Cr-doped perovskite structure halide near infrared light-emitting material and preparation method thereof

A perovskite-type, luminescent material technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problem of weak luminescence intensity of near-infrared luminescent materials, achieve excellent thermal quenching characteristics, simple preparation method, and stable chemical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The chemical composition formula of this embodiment is Cs 2 AgIn 0.9 Cl 6 :0.1Cr 3+ The preparation method of the near-infrared luminescent material is as follows:

[0029] According to the chemical composition formula Cs 2 AgIn 0.9 Cl 6 :0.1Cr 3+ Stoichiometric ratio, weigh CsCl, AgCl, InCl respectively 3 , CrCl 3 The high-purity powder raw materials are ground in an agate mortar and a glove box full of protective atmosphere, so that the raw materials are fully mixed and even. Transfer the mixed raw materials to a quartz tube and vacuum seal the tube, then place it in a high-temperature reaction furnace for sintering at 300-600°C for 1-7 days, take it out after natural cooling, and grind again to obtain a single-phase Cs 2 AgIn 0.9 Cl 6 :0.1Cr 3+ of fluorescent powder.

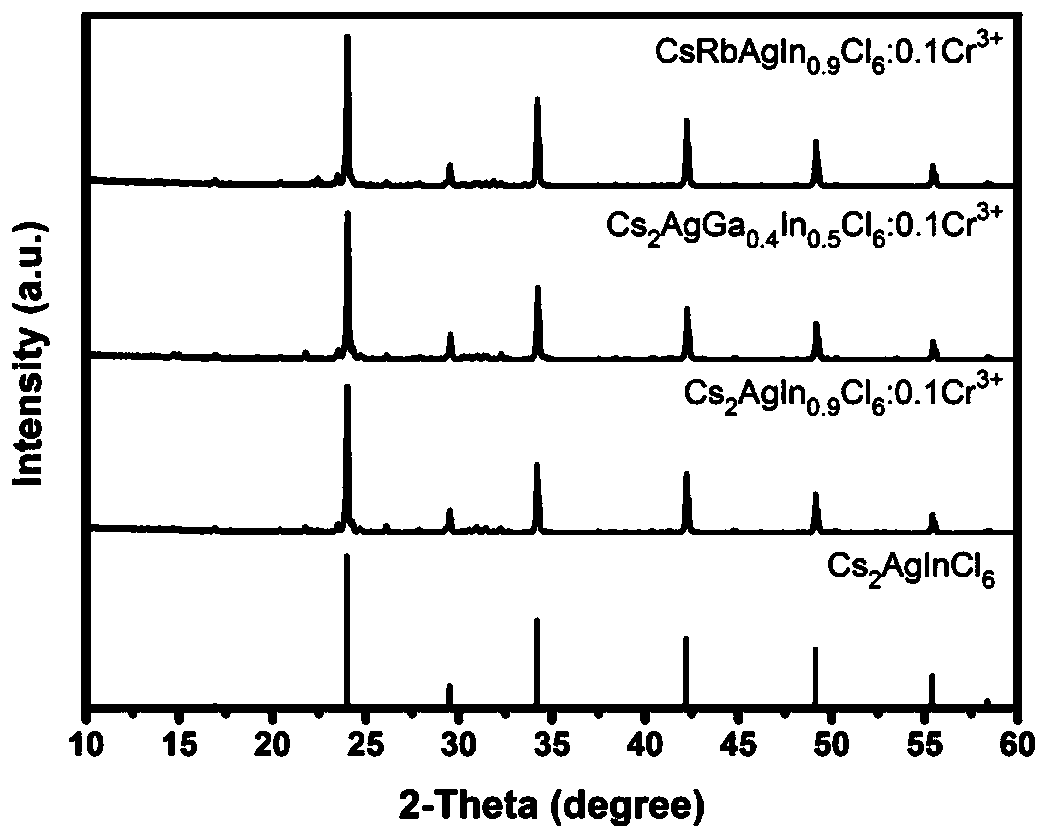

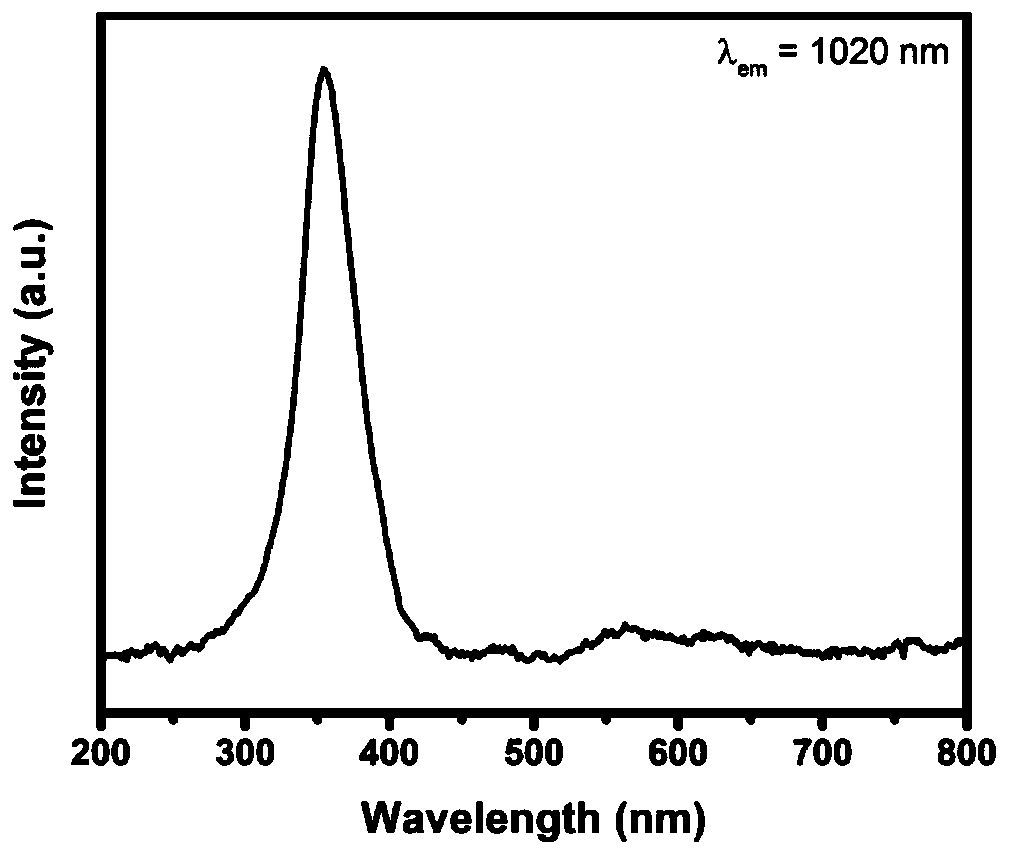

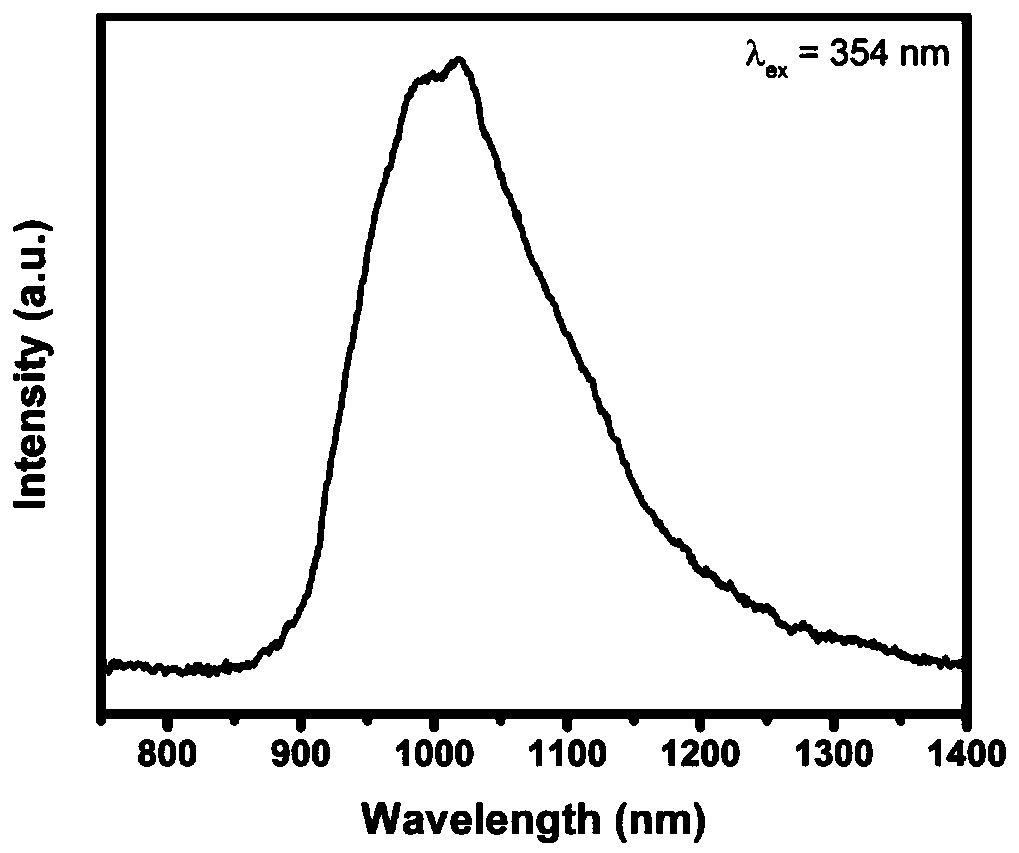

[0030] The powder X-ray diffraction (XRD) spectrum of the near-infrared luminescent material prepared in this embodiment is as follows: figure 1 As shown, the excitation spectrum as fig...

Embodiment 2

[0032] The chemical composition formula of this embodiment is Cs 2 AgGa 0.4 In 0.5 Cl 6 :0.1Cr 3+ The preparation method of the near-infrared luminescent material is as follows:

[0033] According to the chemical composition formula Cs 2 AgGa 0.4 In 0.5 Cl 6 :0.1Cr 3+ Stoichiometric ratio, weigh CsCl, AgCl, GaCl respectively 3 , InCl 3 , CrCl 3 The high-purity powder raw materials are ground in an agate mortar and a glove box full of protective atmosphere, so that the raw materials are fully mixed and even. Transfer the mixed raw materials to a quartz tube and vacuum seal the tube, then place it in a high-temperature reaction furnace for sintering at 300-600°C for 1-7 days, take it out after natural cooling, and grind again to obtain a single-phase Cs 2 AgGa 0.4 In 0.5 Cl 6 :0.1Cr 3+ of fluorescent powder.

[0034] The powder X-ray diffraction (XRD) spectrum of the near-infrared luminescent material prepared in this embodiment is as follows: figure 1 As shown...

Embodiment 3

[0036] The chemical composition formula of this embodiment is CsRbAgIn 0.9 Cl 6 :0.1Cr 3+ The preparation method of the near-infrared luminescent material is as follows:

[0037] According to the chemical composition formula CsRbAgIn 0.9 Cl 6 :0.1Cr 3+ Stoichiometric ratio, weigh CsCl, RbCl, AgCl, InCl respectively 3 , CrCl 3 The high-purity powder raw materials are ground in an agate mortar and a glove box full of protective atmosphere, so that the raw materials are fully mixed and even. Transfer the mixed raw materials to a quartz tube and vacuum seal the tube, then place it in a high-temperature reaction furnace for sintering at 300-600°C for 1-7 days, take it out after natural cooling, and grind again to obtain a single-phase CsRbAgIn 0.9 Cl 6 :0.1Cr 3+ of fluorescent powder.

[0038] The powder X-ray diffraction (XRD) spectrum of the near-infrared luminescent material prepared in this embodiment is as follows: figure 1 As shown, the excitation spectrum as Ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com