Corrugation staggered fuel cell bipolar plate structure

A fuel cell and bipolar plate technology, applied in the direction of fuel cells, fuel cell additives, fuel cell components, etc., can solve the problems of increasing the volume and weight of fuel cells, failing to take into account the power density of fuel cells, etc., to achieve good Effects of performance output and stability, increased weight, increased power density and lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

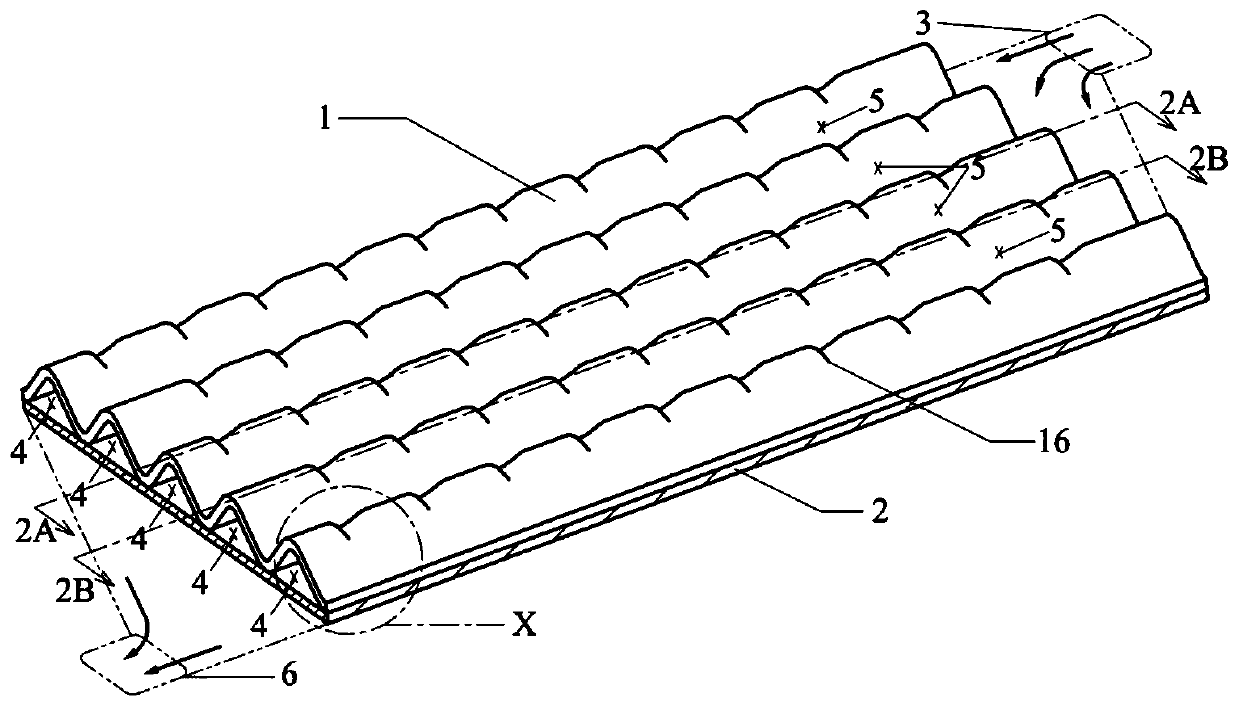

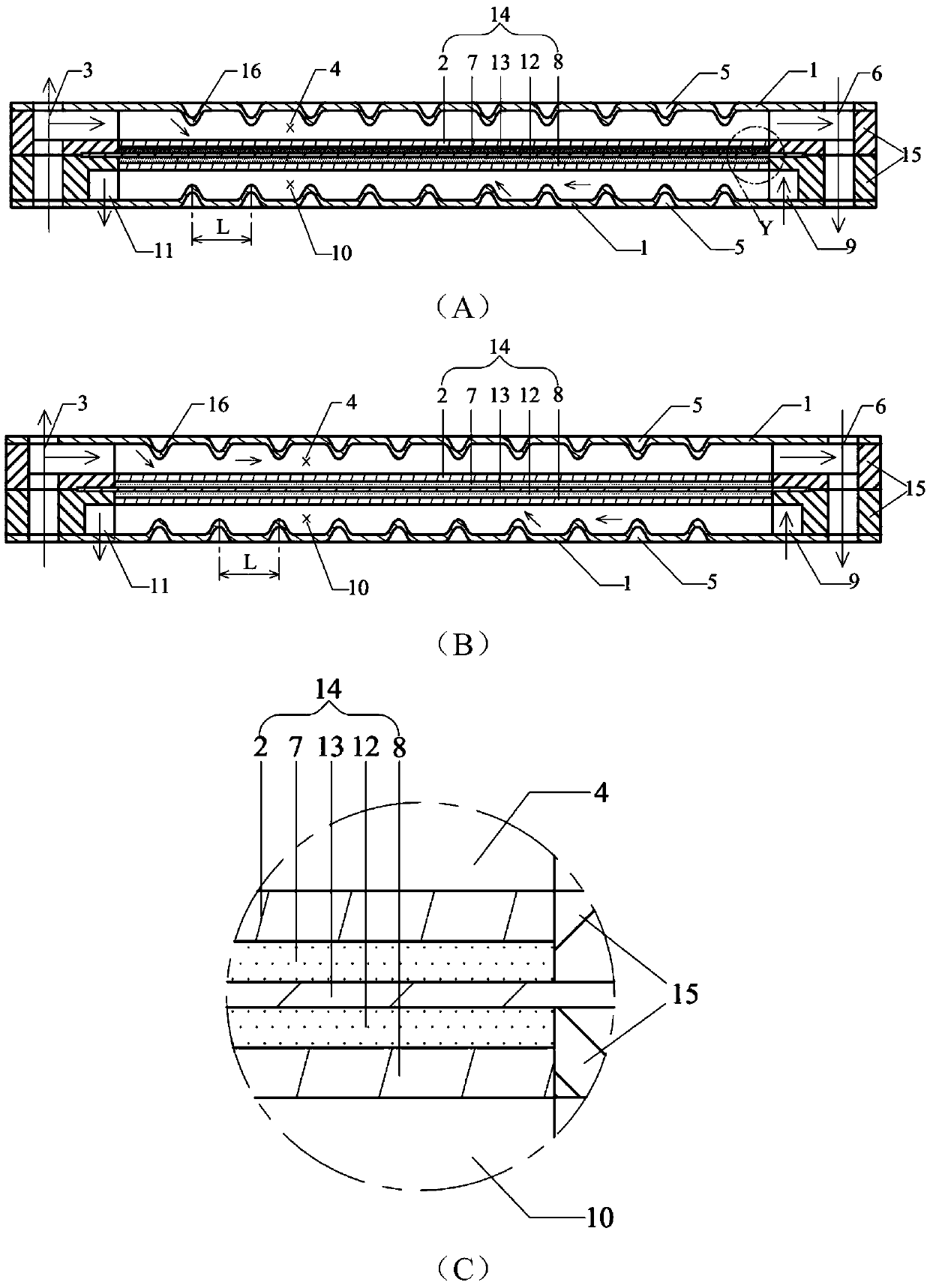

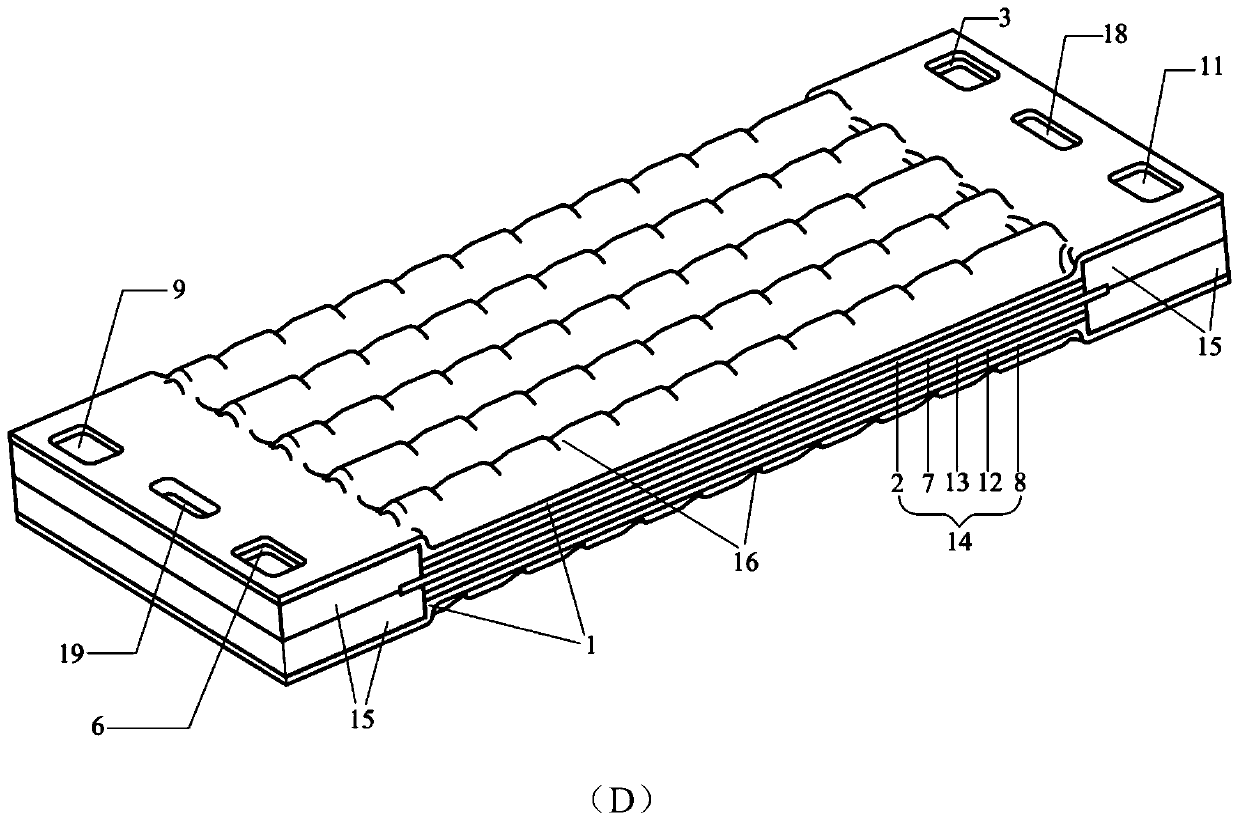

[0035] Such as figure 1 As shown, the specific implementation includes two upper and lower bipolar plates 1 and a membrane electrode assembly 14, and a membrane electrode assembly 14 is arranged between the upper and lower sides of the two bipolar plates 1, such as figure 2 As shown in (A), the membrane electrode assembly 14 is mainly composed of the cathode diffusion layer 2, the cathode catalyst layer 7, the proton exchange membrane 13, the anode catalyst layer 12 and the anode diffusion layer 8 by hot pressing from top to bottom.

[0036] Such as figure 2 (A), figure 2 As shown in (B), the upper bipolar plate 1 and the lower bipolar plate 1 have the same structure, but they are arranged symmetrically up and down; between the upper bipolar plate 1 and the cathode diffusion layer 2, a plurality of cathode gas flow channels arranged in parallel sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com