Anti-failure pneumatic window opener

A window opener and anti-failure technology, which is applied in the direction of wing leaf openers, door/window accessories, wing leaf closers, etc., can solve the problems of windows not being opened in time, hidden safety hazards, suffocation and death of personnel, etc., and achieve structural disassembly and assembly Convenience, good economic benefits, and simple working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

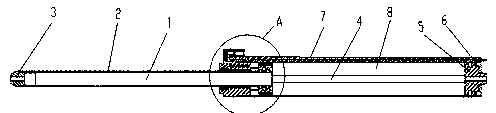

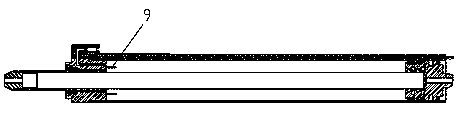

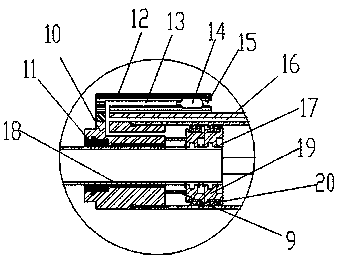

[0023] Such as figure 1 — Figure 4 As shown, a failure-proof pneumatic window opener includes a cylinder body 7, an upper end cover 10 is provided on the top of the cylinder body 7, and a lower end cover 5 is provided at the bottom, and the lower end cover 5 is fixed on the cylinder by a first clamp spring 6. At the bottom of the body 7, an air chamber 8 with a hollow structure is provided inside the cylinder body 7, and the air chamber 8 is cylindrical; the gas spring 1, the gas spring 1 has a sleeve 2, and the bottom of the sleeve 2 A piston 19 that can axially reciprocate in the air chamber 8 is installed, and the piston 19 is fixed on the bottom of the gas spring 1 through the second clip 17. A support rod 4 is installed in the sleeve 2, and the support rod 4. One end is connected to the lower end cover 5, and the other end is located in the sleeve 2. When the gas spring 1 is opened, the support rod 4 pushes the sleeve 2 out of the cylinder body 1. When the gas spring 1 ...

Embodiment 2

[0030] Select an office building in Zhengzhou as the experimental object, with an area of 150 square meters. Experiment time: April 9, 2018, the indoor temperature was 18°C, and the outdoor temperature was 21°C.

[0031]Because the lighting is better near the window, there are usually office desks, chairs or filing cabinets near the window. Therefore, wooden tables and chairs, waste paper and rags are used to simulate the office space.

[0032] Adjust the air source pressure of the window opener to 0.2 MPa, set the burst temperature of the temperature-sensitive glass bulb 14 in the pressure relief device 12 to 68 degrees, ignite combustibles such as wooden tables and chairs, waste paper and rags, and stand at the ignition point 5 Meters away, measure the temperature of the cylinder block 7 of the window opener in real time with a temperature measuring gun. After the fire source is turned off, the air source of the window opener is manually turned off, and the timing is set...

Embodiment 3

[0035] Select an office building in Zhengzhou as the experimental object, with an area of 150 square meters. Experiment time: April 10, 2018, the indoor temperature was 19°C, and the outdoor temperature was 21°C.

[0036] Because the lighting is better near the window, there are usually office desks, chairs or filing cabinets near the window. Therefore, wooden tables and chairs, waste paper and rags are used to simulate the office space.

[0037] The air source pressure of the window opener is adjusted to 0.25MPa, and the bursting temperature of the temperature-sensitive glass bubble 14 in the pressure relief device 12 is set to 68 degrees. Meters away, measure the temperature of the cylinder block 7 of the window opener in real time with a temperature measuring gun. After the fire source is turned off, the air source of the window opener is manually turned off, and the timing is set. At this time, the window opener will automatically open. When the window opener is fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com