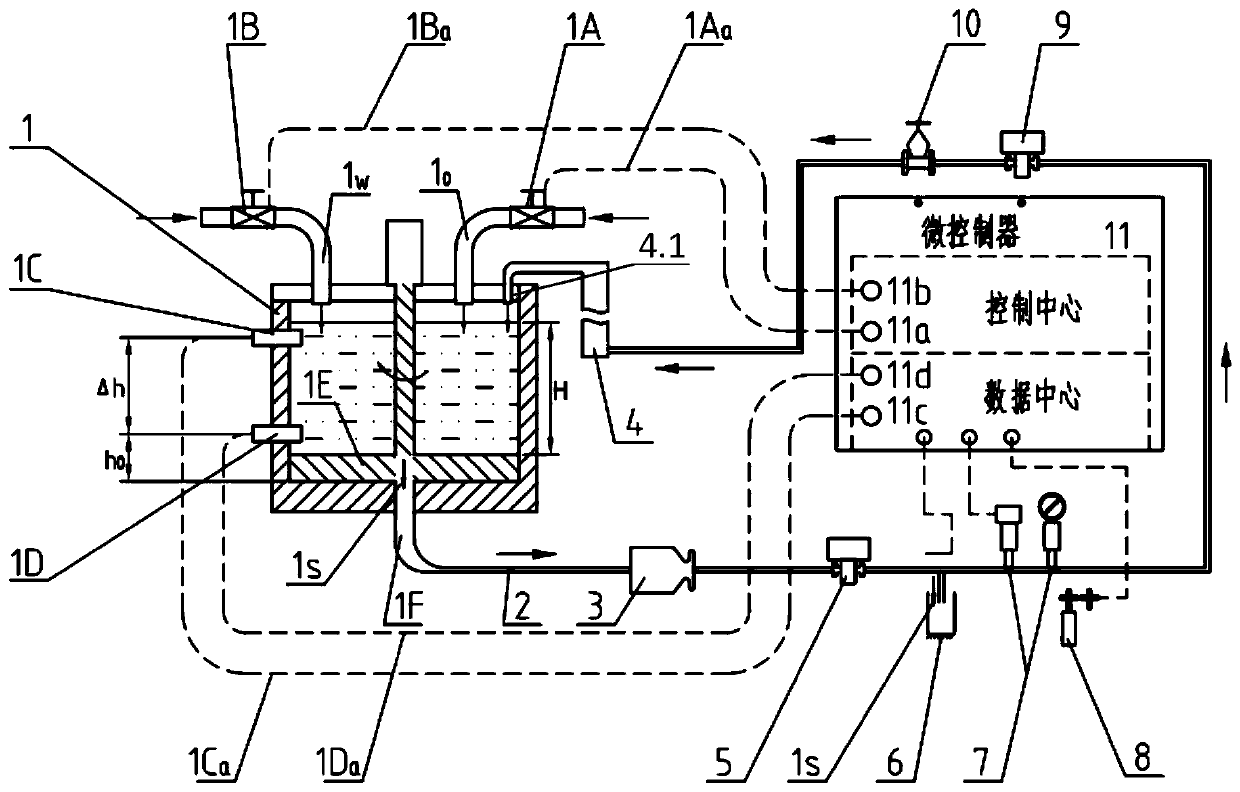

Intelligent small-volume dynamic slurry matching method and system

A small volume, mixing technology, used in chemical instruments and methods, control devices, mixing plants, etc., can solve problems such as unmeasured, unrealizable mixing buckets, waste, etc., and achieve accurate measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

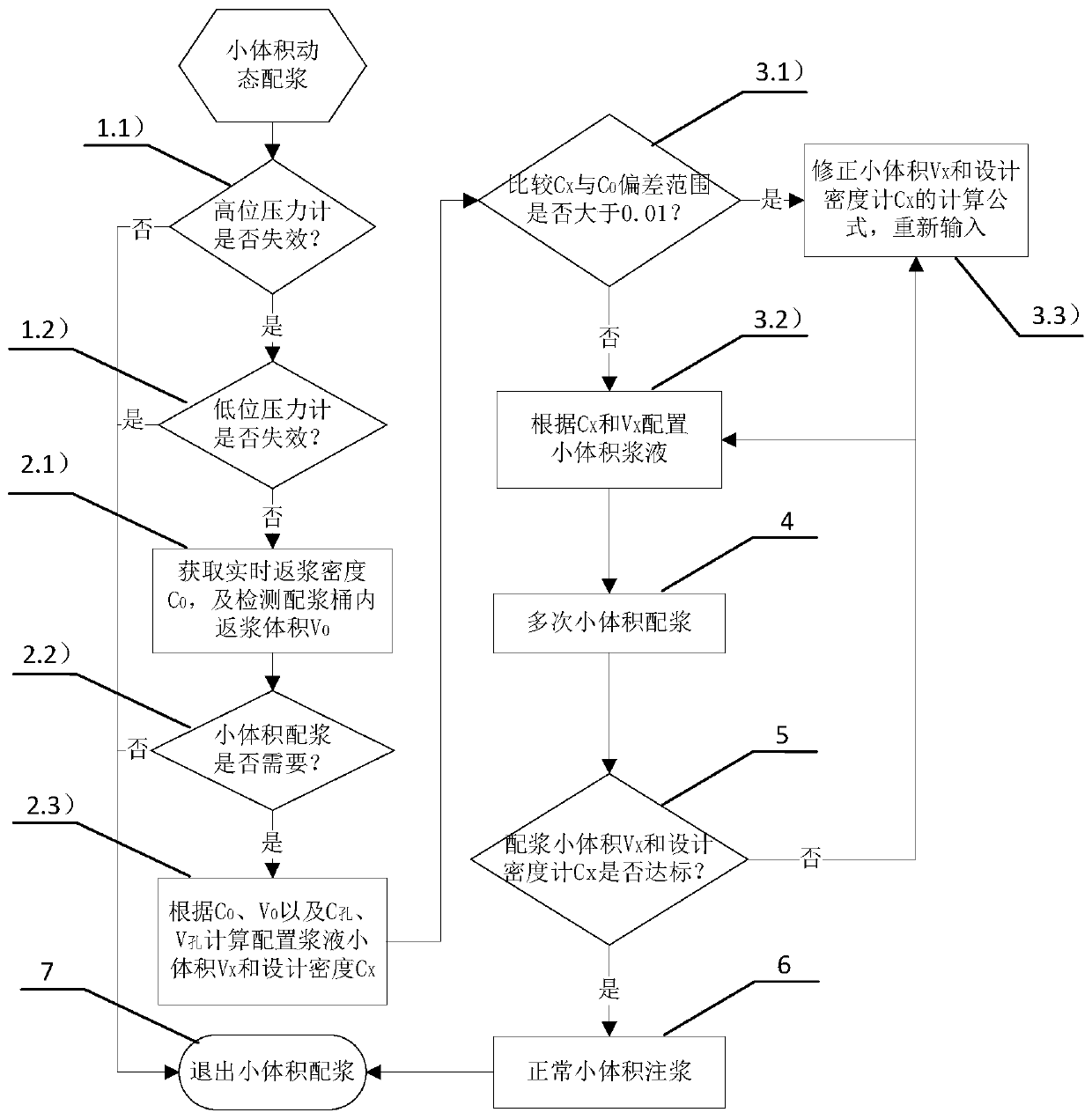

[0055] See image 3 , The intelligent small-volume dynamic slurry mixing method of this embodiment includes the following steps:

[0056] 1.1) Check whether the high pressure gauge 1C is invalid? If not, go to 7) to exit small-volume dynamic slurry mixing; if so, go to 1.2).

[0057] 1.2) Check whether the low pressure gauge 1D is invalid? If yes, go to 7) to exit small-volume dynamic slurry mixing; if not, go to 2.1).

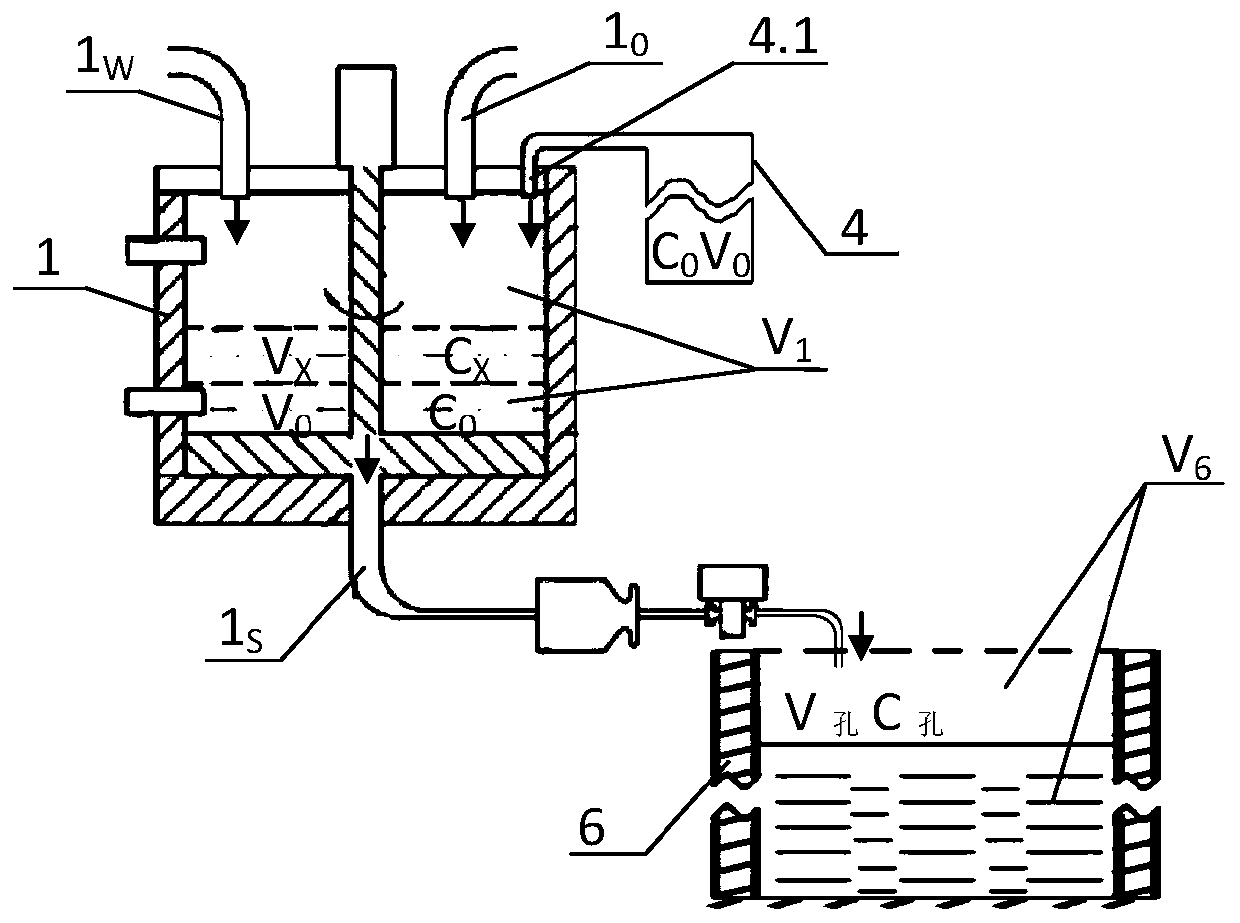

[0058] 2.1) Obtain real-time return density C 0 ; Simultaneously detect the remaining volume V of the slurry in the mixing tank 0 After that, go to 2.2).

[0059] See image 3 , the remaining volume V0 of the slurry in the slurry mixing tank 1, and its density should be the return slurry density C 0 . because see figure 1 , the remaining volume V0 of the slurry in the slurry mixing tank is discharged into the slurry mixing tank from the top arm slurry discharge port 4.1 above the slurry returning tank 4, therefore, the density of the remaining volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com