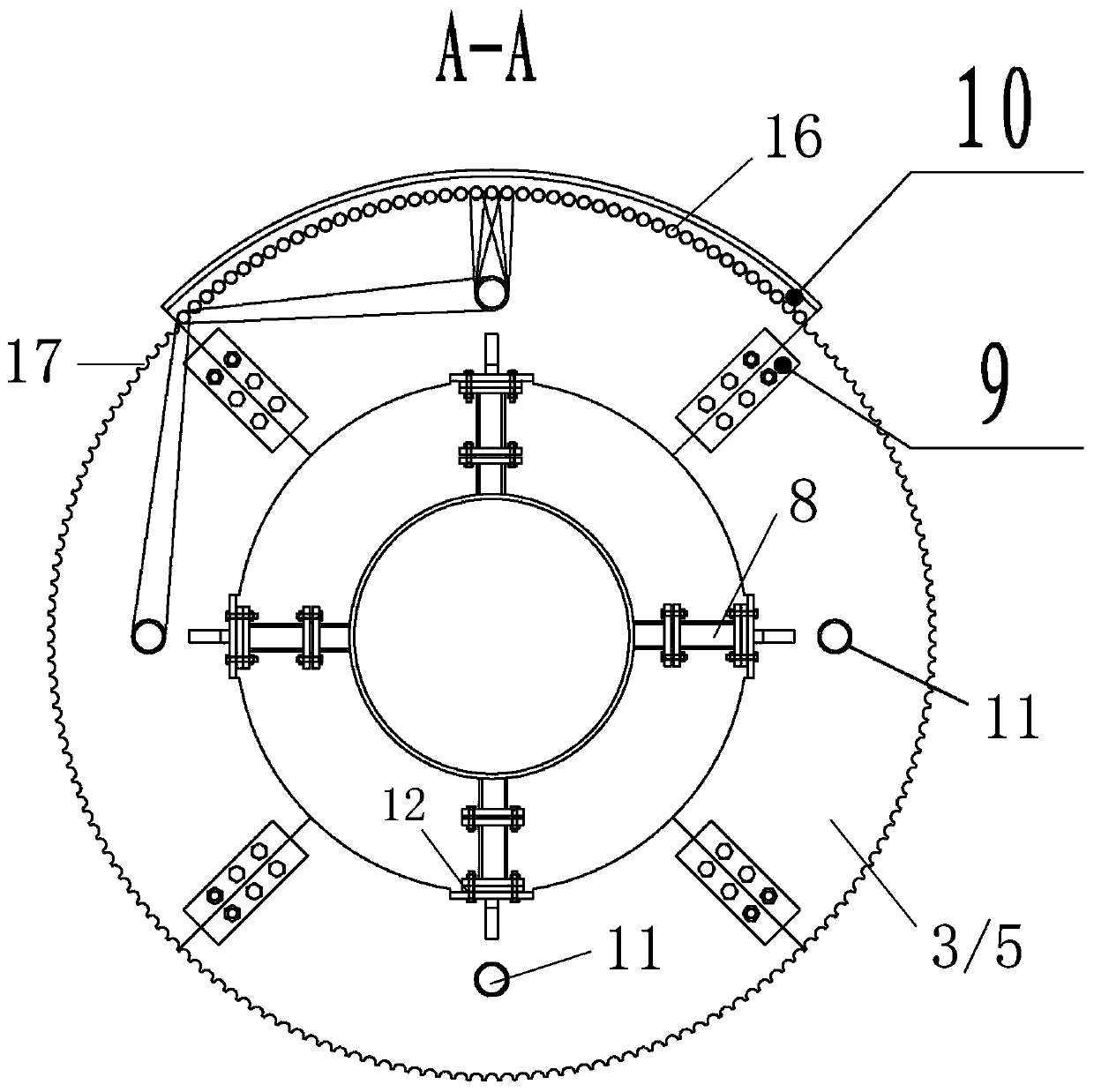

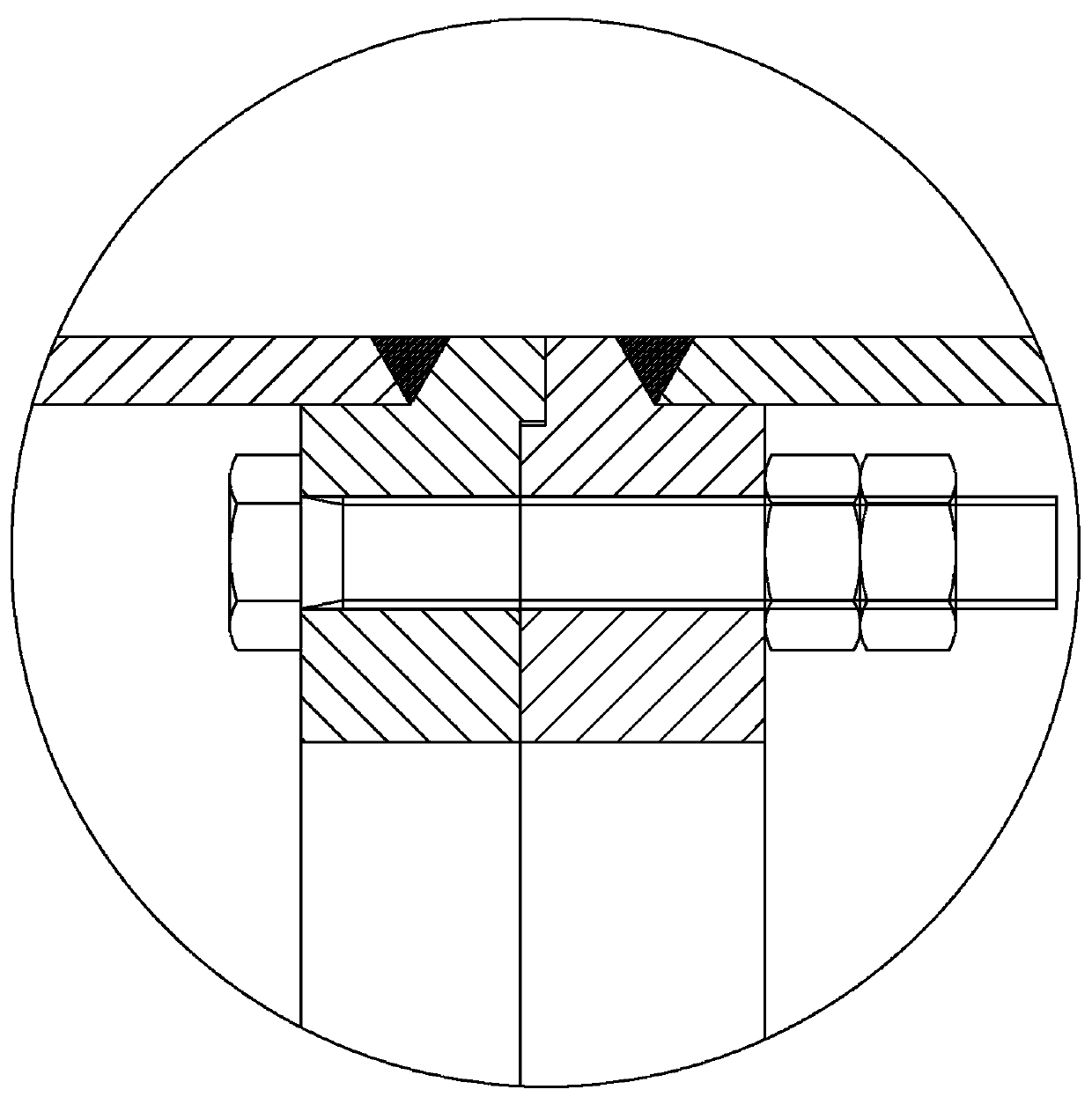

[0026] A water wall assembly tool such as figure 1 — Figure 5As shown: it includes two support platforms 2, each support platform 2 is fixed with a turntable 1, and a mandrel 7 is arranged between the two turntables 1, and the mandrel 7 is cylindrical, and the mandrel 7 is composed of multiple The cylinders are connected by concave and convex flanges; the outside of the mandrel 7 is arranged side by side along the axial direction with multiple supports, all of which are perpendicular to the axial direction of the mandrel 7, and the multiple supports include two port supports 3 and a number of intermediate supports 5, two port supports 3 are respectively located on both sides of the mandrel 7 near the turntable 1, the intermediate supports 5 are evenly distributed in the middle of the mandrel 7, and the thickness of the port supports 3 is greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com