A method for preventing nozzle clogging on high-temperature digital glass printers

A technology of printers and nozzles, which is applied in printing and other directions, can solve problems such as nozzle blockage, affect the normal operation of equipment, and easily produce precipitation, etc., to achieve the effect of reducing precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings.

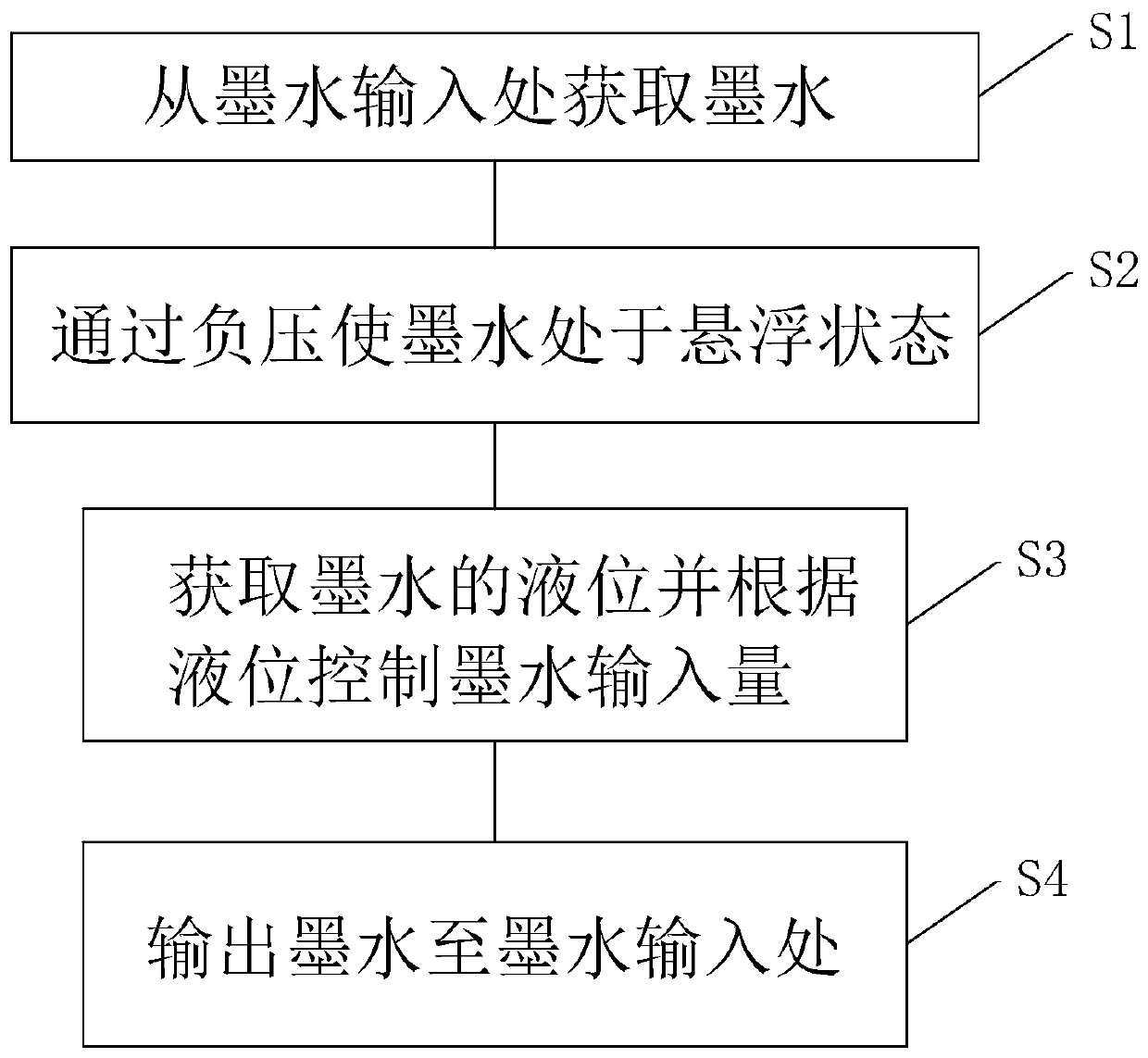

[0054] refer to figure 1 , is a method for preventing nozzle clogging on a high-temperature digital glass printer disclosed by the present invention, comprising:

[0055] S1: Obtain ink from the ink input place; obtain ink from the ink input place through the ink pump.

[0056] S2: The ink is suspended by negative pressure; after the ink is obtained, suction is generated by negative pressure, and the ink itself has gravity. After the suction and gravity are balanced, the ink is in suspension. At this time, the ink is affected by two forces. function, making the ink fully mixed inside. When the ink is in a suspended state, the minimum liquid level information and the maximum liquid level information of the ink are obtained, so as to determine the position of the ink in this segment. Then compare the ink position information with the preset position informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com