Assembly type screw drill metal stator and axial machining and assembling process thereof

A technology of screw drilling tools and metal stators, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of low performance of metal screw drilling tools, failure of stator and rotor cooperation, radial accuracy not meeting the requirements, etc. Achieve the effect of solving insufficient machining accuracy, improving work performance and service life, and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with embodiment the present invention is described in further detail, following embodiment is only descriptive, not restrictive, can not limit protection scope of the present invention with this.

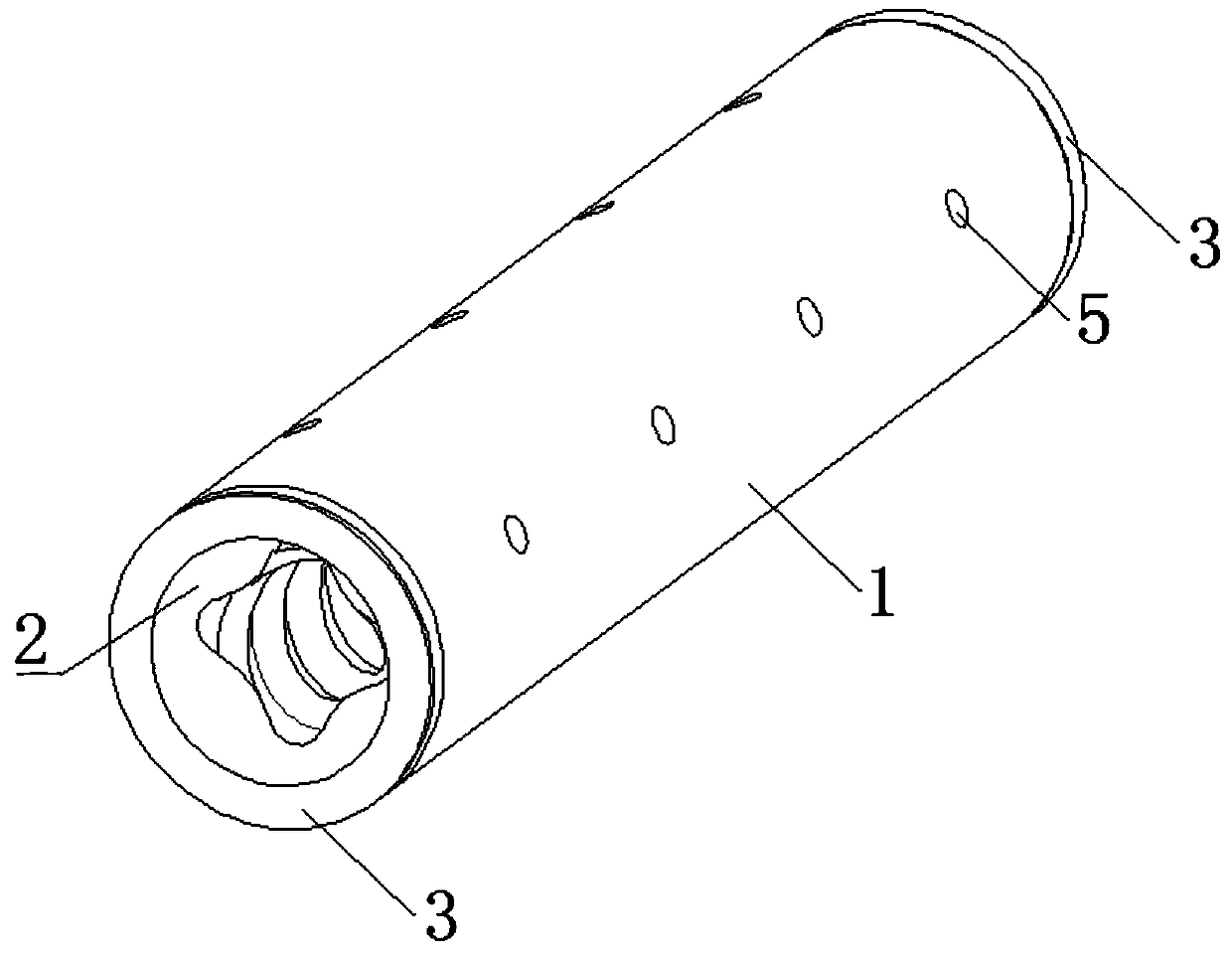

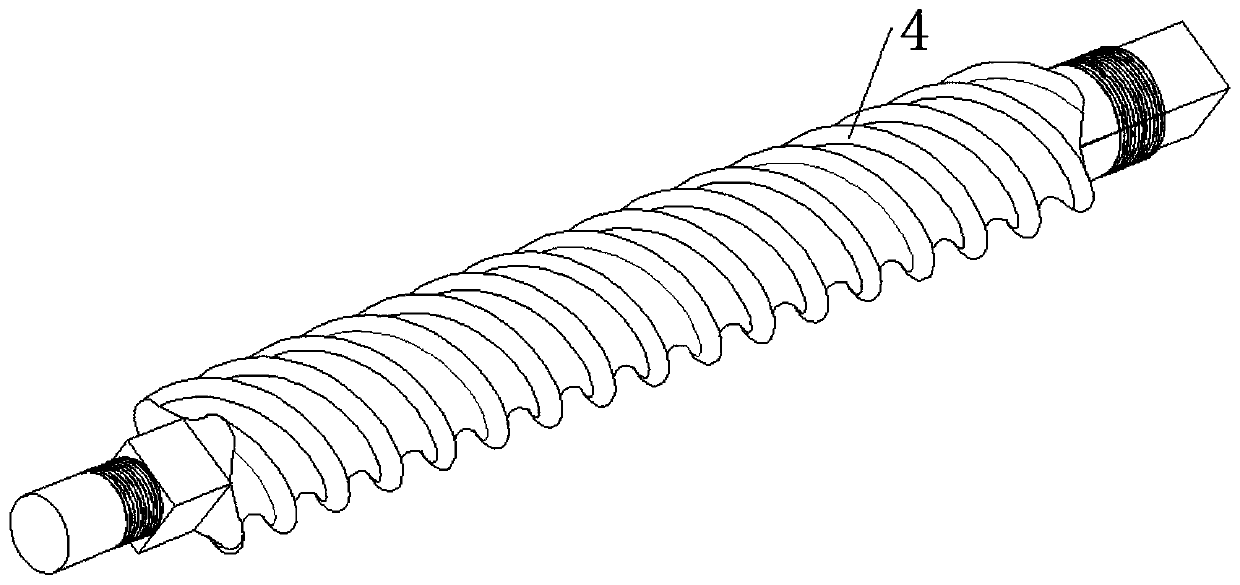

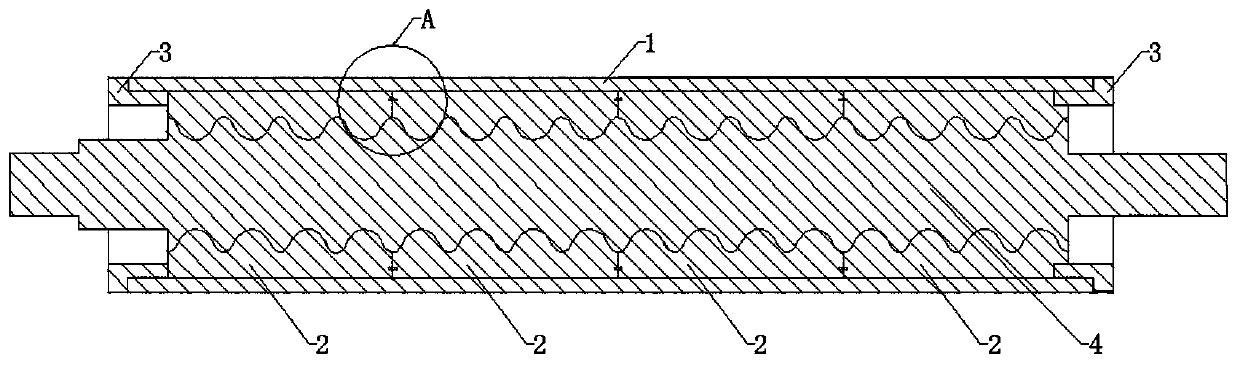

[0032] Such as figure 1 As shown, a metal stator of an assembled screw drilling tool includes a casing 1 (the casing 1 in this application is a steel pipe), a locking joint 3 and a plurality of equal-length stator nipples 2 (in this application, the stator short The "short" in Section 2 does not refer to the specific length, but is a concept relative to the overall length of the stator to be processed), the length of each stator short section 2 is a multiple of its pitch; along each stator short At least three bolt holes 5 are evenly distributed in the circumferential direction of the section 2; the end faces of the multi-section stator subsections 2 are butted in sequence, and the inner helical curves of the butted stator subsections 2 are successively f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com