Characterization method of interfacial polymerization reaction and characterization device of interfacial polymerization reaction

A technology of interfacial polymerization and reaction, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to accurately characterize the kinetic process of interfacial polymerization reaction film formation, and the inability to obtain information on the film formation process of interfacial polymerization film in situ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

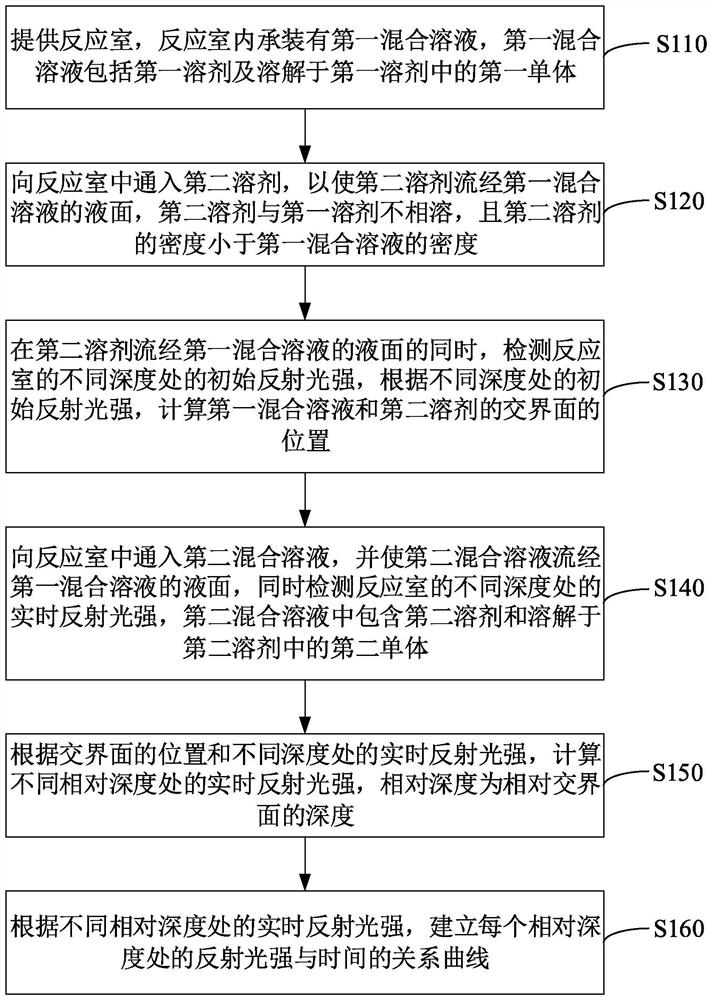

Method used

Image

Examples

Embodiment 1

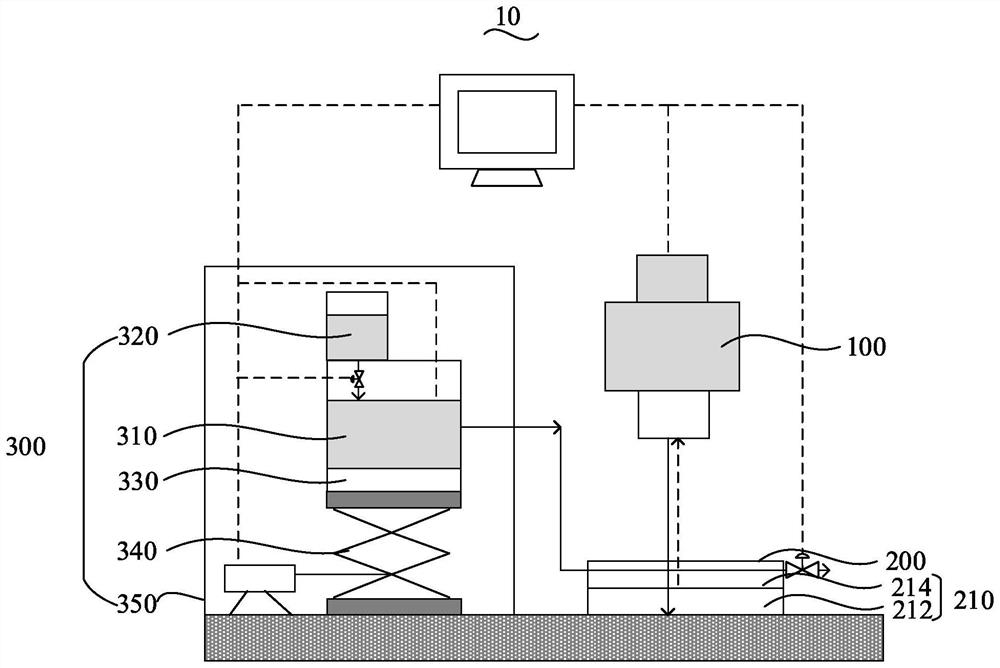

[0114] The optical coherence tomography instrument in the characterization device of the interfacial polymerization reaction in this embodiment adopts a commercial optical coherence tomography instrument (OCT, GANYMEDE-SP5, Thorlabs, the United States), and the horizontal resolution is 2 microns, and the vertical resolution The rate is 4 microns. The combination of the optical coherence tomography unit and the galvanometer makes it possible to perform a series of scans along a straight line or in a rectangular area. In addition, the optical coherence tomography unit in this embodiment uses a spectrometer to analyze the interference pattern, and the frequency-domain optical coherence tomography scanner can make a single-point scanning rate as high as 30,000 Hz.

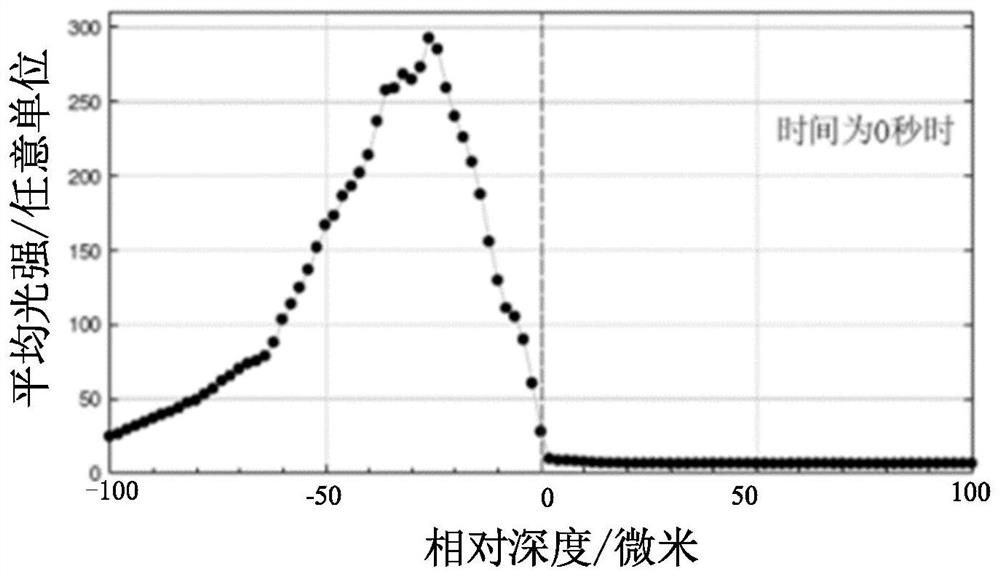

[0115] The reaction mechanism of this example was used to perform characterization tests. The reaction mechanism was assembled from two upper and lower plexiglass plates (180 mm × 90 mm × 15 mm) with a rectangular cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com